Billet turn-over cooling bed device

A billet and cooling bed technology, which is applied in the field of billet turning and cooling bed devices, can solve problems such as poor transportation, heavy workload for maintenance and replacement of turning cooling beds, and achieve high turning efficiency, low equipment maintenance costs, and simplified structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

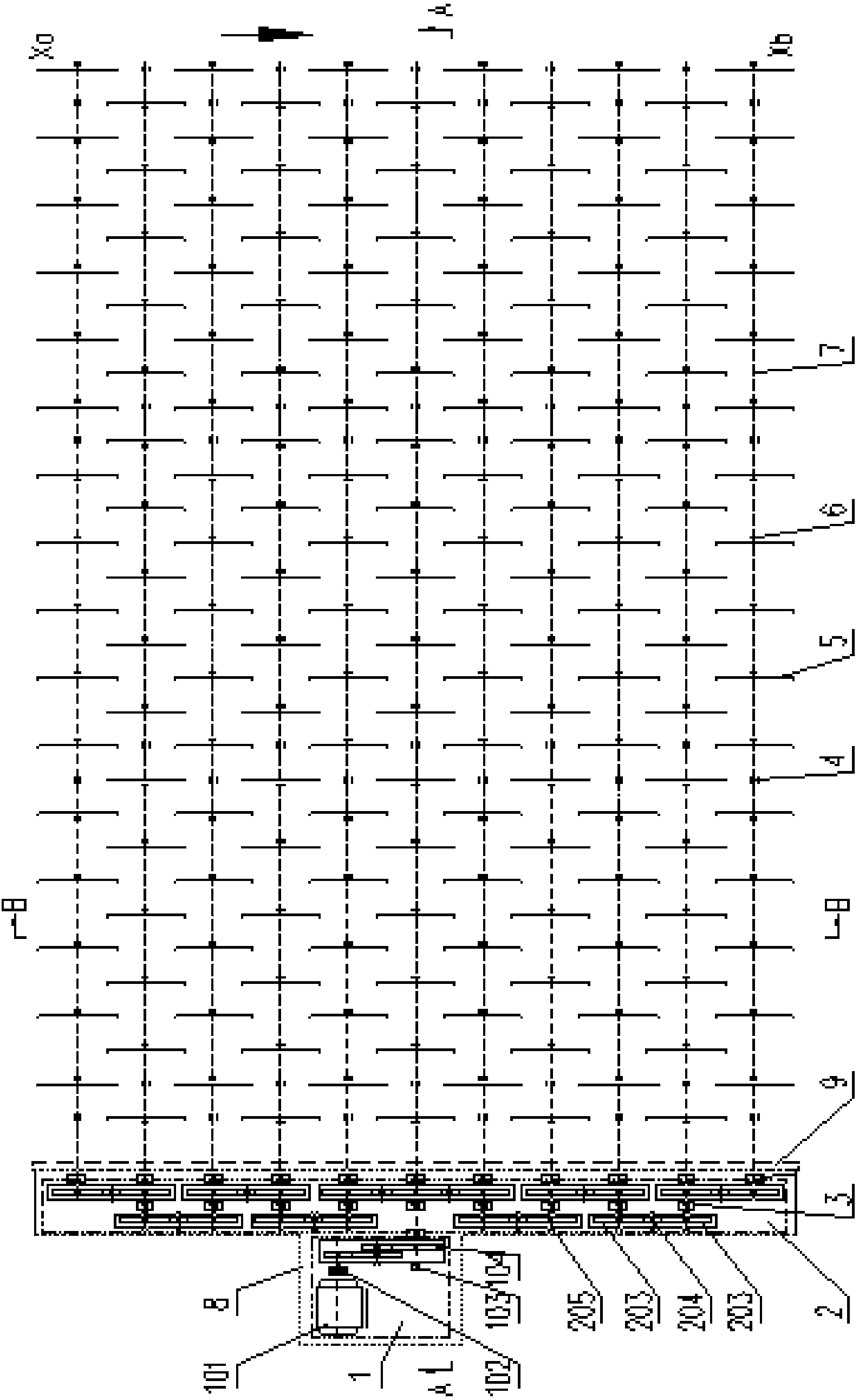

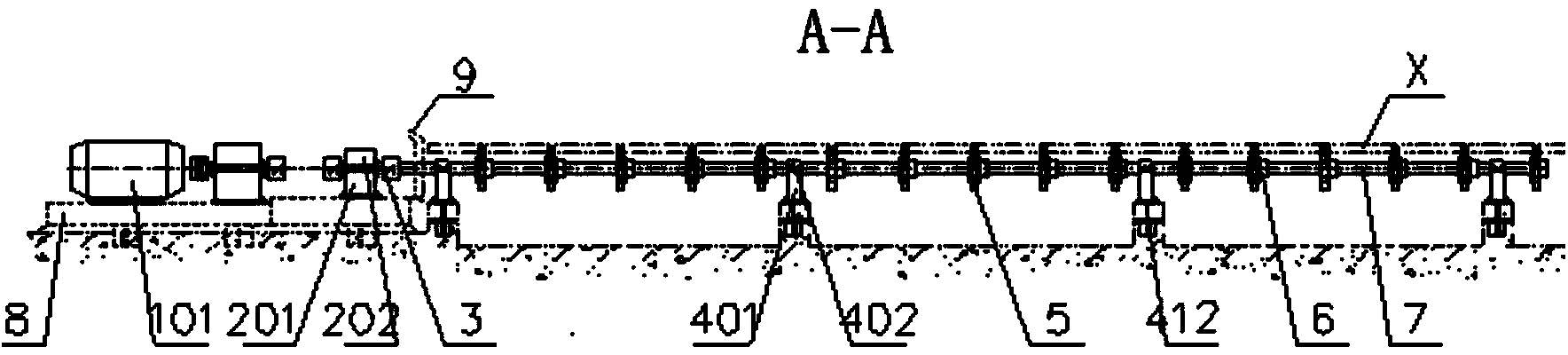

[0049] combine figure 1 , 2 , the billet toothed wheel turning cooling bed device of the present embodiment, the main components are as follows:

[0050] Main transmission 1, one piece, as power system.

[0051] The constant speed transmission device 2 includes a lower casing 201 and an upper casing 202 .

[0052] Nine sets, as a component assembly, the torque magnitude of the input shaft and the output shaft is the same as the rotational speed.

[0053] Coupling 3, thirty-two sets.

[0054] Bearing supporting parts 4, forty-four sets, as assembly parts, adopt split type rolling bearing 411 to do support. The split rolling bearing 411 is a split self-lubricating rolling bearing.

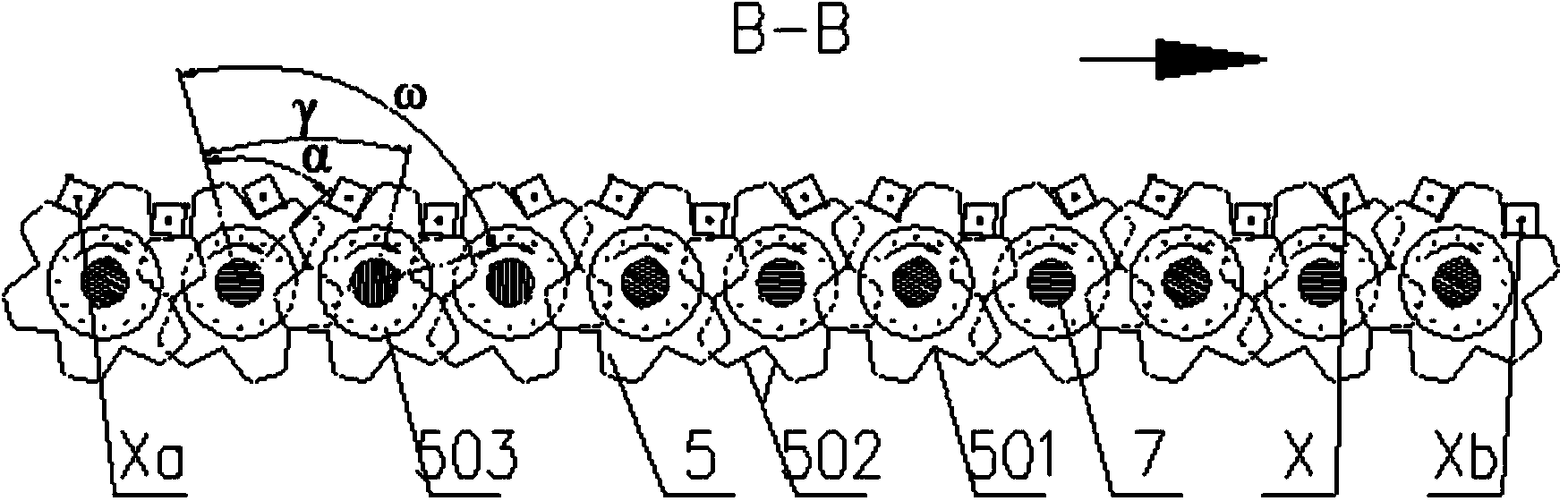

[0055] There are one hundred and seventy-six sets of toothed wheels 5; in order to improve the wear resistance of the material, the toothed working surface 502 on the toothed wheel 5 is quenched. The toothed wheel 5 has 4 to 6 equal tooth shapes, the toothed wheel 5 is split, and the two parts ...

Embodiment 2

[0074] The difference from Embodiment 1 is that the tooth-shaped working surface 502 on the toothed wheel 5 is inlaid with wear-resistant and high-temperature-resistant materials to improve the service life of the materials. Toothed wheel 5 is made up of 4 equal tooth profiles. In this embodiment, the time for the billet to get off the bed from the bed is 40 minutes.

Embodiment 3

[0076] The difference from Embodiment 1 is that the bearing seat 4 is a split self-lubricating sliding bearing. Toothed wheel 5 is made up of 5 equal tooth profiles. In this embodiment, the time for the billet to get off the bed from the bed is 35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com