Compound cast-rolling device for metallurgical bonding of liquid aluminum base strip and single metal or alloy strip

A technology of metallurgical bonding and substrate strips, which is applied in metal processing equipment, metal rolling, metal rolling, etc., can solve problems such as long production cycle, failure of composite interface to achieve metallurgical bonding, complex composite process, etc., and achieve the goal of ensuring processing quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

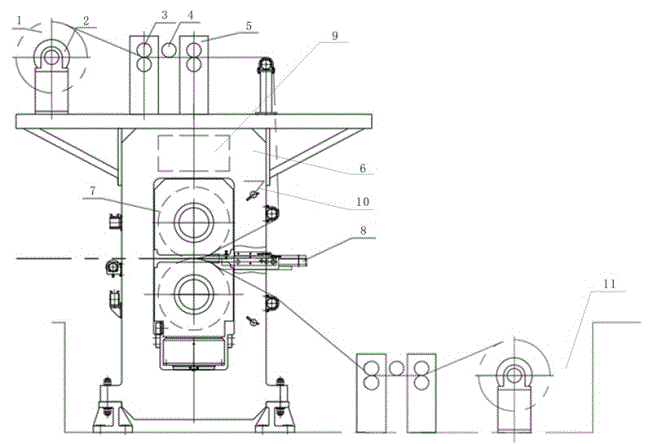

[0029] In conjunction with accompanying drawing, provide embodiment of the present invention as follows:

[0030] Such as figure 1 Shown: the metallurgical combination of the liquid aluminum substrate strip described in this embodiment and a single metal or alloy strip

[0031] The composite casting and rolling equipment mainly includes a casting machine 7, a coiler 2, a heater 9 and a brush mill 4. The casting machine 7 adopts a known horizontal aluminum casting machine, which is fixed on the archway 6 for The front end of the casting nozzle device 8 that sends the core material-aluminum liquid base material into the composite area is located in the composite area at the entrance of the casting rod of the casting machine 7, and the rear end is connected to the aluminum liquid flow tank. Coiler 2 (also called uncoiler) adopts conventional equipment, and its function is to roll the skin material-alloy strip 1 to be compounded. Coiler 2 can be installed with one or two set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com