Gear steel banded structure control process

A banded structure and gear steel technology, which is applied in the field of iron and steel metallurgy manufacturing, can solve the problems of demanding gear steel, failing to meet high-quality gear steel users, and unable to fully reduce the banded structure of gear steel, so as to improve surface quality and suppress Diffusion of carbon and the effect of reducing water penetration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

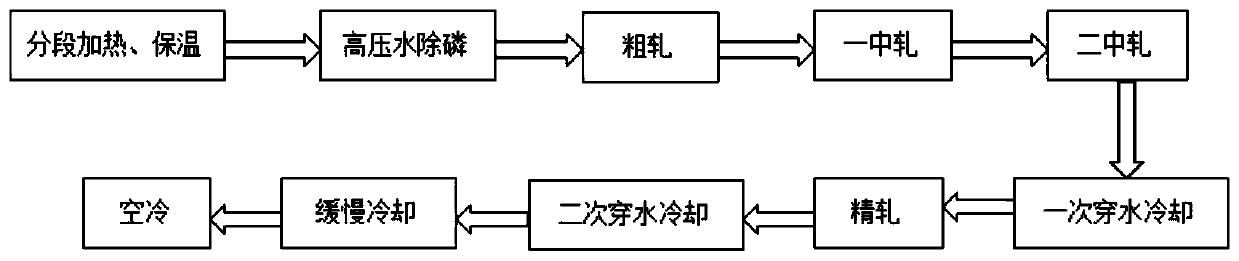

[0030] Step 1: billet heating: send the billet into the heating furnace and heat it in sections, the heating temperature is: preheating section: 750°C; heating stage: 900°C; heating stage two: 1180°C; soaking section: 1180°C; heating The time is 170 minutes, the temperature of the furnace is 1070-1240 ° C, and the heat is kept for 8 hours after the heating is completed;

[0031] Step 2: Rough rolling: the steel slab after heat preservation is dephosphorized by high-pressure water and then sent to the rough rolling unit. The rough rolling temperature is 1080°C;

[0032] Step 3: Intermediate rolling: Send the rough-rolled billet to the first intermediate rolling unit and the second intermediate rolling unit in sequence, the temperature of the first intermediate rolling is 1030°C, and the temperature of the second intermediate rolling is 970°C;

[0033] Step 4: Primary water cooling: send the middle-rolled billet to the first water cooling device for cooling, and the cooling rate...

Embodiment 2

[0039] Step 1: Steel billet heating: Send the billet into the heating furnace and heat it in sections. The heating temperatures are: preheating section: 760°C; heating stage: 1000°C; heating stage two: 1210°C; soaking section: 1210°C; The time is 170 minutes, the temperature of the furnace is 1070 ~ 1240 ° C, and the heat is kept for 9 hours after the heating is completed;

[0040] Step 2: Rough rolling: the steel slab after heat preservation is dephosphorized by high-pressure water and then sent to the rough rolling unit. The rough rolling temperature is 1100°C;

[0041] Step 3: Intermediate rolling: Send the rough-rolled billets to the first intermediate rolling unit and the second intermediate rolling unit in sequence, the temperature of the first intermediate rolling is 1050°C, and the temperature of the second intermediate rolling is 980°C;

[0042] Step 4: Primary water cooling: send the middle-rolled billet to the first water cooling device for cooling, and the cooling ...

Embodiment 3

[0048] Step 1: billet heating: put the billet into the heating furnace and heat it in sections. The heating temperature is: preheating section: 800°C; heating stage: 1100°C; heating stage two: 1240°C; soaking section: 1240°C; heating The time is 170 minutes, the temperature out of the furnace is 1070-1240 ℃, after the heating is completed, it is out of the furnace and kept for 10 hours;

[0049] Step 2: Rough rolling: send the heat-preserved steel slab to the rough rolling unit after dephosphorization by high-pressure water, and the rough rolling temperature is 1140°C;

[0050]Step 3: Intermediate rolling: Send the rough-rolled billet to the first intermediate rolling unit and the second intermediate rolling unit in sequence, the temperature of the first intermediate rolling is 1080°C, and the temperature of the second intermediate rolling is 990°C;

[0051] Step 4: Primary water cooling: send the middle-rolled billet to the first water cooling device for cooling, and the cool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com