Non-contact type conveyor plate having a suction force

A non-contact, adsorption technology, applied in the direction of nonlinear optics, transportation and packaging, conveyor objects, etc., can solve the problems of invalidation, glass rising, trembling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Hereinafter, a non-contact transfer board having an adsorption force according to a preferred embodiment of the present invention will be described with reference to the accompanying drawings.

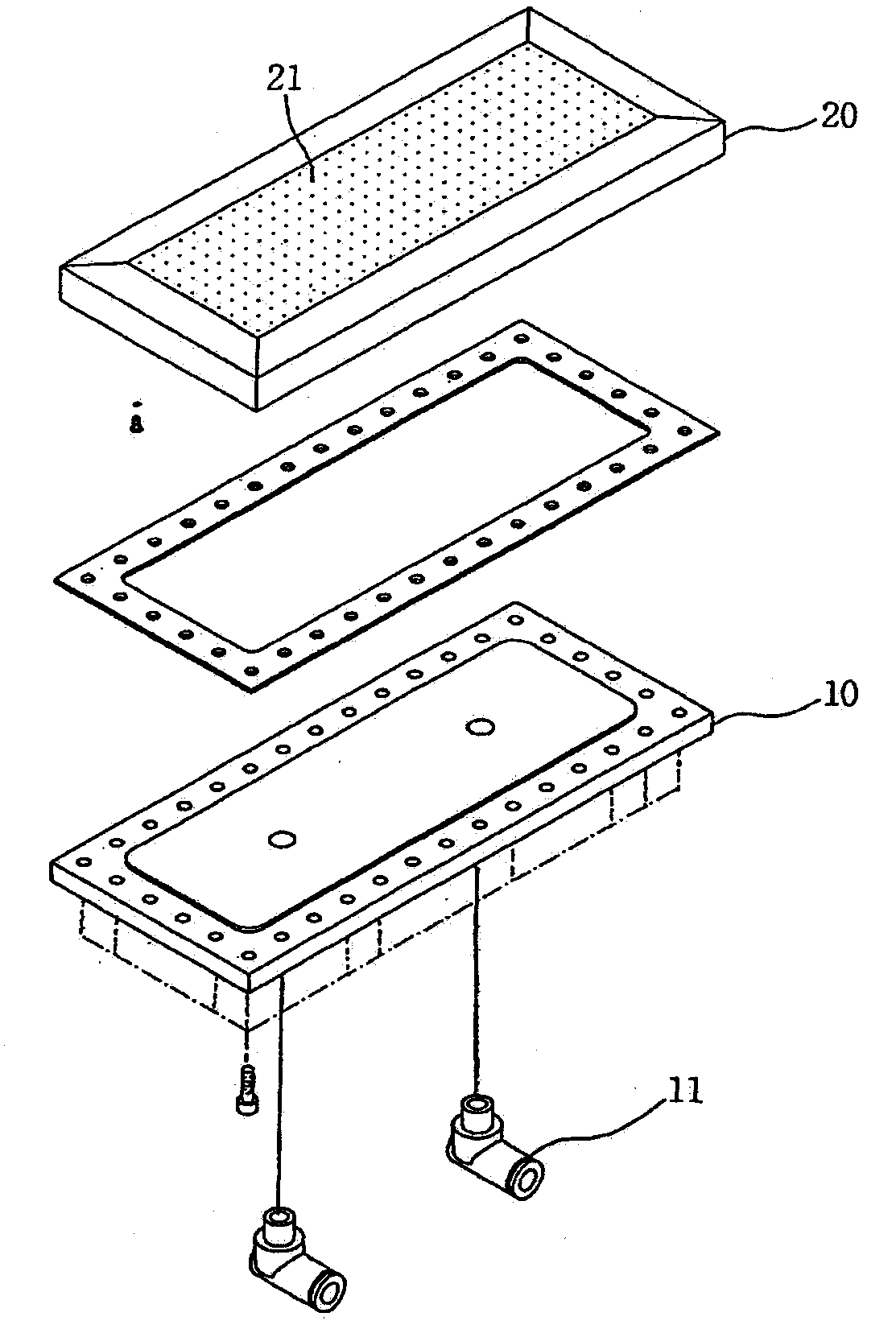

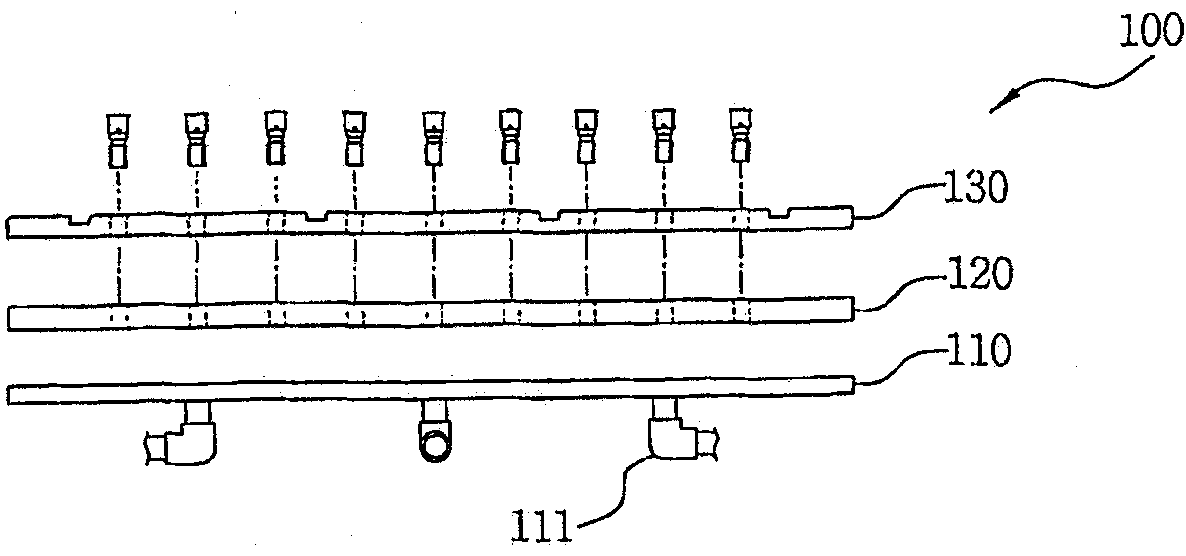

[0027] refer to figure 2 , the transfer board 100 according to the present invention includes a lower board 110 , a middle board 120 , an upper board 130 and air jet bolts 140 .

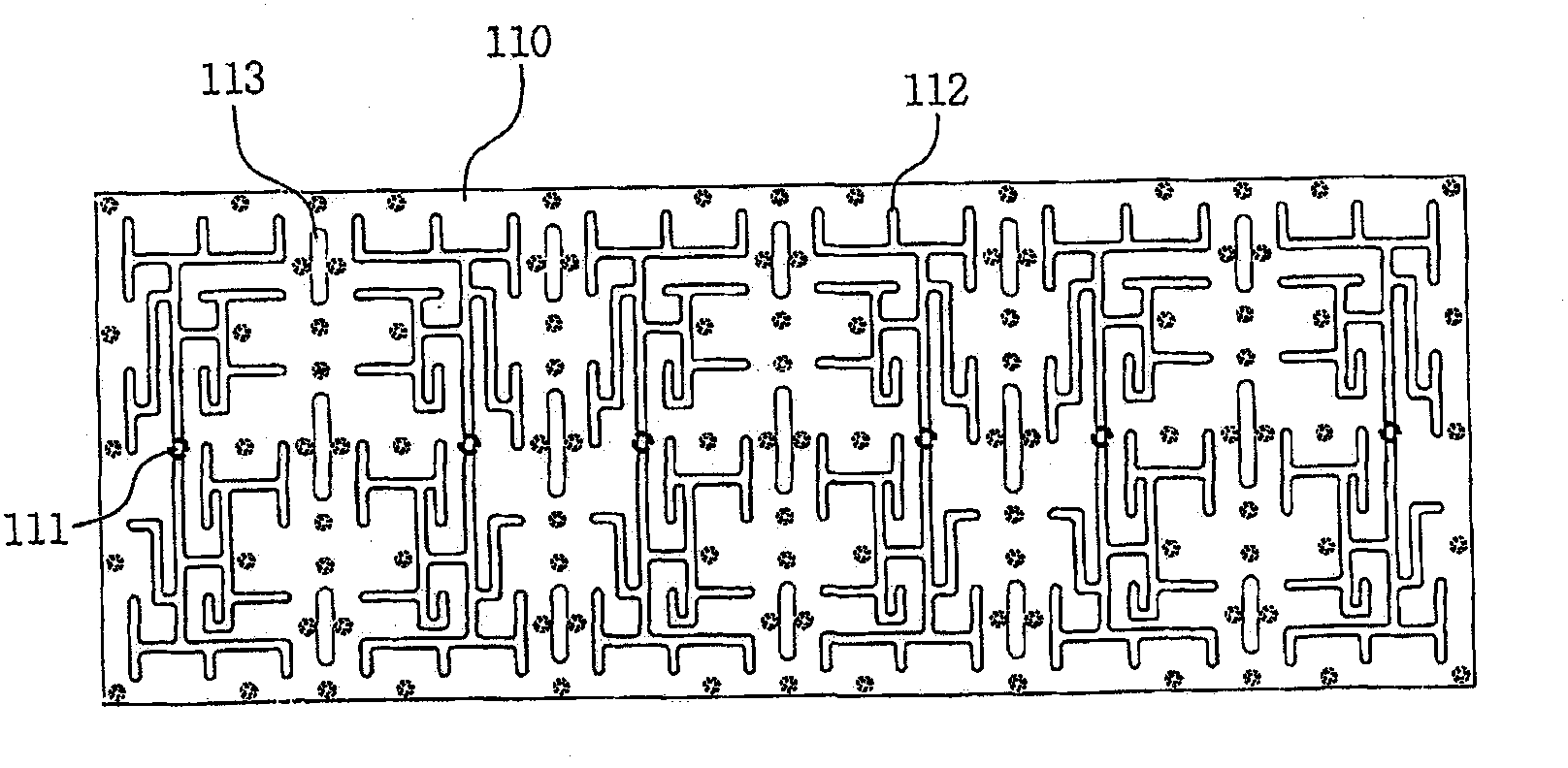

[0028] First, the lower plate 110 is a plate supplied with air from an external compressor (not shown), and a plurality of air connection ports 111 are provided on the lower surface of the lower plate 110, and a small chamber for branching the supplied air is provided on the upper surface of the lower plate 110. 112. Preferably, the small chamber 112 is designed to branch from one air connection port 111 in several to tens of directions, and the small chamber 112 is provided through the entire lower plate 110 . Furthermore, a lower air hole 113 penetrating up and down is provided between the small c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com