Thick plate continuous rolling and continuous plating production line adopting disengagement and engagement method

A production line and thick plate technology, applied in the field of closed-loop continuous rolling automatic clutch device for thick plate continuous production line, can solve the problems of high long-term production cost and increased investment cost of the owner, and achieve the effect of reliable guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

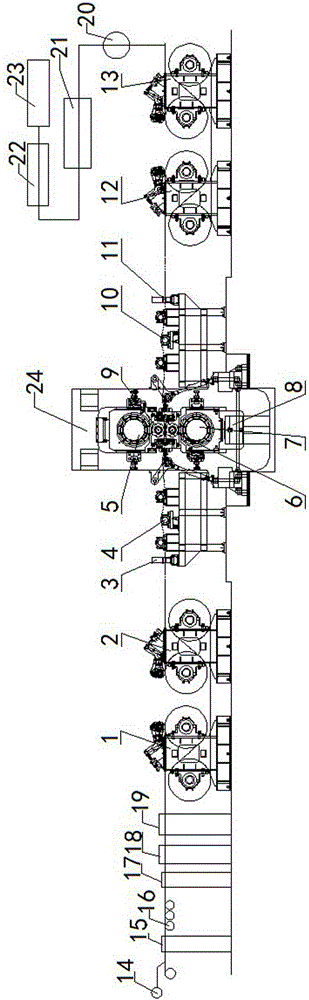

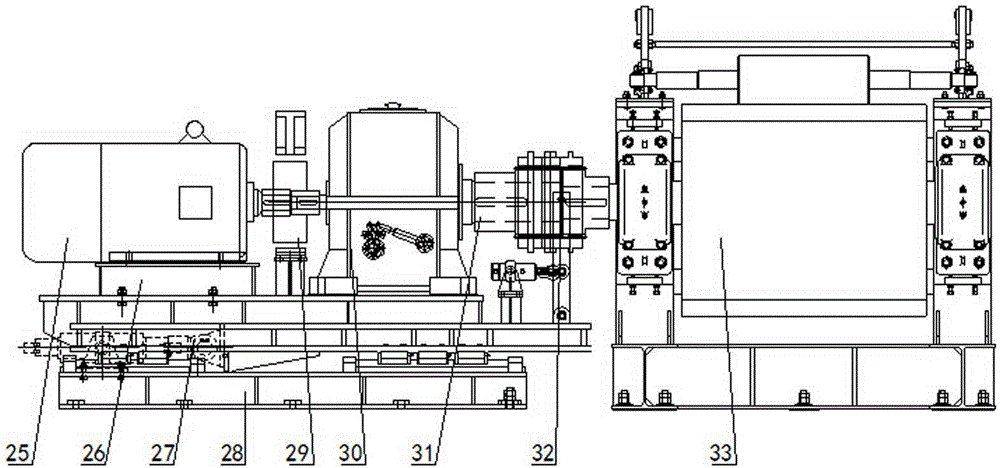

[0013] Such as figure 1 , 2 As shown, a production line for continuous rolling and continuous plating of thick plates by the separation method, the production line includes an uncoiler 14, a narrow lap automatic welding machine 15, an S roll 16, a CPC correction device 17, a cleaning tank 18, and a hot air dryer connected in sequence. 19. Tensioning machine A1, tensioning machine B2, rolling mill 24, tensioning machine C12, tensioning machine D13, jumping roll 20, entrance tension measuring machine II 21, continuous annealing furnace 22, zinc pot 23, rolling mill including upper backup roll 5 , lower back-up roll 7, upper working roll 9, lower working roll 6, AGC cylinder 8, thickness gauge 3, back thickness gauge 11, entrance tension measuring machine Ⅰ4 and exit tension measuring machine 10, upper working roll, lower working roll Symmetrical design, the upper back-up roll is set above the upper work roll, the lower back-up roll is set under the lower work roll, the thicknes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com