Process for producing flat-bulb steel

A production process and technology of bulb flat steel, applied in the direction of manufacturing tools, metal processing equipment, cooling beds, etc., can solve the problems of influence of cross-sectional structure, single specifications, quality defects, etc., to achieve good versatility, good elasticity, profile easy to divide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, the production process of this embodiment is: rectangular billet→heating→BD1 rolling→BD2 rolling→D R D F Rolling→natural cooling on cooling bed→cold cutting and straightening treatment.

[0029] Specific steps are as follows:

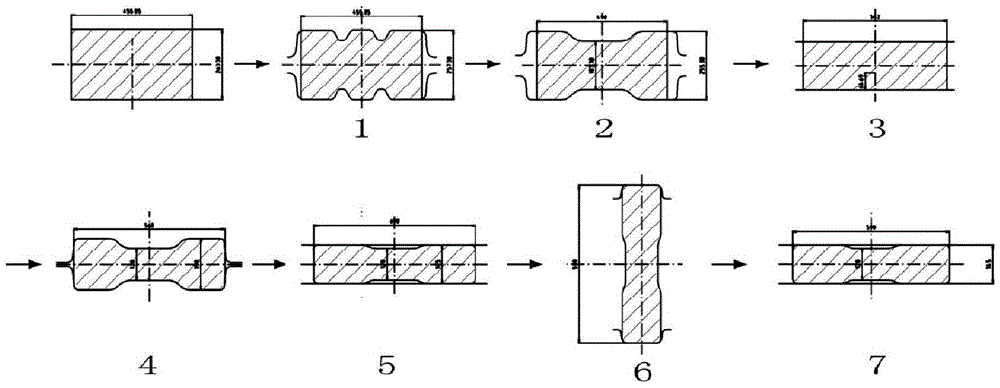

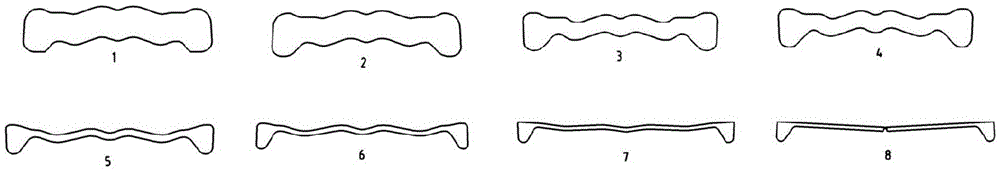

[0030] (1) If figure 1 As shown in the figure, the rectangular blank is widened into a flat blank by the first blanking machine (BD1). Through zone rolling, the extension of the rolling stock is reduced and the extension is increased, so that the amount of extension can be increased by 30% compared with the conventional extension. At the same time, the rectangular billet can be fully extended with a small force, which is suitable for extension Large-sized rectangular blanks.

[0031] BD1 rolling specifically includes 7 passes: the first pass is to press out two grooves on the upper and lower sides of the rectangular billet; the second pass is to flatten the bosses between the two grooves; the third pass 3 times, flatten the bos...

Embodiment 2

[0037] Embodiment 2, the production process of this embodiment is: rectangular billet→heating→BD1 rolling→BD2 rolling→D R D F Rolling→cold bed strong air cooling→cold slitting and straightening treatment. Except for "cooling with strong air cooling on a cooling bed", other processes are the same as those in Embodiment 1, and will not be repeatedly described in this embodiment.

[0038] The specific cooling bed strong air cooling process is D R D F The raw material obtained in the rolling enters the cooling bed workshop 12 for cooling, and the cooling bed workshop 12 is as follows: Figure 4 As shown, including the cooling bed 6, the foundation pit, the ventilator 14 and the forced cooling fan 5, the cooling bed inlet 11 and the cooling bed outlet 7 of the cooling bed workshop 12 are respectively provided with an inlet foundation pit 8 and an outlet foundation pit 9. Both the pit 8 and the outlet foundation pit 9 extend out of the cooling bed workshop 12 , and the length and ...

Embodiment 3

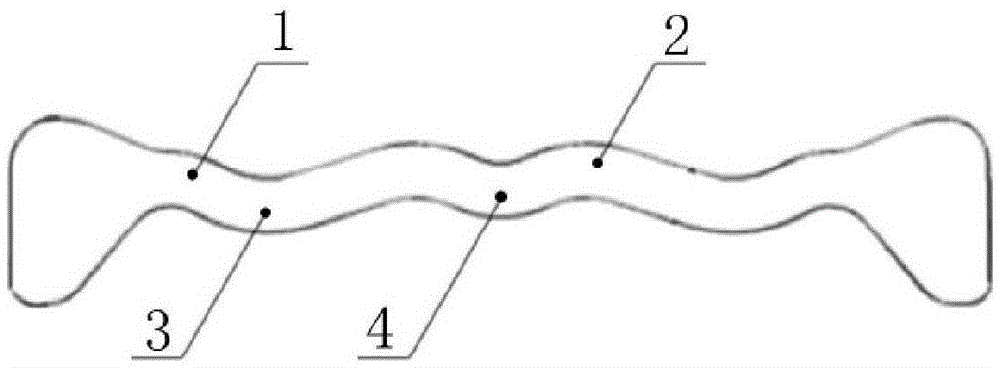

[0040] Embodiment 3, this embodiment is temperature-controlled rolling on the basis of embodiment 1, and the production process is: rectangular billet → heating → BD1 rolling → BD2 rolling → temperature control treatment → D R D F Rolling→cooling→cold cutting and straightening treatment. The temperature control treatment is as follows: after BD2 rolling, the temperature of the "wave-shaped" material shape is 940°C to 1010°C, and the material shape is then cooled by a water curtain to reduce the temperature to 700°C to 750°C, and the temperature remains in this temperature range. D inside R D F rolling. Its purpose is to increase the elasticity of the bulb flat steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com