Method and device for improving super-rapid cooling evenness of hot rolled steel plate

A technology for ultra-rapid cooling and hot-rolling of steel plates, applied in cooling bed, metal rolling, metal rolling, etc., can solve the problems of head and tail warping, large cooling rate, and uneven mechanical properties of the same plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

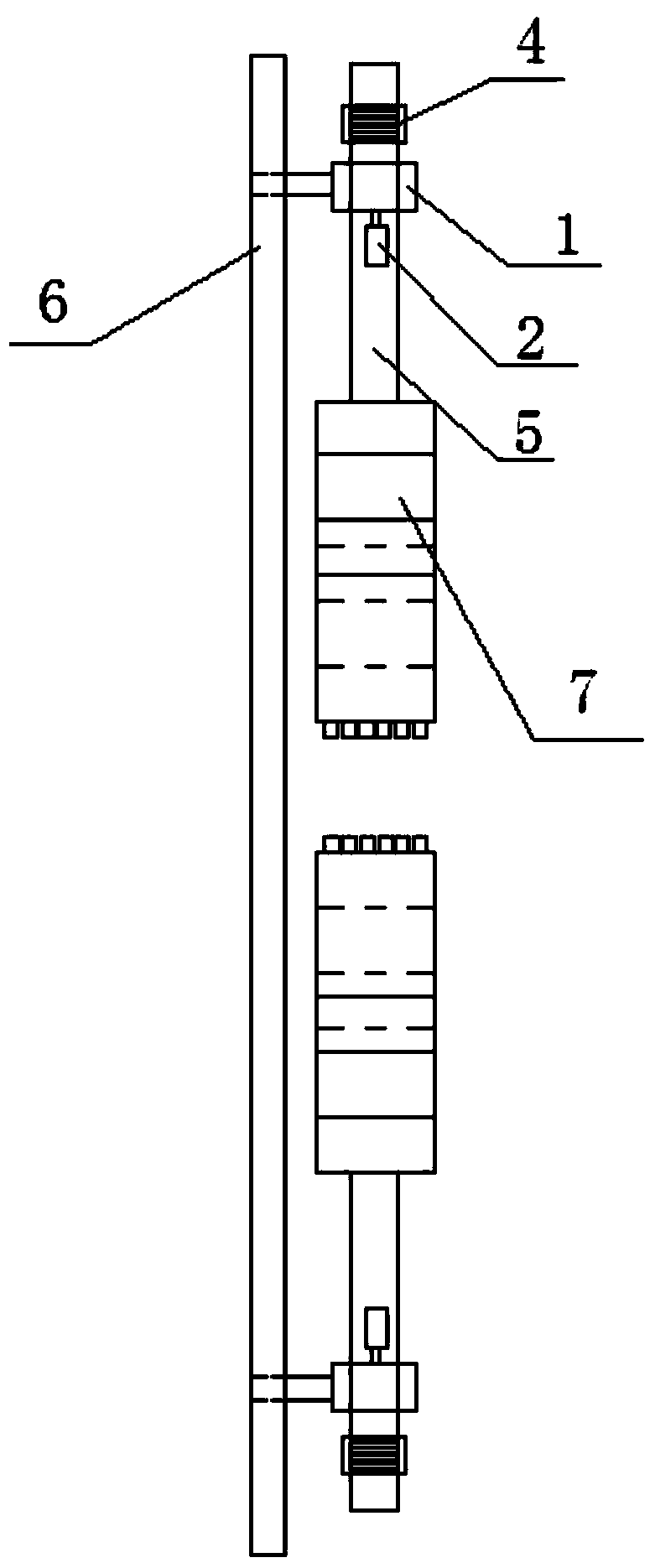

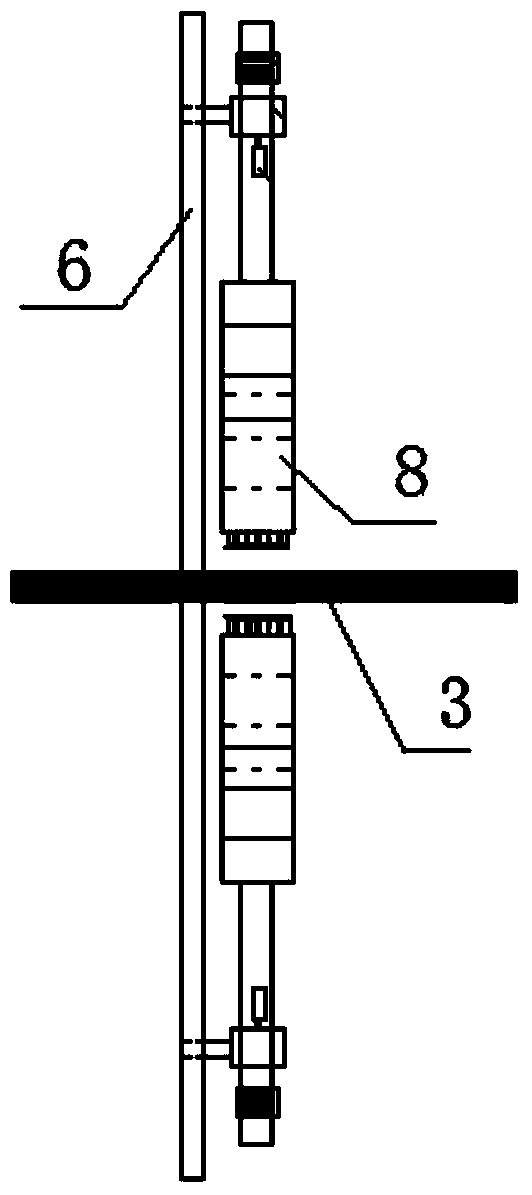

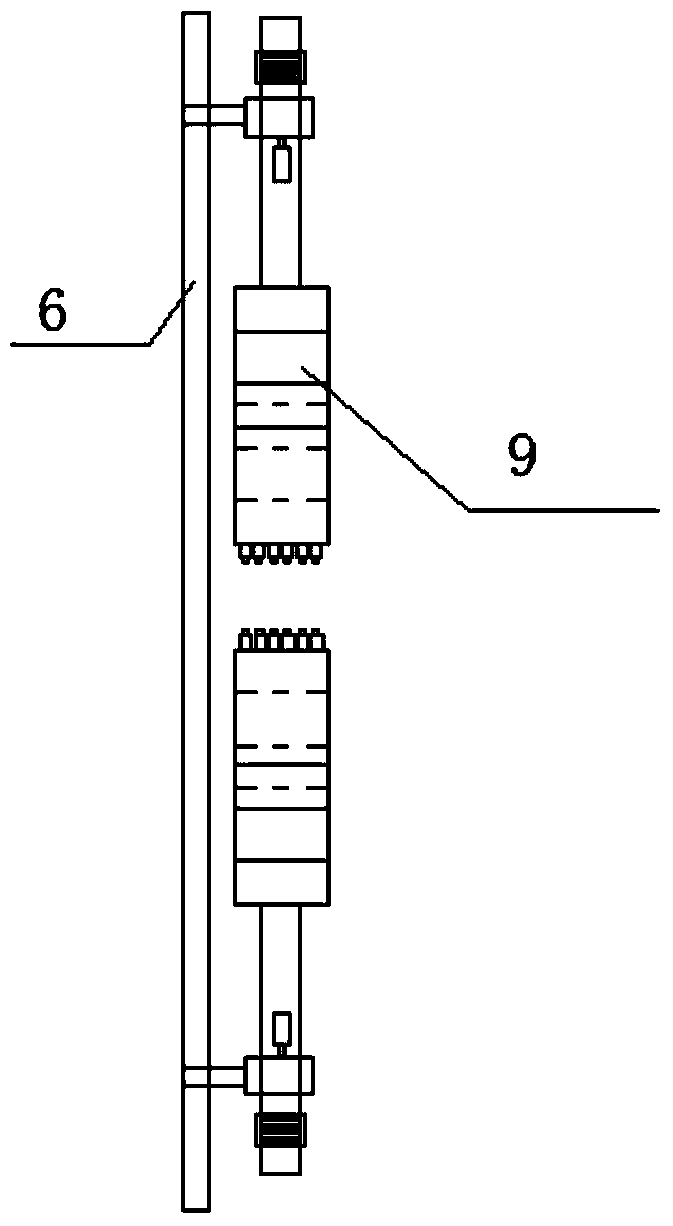

[0027] see Figure 8 , according to the needs of the cooling steel plate 3, step 1, according to the needs of the cooling steel plate 3, an ultra-rapid cooling mechanism, a laminar flow cooling mechanism and a high-density straight header cooling mechanism are set on the support 6; step 2, when the steel plate 3 enters the cooling area, Put the steel plate 3 into the bracket 6, and set the 5-7 sections of ultra-fast cooling headers of the ultra-rapid cooling mechanism, the 5-7 sections of laminar flow cooling headers of the laminar flow cooling mechanism, and high-density direct collectors on the upper and lower ends of the steel plate 3. 5-7 sections of high-density straight headers of the tube cooling mechanism; the distance between each adjacent header is within 5mm; step 3, turn on the drive motor 2 on the laminar flow cooling header, high-density straight header and ultra-fast cooling header ; Step 4, the drive motor 2 drives the gear box 1 on the laminar flow cooling hea...

Embodiment 2

[0029] According to the needs of the cooling steel plate 3, step 1, according to the needs of the cooling steel plate 3, set a high-density straight header cooling mechanism, an ultra-fast cooling mechanism or an air-water atomization cooling mechanism on the support 6; step 2, when the steel plate 3 enters the cooling area, The steel plate 3 is sent into the bracket 6, and the upper and lower ends of the steel plate 3 are respectively provided with 5-7 high-density straight headers of the high-density straight header cooling mechanism, 5-7 ultra-fast cooling headers of the ultra-fast cooling mechanism or air 5-7 air-water atomization headers of the water atomization cooling mechanism; step 3, turn on the drive motor 2 on the high-density straight header, ultra-fast cooling header or air-water atomization header; step 4, drive the motor 2 Drive the gearbox 1 on the high-density straight header, ultra-fast cooling header or air-water atomization header, and the gear box 1 drives...

Embodiment 3

[0031]According to the needs of the cooling steel plate 3, step 1, when the steel plate 3 enters the cooling area, a laminar flow cooling mechanism, an ultra-rapid cooling mechanism or an air-water atomization cooling mechanism is set on the support 6 according to the needs of the cooling steel plate 3; Step 2, the steel plate 3 into the bracket 6, the upper and lower ends of the steel plate 3 are respectively provided with 5-7 sections of laminar flow cooling headers of the laminar flow cooling mechanism, 5-7 sections of ultra-rapid cooling headers of the ultra-rapid cooling mechanism, or 5-7 sections of the air-water atomization cooling mechanism. 5-7 stages of air-water atomization header; step 3, turn on the drive motor 2 on the laminar flow cooling header, ultra-fast cooling header or air-water atomization header; step 4, drive motor 2 to drive the laminar flow cooling header The gear box 1 on the tube, ultra-fast cooling header or air-water atomization header, and the gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com