Residual stress control method of hundred-meter heavy rail

A technology of residual stress and control method, which is applied in the direction of rolling mill control device, metal rolling, manufacturing tools, etc., can solve the problems of rail scratches, failure to meet the technical requirements of 100-meter rails, and difficult synchronization of rails, etc., and improve the pass rate , meet the standard requirements, and improve the effect of flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

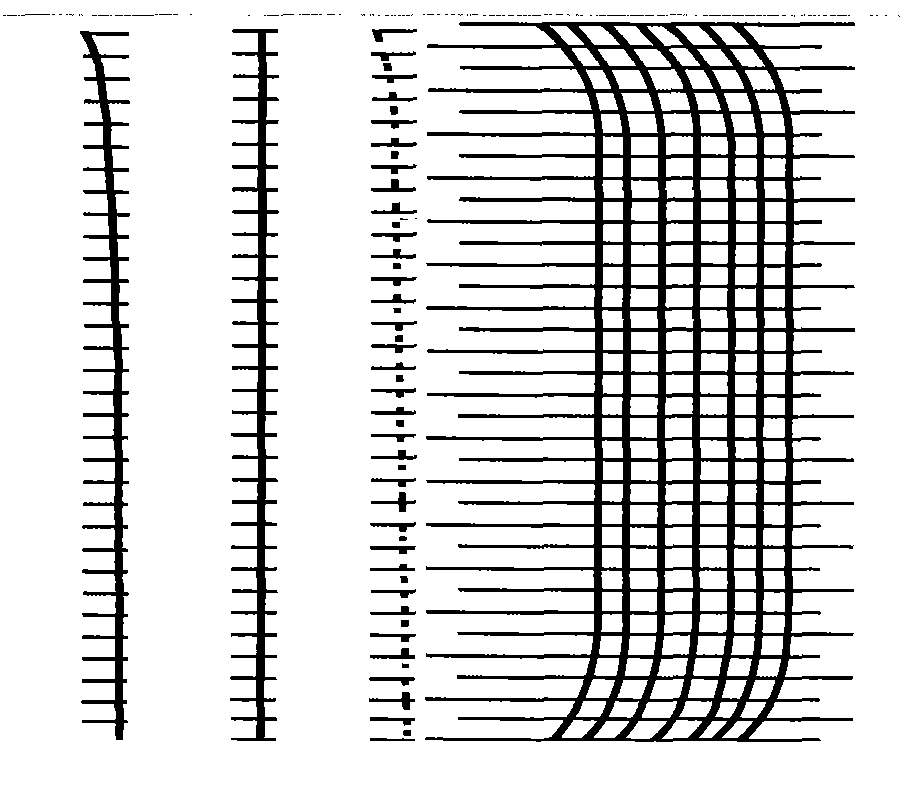

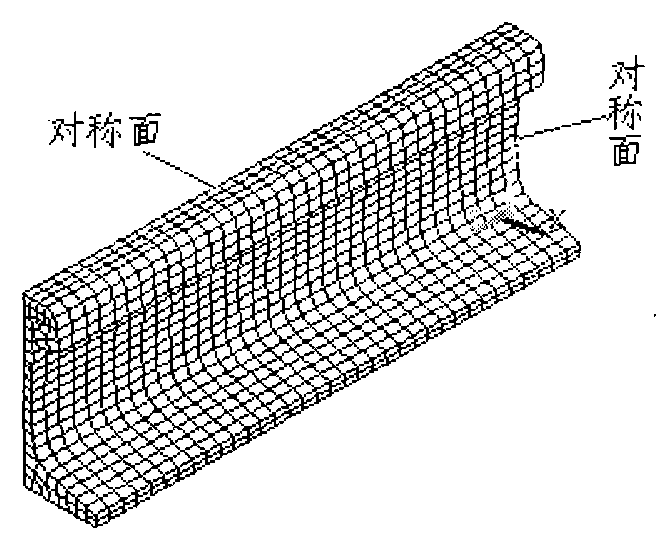

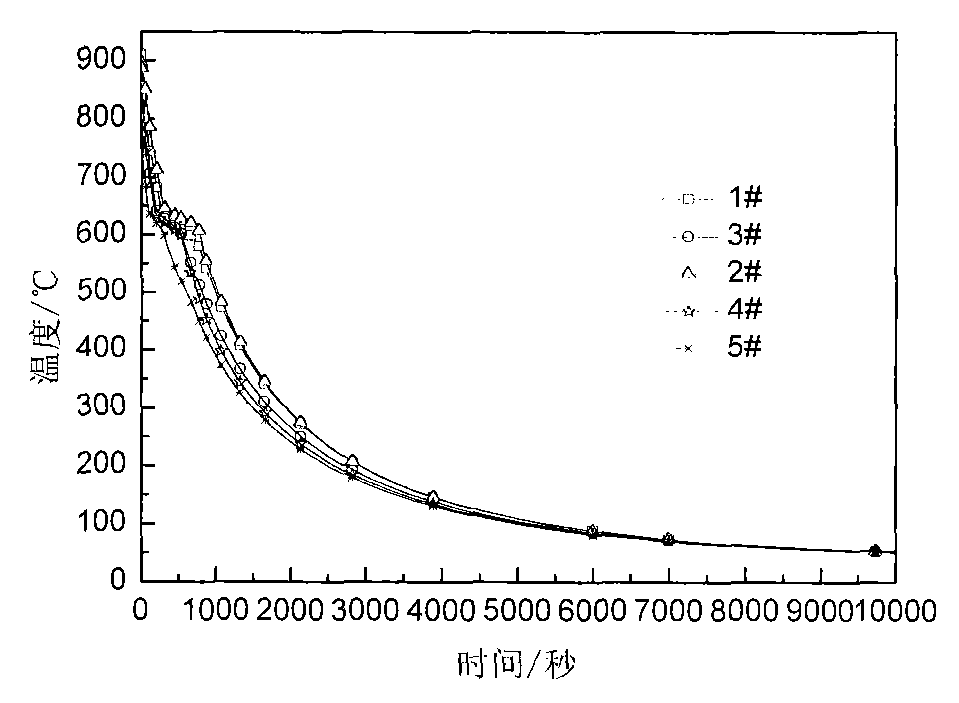

[0024] Large-arc pre-bending is used to optimize the process parameters, and the 100-meter rail is sent to the cooling bed after rolling. figure 1 As shown, in the actual production of steel rails, due to factors such as different furnace numbers of steel ingots and different rolling rhythms, the temperature of the cooling bed on the steel rails is also not the same. The temperature of the head is 850-930°C as the on-site condition, the on-site data and the photos of the on-site cooling effect are as follows Image 6 . The traversing process of the present invention is divided into two stages: translation and pre-bending. During translation, each traversing trolley starts and stops at the same speed at the same speed, pushes the 100-meter steel rail from the left side of the entrance roller table to the right side, pushes the 100-meter steel rail straight in a hot state, and corrects the starting point. The 100-meter rail is translated by 800-900mm to form a straight line, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com