Method and device for controlling milling deformation of large sized structural member

A technology for large-scale structural parts and milling processing, applied in the field of mechanical processing, can solve problems such as large deformation and easy damage, and achieve the effects of good quality, control of residual stress in milling, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

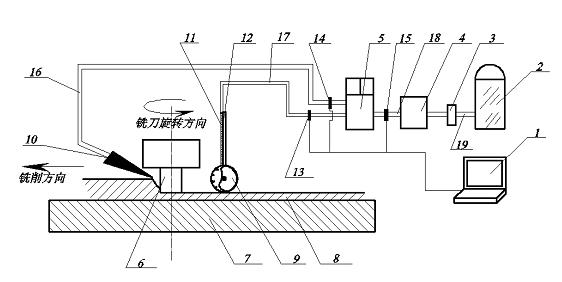

[0024] Such as figure 1 shown.

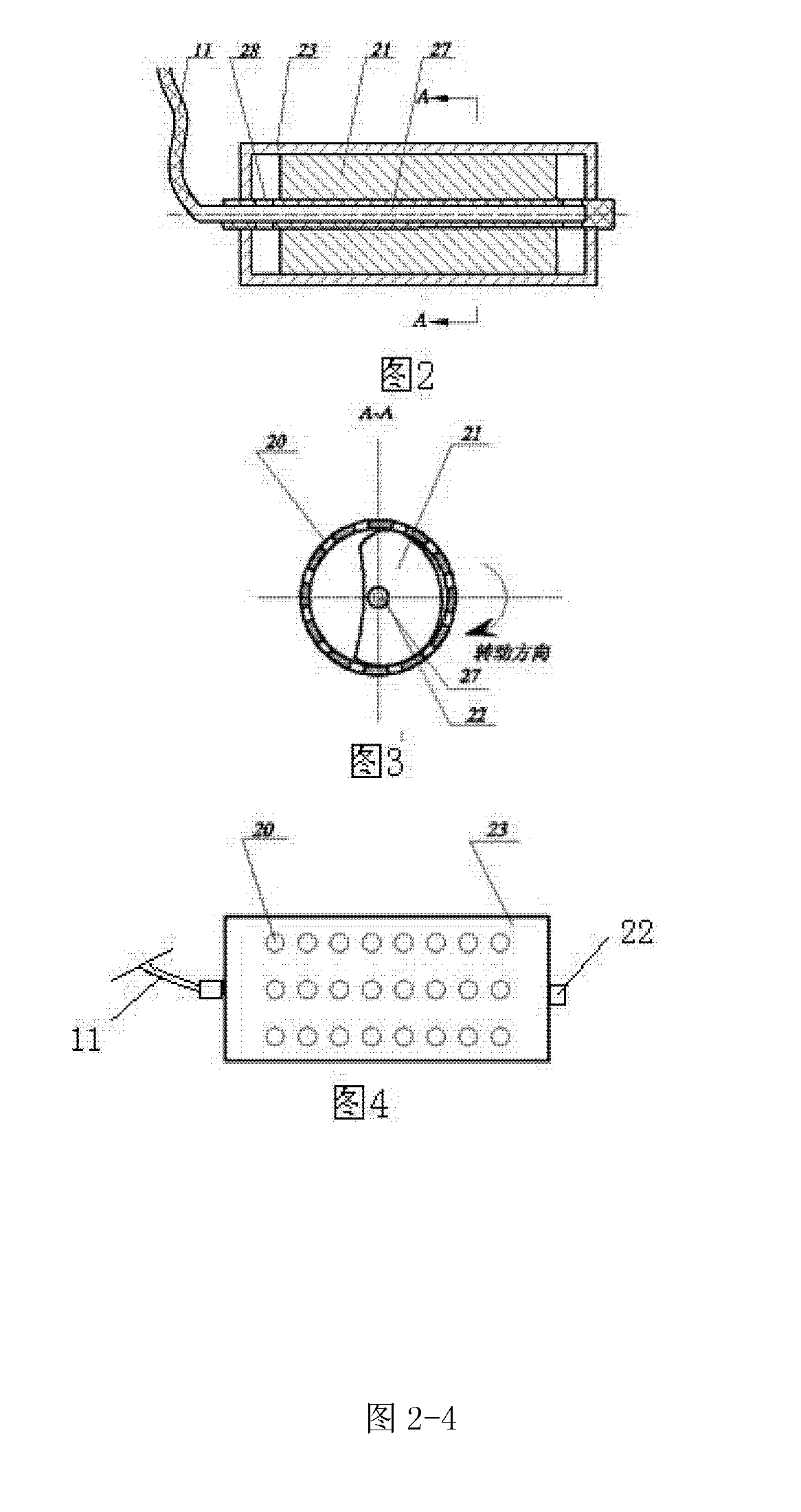

[0025] A control method for milling deformation of large structural parts, it is by adding a deformation controller behind the milling cutter (such as figure 2 shown) to roll the machined surface, the pressure wheel in the deformation controller sprays high-pressure coolant from the inside to the machined surface during the rolling process, and the deformation is controlled at within the set range.

Embodiment 2

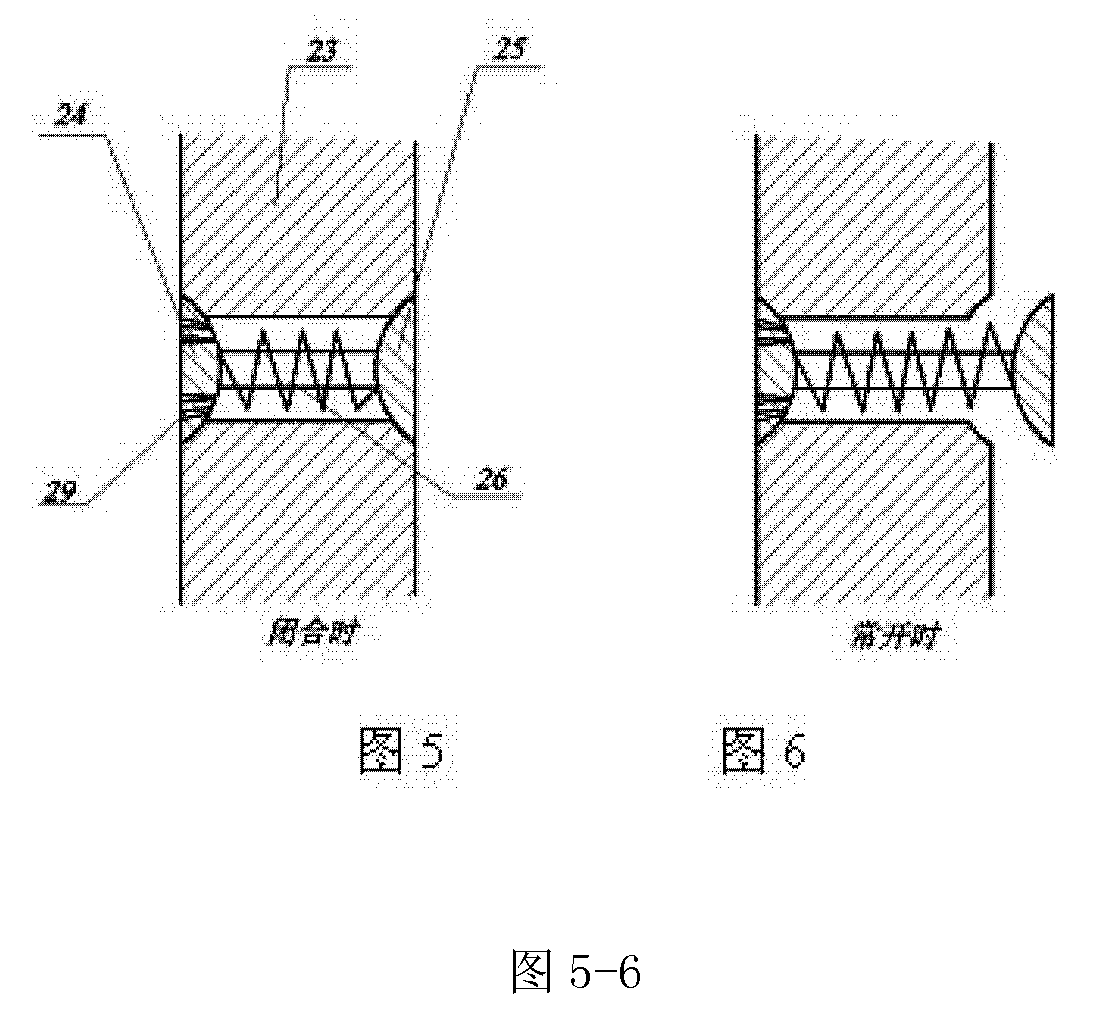

[0027] Such as Figure 1-6 shown.

[0028] A control device for milling deformation of large structural parts, which includes a coolant pump 4, a supercharger 5 and a coolant nozzle 10, the input end of the coolant pump 4 is connected to the coolant tank or pool 2 through a pipeline 19, and the pipeline Also can be installed with filter 3 on 19, to guarantee the cleanliness of coolant, the output end of coolant pump 4 links to each other with the input end of supercharger 5 by pipeline 18, can also be installed on pipeline 18 and be controlled by electrical control The electric valve 15 of the system 1 (which can be controlled by a computer), the supercharger 5 is connected with two outputs, one of which is connected to the coolant nozzle 10 through the pipeline 16, and the other output can be connected to the soft nozzle through the pipeline 17 first. The pipe 11 is connected, and then connected with the liquid inlet of the deformation controller 9 through the flexible pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com