Fried bread stick cutting machine

A technology of cutting machine and deep-fried dough sticks, which is applied in the fields of dough cutting machinery, baking, food science, etc. It can solve the problems of different sizes of deep-fried dough sticks, increase the fatigue intensity of catering staff, etc., and achieve the effect of reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

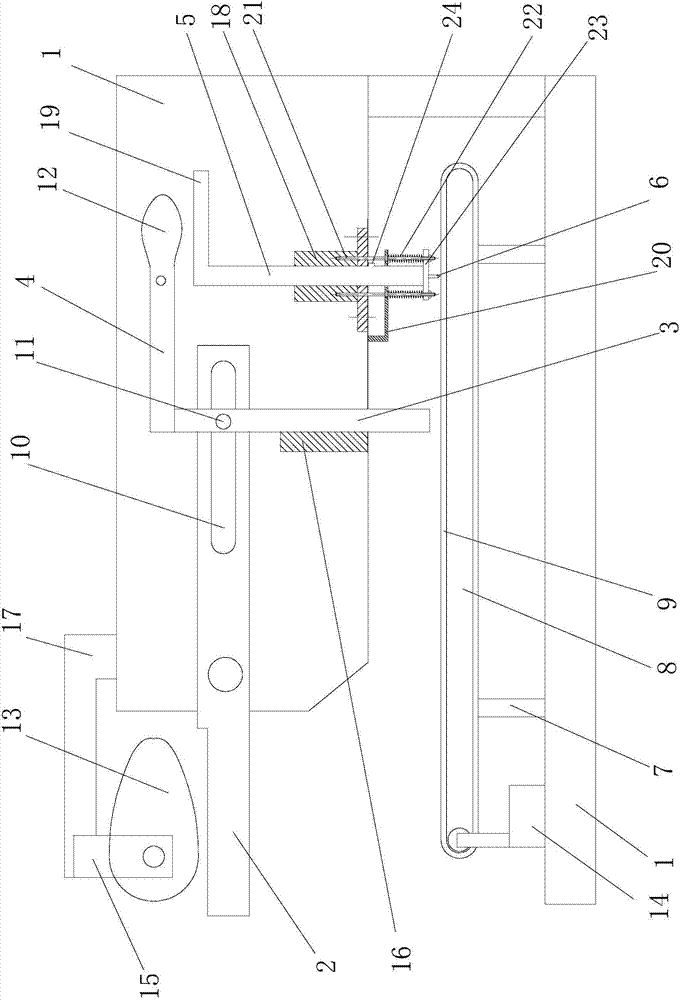

[0016] As shown in the figure, the fried dough stick cutting machine of the present invention includes a base 1, a connecting rod 2, a straight rod 3, a rocker 4, a push rod 5 and a blade 6; A conveyor belt 9 for transferring fabrics is provided on the top, and a first motor 14 for driving the conveyor belt 9 to move is provided on the base 1; the middle part of the connecting rod 2 is hinged with the base 1, and the right end of the connecting rod 2 is provided with a chute 10; The straight rod 3 is slidably fitted on the base 1 through the first guide device, and the straight rod 3 is provided with a cylindrical pin 11 which is slidably fitted with the chute 10; the middle part of the rocker 4 is hinged with the base 1, and the left end of the rocker 4 is located Above the rod 3, the right end of the rocking rod 4 is provided with a first cam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com