Method for machining metal protective cover

A processing method and metal protection technology, applied in the processing field of metal protective cover, can solve the problem of high cost, and achieve the effect of reducing processing cost and shortening processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The wave shearing process of the present invention will be further described below in conjunction with the accompanying drawings.

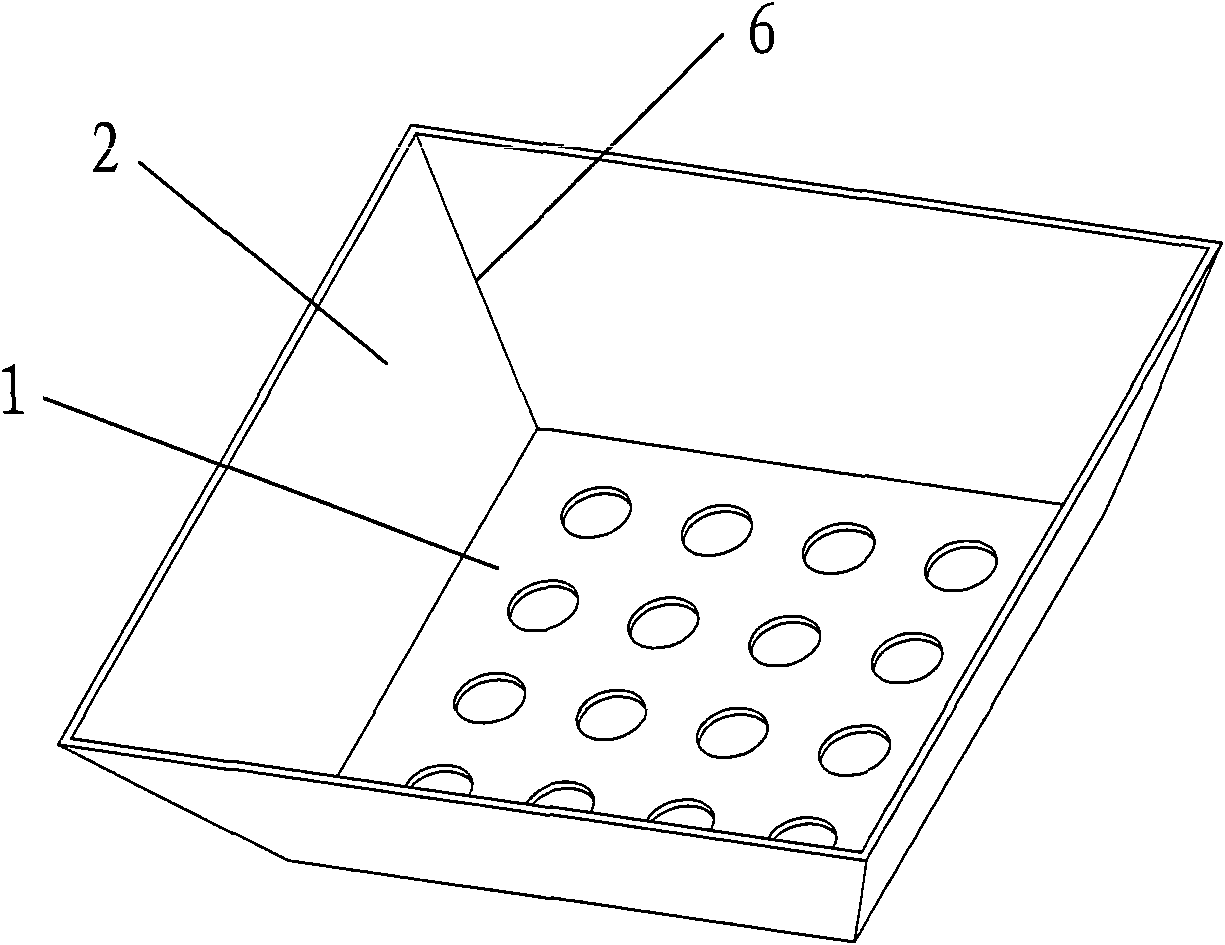

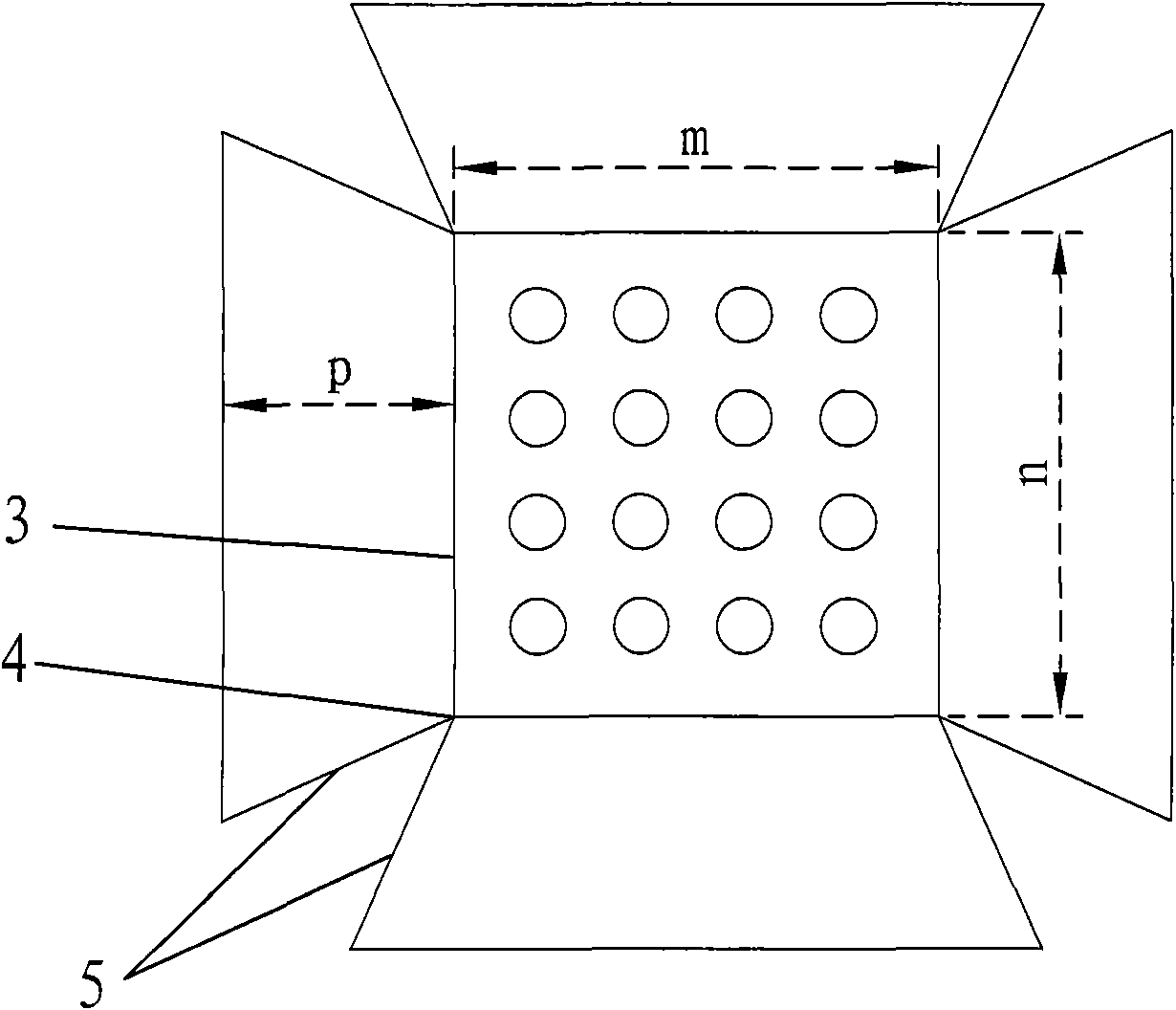

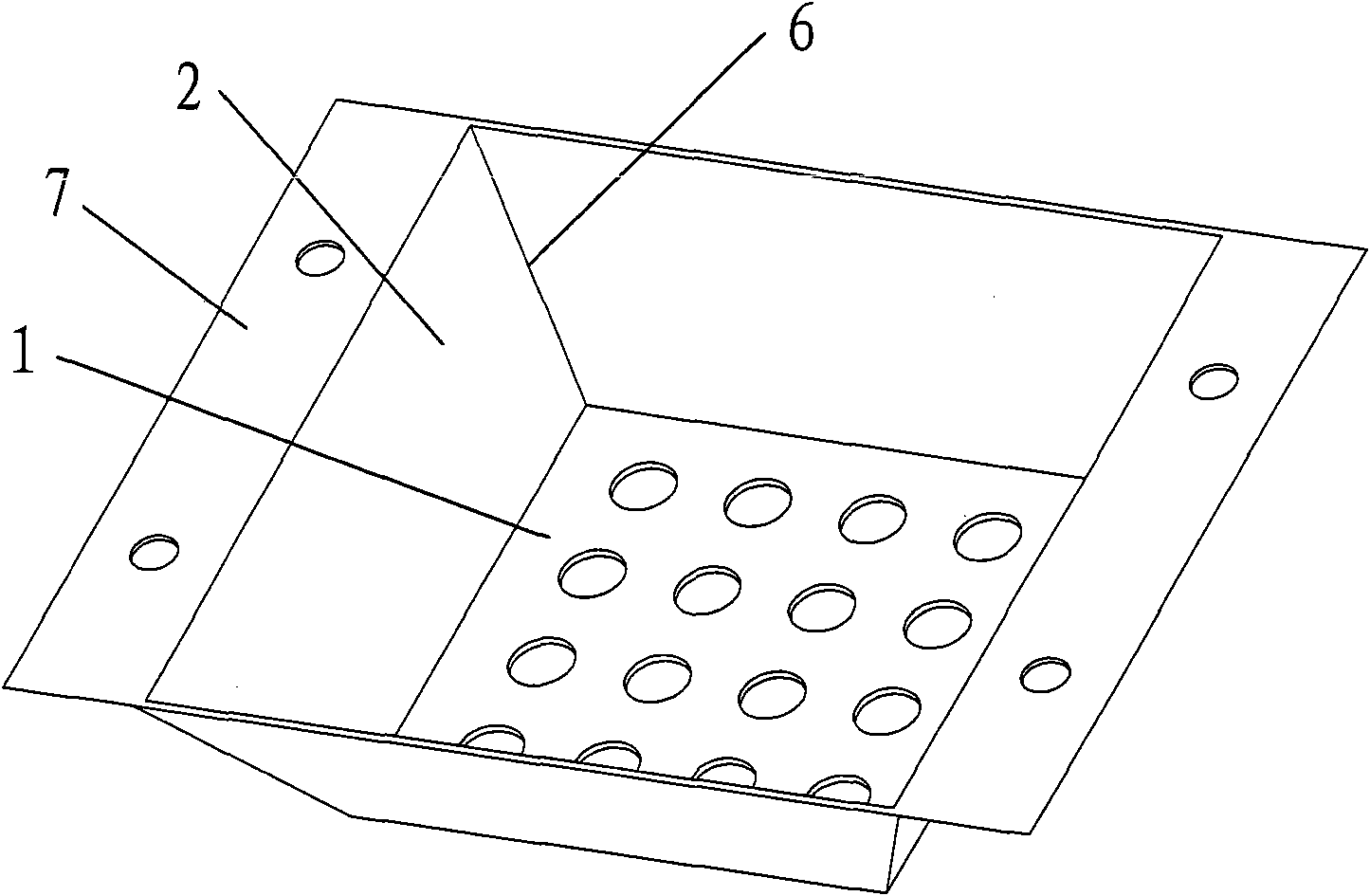

[0020] as attached figure 1 , 2 Shown protective cover, the bottom surface 1 shape of this protective cover is rectangular, and the side 2 shape is isosceles trapezoidal, and the processing method of the large protective cover of the present invention comprises the following steps:

[0021] a. Take a rectangular steel plate. The length dimension x of the steel plate is equal to the sum of the length of the bottom surface 1 of the protective cover and the width of the two sides 2. The width dimension y of the steel plate is equal to the width of the bottom surface 1 of the protective cover and the width of the two sides. The sum of the widths of the sides 2, for example, the length of the bottom surface 1 is m, the width is n, and the width of the sides 2 is p, then x=m+2p, y=n+2p;

[0022] b. Draw four end-to-end first fold lines 3 that a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com