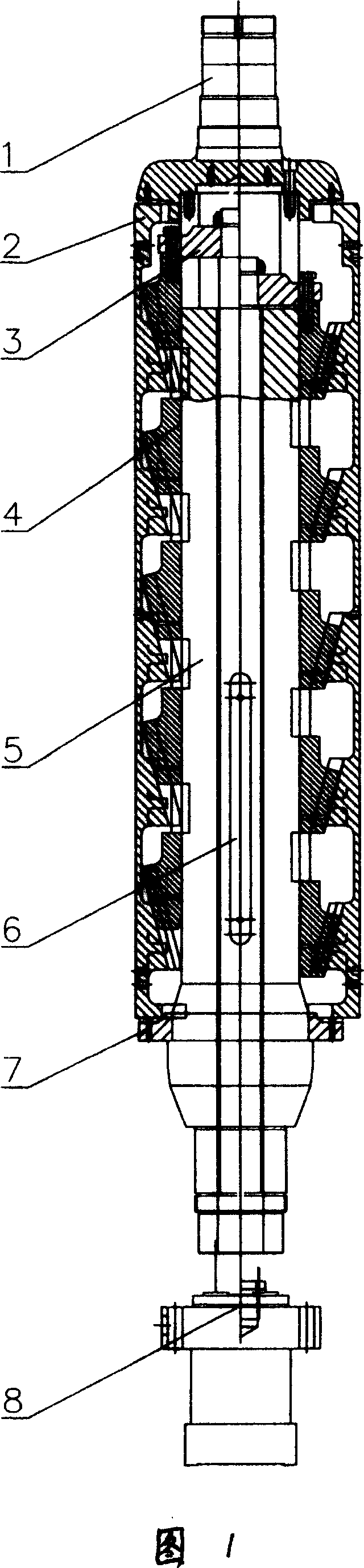

Oblique wedge type barrel arbor decoiler on flying shear line

A technology of reel shaft and uncoiler, applied in the field of cantilever shaft, to achieve the effect of increasing diameter, improving strength, and simple connection design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

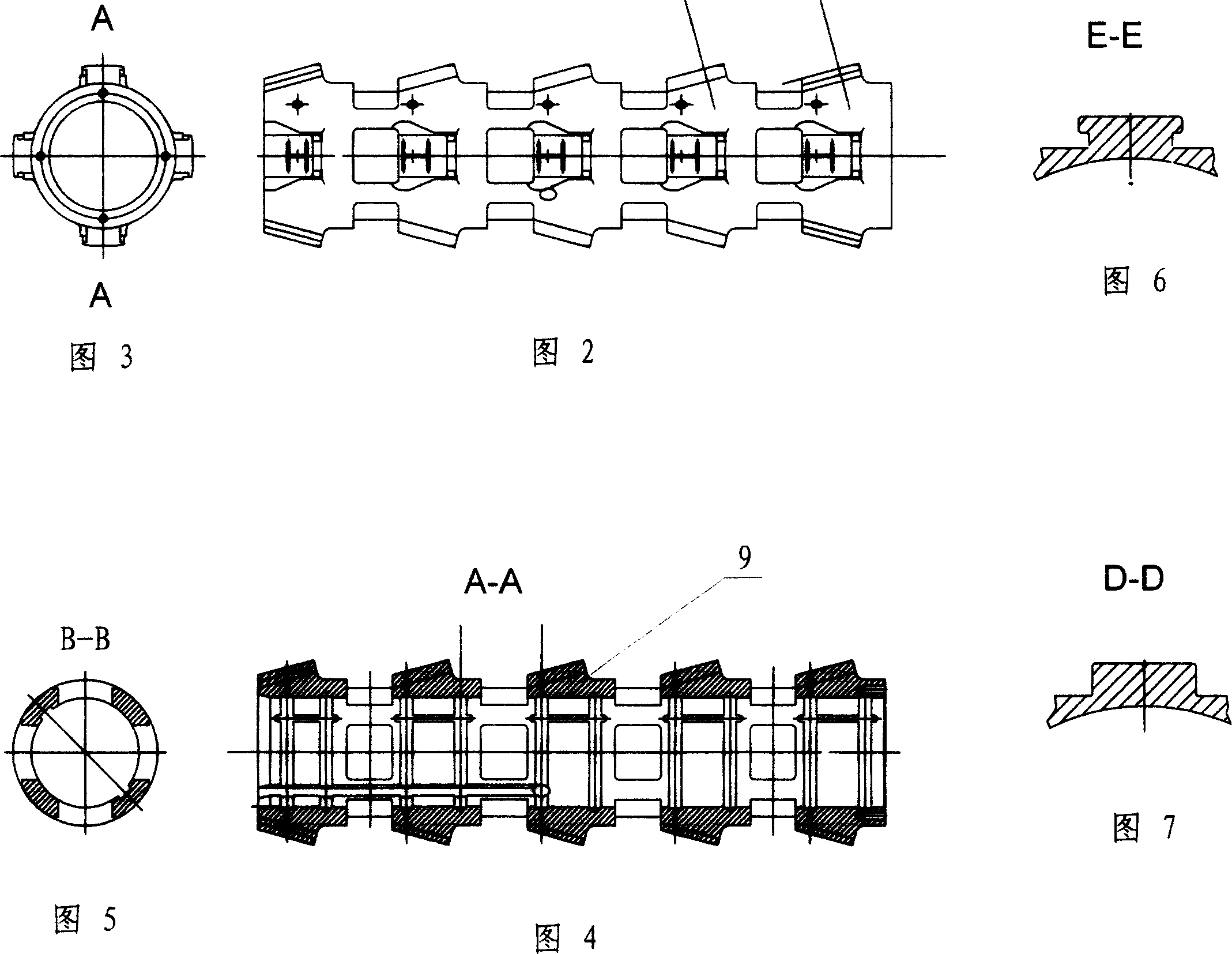

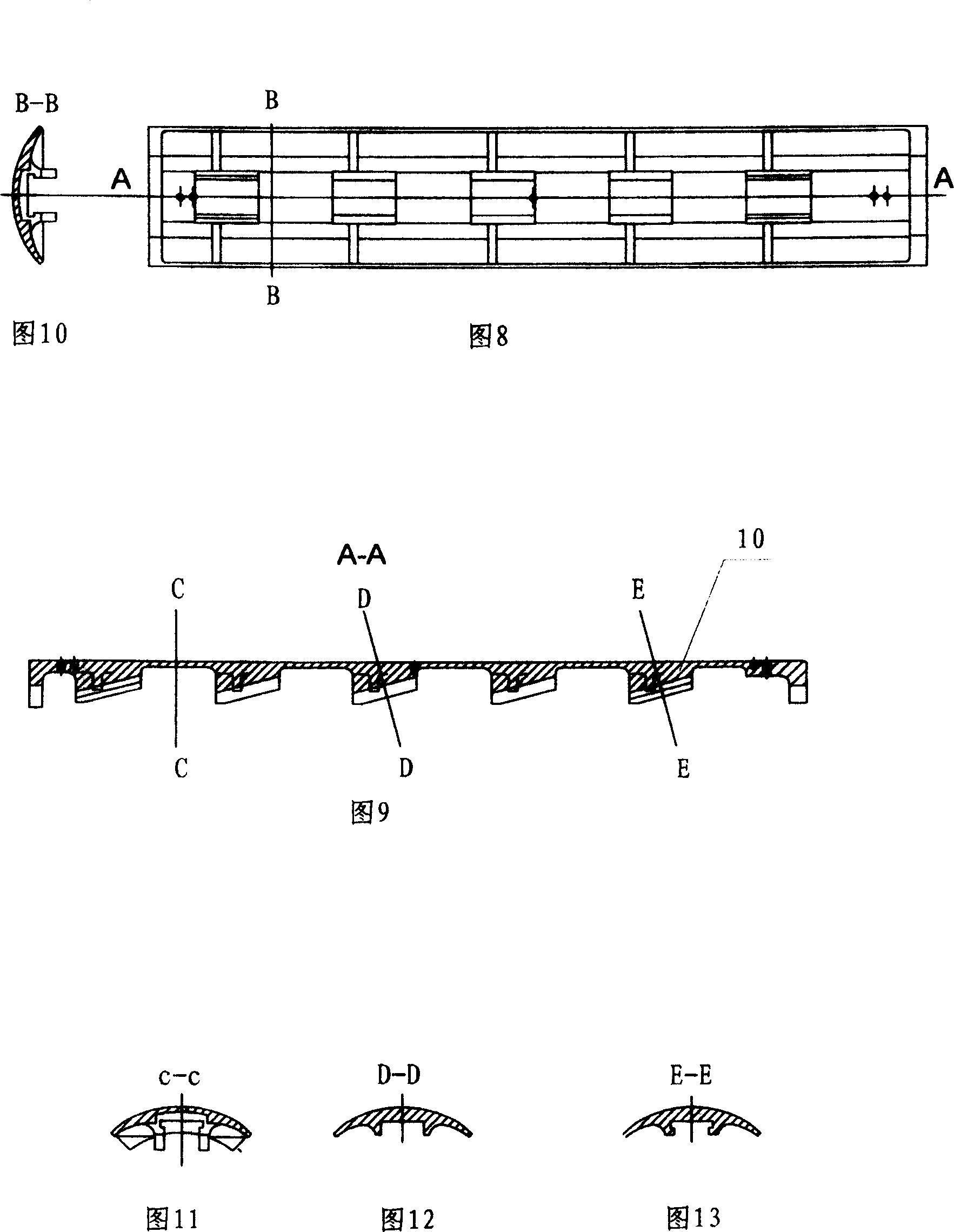

[0025] The present invention specially designs a shaft sleeve 4, and four rows, five wedge blocks 9 in each row are evenly distributed on the outer surface of the shaft sleeve 4; the cross sections of the eight wedge blocks 9 at both ends of the shaft sleeve 4 are T-shaped.

[0026] Four arched plates 2 are also arranged on the outer layer of the shaft sleeve 4. The cross section of the arched plates 2 is 1 / 4 arc-shaped. The slope of the wedge 10 is in surface contact with the slope of the wedge 9 on the outer surface of the bushing 4; the two wedges 10 at the end of the arched plate 2 have T-shaped grooves in section.

[0027] The cross-section of the two ends of the axle sleeve 4 is a T-shaped wedge block 9 that can be dropped into the T-shaped groove 10 of the wedge block at the end of the arcuate plate 2, and can slide mutually. In this way, the four arched plates 2 are respectively connected to the outer surface of the bushing 4 through the T-shaped groove structure. When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com