H-type shape steel vertical rolling method and apparatus

An H-beam, vertical technology, used in the driving device of metal rolling mill, metal rolling, metal rolling, etc., can solve the rising rolling force and torque, increase the difficulty of rolling, and reduce the energy consumption of rolling production. Increase and other problems, to achieve the effect of small rolling force and torque, expanding the scope of application, and reducing the temperature drop of the rolled piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

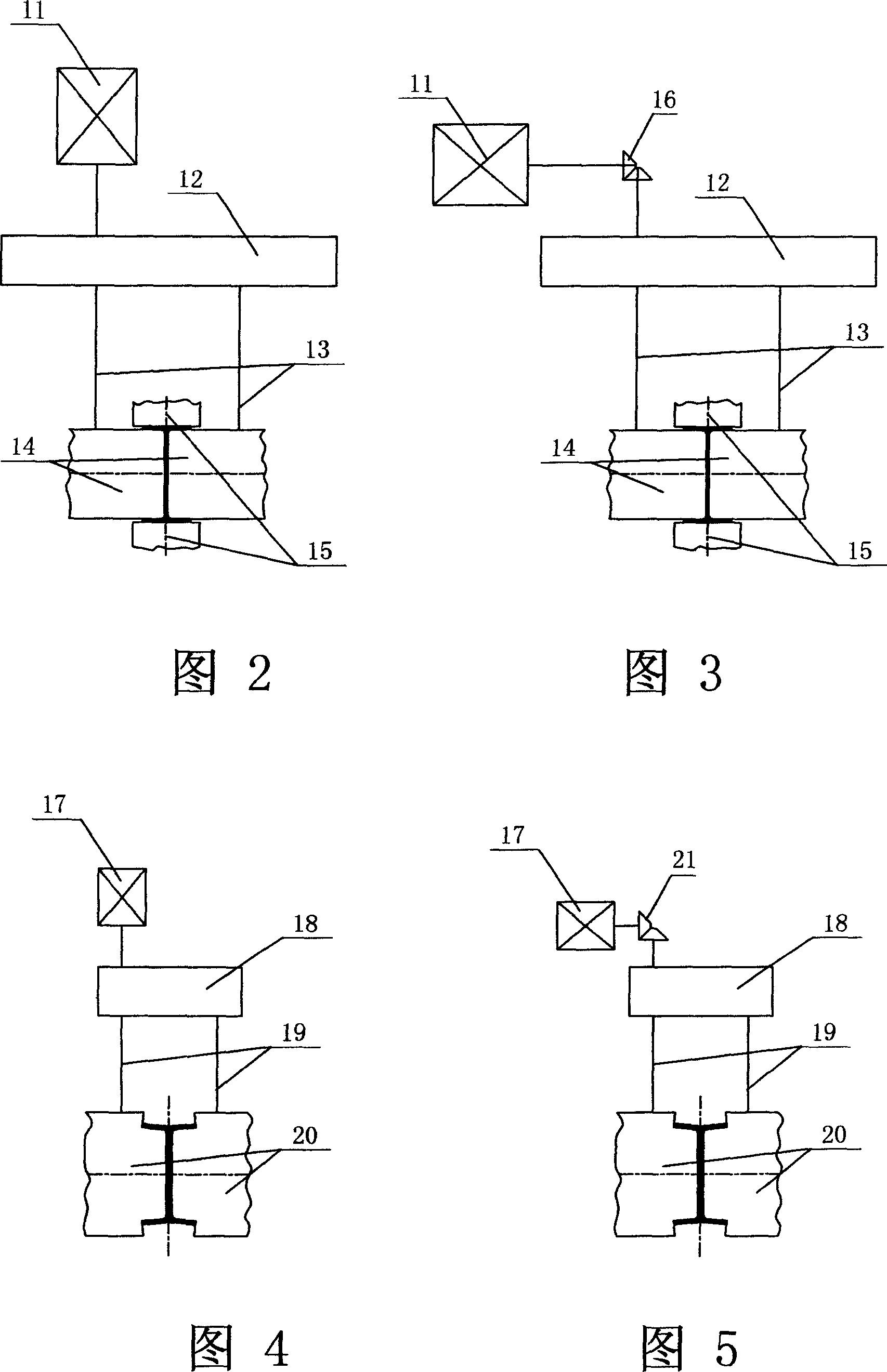

[0020] Embodiment 2. It can be seen from FIG. 3 that the main motor 11 is connected to the gearbox 12 via a bevel gear 16, preferably a spiral bevel gear.

[0021] As can be seen from FIG. 4 , the vertical edger 7 is provided with a vertical roller 20 , which is connected by a transmission shaft 19 and a gear box 18 provided thereon, and the main motor 17 is directly connected with the gear box 18 .

Embodiment 3

[0022] Embodiment 3. As can be seen from FIG. 5 , the main motor 17 is connected to the gearbox 18 via a bevel gear 21 , preferably a spiral bevel gear.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com