Portable automatic feeding manual pile driving equipment and pile driving method

A piling device and automatic feeding technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, can solve the problems of small piling workload, high safety factor, and large noise, so as to avoid safety accidents, improve piling quality, The effect of improving the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

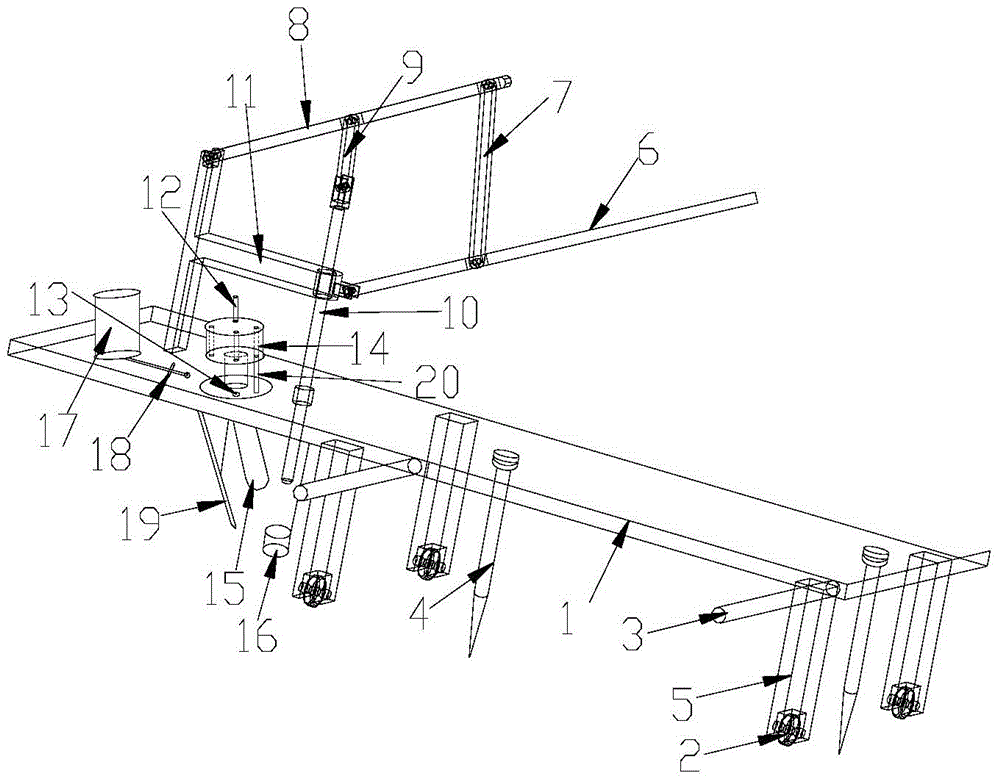

[0024] Such as figure 1 As shown, the portable automatic feeding manual piling device of the present invention includes a frame 1, a runner 2, a handrail 3, a screw 4, a support column 5, a pressing bar 6, a first connecting rod 7, a rocking bar 8, and a second connecting rod 9, striking rod 10, bracket 11, handle 12, discharge hole 13, stake through hole 14, stake transition groove 15, positioning tube 16, water tank 17, switch 18 and water pipe 19.

[0025] Holding the handrail 3 of the frame 1, the piling device is moved to the position where piling is required, and the screw 4 is screwed into the ground to prevent the piling device from trembling during work. Turn on the switch 18 of the water tank 17, and the water pipe 19 will spray water to the ground below the positioning pipe 16, which can reduce the friction between the stake and the ground in the piling process, thereby improving the piling efficiency. Rotating handle 12 can drive barrel to rotate, and when stake t...

Embodiment 2

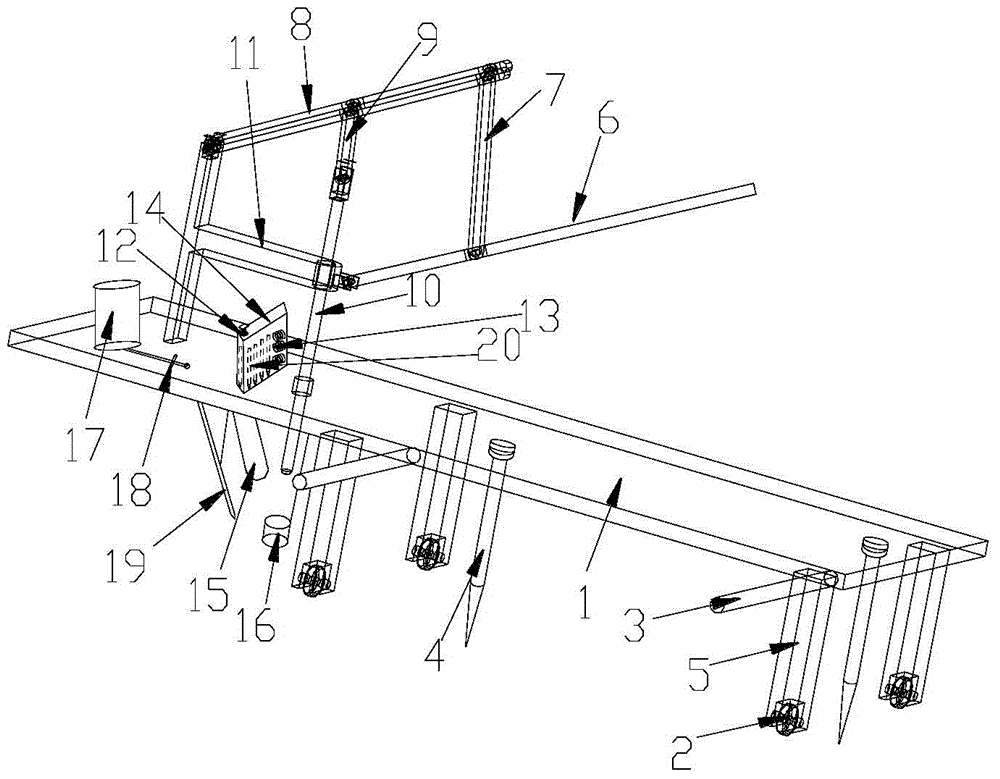

[0027] Such as figure 2 As shown, the portable automatic feeding manual piling device of the present invention includes a frame 1, a runner 2, a handrail 3, a screw 4, a support column 5, a pressing bar 6, a first connecting rod 7, a rocking bar 8, and a second connecting rod 9. The impact rod 10, the bracket 11, the discharge switch 12, the spring 13, the barrel 14, the stake transition groove 15, the positioning pipe 16, the water tank 17, the switch 18 and the water pipe 19.

[0028]Holding the handrail 3 of the frame 1, the piling device is moved to the position where piling is required, and the screw 4 is screwed into the ground to prevent the piling device from trembling during work. Turn on the switch 18 of the water tank 17, and the water pipe 19 will spray water to the ground below the positioning pipe 16, which can reduce the friction between the stake and the ground in the piling process, thereby improving the piling efficiency. Press down the discharge switch 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com