Method for producing hot-rolling U-shaped steel sheet pile with residual stress less than 100 MPa

A technology of residual stress and production method, applied in the direction of metal rolling, metal rolling, manufacturing tools, etc., can solve the added value discount of hot-rolled U-shaped steel sheet piles, reduce the market competitiveness of hot-rolled U-shaped steel sheet piles, increase equipment Budget and production costs and other issues to achieve the effect of improving market competitiveness, improving the effect of piling use, and facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

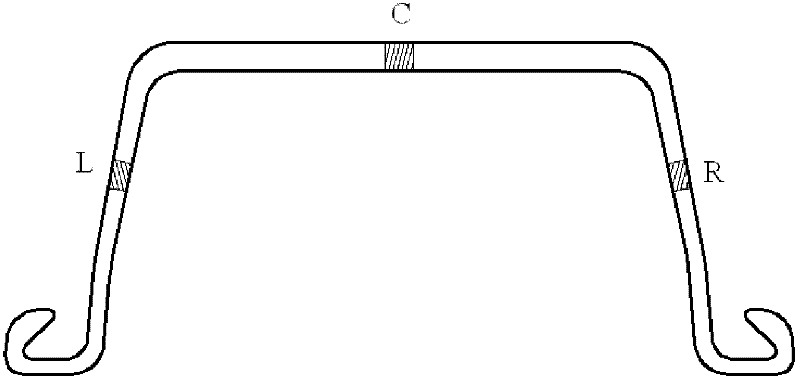

Image

Examples

Embodiment Construction

[0020] The following is a further detailed description:

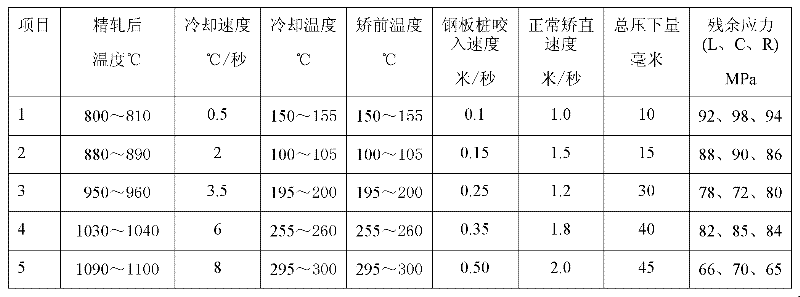

[0021] The following table is a statistical table of process parameters and residual stress detection results of each embodiment.

[0022] Process parameters and residual stress detection results of each embodiment

[0023]

[0024] It can be seen from the table that by adopting the present invention, the residual stress of the hot-rolled U-shaped steel sheet pile is completely controlled within 100 MPa, thereby effectively improving the piling effect of the hot-rolled U-shaped steel sheet pile, and fully meeting the needs of users. And the process is simple, without adding equipment, which creates conditions for reducing production costs and improving user market competitiveness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com