Movable tray stack type material cold bed

A stacking and pallet technology, applied in cooling beds, metal processing equipment, metal rolling, etc., can solve the problems of low cooling efficiency, large floor space, and inability to recover material sensible heat, and achieve high space utilization and land occupation. small area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

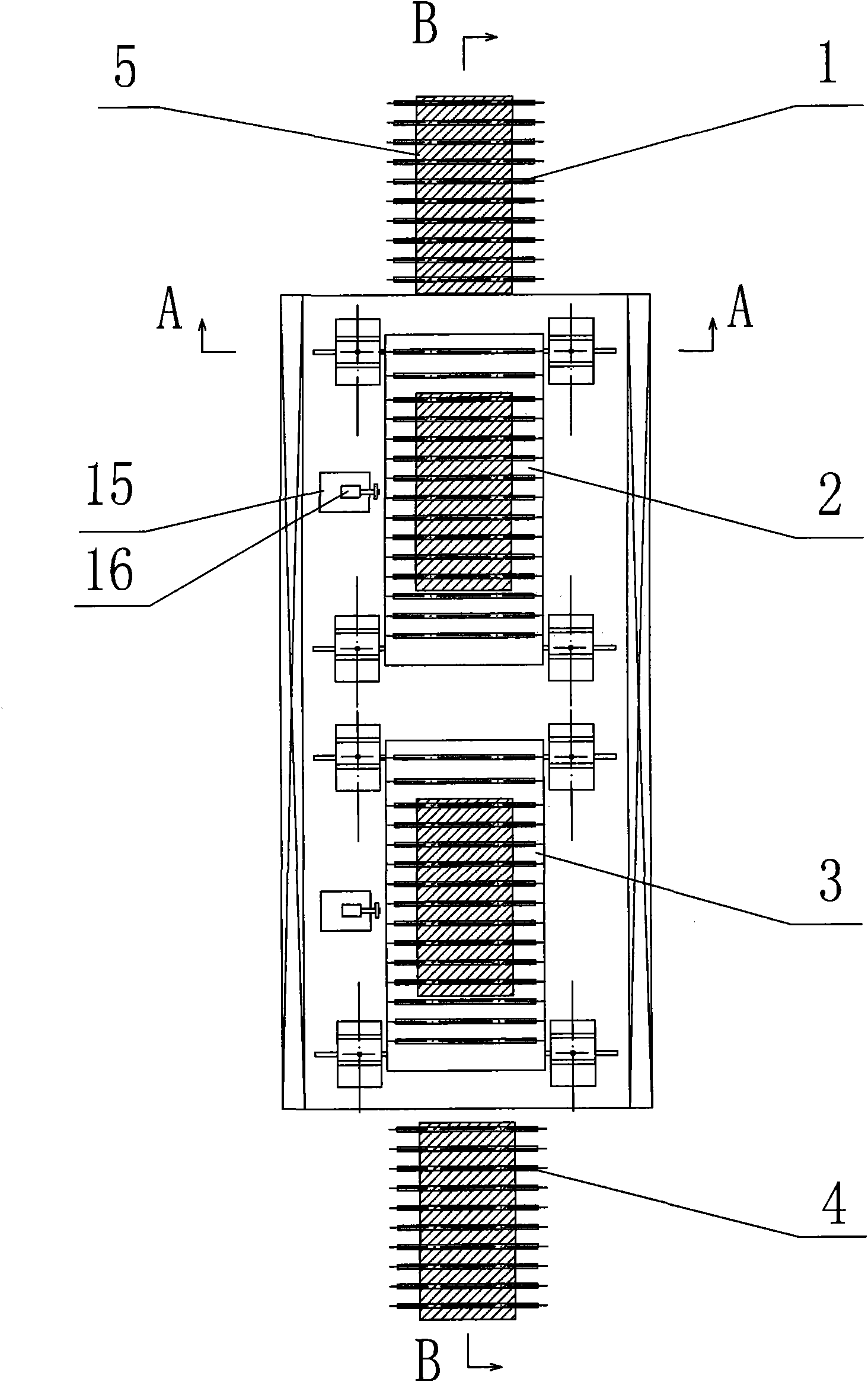

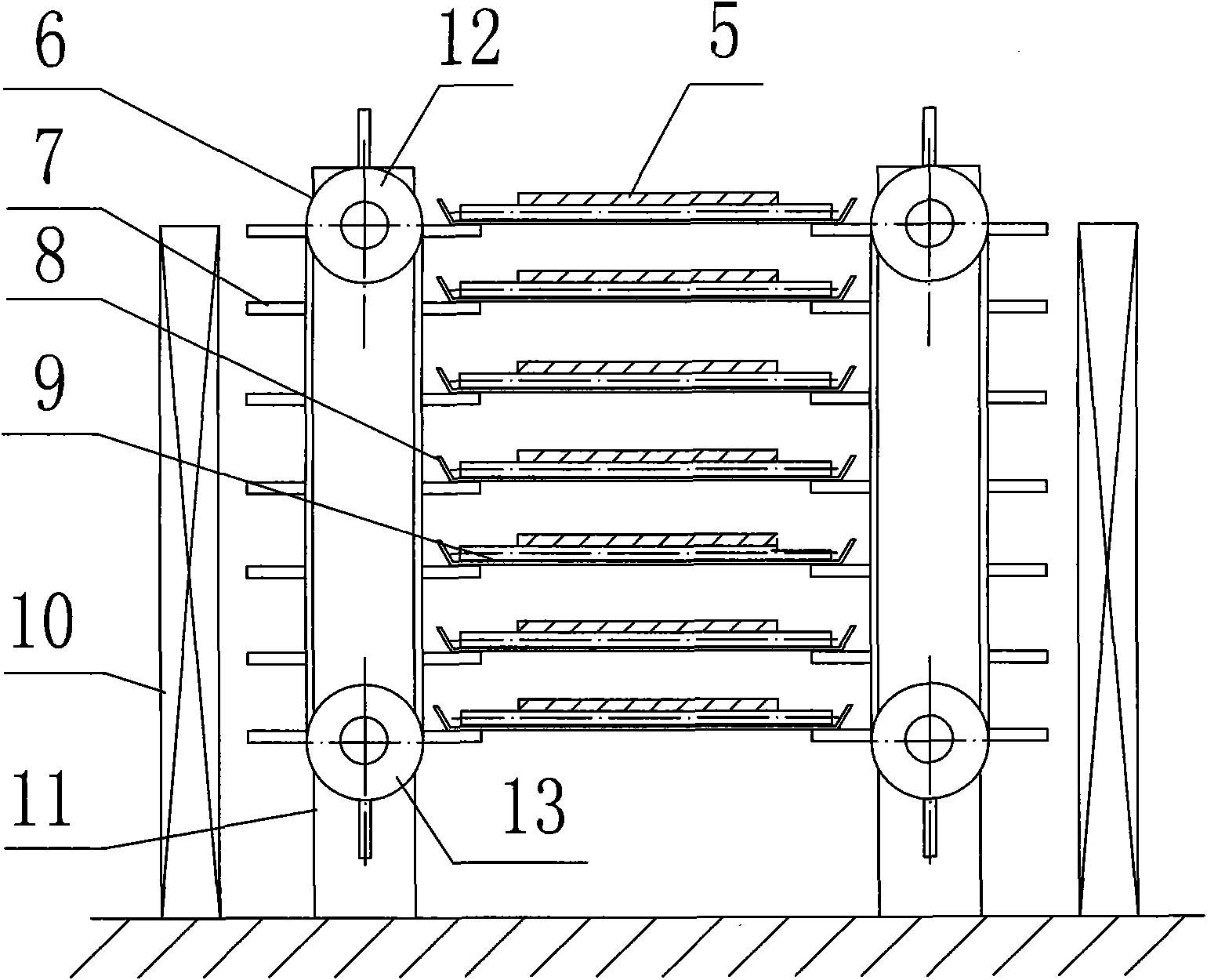

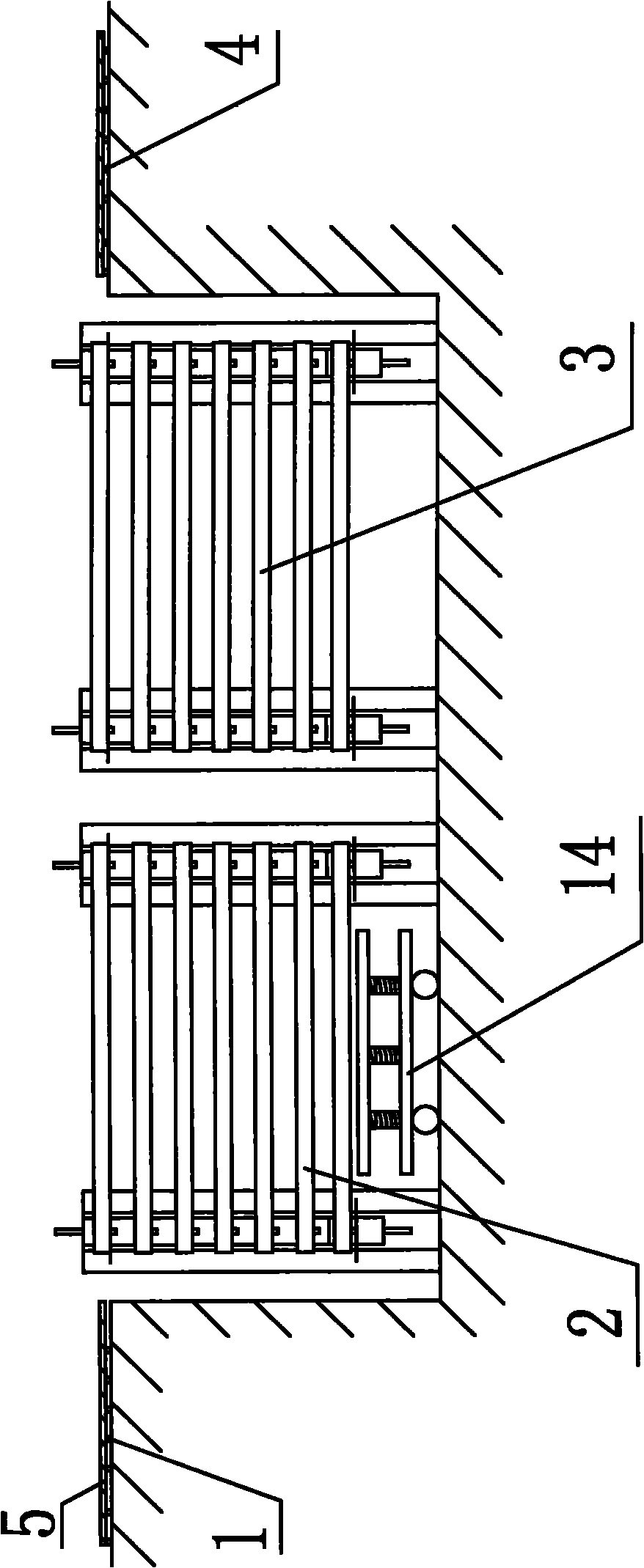

[0013] Such as figure 1 , figure 2 , image 3 As shown, the movable tray stacking type material cooling bed includes steel plate downward stacking 2, steel plate upward stacking 3, and transport trolley 14; Arrangement (compact arrangement); the feeding roller conveyor 1 and the discharging roller conveyor 4 are set on the foundation respectively; The roller table and the uppermost roller table (based on the central axis or upper end of the roller table) of the steel plate upward stack 3 are all located on the same plane [also with the roller table of the feeding roller conveyor 1 and the discharge roller conveyor The roller tables of 4 are located on the same plane]; the left and right sides of the downward stacking of steel plates 2 and the upward stacking of steel plates 3 are respectively provided with heat exchangers 10[ figure 2 The left in the middle is left, and the right is right; figure 2 The inside of the paper is the front (ie figure 1 above the center), fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com