Electro-hydraulic servo system adaptive robust control method based on low-frequency learning

An electro-hydraulic servo system, self-adaptive robust technology, applied in the direction of self-adaptive control, general control system, control/adjustment system, etc., can solve problems such as system instability, flutter of sliding mode surface, deterioration of control performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

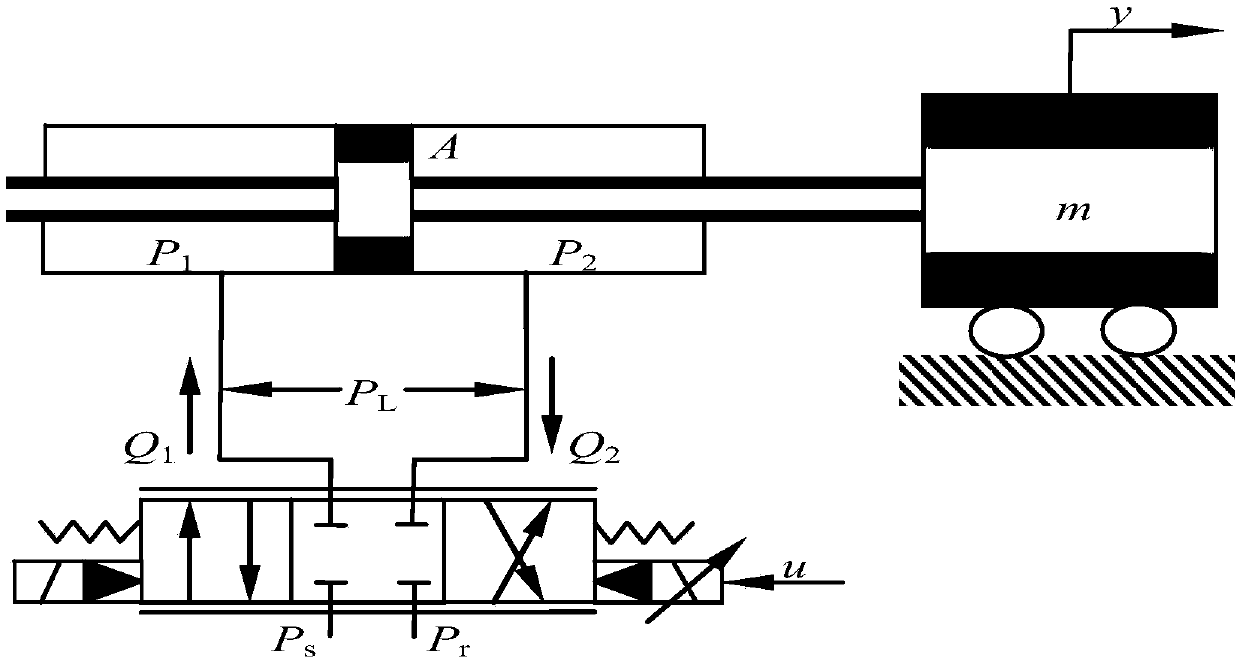

[0145] In order to assess the performance of the designed controller, the following parameters are taken in the simulation to model the hydraulic system:

[0146] m=30kg, B=8000, A=904.778mm 2 , V=3.98×10 -5 m 3 , P s =10MPa, P r =0

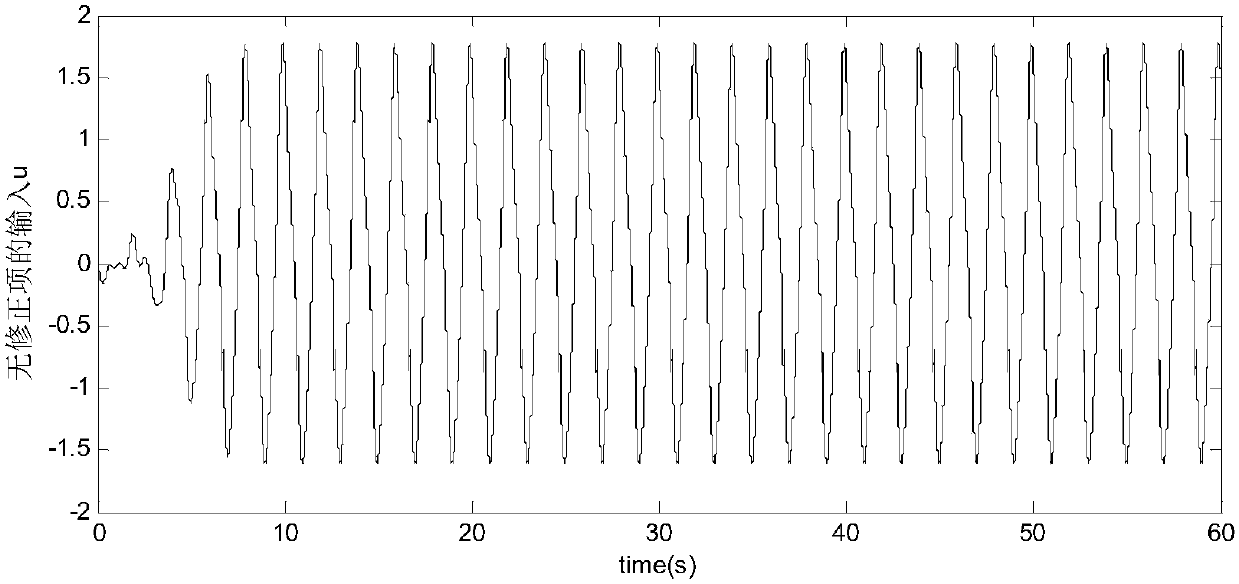

[0147] The desired instruction for a given system is x 1d =0.02sin(t)[1-exp(0.01t 3 )] (m).

[0148] time-varying interference

[0149] White noise (sin(30*pi*t)+50sin(40*pi*t)+50sin(50*pi*t))*0.00001.

[0150] Take the following controller for comparison:

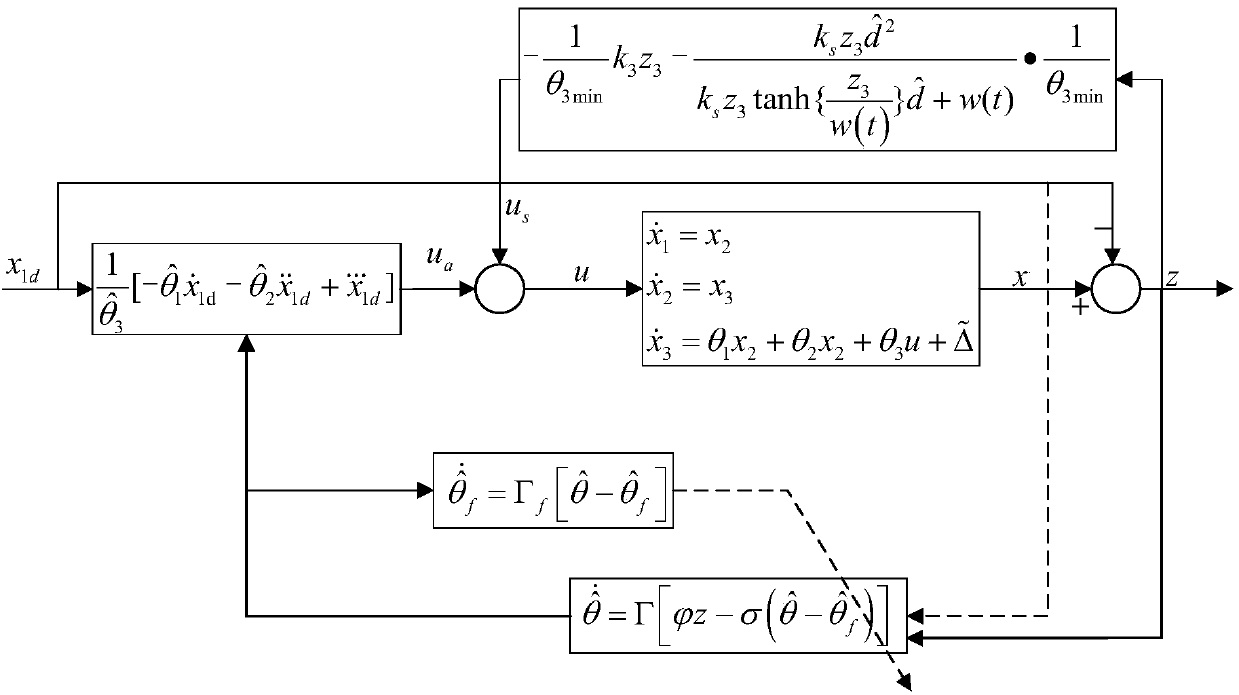

[0151] Adaptive robust controller: take the controller parameter k 1=300,k 2 =300,k 3 =85,k s =1; parameter initial value Adaptive rate gain Γ 1 =250000, Γ 2 =15000, Γ 3 =0.01, Γ=1×e -6 .

[0152] Adaptive robust low-frequency learning controller: take the controller parameter k 1 =300,k 2 =300,k 3 =85,k s =1; parameter initial value Adaptive rate gain Γ 1 =250000, Γ 2 =15000, Γ 3 =0.01, Γ=1×e -6 ; Correction item gain σ=0.001, Γ f1 =250000, Γ f2 =0.05, Γ f3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com