Method for reducing residual stress of high-speed extrusion formed blades

A technology of extrusion forming and residual stress, which is applied in the field of forging, can solve problems such as complex process, high energy consumption, and increased manufacturing cost, and achieve the effects of reducing residual stress, improving pass rate, and reducing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

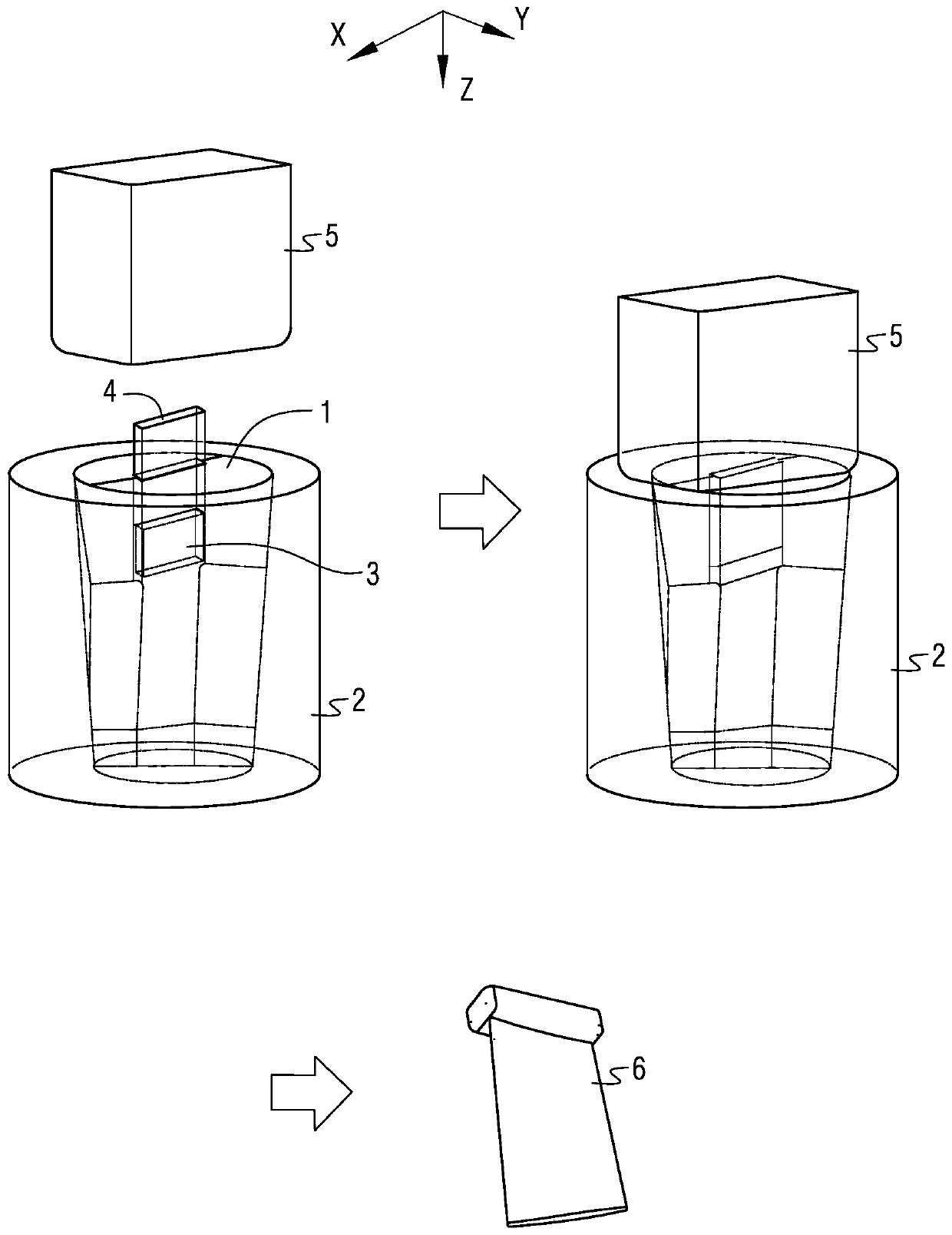

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings. Wherein, the same parts adopt the same reference numerals.

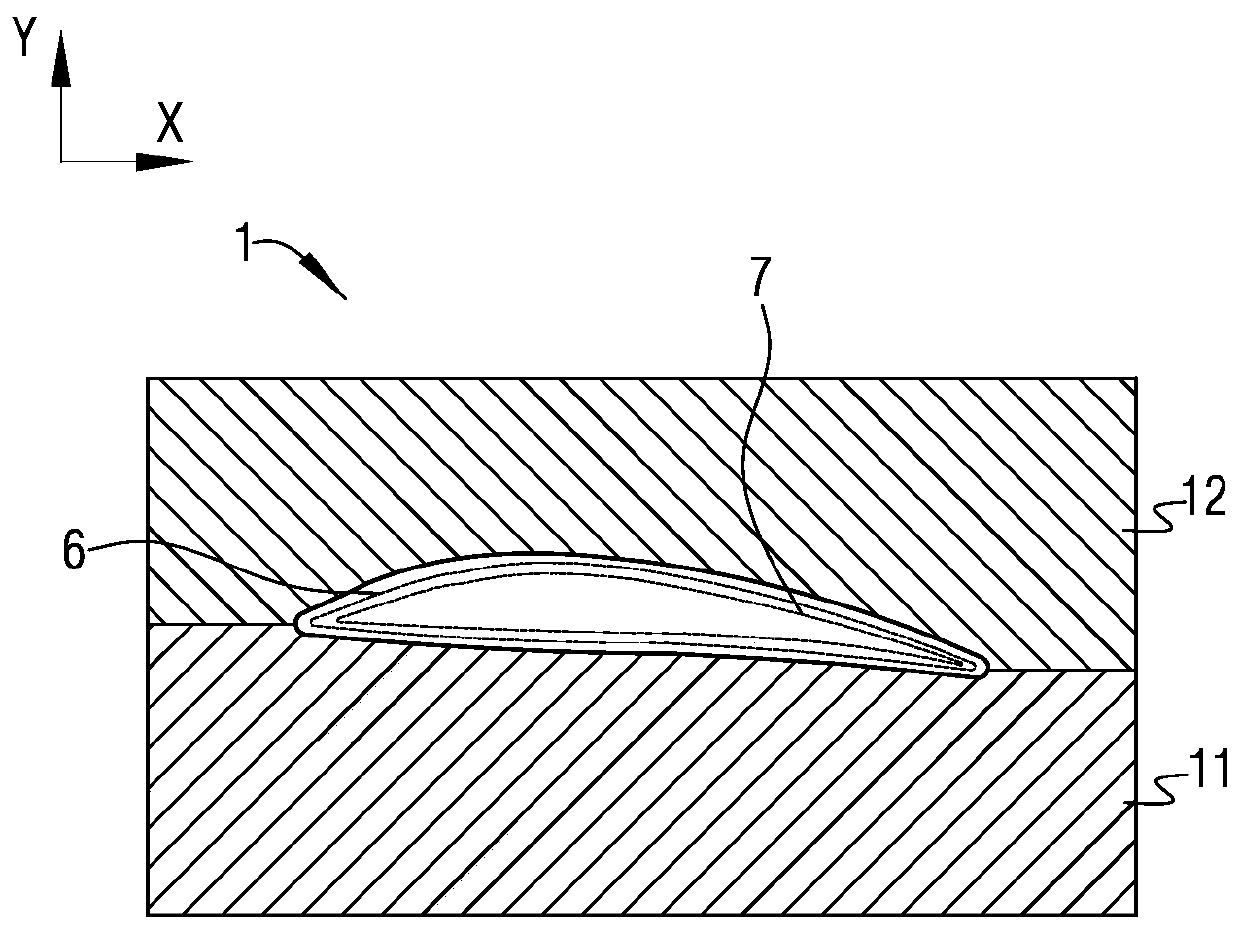

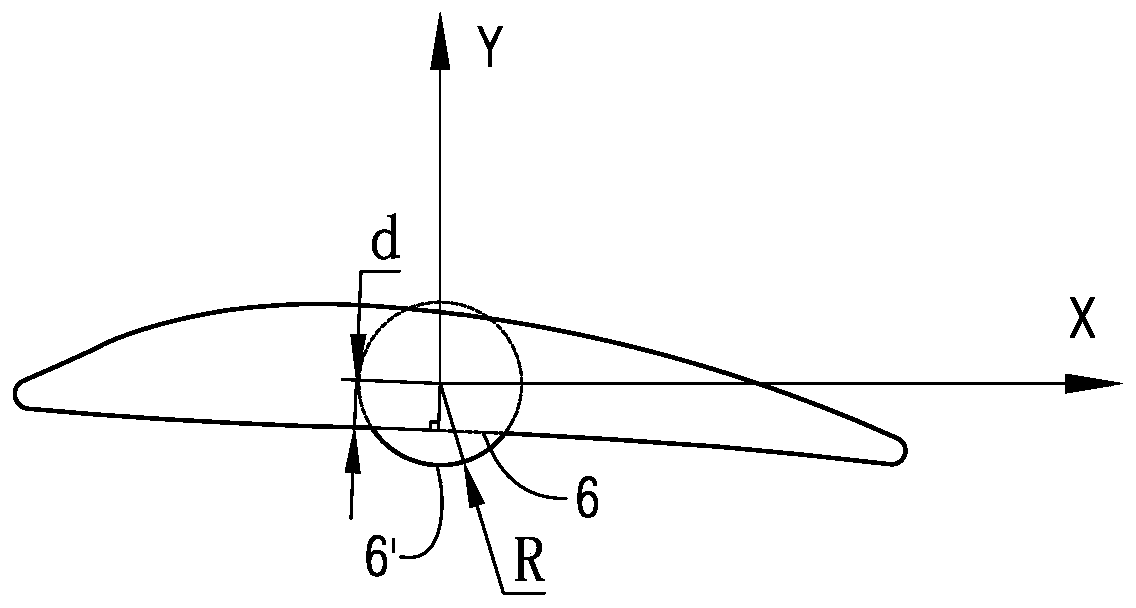

[0031] As mentioned in the background art, the existing high-speed extrusion molding process has the disadvantages of large residual stress and easy bending deformation of the blade. The inventor has carried out in-depth calculation and analysis on its principle, see figure 2 As shown, in the cavity of the blade body part formed by the blade pot mold 11 and the blade back mold 12, since the contour line of the blade back is longer than the contour line of the blade pot, when the blade blank is extruded at a high speed , the surface area of the metal in contact with the leaf back mold 12 is greater than the surface area in contact with the leaf basin mold 11, which eas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com