Non-going-forward device for small-pitch stepper cooling bed

A step-by-step, tooth-pitch technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve problems affecting the quality of steel pipes, bending deformation of hot steel pipes, etc.

Inactive Publication Date: 2010-08-11

TAIYUAN HEAVY IND

View PDF0 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to overcome the shortcomings of the prior art and provide a stepping device for a step-by-step cooling bed with a small tooth pitch to solve the problem that when the steel pipe needs to stay on the cooling bed, the hot steel pipe will be bent and deformed, which will affect the quality of the steel pipe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a non-going-forward device for a small-pitch stepper cooling bed, and relates to hot-rolled steel pipe cooling equipment. The invention comprises a fixed rack, a movable rack and a transmission mechanism, wherein the movable rack is supported by two groups of No.I eccentric wheels, and a group of No.II eccentric wheels drive the movable rack through a connecting rod, a lever, a pull rod and a rocker; and a group of eccentric wheels of the two groups of No.I eccentric wheels and the No.II eccentric wheels are coaxial, and a motor is driven by a speed reducer, so that the movable rack moves along the elliptical trajectory. The invention is characterized in that the pull rod between the lever and the rocker is connected with a hydraulic cylinder in series. The invention solves the problems that hot steel pipes bends and deforms to affect the quality of the steel pipes when the steel pipes need to stay on the cooling bed. When the steel pipes stay on the cooling bed, the steel pipes can roll in the rack of the cooling bed and can not go forward, so that the steel pipes can be straightened when being cooled.

Description

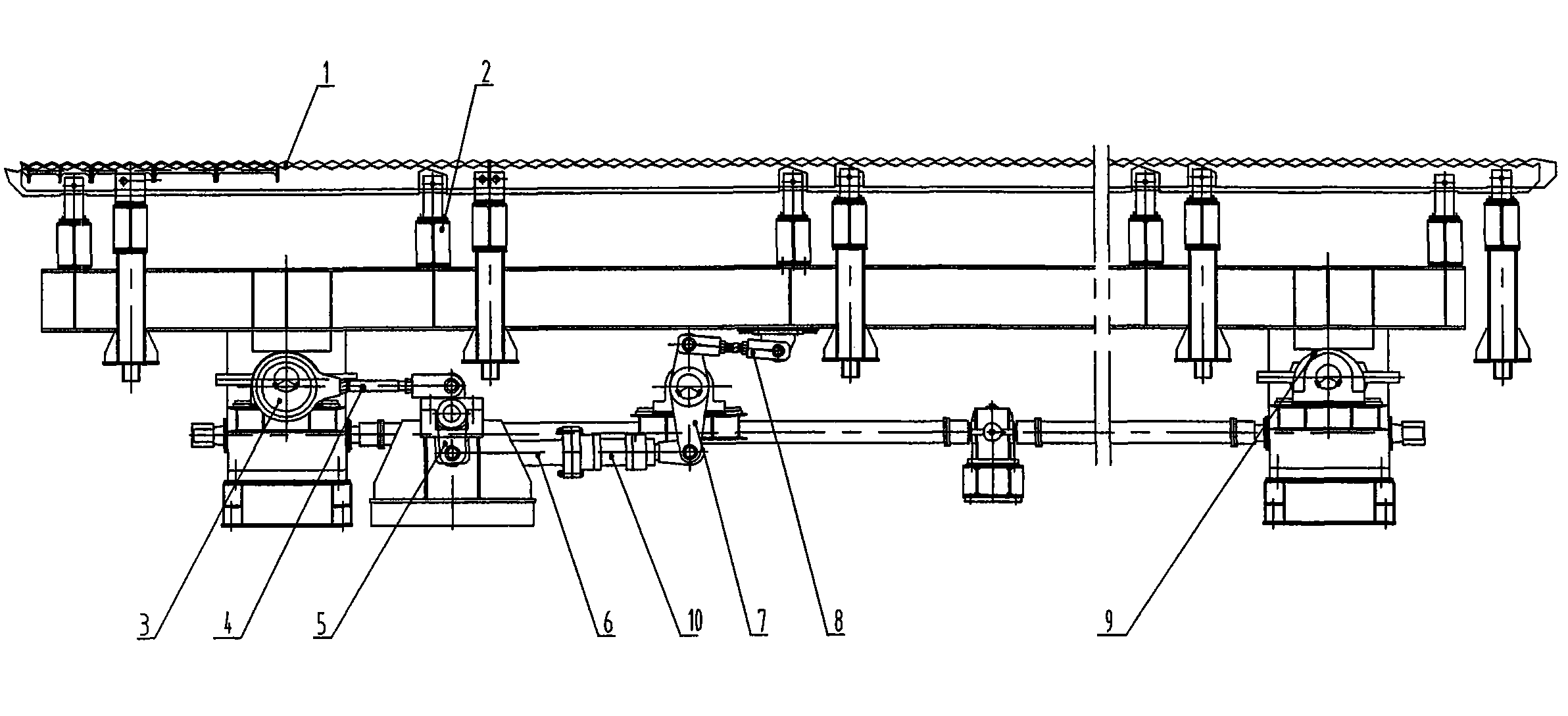

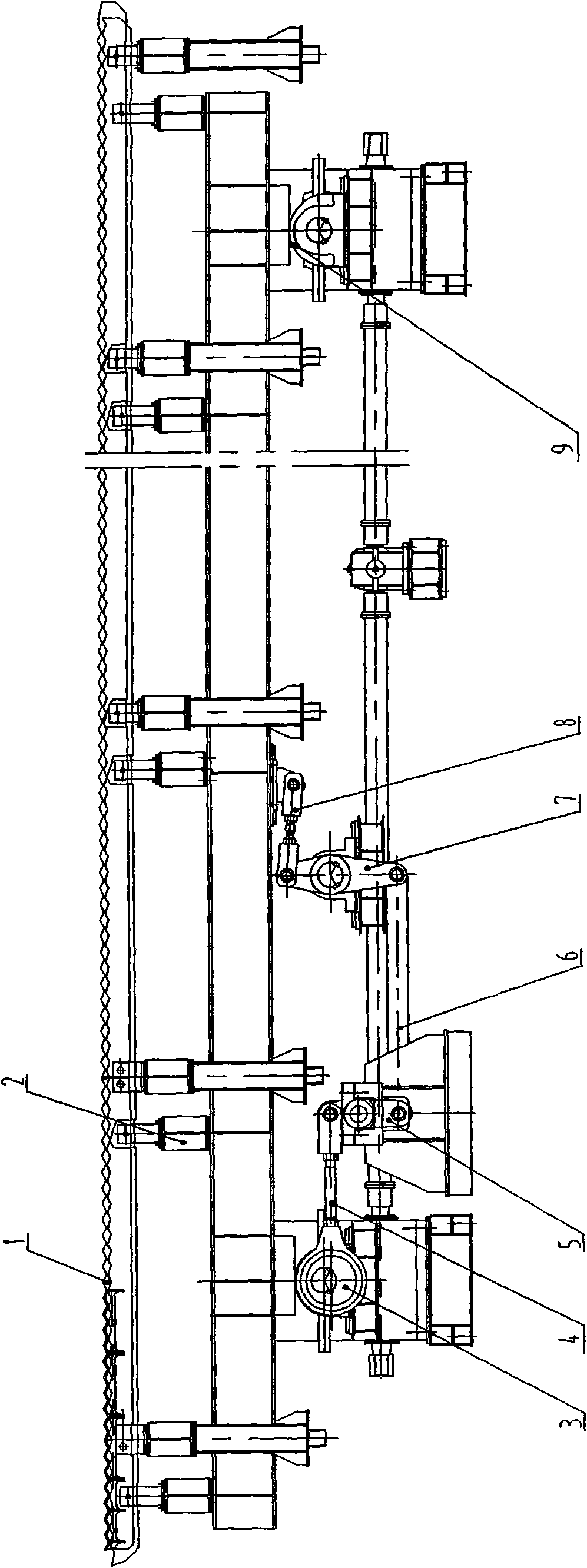

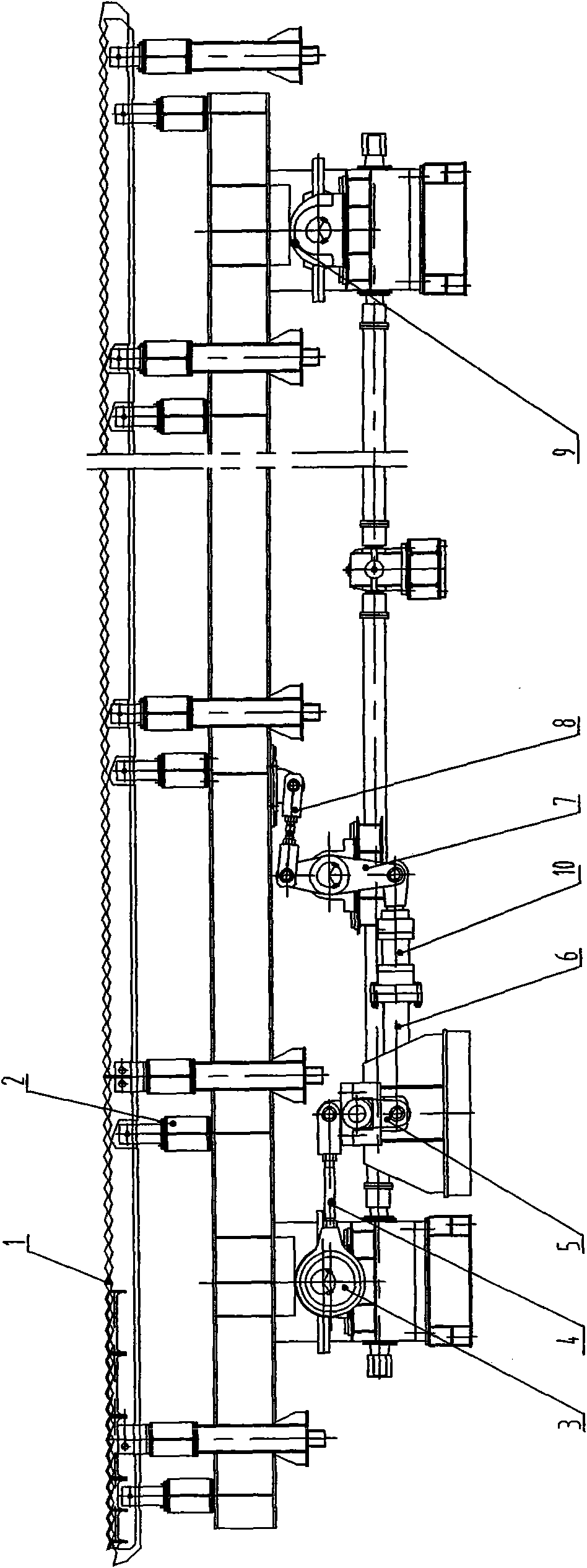

Stepping device for stepping cooling bed with small tooth pitch technical field The invention belongs to cooling equipment for hot-rolled steel pipes, in particular to a transmission device for a small-tooth-pitch step-type cooling bed in a seamless steel pipe production unit. Background technique The step-by-step cooling bed with small tooth pitch is installed behind the sizing (reducing) machine, and accepts the hot-rolled steel pipe output by the sizing (reducing) machine, cools it to the required temperature, and transports it to the next station. The small pitch step-type cooling bed device of prior art is shown in Figure 1, comprises: fixed rack 1, moving rack 2 and its transmission mechanism, moving rack 2 is supported by two groups of No. I eccentric wheels 9, by A group of No. II eccentric wheels 3 drives the mobile rack 2 through the connecting rod 4, lever 5, pull rod 6, rocker 7, and adjusting pull rod 8; Coaxial, and driven by the motor through the reducer, t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21B43/00

Inventor 赵玉洁

Owner TAIYUAN HEAVY IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com