Method for making silicon-base micro-mechanical adjustable light wave-filter with wide frequency domain

A manufacturing method and optical filter technology, which are applied in the fields of instruments, optics, nonlinear optics, etc., can solve the problems of unfavorable manufacturing of optical devices, low working stability, and difficult thickness control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

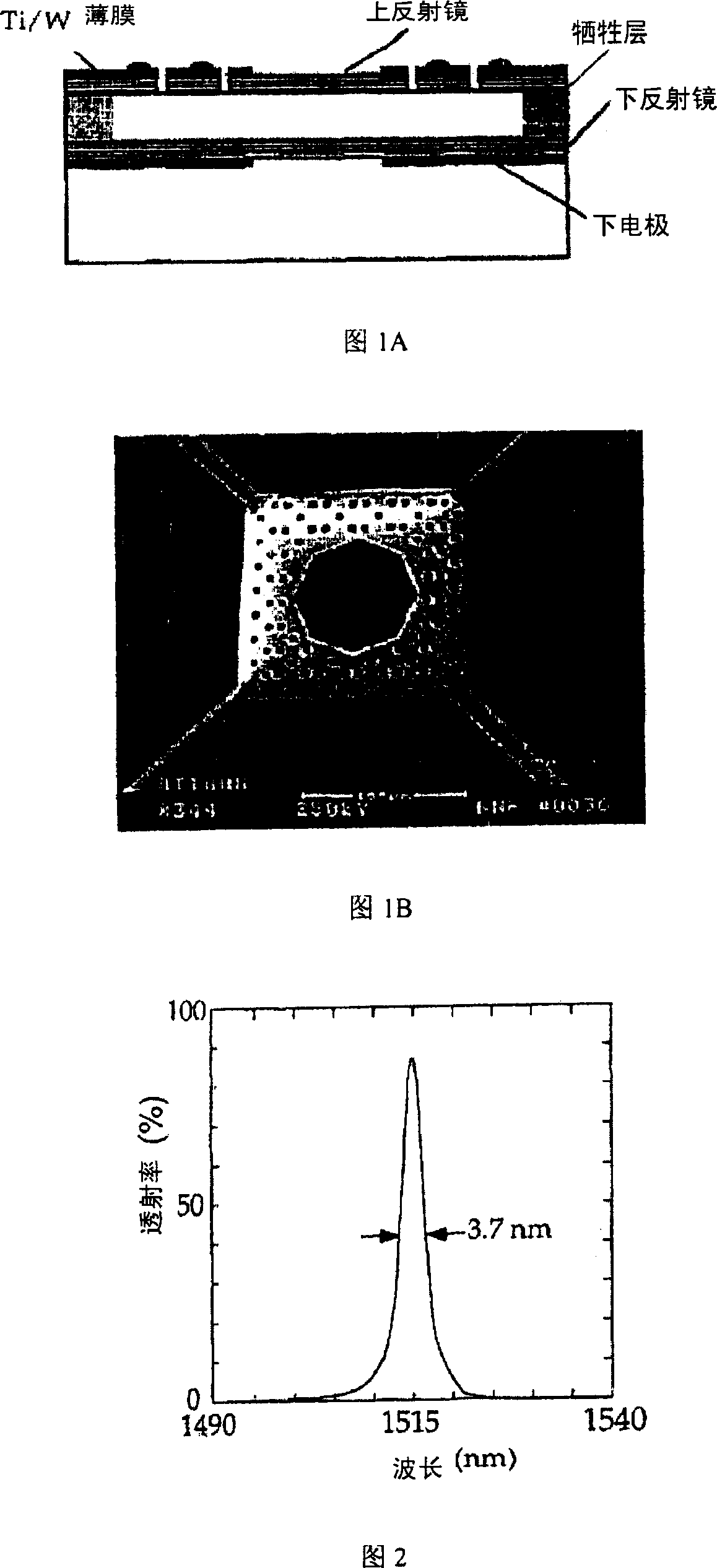

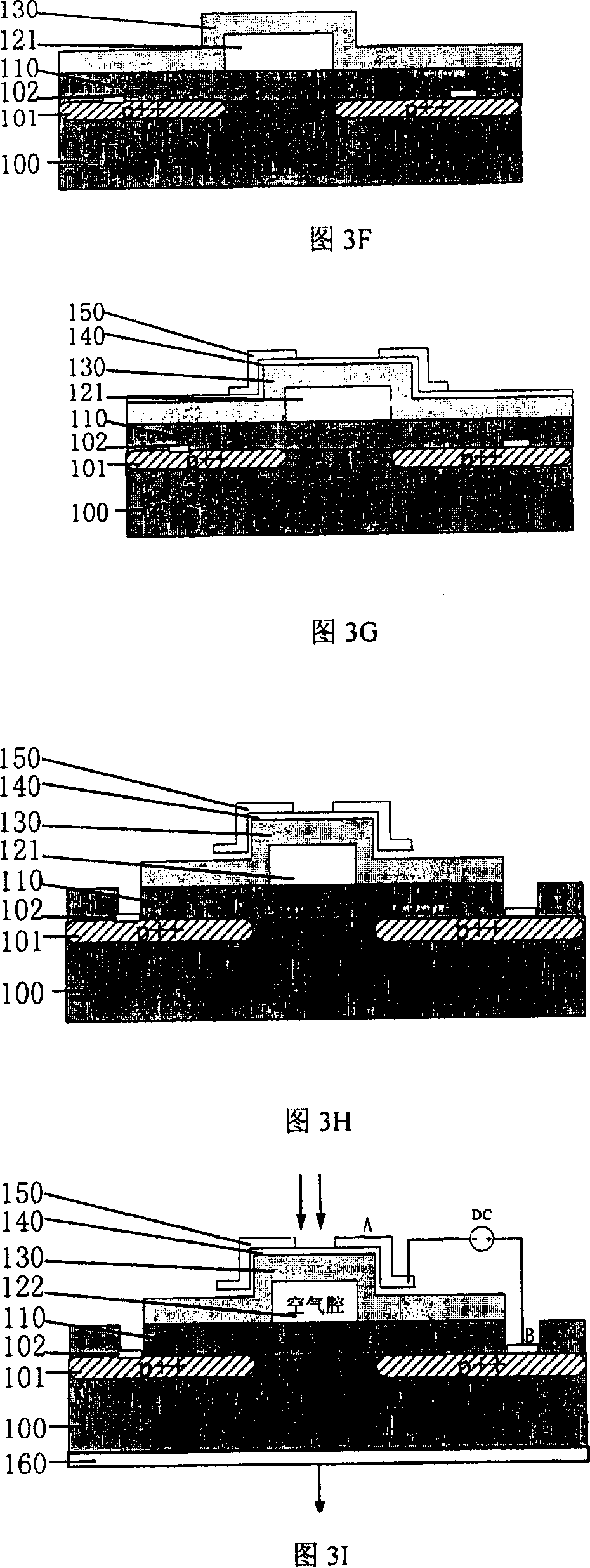

[0030] Please refer to Fig. 3A-I, a manufacturing method of a silicon-based micro-mechanical tunable optical filter with a wide frequency domain according to the present invention adopts a low-temperature surface micro-mechanical process, and the entire process temperature does not exceed 300°C; the manufacturing method includes the following steps:

[0031] a) Make a first electrode 101 on the substrate 100, this electrode is one of the electrode plates that generate electrostatic attraction, and make an electrode lead-out hole 102 in the electrode layer, the first electrode 101 is a highly doped n-region , highly doped p region;

[0032] b) making a first reflector 110 on the first electrode 101, which is one of the necessary reflectors for the filter;

[0033] c) Make a sacrificial layer 121 on the first reflector 110. The thickness of the sacrificial layer determines the working mode of the filter. When released, the air cavity formed constitutes the resonant cavity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com