Patents

Literature

41 results about "Mill finish" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mill finish is the surface texture (or finish) of metal after it exits a rolling mill, extrusion die, or drawing processes, including sheet, bar, plate, or structural shapes. This texture is usually rough and lacks lustre; it may have spots of oxidation or contamination with mill oil. Most mill finish surfaces are machined or treated with polishing, industrial etching, or some other surface finishing process before they are considered complete.

Rolling production method capable of reducing hardness of 42CrMo

ActiveCN106216391AMeet the national standardMeet user needsTemperature control deviceWork treatment devicesAutomatic controlContinuous rolling

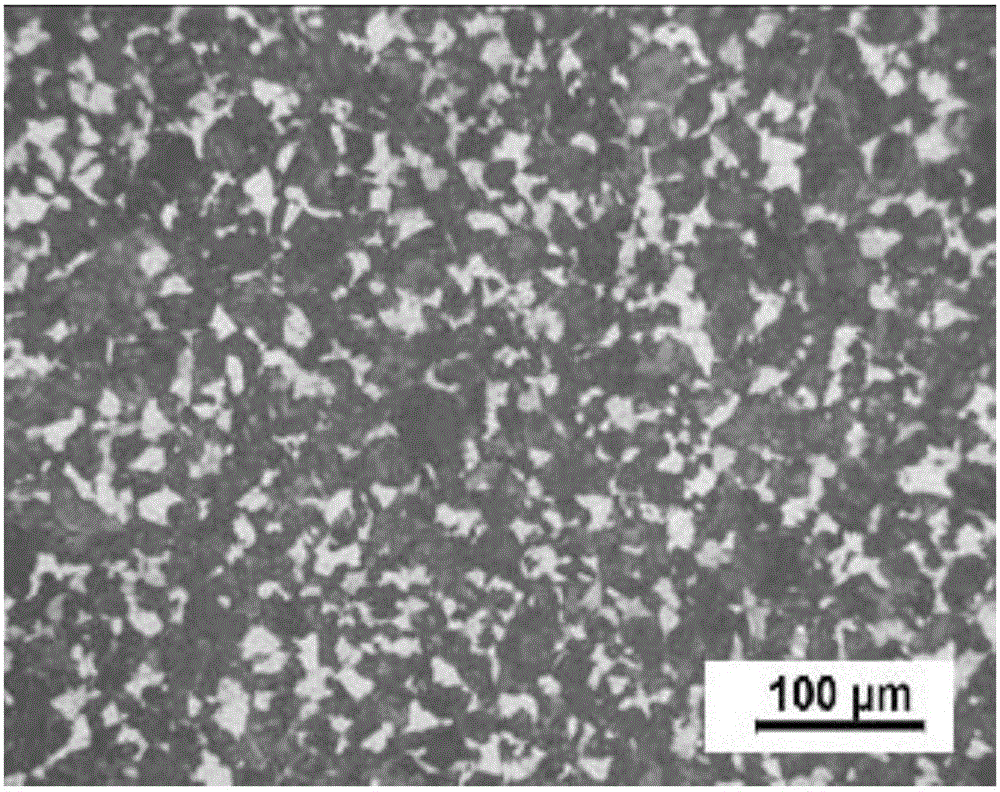

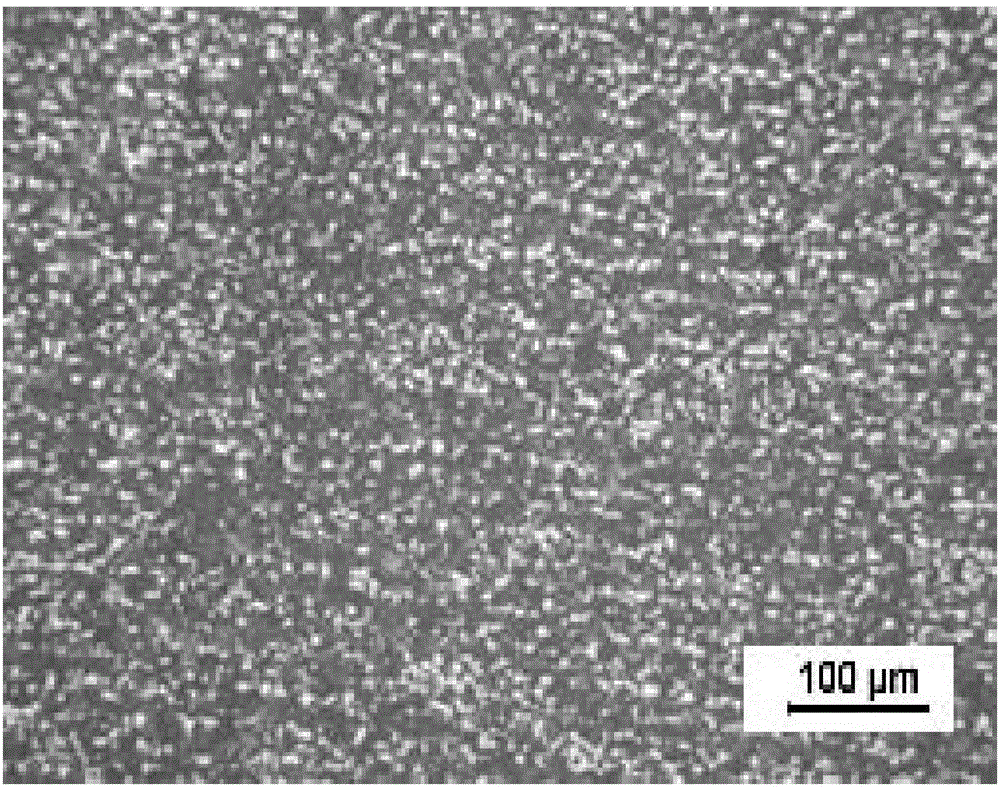

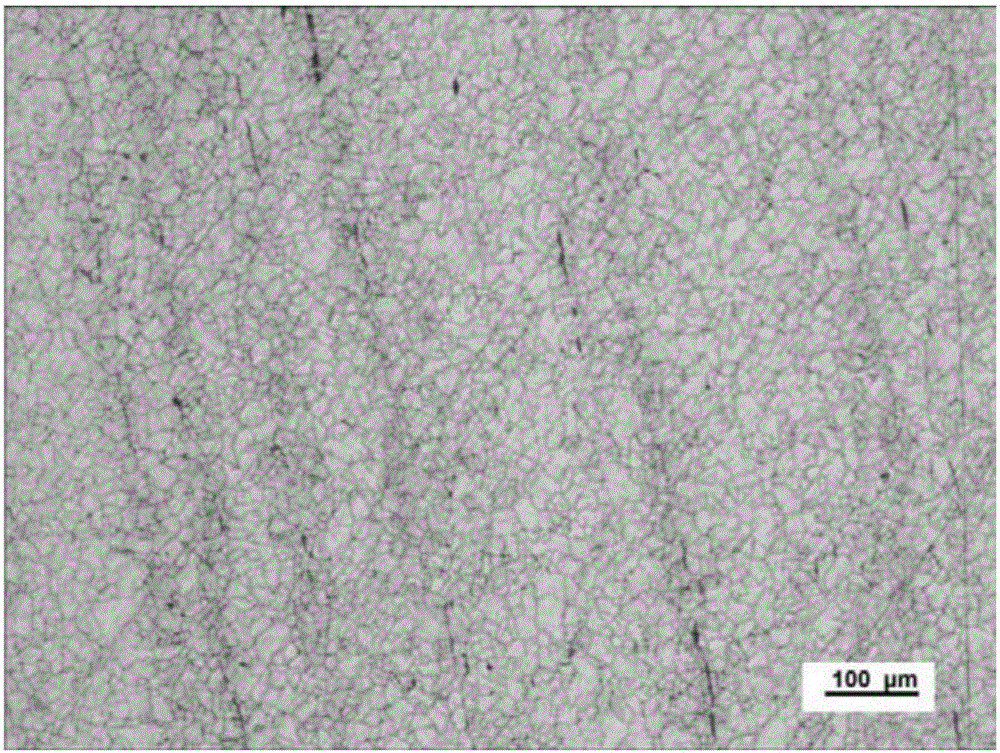

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

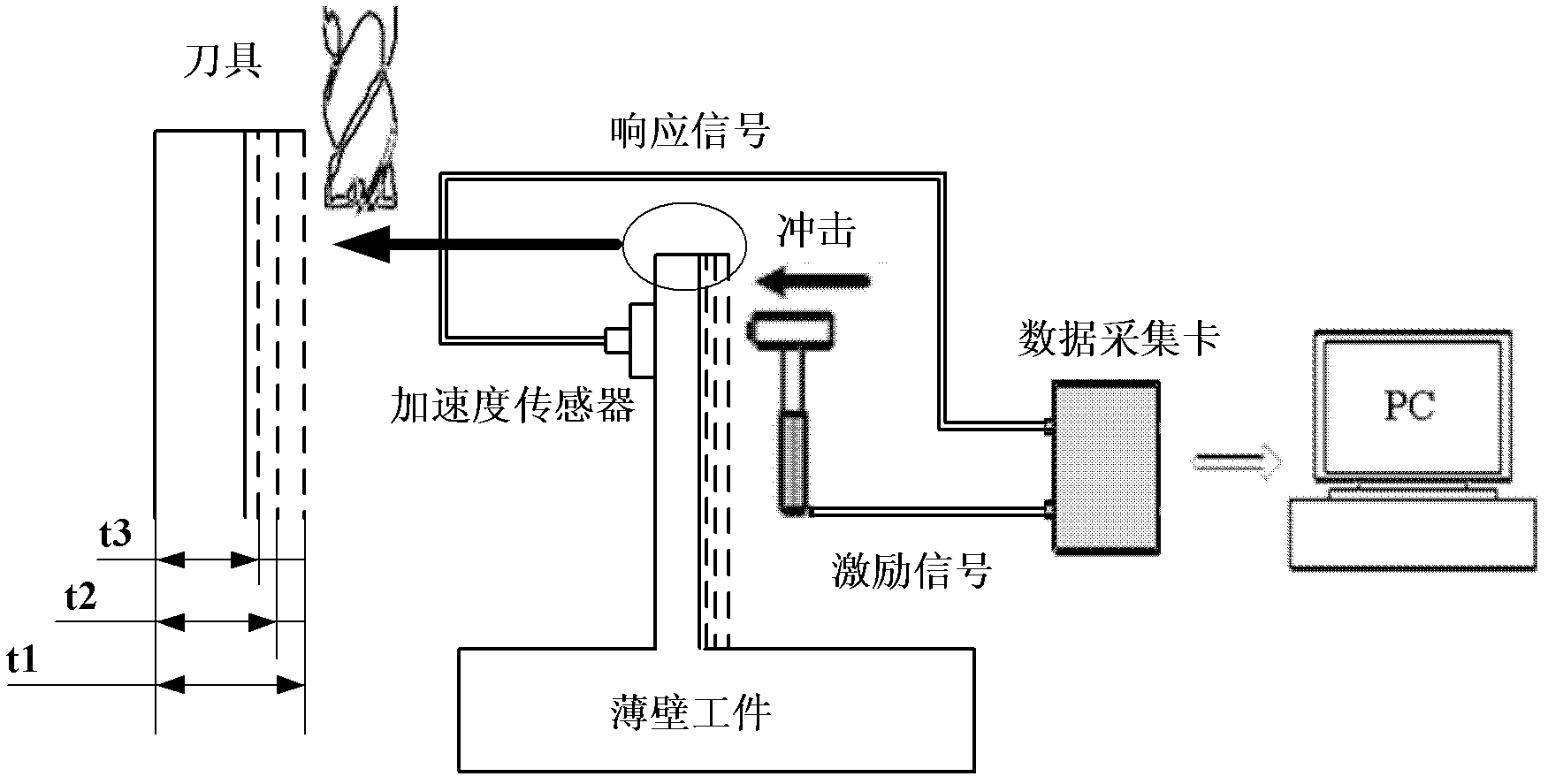

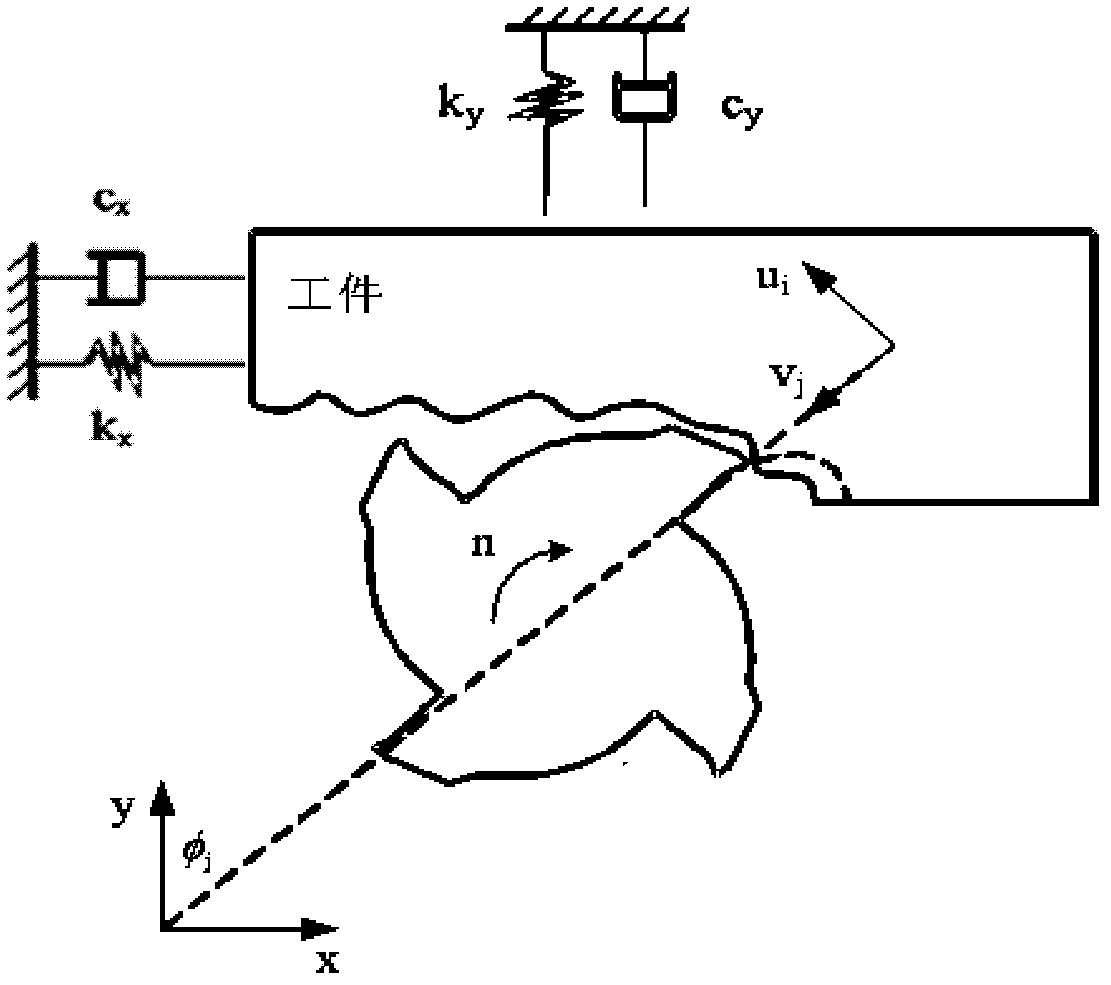

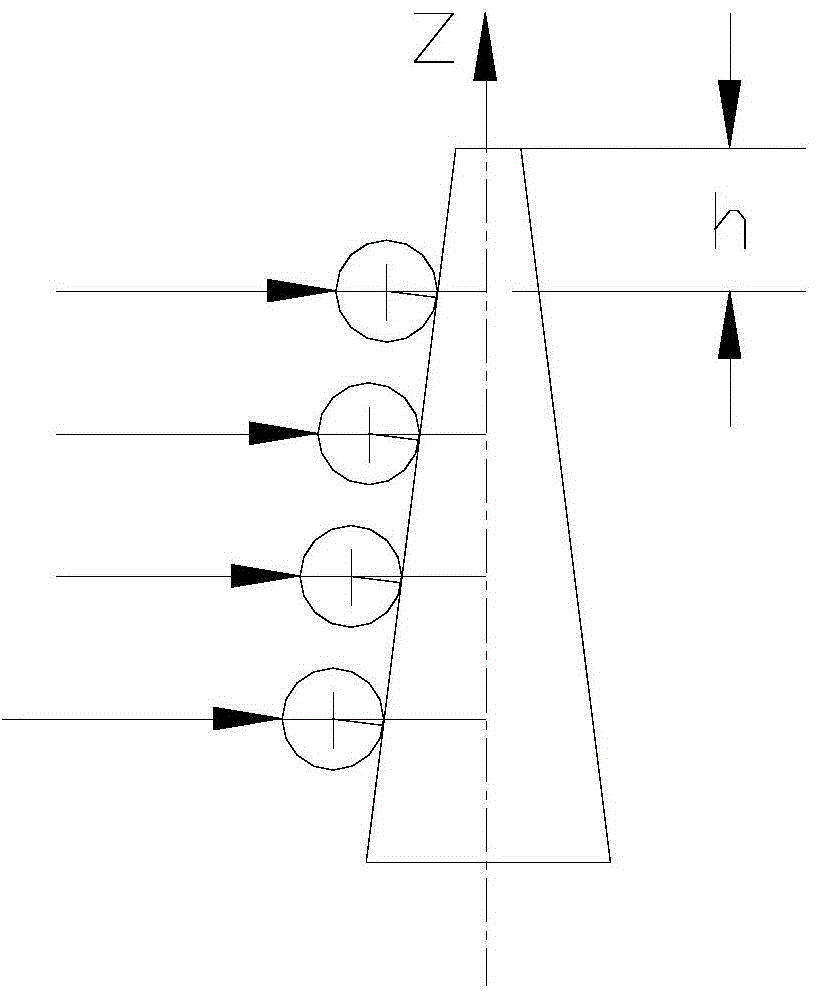

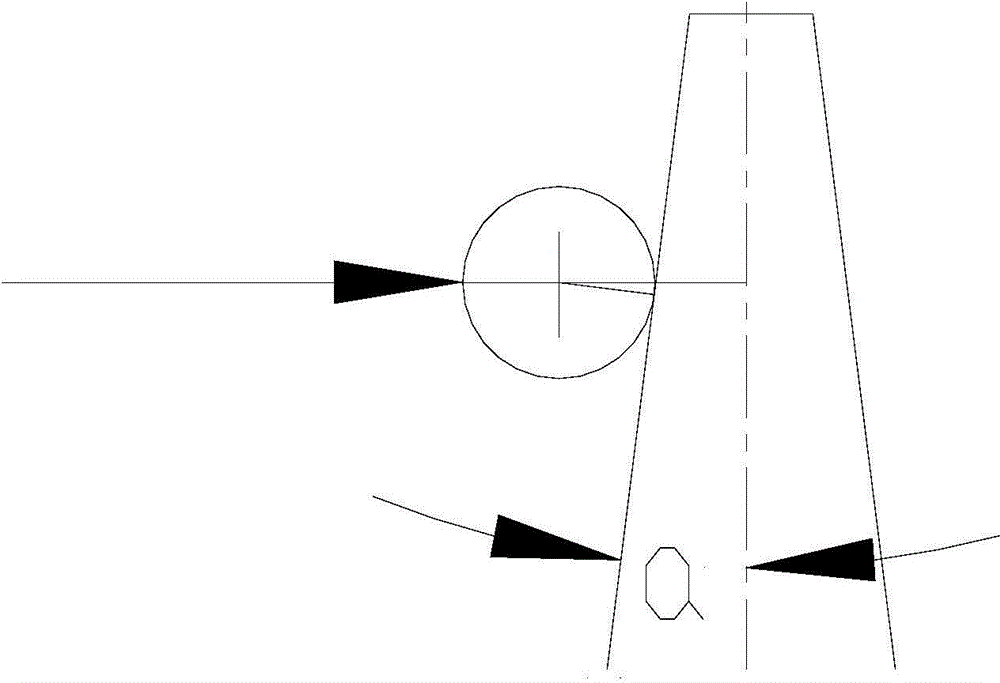

Milling finish machining method based on dynamic rigidity of impeller blade

ActiveCN102554326ASolve the problem of cutting chatterImprove processing stabilityMilling equipment detailsSpecial data processing applicationsImpellerDiagnostic Radiology Modality

The invention discloses a milling finish machining method based on the dynamic rigidity of an impeller blade. The dynamic modality of the impeller blade is obtained through a standard modal test, a flutter model is introduced to obtain a stability criterion, and reasonable machining parameters are acquired. The method comprises the followings steps of: 1, performing the modal test to measure the dynamic modality of the impeller blade; 2, building a milling stability model of the impeller blade; 3, studying the dynamic rigidity stability of the impeller blade; 4, obtaining a cutting stability condition under the dynamic rigidity of the impeller blade; and 5, verifying the cutting stability condition and adopting the finally optimized cutting parameters to machine. The problem of cutting flutter caused by milling of thin-walled parts such as the blade is solved by the method, and the machining stability is obviously improved by optimizing the cutting parameters. The method is suitable for finish machining of various thin-walled parts.

Owner:SHANGHAI JIAO TONG UNIV

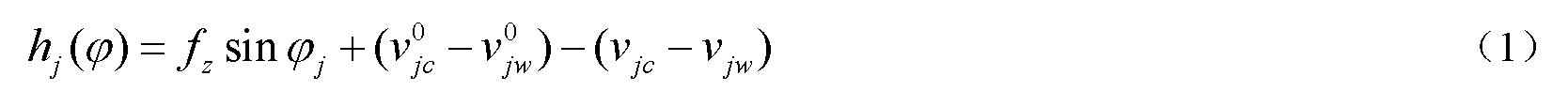

Low helical abrasion-proof drill rod for mash gas pumping drilling construction and machining process thereof

InactiveCN101280667AExtended service lifeDrilling rodsMetallic material coating processesWear resistantLiquid slag

The invention discloses a low spiral wear resistant drill rod applied to drilling construction in gas extraction and a processing technique thereof. The drill rod is a mill finish round drill rod, the center of the drill bar is provided with an inner bore, the two ends are provided with connecting threads and the outer surface of the mill finish drill rod is provided with a spiral alloy coating. The processing technique of the drill rod has the following steps: first, a normal round drill rod is made according to normal methods; second, the surface of the round drill rod is coated with spiral alloy convex reinforcements; third, heating treatment is carried out to relieve stress and the drill rod is aligned. On one hand, the low spiral wear resistant drill rod applied to drilling construction in gas extraction improves the wear resistant performance of the drill rod and prolongs the service life of the drill rod; on the other hand, the center of the drill rod is provided with the inner bore, which endows the drill rod with the function of liquid slag discharge, and the outer surface of the mill finish drill rod is provided with the spiral alloy coating, which endows the drill rod with the function of mechanical slag discharge. The drill rod is applicable to the drilling construction on weak coal seams, outburst coal seams and rocks in gas extraction.

Owner:SHANXI LUAN MINING GRP +1

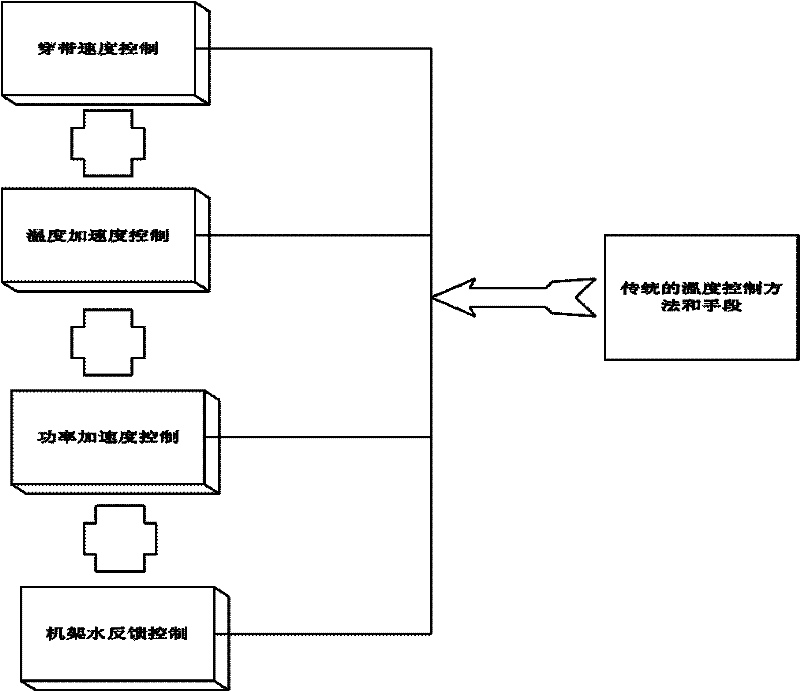

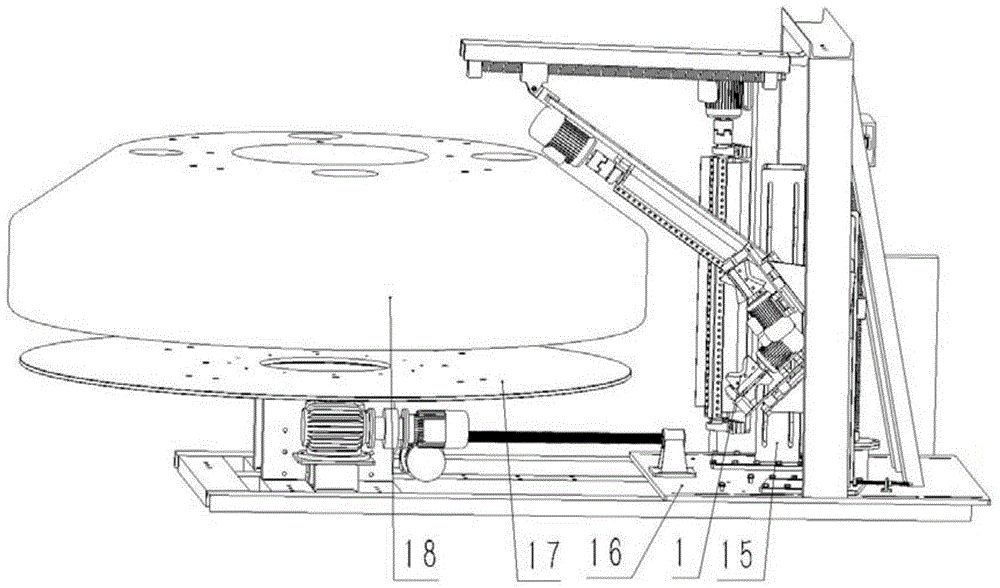

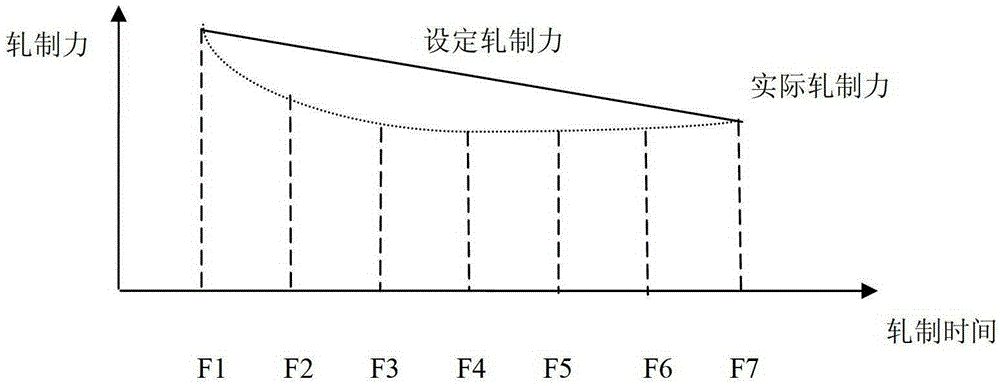

Method for guaranteeing hot continuous rolling mill finish rolling outlet temperature

ActiveCN102688900AImprove thermoregulation efficiencyTemperature control deviceStrip steelContinuous rolling

The invention discloses a method for guaranteeing hot continuous rolling mill finish rolling outlet temperature, which comprises the following steps of: 1. dividing a rolled strip steel into a plurality of logical sections by using a certain length as unit; 2. calculating the real steel casting speed of all logical sections at the mill finish rolling outlet; 3. calculating the real temperature of the logical sections at the mill finish outlet according to the calculated real steel casting speed; and 4. calculating the needed water drainage mount of a rack cooled water when the real temperature of the logical sections at the mill finish rolling outlet is regulated at the finishing target temperature. According to the method, the volume of the cooled water in the finish rolling racks to be increased or reduced relative to a strip steel head can be calculated, set or regulated in advance through the deviation between the predicted finishing temperature of all sections and the target finishing temperature, so that the finishing temperature of the strip steel can be accurately controlled.

Owner:BAOSHAN IRON & STEEL CO LTD

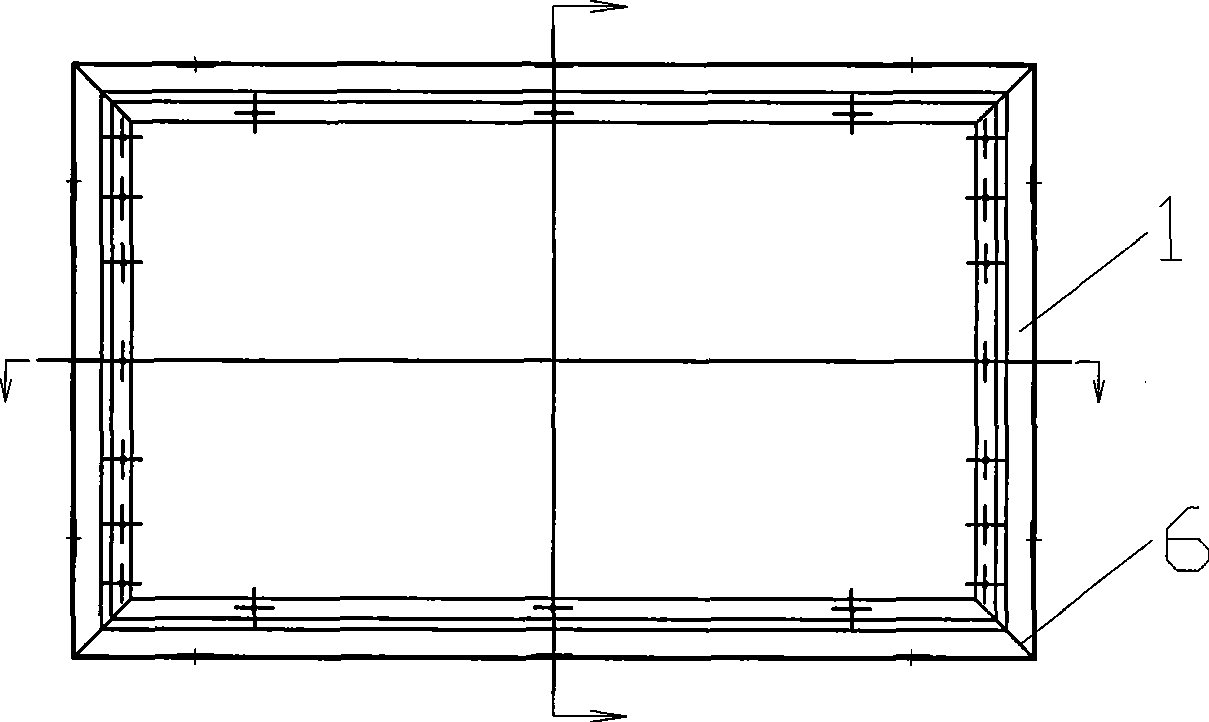

Aluminium section bar panel frame and method for manufacturing the same

The invention provides an aluminum section panel frame and a processing and manufacturing method thereof. The aluminum section panel frame is a quadrilateral frame which is formed by mutual connection of every two of four frame strips, the frame strips are composed of extrusion profile strips with irregular cross section, the frame strip edges around the quadrilateral frame are scarfing edges capable of fastening a channel, and the scarfing edges are vertical to the upper surface of the quadrilateral frame; and the opposite upper surface of the inside opposite to the frame strip edges on the frame strips is provided with irregular connecting edges which extend inwards and the irregular connecting edges are connected to inside edges which are parallel to the frame strip edges. The processing and manufacturing method of the panel frame comprises the following steps: (a) melting an aluminum ingot: performing heat insulation on the aluminum ingot by a full-automatic continuous aluminum melting holding furnace to ensure the complete melting of the aluminum ingot; (b) making an aluminum section: extruding a shaped section from an aluminum section extruder; (c) blanking and notching: performing angle cutting at 45 degrees or a random angle and any shape at two ends; (d) welding and forming: performing welding and forming by a welder; and (e) performing surface treatment: performing the surface treatment by aluminum oxidation and the like. The aluminum section panel frame is characterized by simple structure, convenient use, good surface effect of the manufactured frame, surface treatment by adopting various mill finishes or multicolor oxidation and the like, being capable of realizing various frames of section parts and the like.

Owner:ZHEJIANG OUR ELECTRICAL

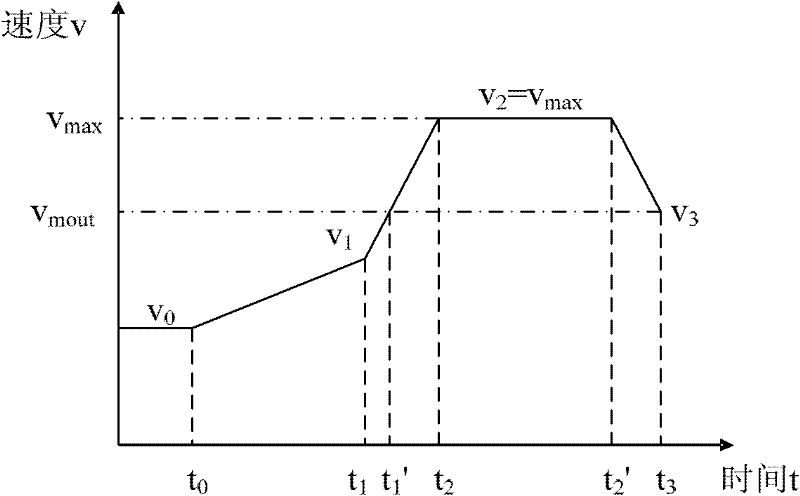

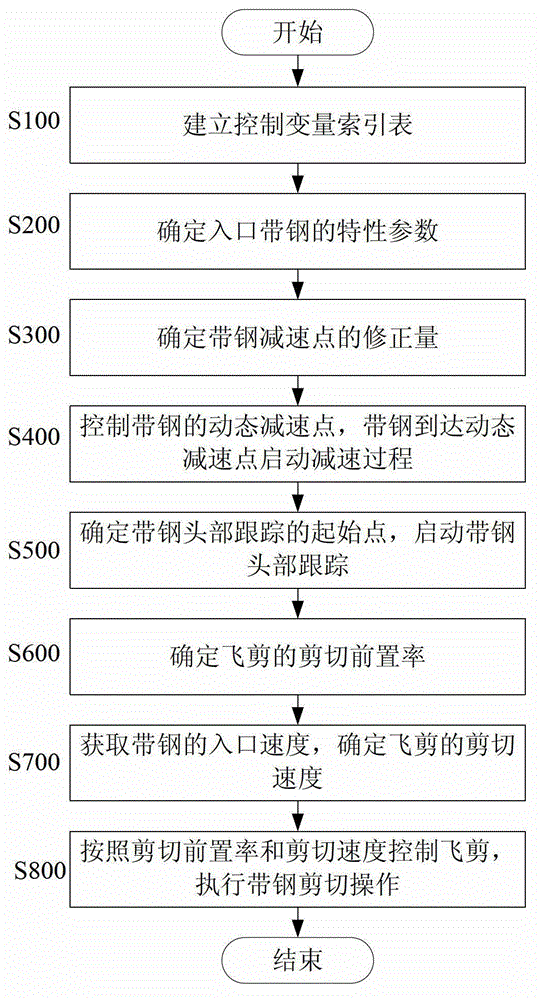

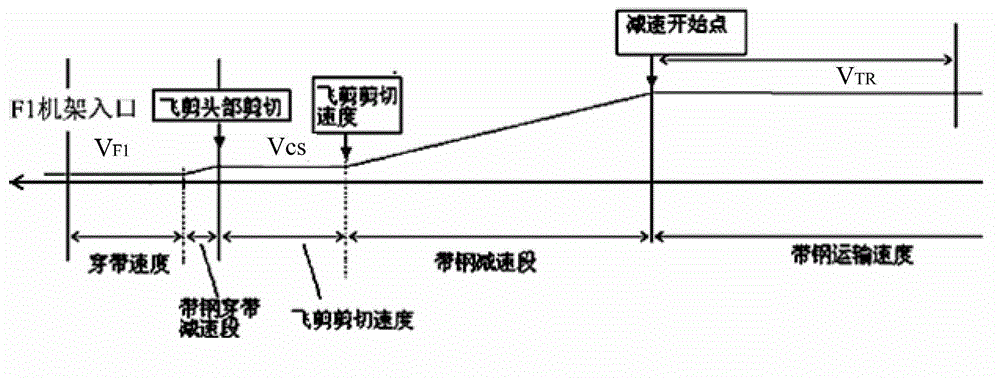

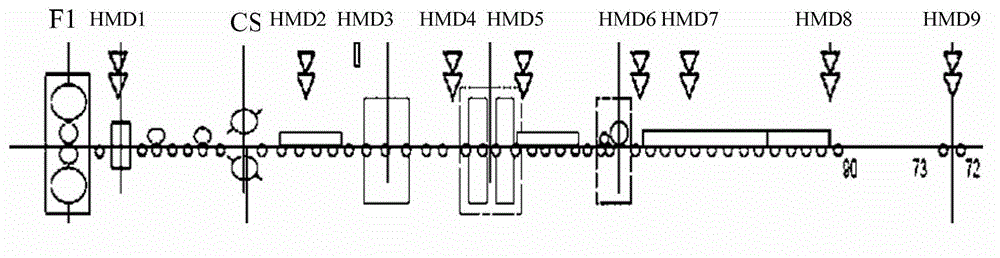

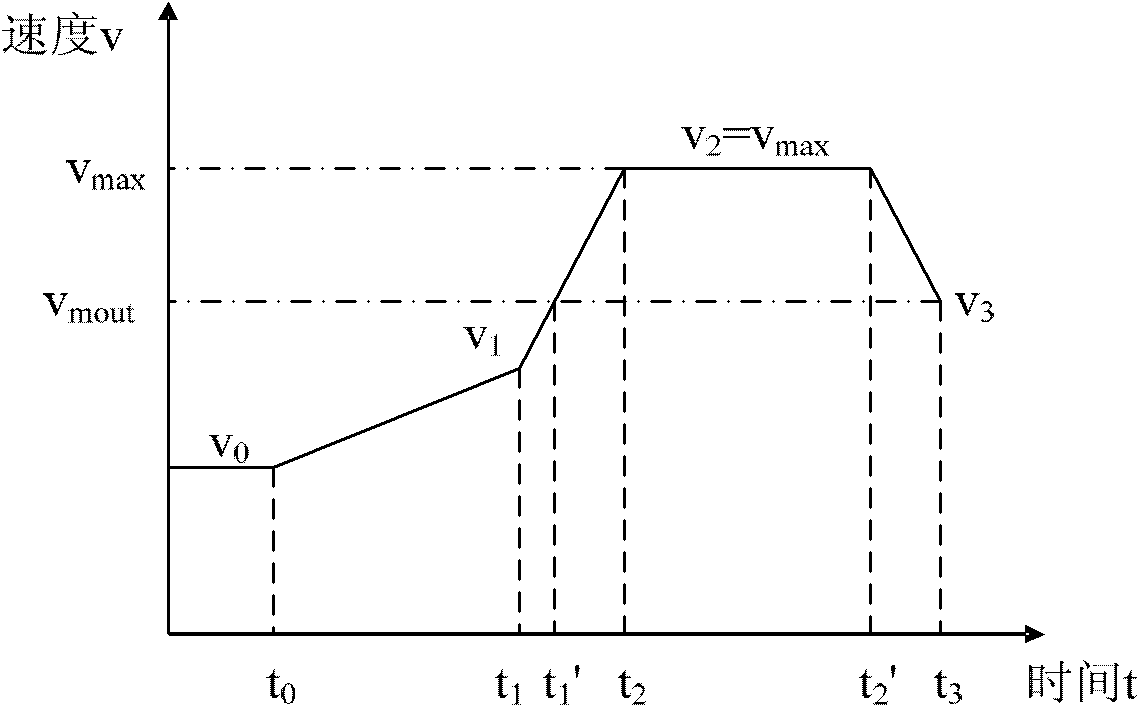

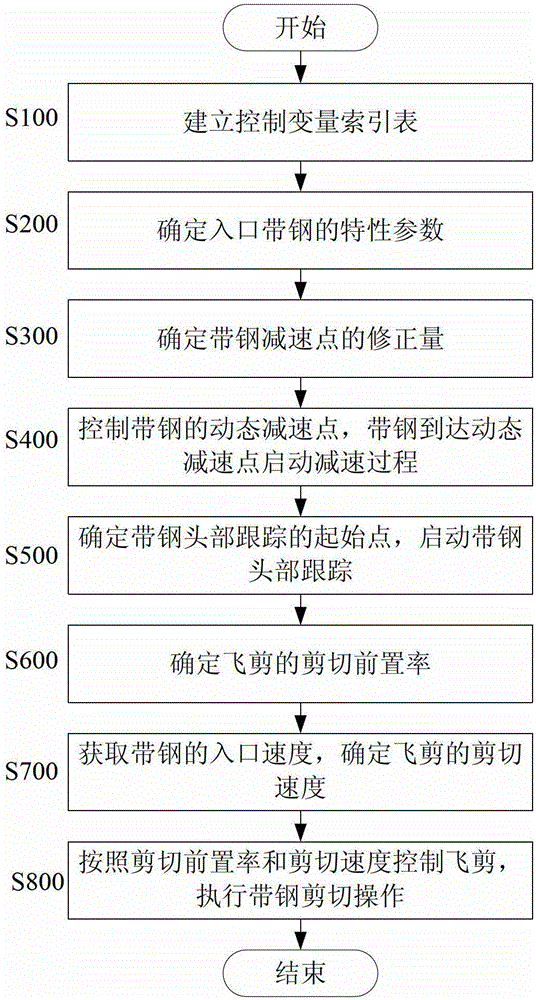

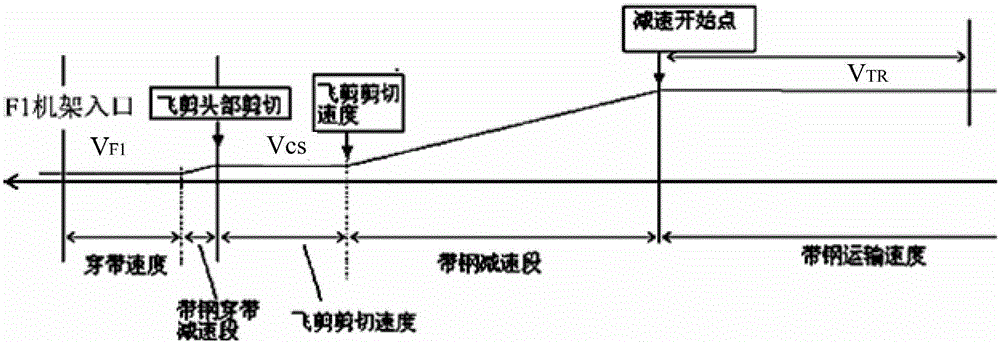

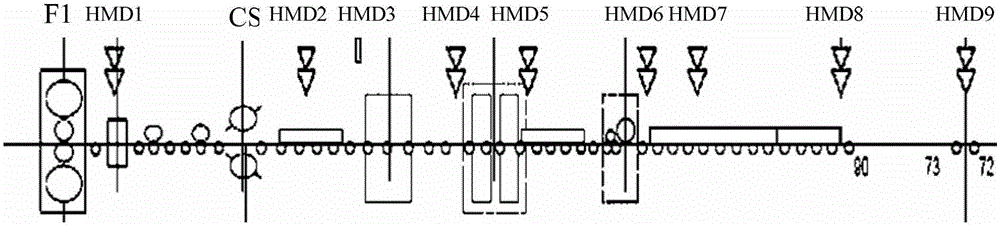

Hot continuous rolling mill finish rolling inlet variable speed control method

ActiveCN103934276ARealize multi-level controlSave shipping timeRoll mill control devicesMetal rolling arrangementsTransport timeStrip steel

The invention provides a hot continuous rolling mill finish rolling inlet variable speed control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling entrance speed of finish rolling strip steel of a hot continuous rolling mill through computer programs. According to four sets of compensation factors, feature parameters of the entering strip steel are determined; according to the feature parameters of the strip steel, speed reducing point correction of the strip steel is determined; according to the speed reducing point correction, a target speed reducing point of the strip steel is determined, and a dynamic speed reducing point is controlled; according to the target speed reducing point of the strip steel, a tracking start point of the head of the strip steel is determined; according to the feature parameters of the strip steel, the shear front-arranging rate of a flying shear is determined; according to the entrance speed of the strip steel and the shear front-arranging rate of the flying shear, the shearing speed of the flying shear is determined. Speed change points are determined according to the types and specifications of steel, the speed of the strip steel before flying shear is controlled in a multilevel mode, conveying time of the strip steel in an intermediate roller way is saved, the rolling efficiency of different strip steel can be maximized, and the rolling efficiency of the strip steel in the hot rolling process is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

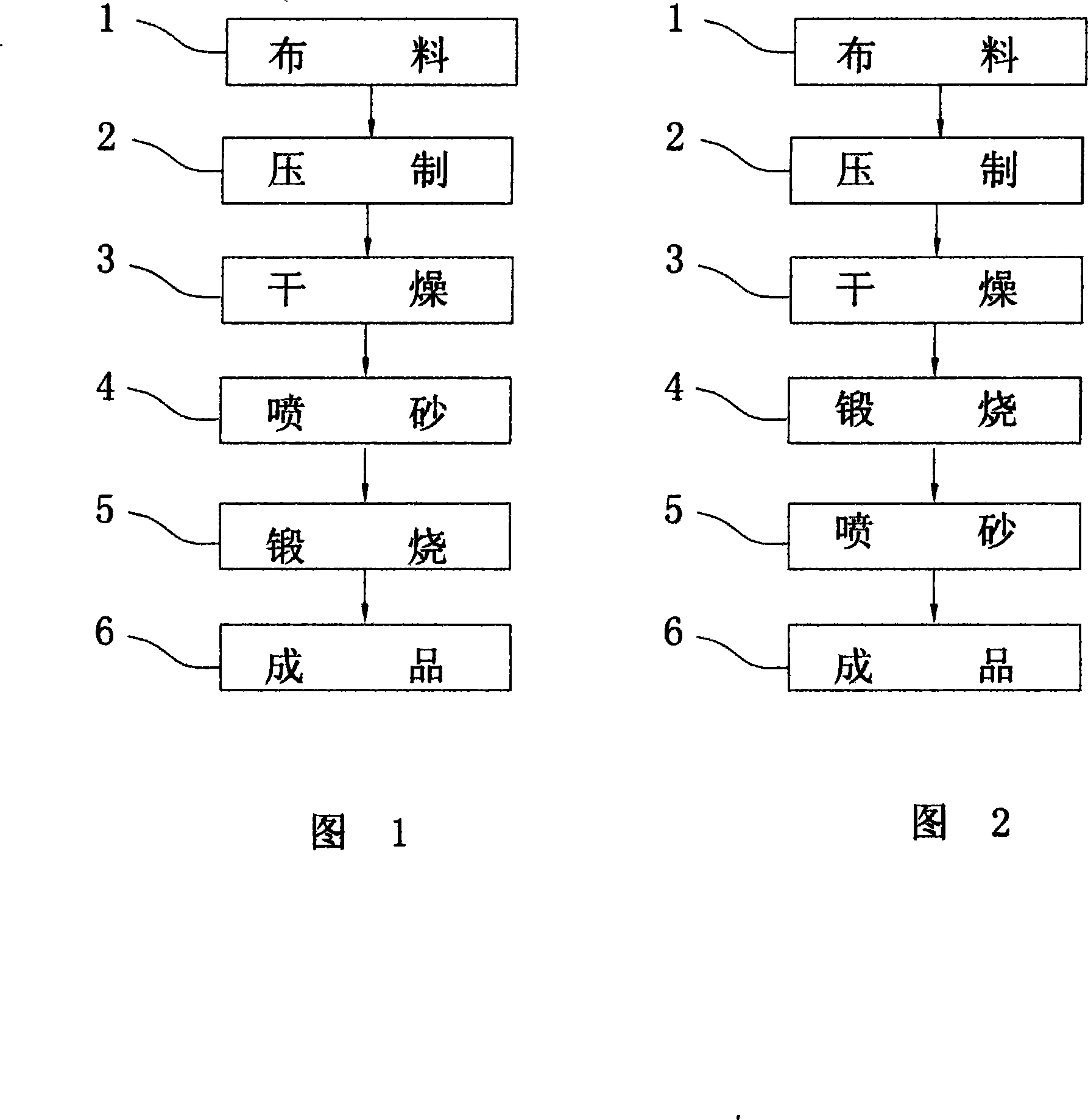

Method for processing ceramic wall and floor tiles

InactiveCN101229974AImprove fatigue resistanceImprove adhesionAbrasion apparatusFeeding arrangmentsManufacturing cost reductionAbrasive blasting

The invention relates to a method for processing ceramic wall tiles, which comprises the following steps: ceramic material cloth is pressed, dried, sandblasted and then burnt to finished products. By adopting the technical proposal in the invention, in particular the arrangement of the sandblasting before roasting of raw bricks replaces conventional grinding and polishing process so that a surface form of the raw bricks takes the change to obtain designed decorative designs and patterns. The raw bricks are produced through sandblasting micropowder cloth and diversified mill finishes and sub-mill finishes as well as diversified wall tiles with distinct decorative designs and patterns. Compared with the conventional process, the invention has high yield and more importantly, the invention can greatly reduce the environmental pollution caused by electrical power and water resource, improve labor environment and diminish noise and dust in working environment as well as reducing manufacture cost and promoting market competitiveness of the products.

Owner:杨晓东

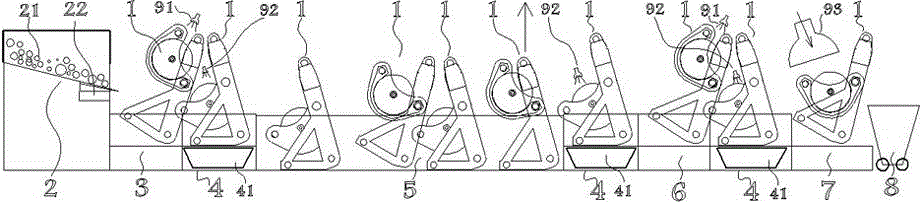

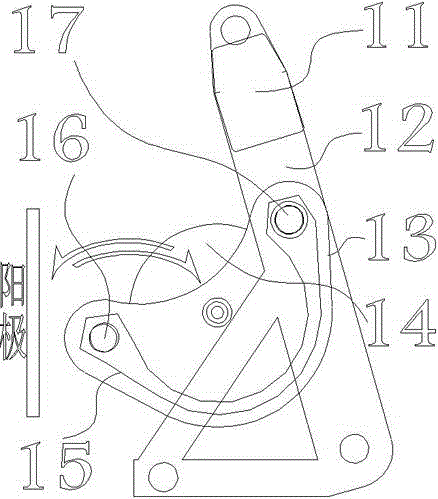

Fully-automatic roll plating method and production line in step-by-step passing manner

The invention relates to a fully-automatic roll plating method and production line in a step-by-step passing manner. A travelling crane and other expensive equipment are not adopted during the transferring of materials, so that the construction cost of the whole production line is low; and the upgrading renovation of an electroplating production enterprise are carried out without pressure. A rolling barrel is open, so that electric ions between a plated product and an anode can be exchanged and transferred in a barrier-free manner; and cathode conducting wires are fixedly connected, so that the lost electric energy due to the poor contact of traditional electrode hanging rods is reduced. Thus, the actual production proves that the electroplating time and the electric energy can be saved by more than 40% under the same electroplating condition by utilizing the fully-automatic roll plating method provided by the invention. The experiment proves that a product which has the same quality as the quality effect obtained by the machined product with the mill finish less than 2*2mm in a rack plating manner can be plated by the fully-automatic roll plating production line in the step-by-step passing manner. In the production line, a centrifugal dirt collector is arranged at the lower part of each cleaning tank, so that the cleaning water can be used for a long time, i.e., the discharge of sewage is reduced by 40%. Thus, the energy conservation and the environment friendliness are realized.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Method for manufacturing laser direct plating tipping paper

InactiveCN101100833AAdvanced and reasonable technologySolve environmental problemsSpecial paperPaper/cardboardPaper manufacturingCinnamic acid

The invention discloses radium irradiating direct plating Chinese water pine paper manufacturing method. It includes the following steps: mixing cinnamic acid latex with hydrophilic thickening agent in weight percentage of 97%-99% and 1%-3%, standing more then 12 hours to form hydrophilic paint; coating hydrophilic paint on BOPP film with 8-10g / sq m wet coating weight; jointing the base paper with the coating surface; mill finish; drying to make the water content be 5%-8%; peeling off the BOPP film; aluminum plating in vacuum to obtain the finished product. The invention has the advantages of simple, reasonable, scientific select material, good for increasing cigarette grade, reducing its influence for people's health.

Owner:扬州海克赛尔新材料有限公司

Waste gas treatment device

ActiveCN104964290AAvoid burnsHigh trafficHollow article cleaningIncinerator apparatusInsulation layerCombustion chamber

The invention discloses a waste gas treatment device. The waste gas treatment device comprises a combustion chamber, a first settling basin, a first spray pipe, a second settling basin and a second spray pipe. The combustion chamber is sequentially provided with a heat insulation layer, an adhesive layer and a mill finish layer from outside to inside. The first settling basin is arranged below the combustion chamber. The first spray pipe is connected with the combustion chamber and the first settling basin, and is a hollow cylinder. Containing space is arranged between the inner wall and the outer wall of the first spray pipe. Three layers of round through holes are formed in the inner wall of the first spray pipe in the circumferential direction at intervals. A water inlet hole connected with a control valve is formed in the outer wall of the first spray pipe. The second settling basin is communicated with the first settling basin. One end of the second spray pipe is communicated with the second settling basin, and the other end of the second spray pipe is communicated with the atmosphere. The spray pipes are provided with interlayers, and by means of the round through holes, the contact face of liquid and gas is increased, and the treatment capacity of liquid washing to waste gas is improved. Due to an inner wall cleaning device, the service life of a main shaft is prolonged, and the inner wall of the combustion chamber can be treated by combining the scaling degree of the inner wall.

Owner:沈阳亿海嘉行电子科技有限公司

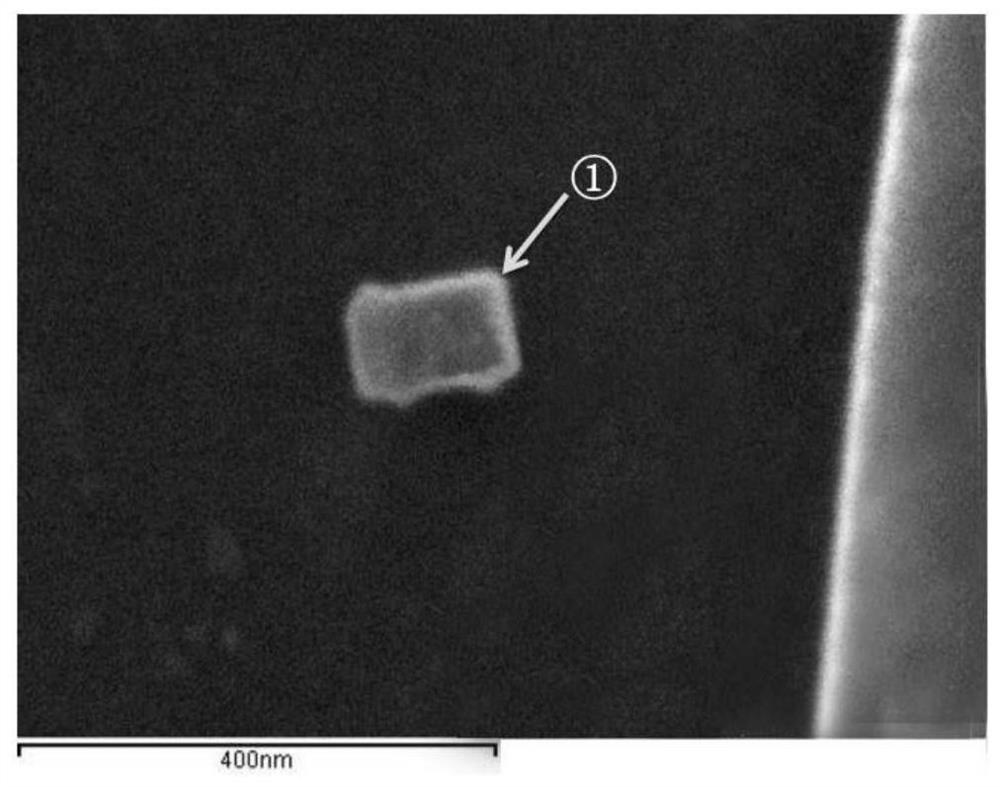

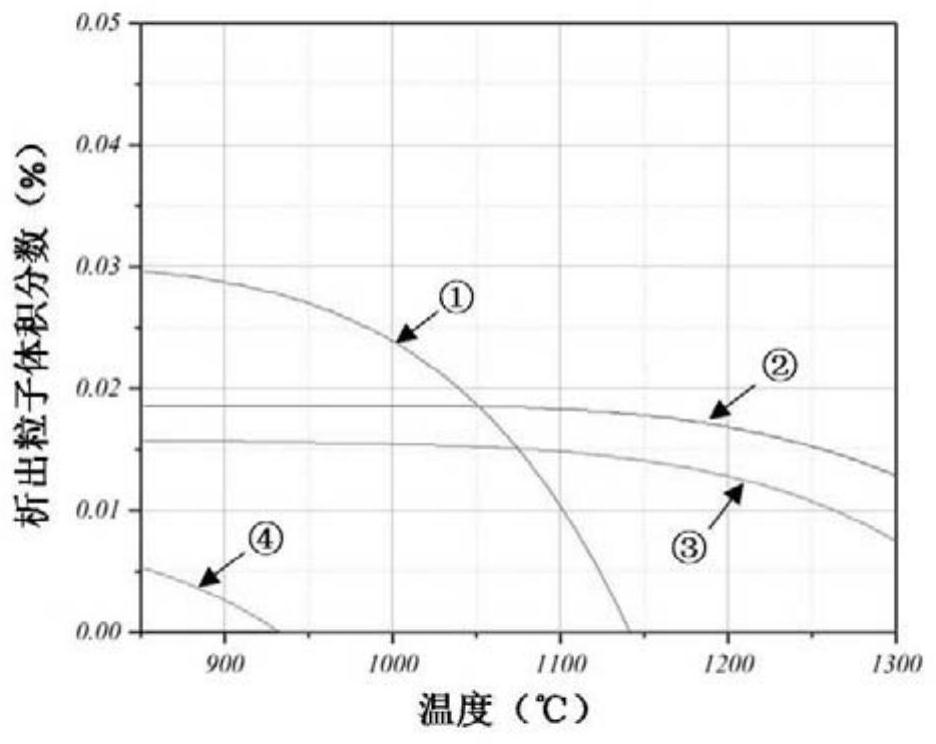

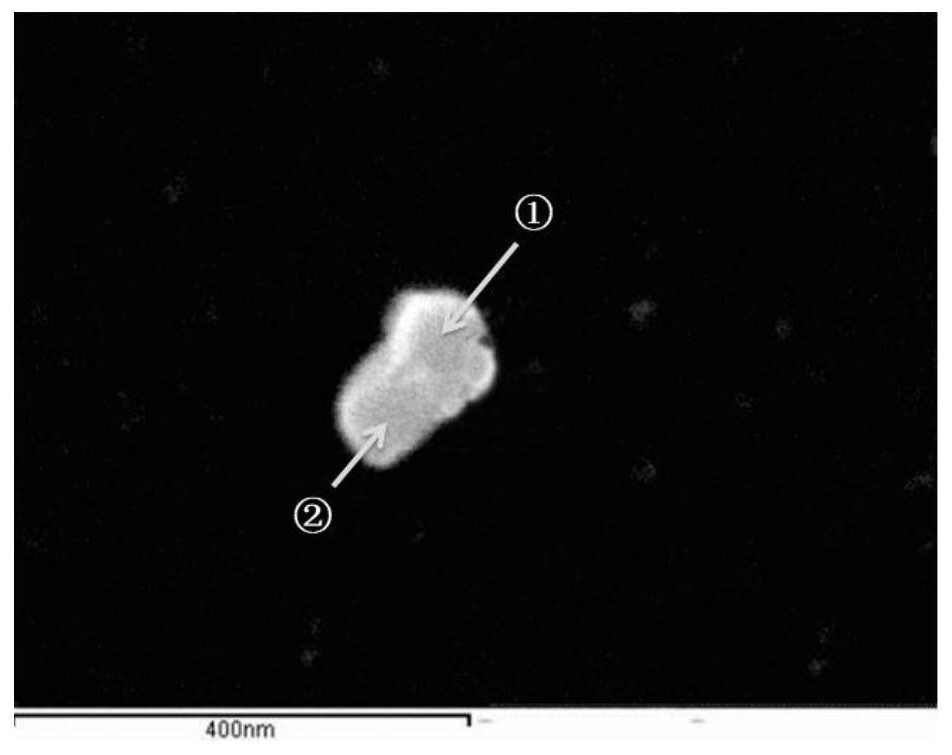

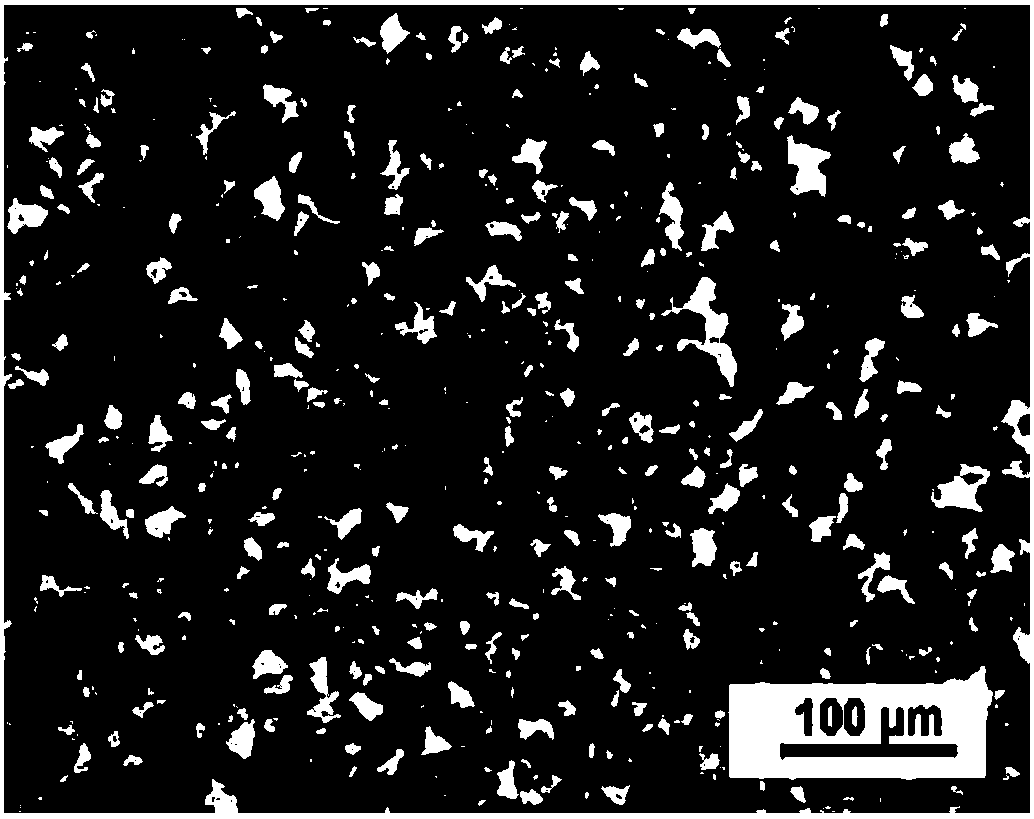

Thick and heavy hot-rolled H-shaped steel capable of inhibiting grain growth and production method thereof

ActiveCN112410665APromote precipitationReduce strain-induced precipitationTemperature control deviceMetal rolling arrangementsMolten steelHeating furnace

The invention discloses thick and heavy hot-rolled H-shaped steel capable of inhibiting grain growth and a production method thereof, and belongs to the technical field of iron and steel smelting. TheH-shaped steel comprises the following components in percentage by weight: 0.05%-0.20% of C, 0.10%-0.50% of Si, 0.80%-1.60% of Mn, 0.02%-0.04% of Nb, 0.008%-0.015% of Ti, 0.003%-0.005% of N, and thebalance of iron and other impurities. The production method of the thick and heavy hot-rolled H-shaped steel comprises the following production steps of molten steel smelting, casting blank continuouscasting, heating by a heating furnace, cogging mill rough rolling, universal mill finish rolling and cooling by a cooling bed, wherein the cooling speed of a continuous casting blank is controlled tobe smaller than 5 DEG C / s in the casting blank continuous casting process. In order to overcome the technical problem of Ti / Nb composite microalloying in the actual production process, the size and volume fraction of TiN second-phase particles are regulated and controlled by controlling the components of Ti and N; and epitaxial growth of the NbC-attached TiN particles is achieved through the optimized size and volume fraction of the TiN particles in cooperation with control over the cooling speed, and therefore it is guaranteed that the grain size of austenite obtained after final rough rolling is smaller than 50 micrometers.

Owner:MAANSHAN IRON & STEEL CO LTD

Milling finish machining method for side wall of difficult-to-cut material or large-size three-dimensional molded surface part

InactiveCN104551144AImprove machining accuracyImprove detection accuracyMeasurement/indication equipmentsMilling equipment detailsSurface layerHardness

The invention discloses a milling machining error online detection self-adapted machining method for a side wall of a difficult-to-cut or large-size three-dimensional molded surface part. The method comprises the following steps: after machining a three-dimensional molded surface layer by layer, measuring an appearance error of the three-dimensional molded surface; and automatically calculating compensation according to a detection value to determine a final finish machining track so as to finish the finish machining of the three-dimensional molded surface. According to the milling machining error online detection self-adapted machining method, a part size in a machining process is measured so that machining comprehensive errors caused by the factors including tool abrasion, part rigid deformation, non-uniform hardness and the like are eliminated, and the machining precision of the difficult-to-cut or large-size three-dimensional molded surface part is greatly improved.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

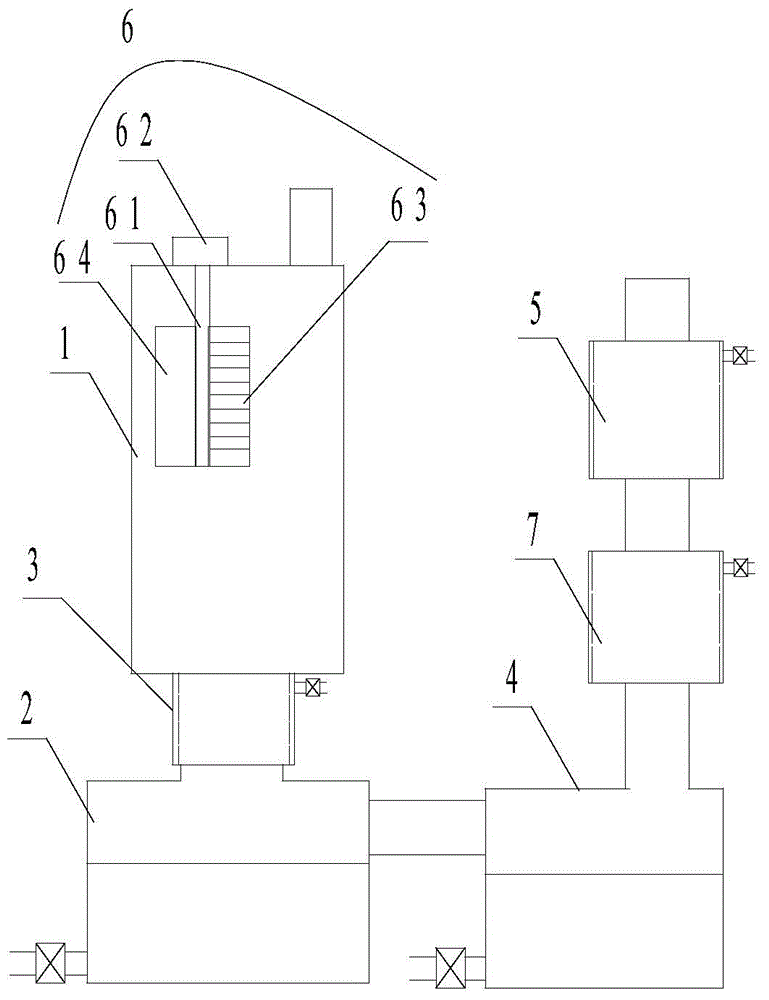

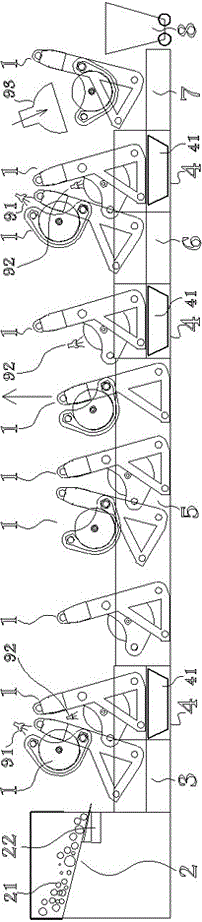

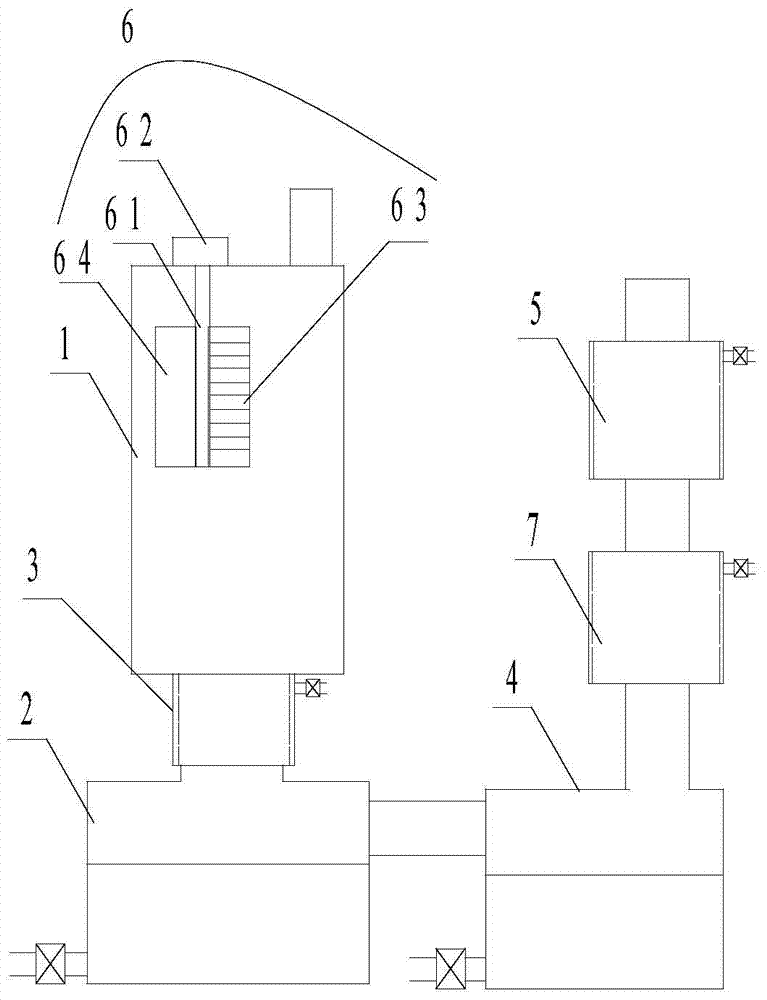

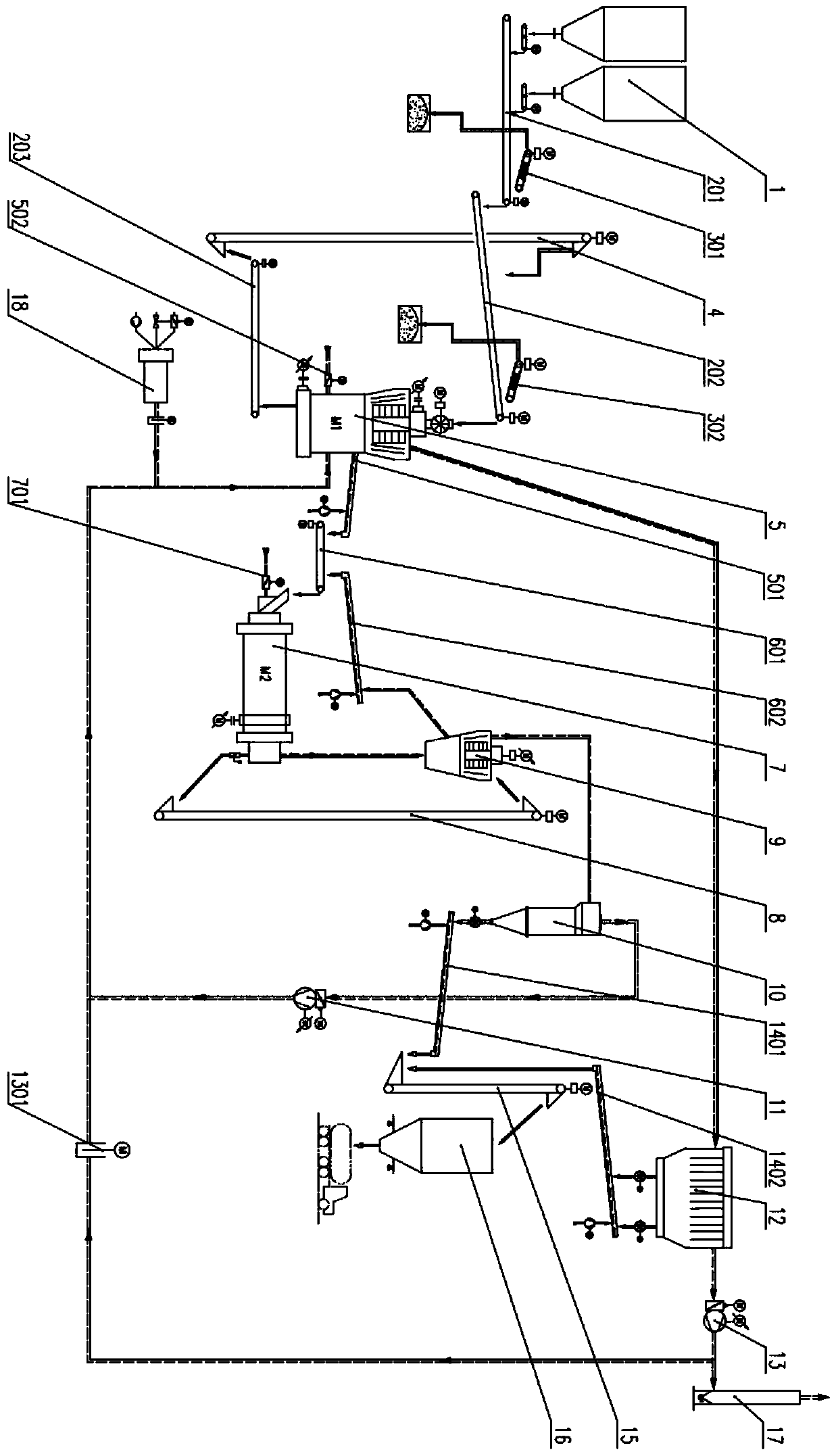

Semi-finished milling system

ActiveCN105498927AImprove grinding efficiencyReduce energy consumptionGrain treatmentsWork in processConveyor belt

A semi-finished milling system is characterized by comprising a raw material warehouse (1), a first raw material conveying belt (201), a second raw material conveying belt (202), a third raw material conveying belt (203), a first iron remover (301), a second iron remover (302), a first lifter (4), a vertical mill (5), a semi-finished product conveyor belt (601), a semi-finished product conveying air chute (602), a ball mill (7), a second lifter (8), a powder concentrator (9), a cyclone dust collector (10), a first fan (11), a bag type dust collector (12), a second fan (13), a vertical mill finished product conveying air chute (1401), a ball mill finished product conveying air chute (1402), a third lifter (15) and a finished product storage warehouse (16). Through regulating the fineness and the feed quantity of coarse particle products entering the ball mill, the milling efficiency and the power consumption of the ball mill are controlled, and the high milling efficiency and low energy consumption characteristics of the novel vertical mill are exerted to an utmost extent. Finally, the milling efficiency of the whole milling system is increased, and the energy consumption of the whole milling system is reduced.

Owner:LOESCHE (SHANGHAI) CO LTD +1

Antimicrobial milled finishing agent, preparation method and uses thereof

The invention relates to an antibiotic fulling finishing agent, a preparation method and application thereof, comprising the components of: organic-inorganic complex antibiotic finishing agents, a surfactant and distilled water based on the weight percent of 30%-50%:25%-30%:the balance: the preparation method comprises the step of: stirring the organic-inorganic complex antibiotic finishing agents, the surfactant and the distilled water for 15-20min at room temperature to be mixed uniformly for formulating the antibiotic fulling finishing agent; the method is applied to fiber products. The fiber product subjected to the treatment of the finishing agent is less in fuds and plumped in hand felling; the invention is excellently bacteriostatic against staphylococcus aureus, colon bacillus and candida albicans, prominent in deodorization function, simple in the preparation method and suitable for industrial production.

Owner:DONGHUA UNIV +1

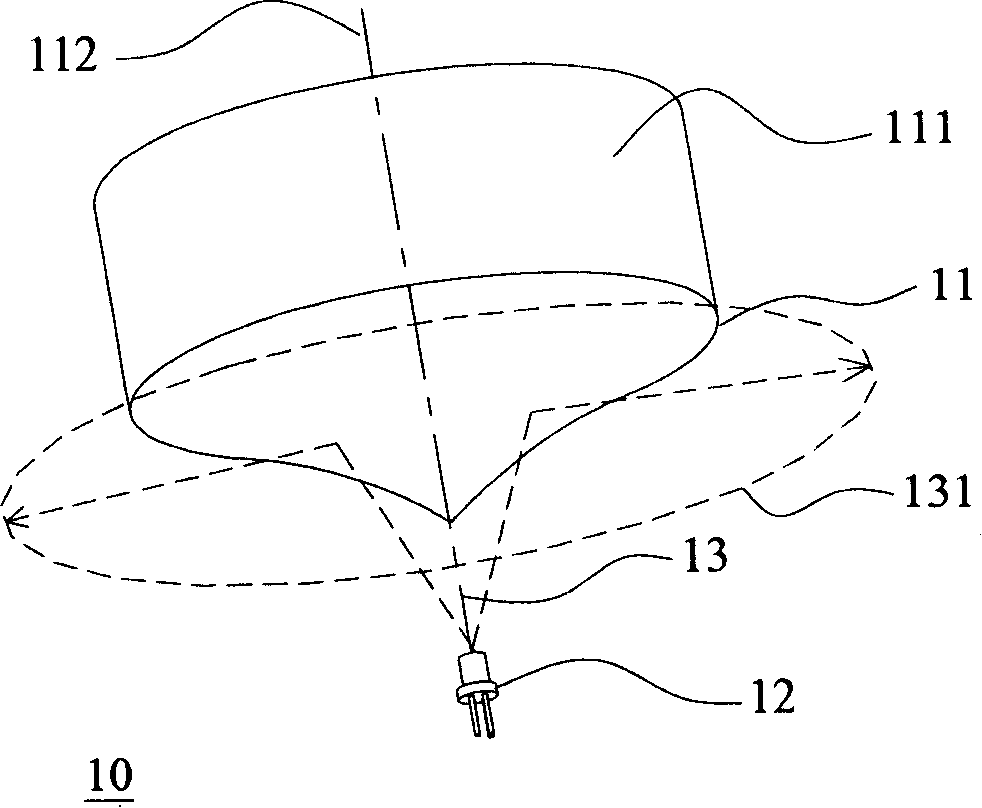

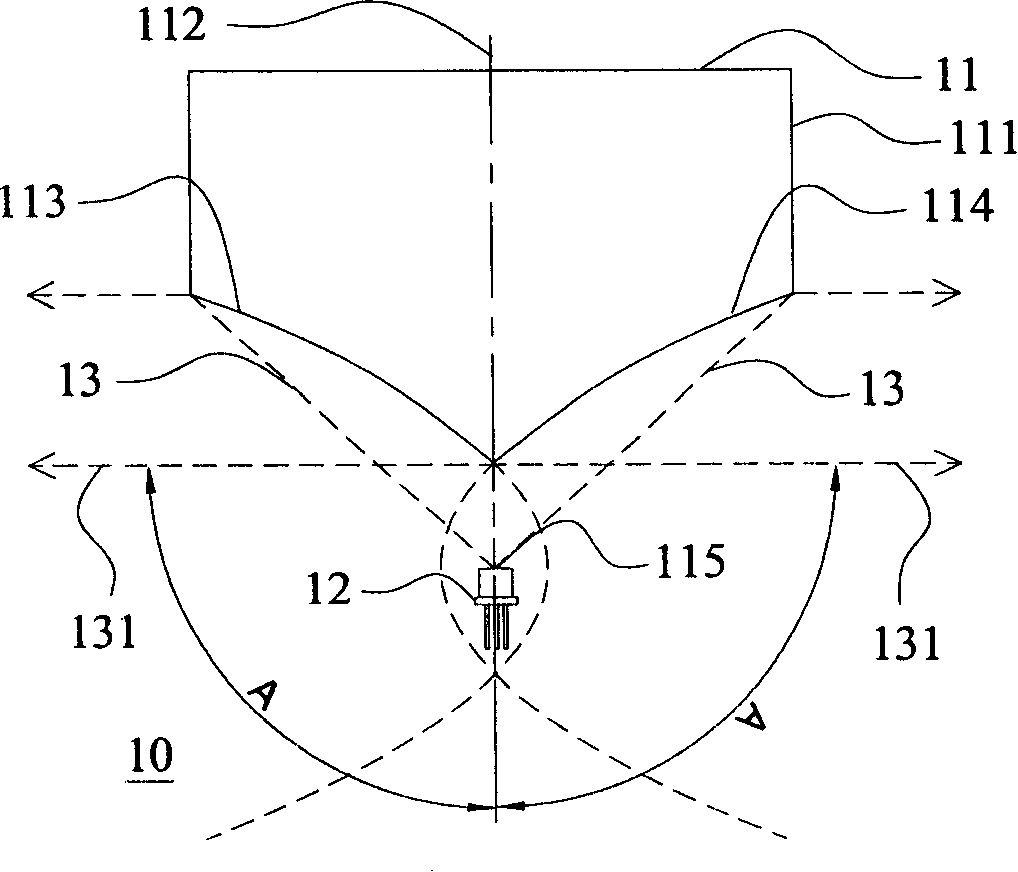

Conical reflecting mirror and device using same

The invention relates to a taper reflector. The section which winds a vertical axes passing through the body is designed to be two taper curves which respectively extend toward two sides from the vertical axes, and focuses of the two taper curves are overlapped on the vertical axes. Besides, an applying device consists of a taper reflector and a laser diode can spread the beams of light generated by the laser diode to an umbrella-shaped mill finish which has a preset included angle with the vertical axes of the taper reflector.

Owner:QUARTON

Step-by-step transmission of fully automatic barrel plating method and production line

The invention relates to a fully-automatic roll plating method and production line in a step-by-step passing manner. A travelling crane and other expensive equipment are not adopted during the transferring of materials, so that the construction cost of the whole production line is low; and the upgrading renovation of an electroplating production enterprise are carried out without pressure. A rolling barrel is open, so that electric ions between a plated product and an anode can be exchanged and transferred in a barrier-free manner; and cathode conducting wires are fixedly connected, so that the lost electric energy due to the poor contact of traditional electrode hanging rods is reduced. Thus, the actual production proves that the electroplating time and the electric energy can be saved by more than 40% under the same electroplating condition by utilizing the fully-automatic roll plating method provided by the invention. The experiment proves that a product which has the same quality as the quality effect obtained by the machined product with the mill finish less than 2*2mm in a rack plating manner can be plated by the fully-automatic roll plating production line in the step-by-step passing manner. In the production line, a centrifugal dirt collector is arranged at the lower part of each cleaning tank, so that the cleaning water can be used for a long time, i.e., the discharge of sewage is reduced by 40%. Thus, the energy conservation and the environment friendliness are realized.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

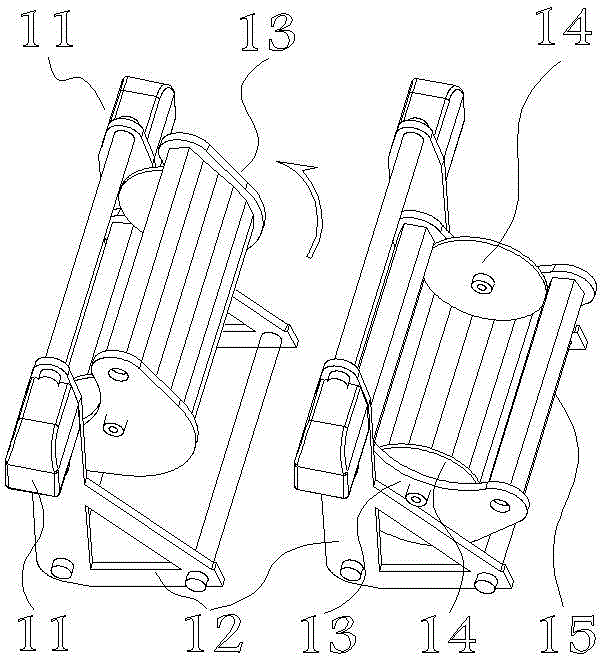

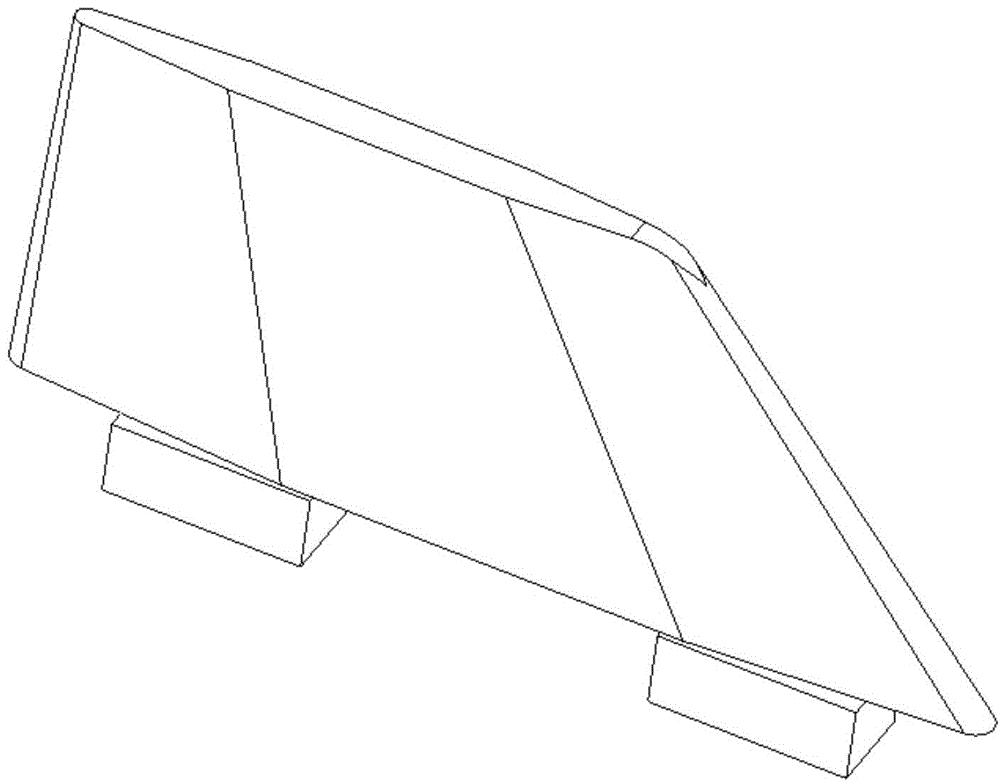

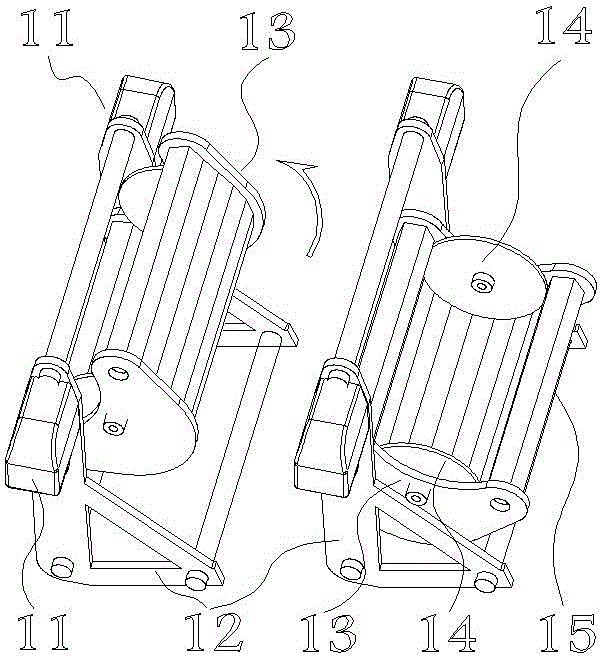

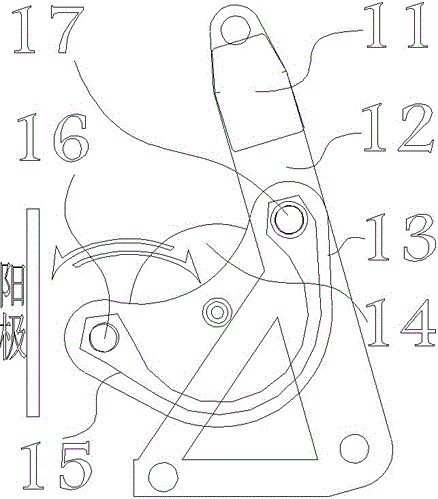

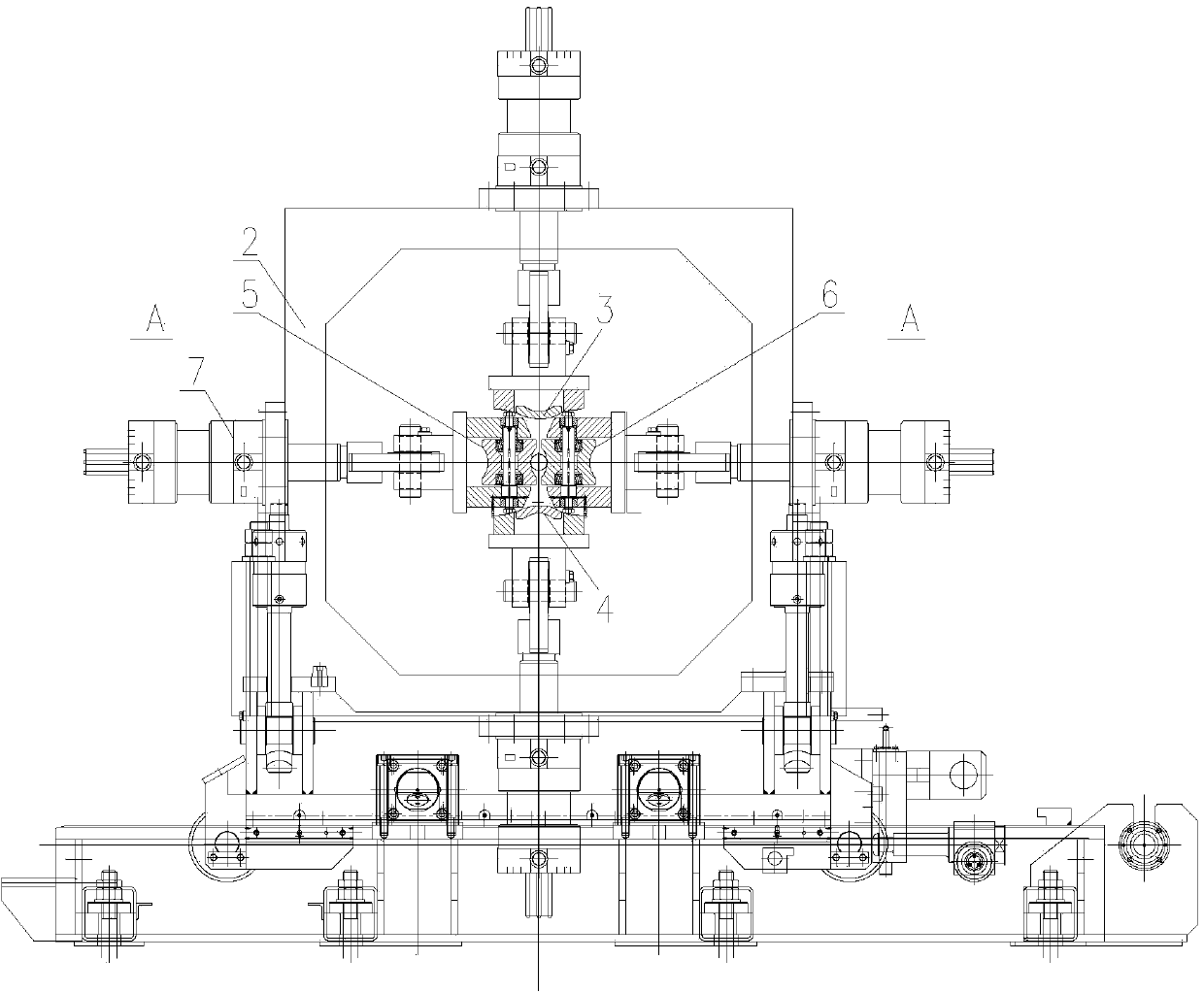

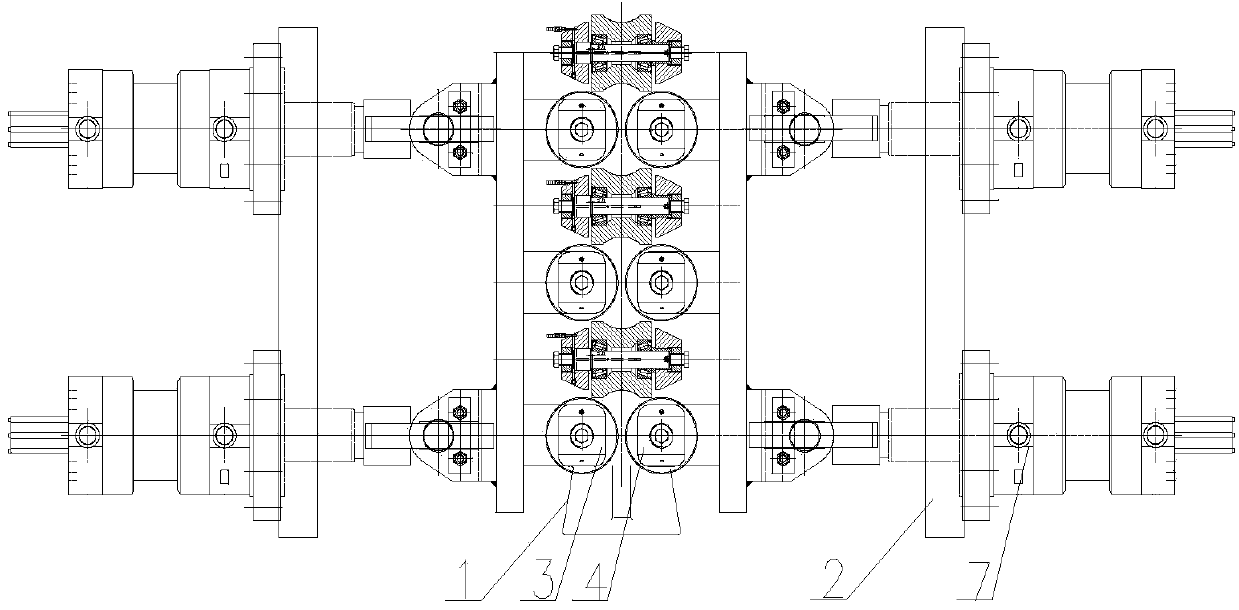

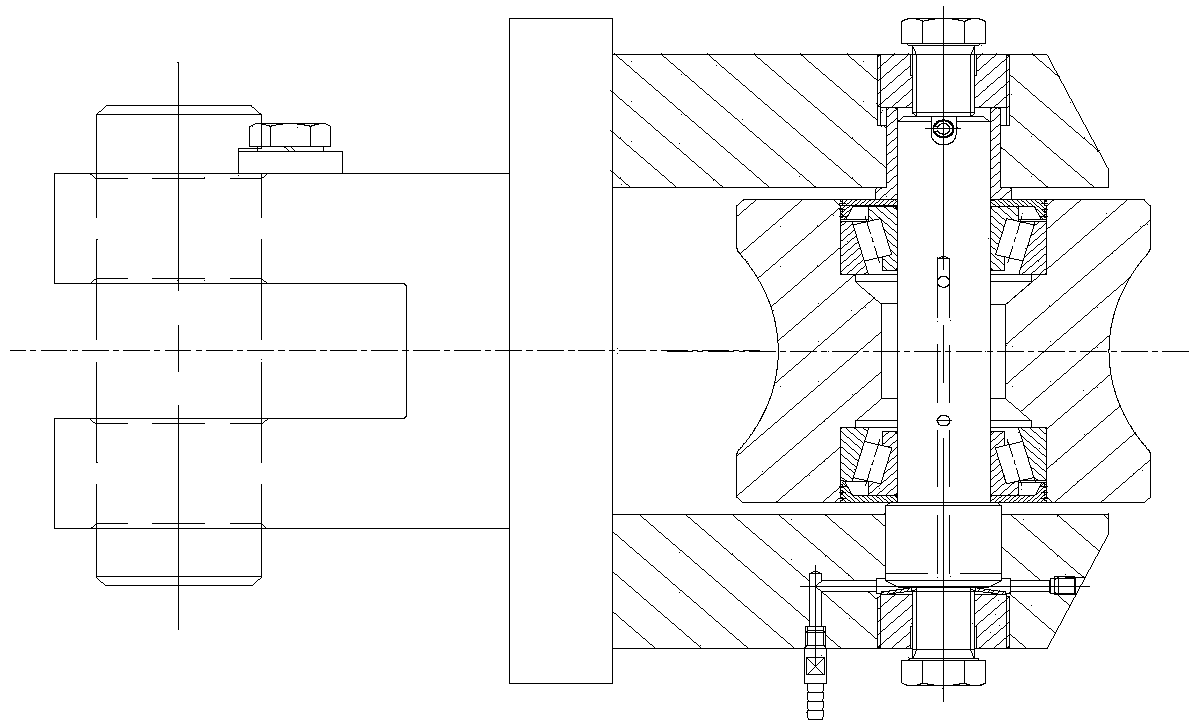

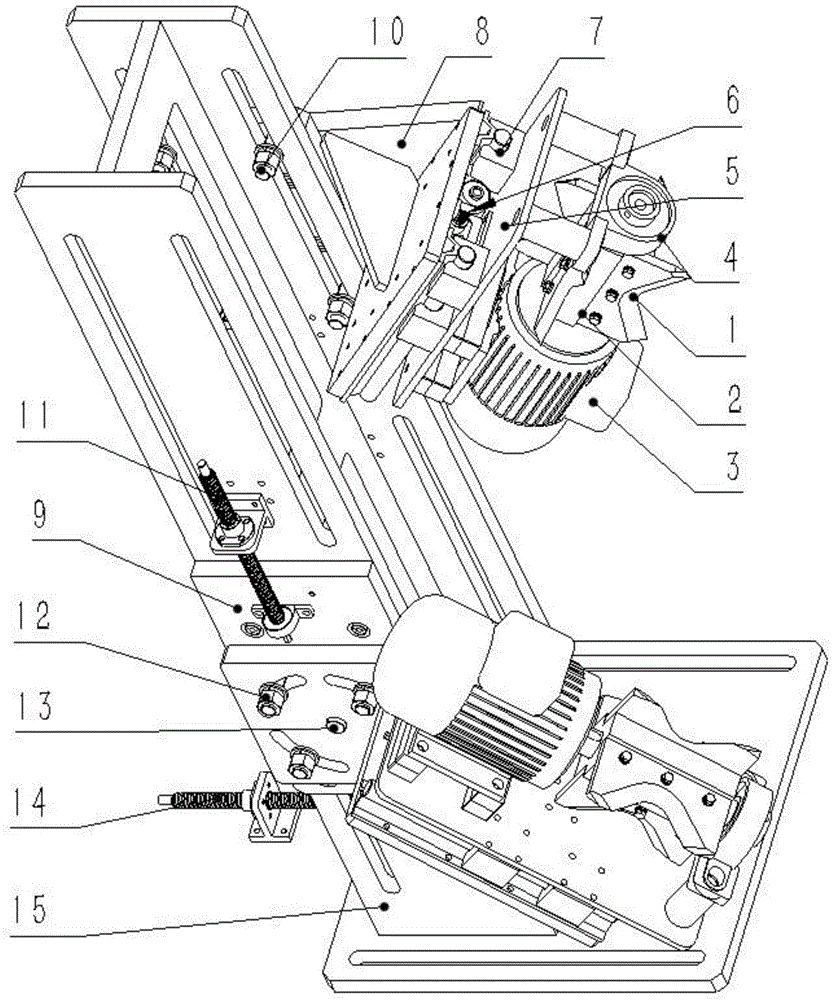

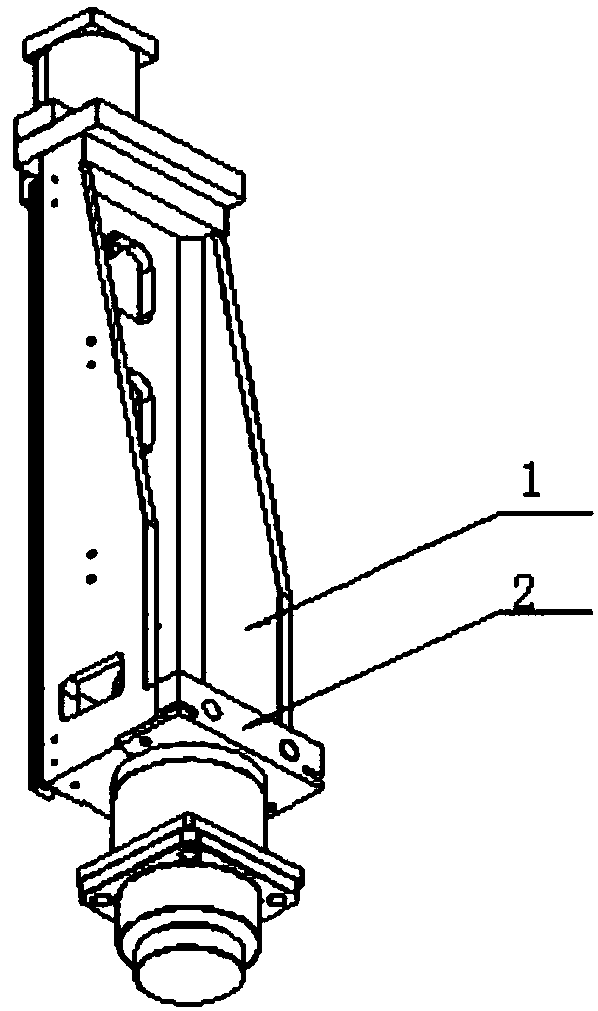

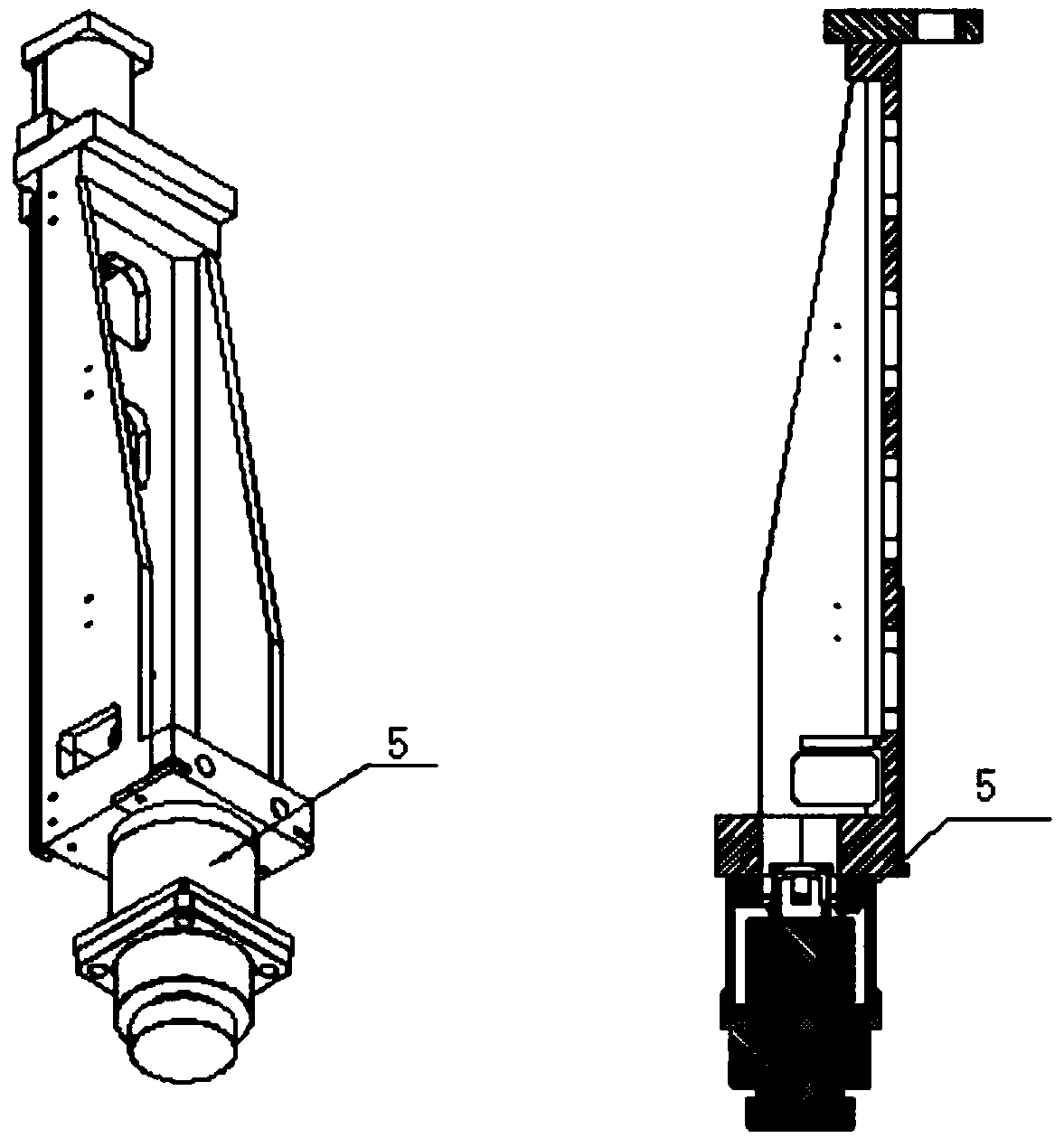

Online treatment device for large bar rolled piece bend

The invention discloses an online treatment device for large bar rolled piece bend. The online treatment device comprises an overall framework, a horizontal straightening roller pair and a vertical straightening roller pair, the horizontal straightening roller pair is arranged on the left side and the right side of the overall framework, the vertical straightening roller pair is arranged on the upper side and the lower side of the overall framework, the horizontal straightening roller pair and the vertical straightening roller pair respectively form a horizontal straightening hole and a vertical straightening hole or jointly form a straightening hole, and roller gap adjustment driving devices for adjusting the positions of the horizontal straightening roller pair and the vertical straightening roller pair are further arranged on the overall framework. After the online treatment device is mounted on a large bar continuous mill finish rolling frame, a rolled piece is treated online by the horizontal straightening roller pair and the vertical straightening roller pair, the size of the straightening hole can be adjusted by the roller gap adjustment driving devices to adapt to bars with different specifications, and the online treatment device successfully solves the problems that rolled pieces still bend after cooling collection due to bending of finished product pass rolled pieces in the rolling process of a large bar production line, manpower is wasted in treatment and production cost is increased.

Owner:CISDI ENG CO LTD

Non-medicine antibiotic gauze mask

InactiveCN1565672AAvoid enteringAvoid it happening againRespiratory apparatusAntibiotic YEngineering

A non-pharmaceutical antibacterial mask is disclosed. A piece of antibacterial cloth is sewed outside of the gauze, in the upper end inside of which there is a nose bridge sealed frame. The preparation of the said antibacterial cloth comprises following steps: desizing all cotton fabric, bolling off, mercerizing, dyeing, dipping into the antibacterial sanitary finish and water mixed liquor in ratio of (15:20):1, drying, then repeat the dipping, mill finishing. The invention sews double layer antibacterial cloth outsider of the gauze, thus sets double filter barrier for respiratory tract, enables the bacteria to stop breath, to deform, to crack and to die outside of the human body, enhances protection property and leads to effective prevention for SARS occurrence and infection. It has no drug flavor, no irritability, being safe and reliable to human body. It can also prevent pathogen entering from the nose bridge interspace into human body due to the set of the nose bridge sealed frame inside of the sewed antibacterial cloth.

Owner:尚桂莲

A kind of rolling production method that reduces 42crmo hardness

ActiveCN106216391BImprove straightnessReduce operating labor intensityTemperature control deviceWork treatment devicesAutomatic controlMechanical property

The invention belongs to the field of production machining of special steel of the metallurgical industry, and relates to a rolling production method capable of reducing hardness of 42CrMo. A 42CrMo casting blank serves as a raw material, and the method sequentially comprises following working procedures of heating, descaling, a rough rolling, cooling after rough rolling, continuous rolling, through water cooling, bar reducing sizing mill finish rolling, cooling bed cooling and finally obtaining a finished product bar; by the adoption of the technology, the site operation is simple, online automatic control is easily achieved, and operation labor intensity of a worker is reduced; through the online controlled rolling controlled cold technology, straightness of the 42CrMo steel grade is greatly improved; the subsequent heat treatment technology (annealing technology) is reduced, production cost is saved, the production period is shortened, and the steel market competitiveness is improved; the hardness value range of the obtained 42CrMo steel ranges from 220 HBW to 260 HBW; a metallographic structure comprises ferrite and pearlite; the banded structure is smaller than or equal to 2 levels; the grain size is larger than or equal to 8 levels; and the mechanical property can meet the national standard and user needs.

Owner:DAYE SPECIAL STEEL CO LTD

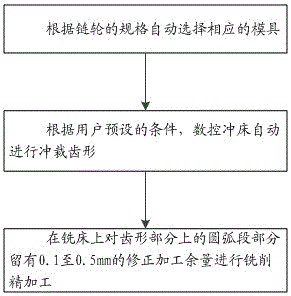

Chain wheel tooth form precision processing technology

The invention discloses a chain wheel tooth form precision processing technology comprising the following steps: automatically selecting a corresponding die according to specification of the chain wheel; automatically performing tooth form punching through a numerical control punch according to user preset conditions; carrying out milling finish machining on 0.1-0.5 mm correction processing balance reserved on an arc segment of a tooth form portion on a milling machine, thus providing high machining efficiency and good processing precision in the chain wheel tooth form processing.

Owner:CHENGDU HENGTONG ZHAOYE PRECISION MACHINERY

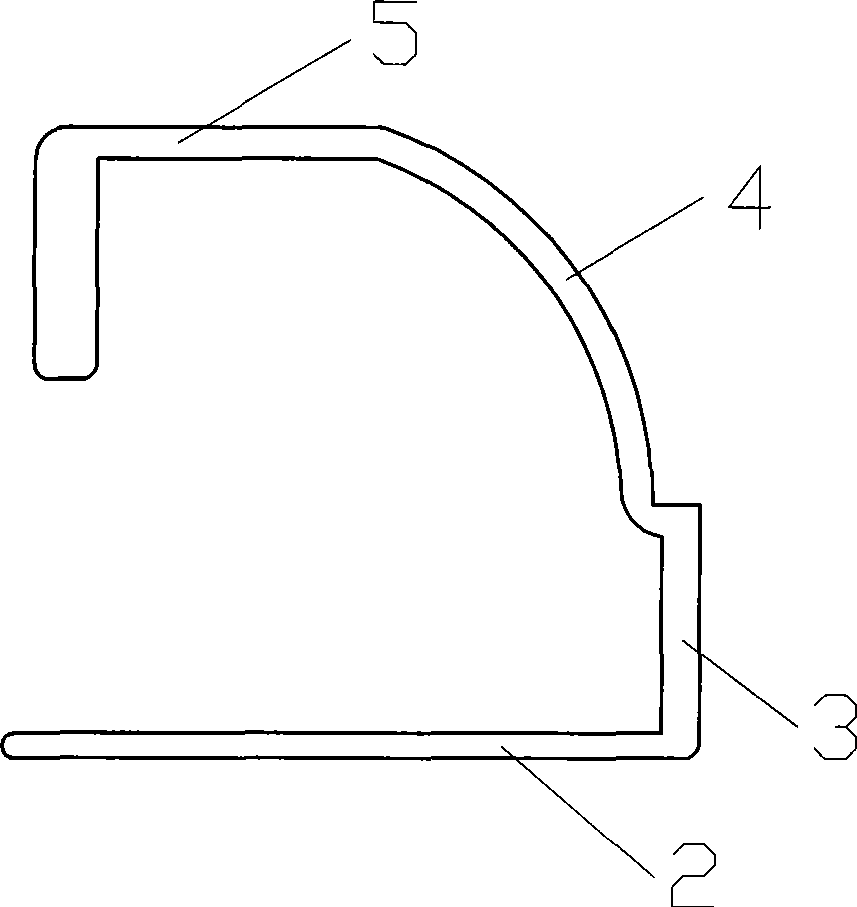

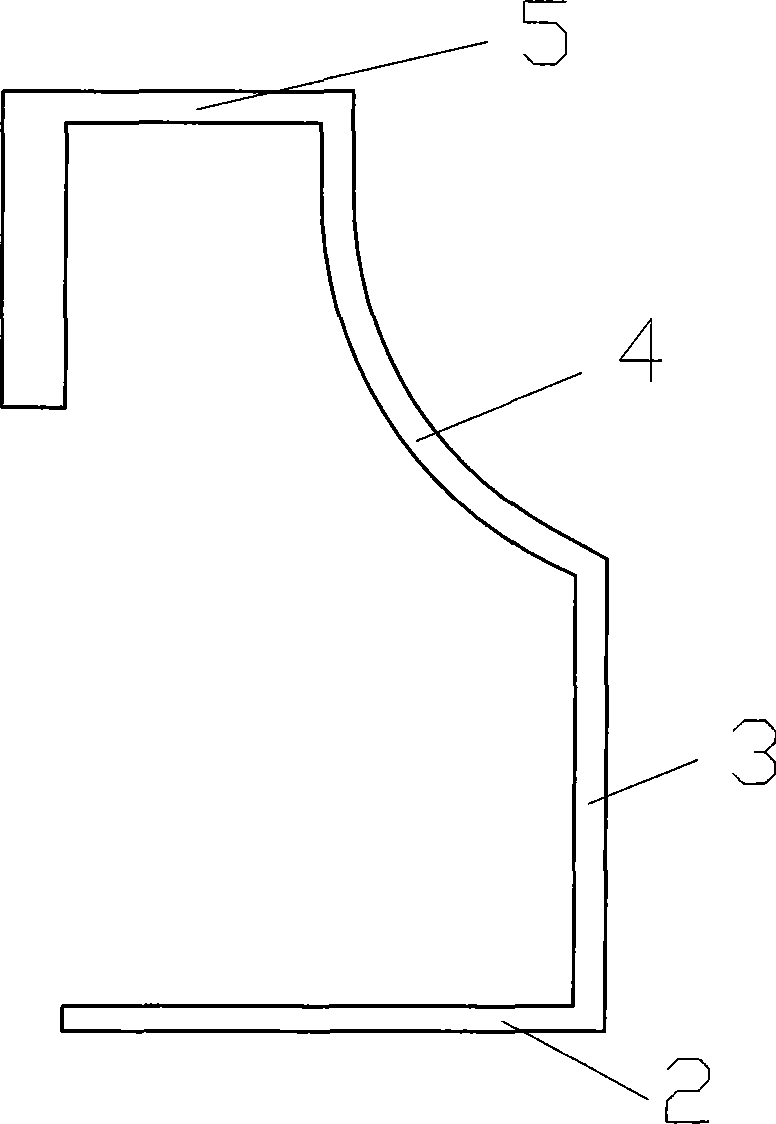

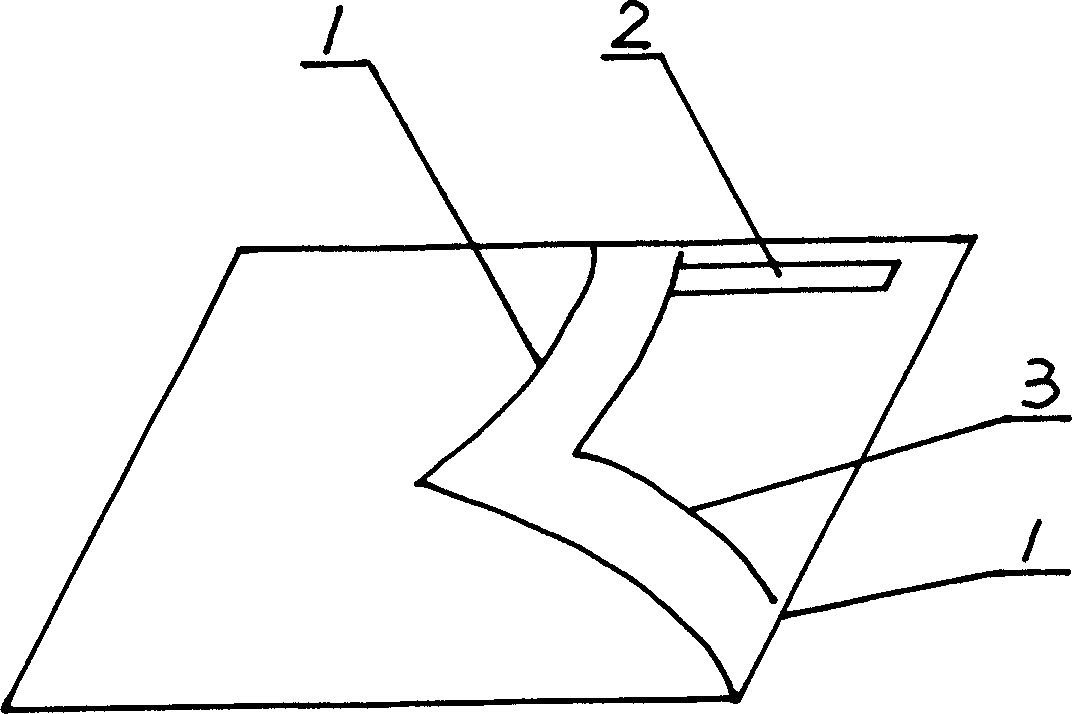

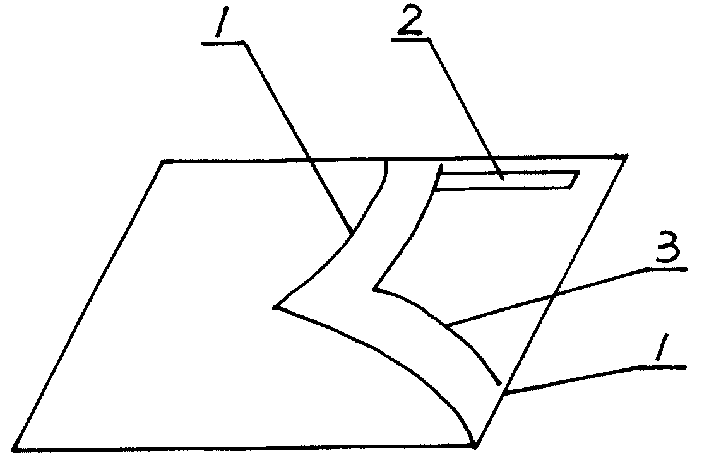

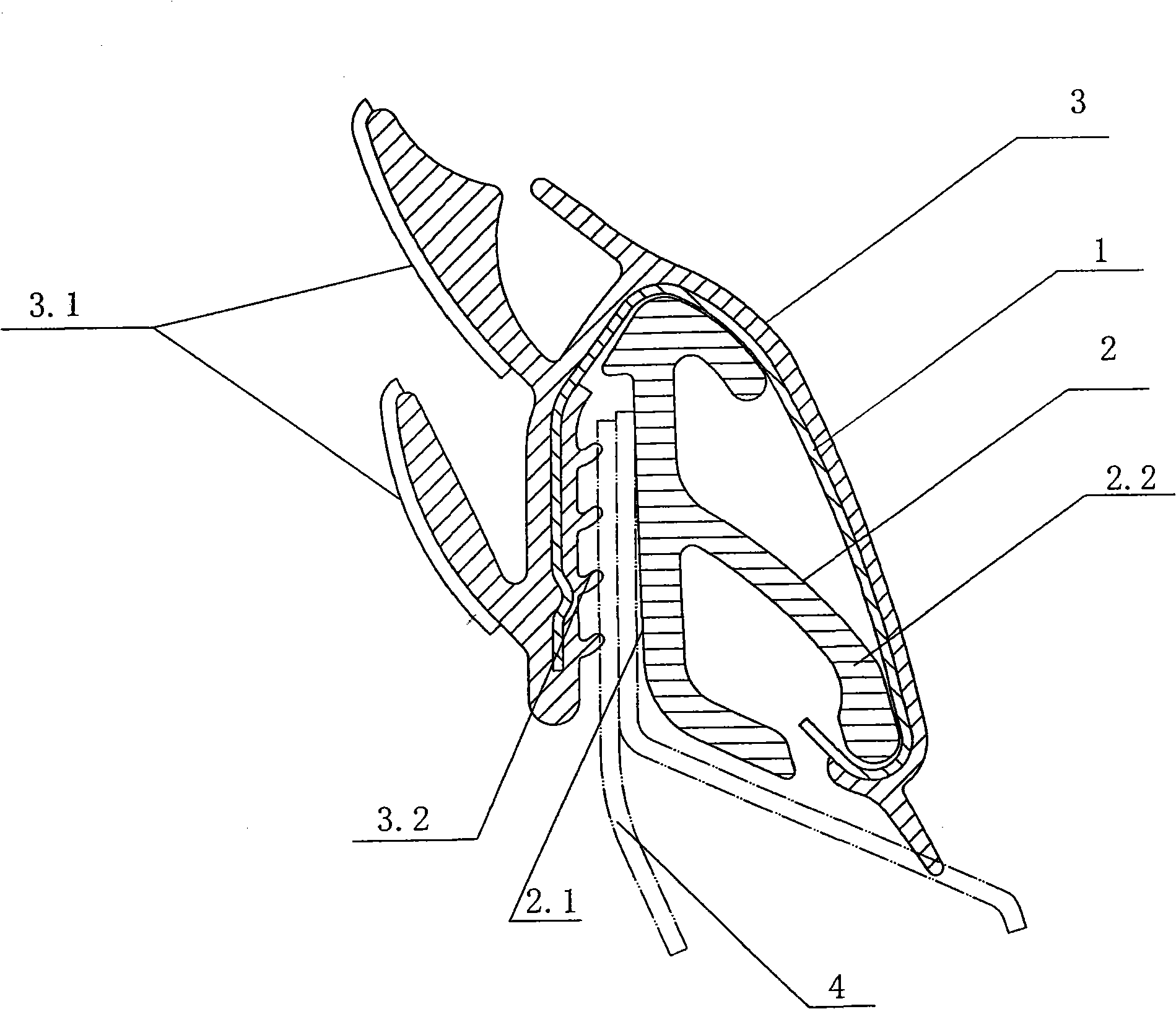

Novel sealing strip on the outside of vehicle-door

InactiveCN101332759AReduce lifting resistanceReduce frictionEngine sealsVehicle sealing arrangementsEngineeringMetal

The invention relates to a novel vehicle door outer side seal strip which comprises a metal skeleton (1), an arc pressing strip (2) and wrapping sides (3). The appearance of the metal skeleton (1) is in a strip shape; the section of the metal skeleton (1) is a structure similar to a reverse 'U'; the inner side of the half side far from the glass of a vehicle window and the inner side of top part of the metal skeleton (1) are provided with the arc pressing strip (2) in an embedding way; the arc of the arc pressing strip (2) faces to the glass of the vehicle window; the novel vehicle door outer side seal strip is characterized in that the half side near the glass of the vehicle window, the top part and the outer side of the half side far from the glass of the vehicle window are all coated with the wrapping sides (3); the sides of the wrapping sides (3) contacted with the glass of the vehicle window are manufactured with a flocking burr (3.1); the inner side of the half side of the metal skeleton (1) near the glass of the vehicle window is coated with the wrapping sides (3); the contact location of the inner sides of the wrapping sides (3) with the sheet metal of the vehicle door is provided with a burr (3.2); the side of the arc pressing strip (2) near the burr (3.2) is a mill finish (2.1); a nip forms between the mill finish (2.1) and the burr (3.2); the side of the arc pressing strip (2) far from the burr (3.2) is provided with a reverse burr (2.2). The novel vehicle door outer side seal strip can reduce the lifting resistance of the sheet metal of the vehicle door and improve the beauty of the appearance.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

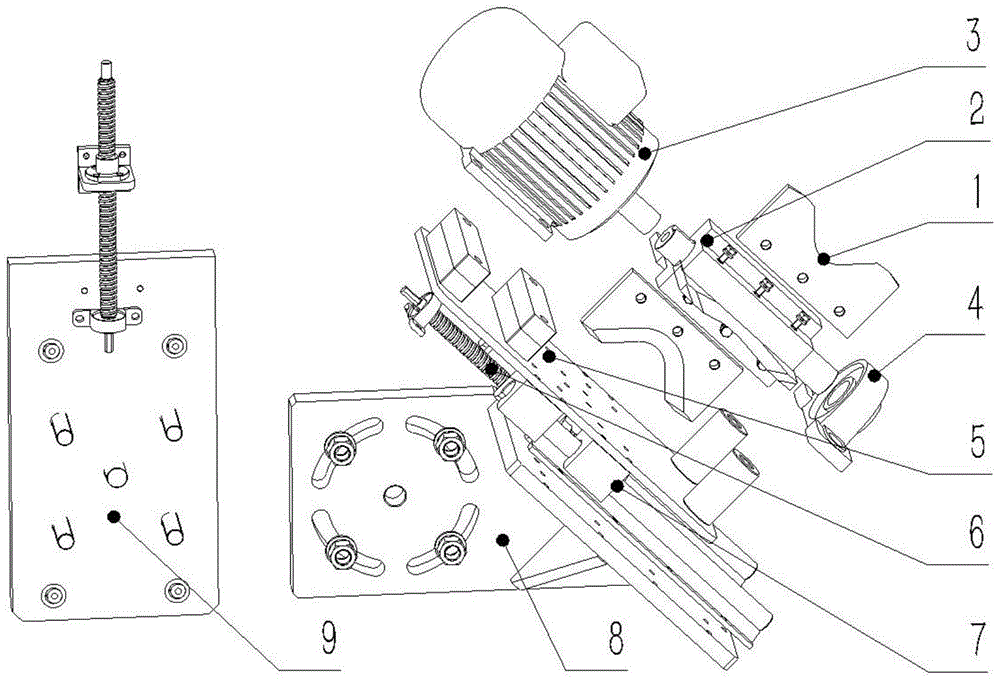

Foam floating body core circular bead milling finishing device

InactiveCN105033337ARegular shapeImprove surface qualityMilling cuttersFeeding apparatusBall screwKnife blades

A foam floating body core circular bead milling finishing device is characterized by comprising circular bead blades, a cutter, a motor, a bearing, a tool installation plate, a tool ball screw adjusting mechanism, a sliding rail, a tool support, a vertical adjusting installation plate, a rotating pin shaft, a tool support ball screw adjusting mechanism, a system support and a system support ball screw adjusting mechanism. The foam floating body core circular bead milling finishing device has the advantages that a machining center with a plurality of tools is adopted, and two independent circular bead tool subsystems can be loaded at the same time and can simultaneously or independently carry out milling finishing; the circular bead blades with different radii can be replaced and can mill edge circular beads of rotating type foam floating bodies with different positions, different inclination angles and different circular bead radii; edge circular bead milling of the appearance of foam floating body cores is achieved, the appearance of the machined foam floating body cores is regular, and the surface quality is good.

Owner:STATE OCEAN TECH CENT +1

Method for guaranteeing hot continuous rolling mill finish rolling outlet temperature

ActiveCN102688900BImprove thermoregulation efficiencyTemperature control deviceStrip steelContinuous rolling

The invention discloses a method for guaranteeing hot continuous rolling mill finish rolling outlet temperature, which comprises the following steps of: 1. dividing a rolled strip steel into a plurality of logical sections by using a certain length as unit; 2. calculating the real steel casting speed of all logical sections at the mill finish rolling outlet; 3. calculating the real temperature of the logical sections at the mill finish outlet according to the calculated real steel casting speed; and 4. calculating the needed water drainage mount of a rack cooled water when the real temperature of the logical sections at the mill finish rolling outlet is regulated at the finishing target temperature. According to the method, the volume of the cooled water in the finish rolling racks to be increased or reduced relative to a strip steel head can be calculated, set or regulated in advance through the deviation between the predicted finishing temperature of all sections and the target finishing temperature, so that the finishing temperature of the strip steel can be accurately controlled.

Owner:BAOSHAN IRON & STEEL CO LTD

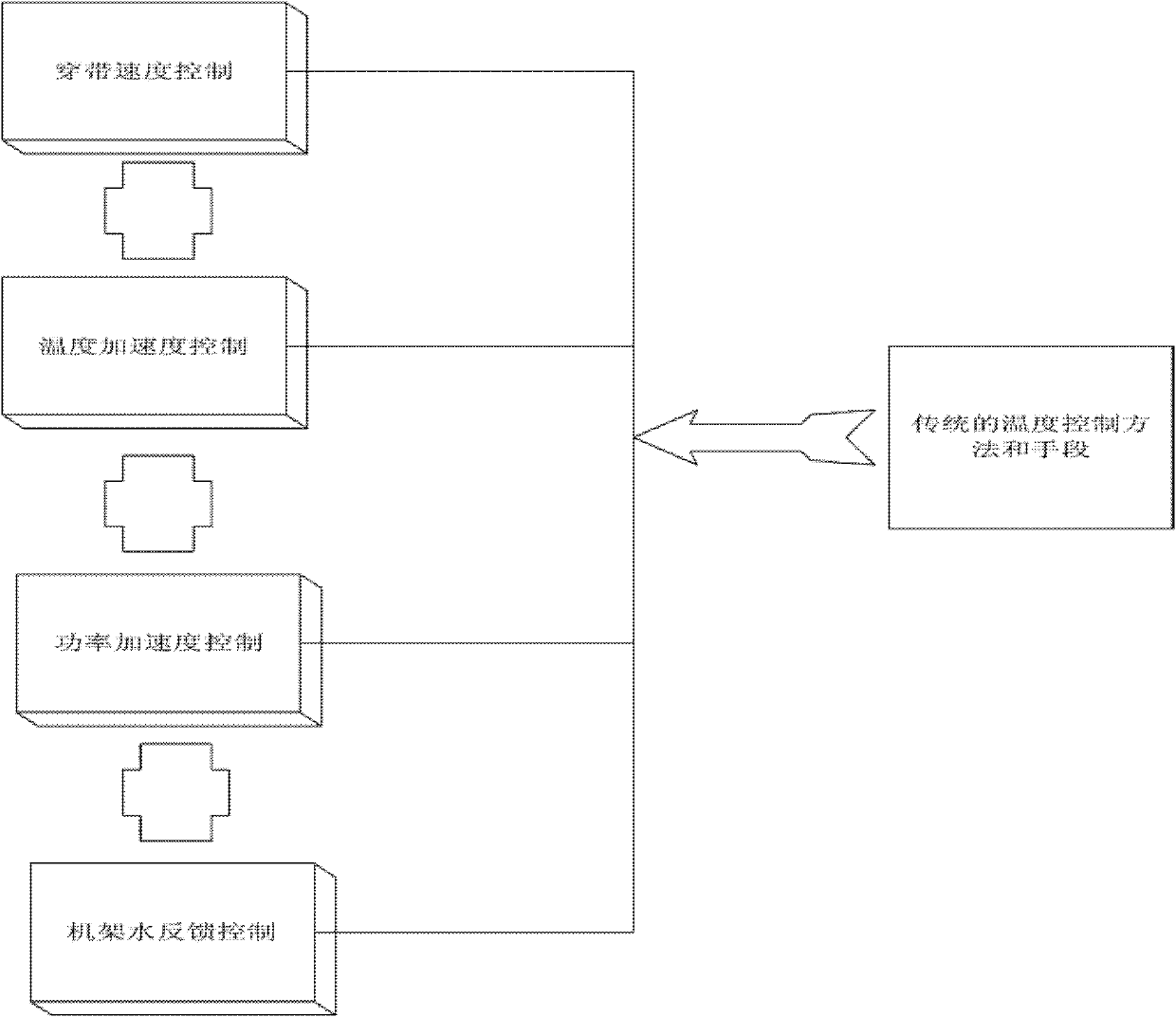

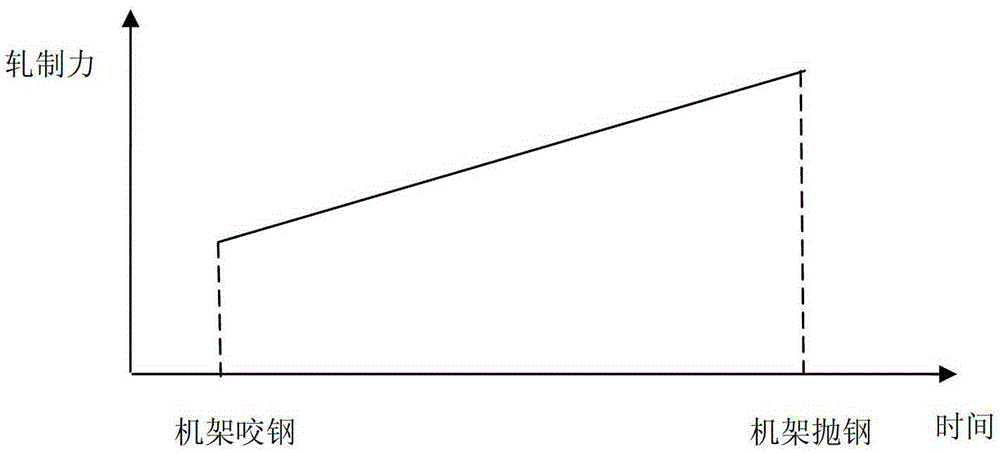

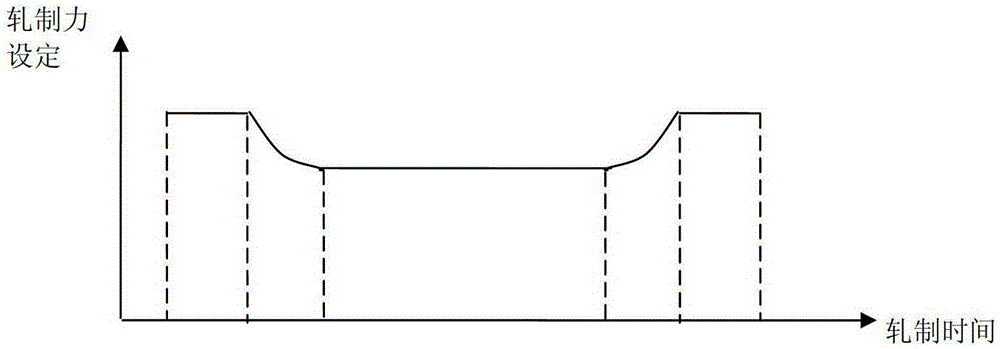

A method for dynamic stiffness control of hot rolling mill finishing mill stand

A hot continuous rolling mill finishing mill group rack dynamic stiffness control method includes: (1) performing control on initial threading rack head stiffness; (2) tracking and calculating actual positions of the head of a band steel; (3) performing primary control which is first time variable stiffness control after threading on rack stiffness; (4) controlling actual positions of the band steel; (5) performing constant stiffness control on the band steel; (6) controlling actual positions of the tail of the band steel; (7) performing rack stiffness control which is second time variable stiffness control of the band steel before steel throwing; (8) performing rack initial stiffness control in the steel throwing stage. The hot continuous rolling mill finishing mill group rack dynamic stiffness control method achieves the purpose of improving quality control of a roll surface of a rack mill roll by controlling related dynamic variable stiffness in the rolling process of the rack, in other words by controlling stiffness of a rolling mill twice according to different positions of the band steel.

Owner:BAOSHAN IRON & STEEL CO LTD

A waste gas treatment device

ActiveCN104964290BAvoid burnsHigh trafficHollow article cleaningIncinerator apparatusCombustion chamberInsulation layer

The invention discloses a waste gas treatment device. The waste gas treatment device comprises a combustion chamber, a first settling basin, a first spray pipe, a second settling basin and a second spray pipe. The combustion chamber is sequentially provided with a heat insulation layer, an adhesive layer and a mill finish layer from outside to inside. The first settling basin is arranged below the combustion chamber. The first spray pipe is connected with the combustion chamber and the first settling basin, and is a hollow cylinder. Containing space is arranged between the inner wall and the outer wall of the first spray pipe. Three layers of round through holes are formed in the inner wall of the first spray pipe in the circumferential direction at intervals. A water inlet hole connected with a control valve is formed in the outer wall of the first spray pipe. The second settling basin is communicated with the first settling basin. One end of the second spray pipe is communicated with the second settling basin, and the other end of the second spray pipe is communicated with the atmosphere. The spray pipes are provided with interlayers, and by means of the round through holes, the contact face of liquid and gas is increased, and the treatment capacity of liquid washing to waste gas is improved. Due to an inner wall cleaning device, the service life of a main shaft is prolonged, and the inner wall of the combustion chamber can be treated by combining the scaling degree of the inner wall.

Owner:SHENYANG BAIYUN MACHINERY

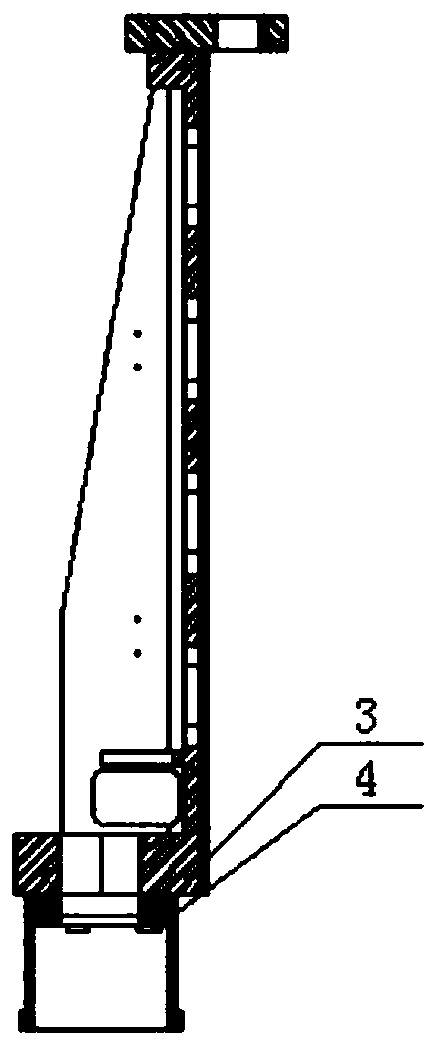

Ram of electric spark forming machine suitable for C-axis mounting

InactiveCN108620697AEasy to replaceGuaranteed aestheticsElectrical-based auxillary apparatusEngineeringMachine tool

The invention discloses a ram of an electric spark forming machine suitable for C-axis mounting. The ram comprises a Z-axis lifting supporting plate and cutter clamping plate split mounting structure,an insulating mechanism and a C-axis mounting seat split mounting structure. A Z-axis lifting supporting plate and a cutter clamping plate are split, thereby being easy to process and convenient to detach and maintain; and meanwhile, in order to guarantee the assembling precision, the cutter clamping plate can be mounted on the Z-axis lifting supporting plate after the bottom and a semicircle orifice of the cutter clamping plate are coarsely machined, and the cutter clamping plate and the Z-axis lifting supporting plate are matched together for mill finish machining, so that the perpendicularity of a C-axis mounting surface and a linear rail mounting surface and the precision of a large round hole are guaranteed. The insulating mechanism is composed of an insulating board and an insulating cover. The insulating board blocks a current between a head and a machine tool main body, and the insulating cover blocks a current between a head fixing screw and the machine tool main body, so that the machine tool is in an absolutely safe state during processing.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

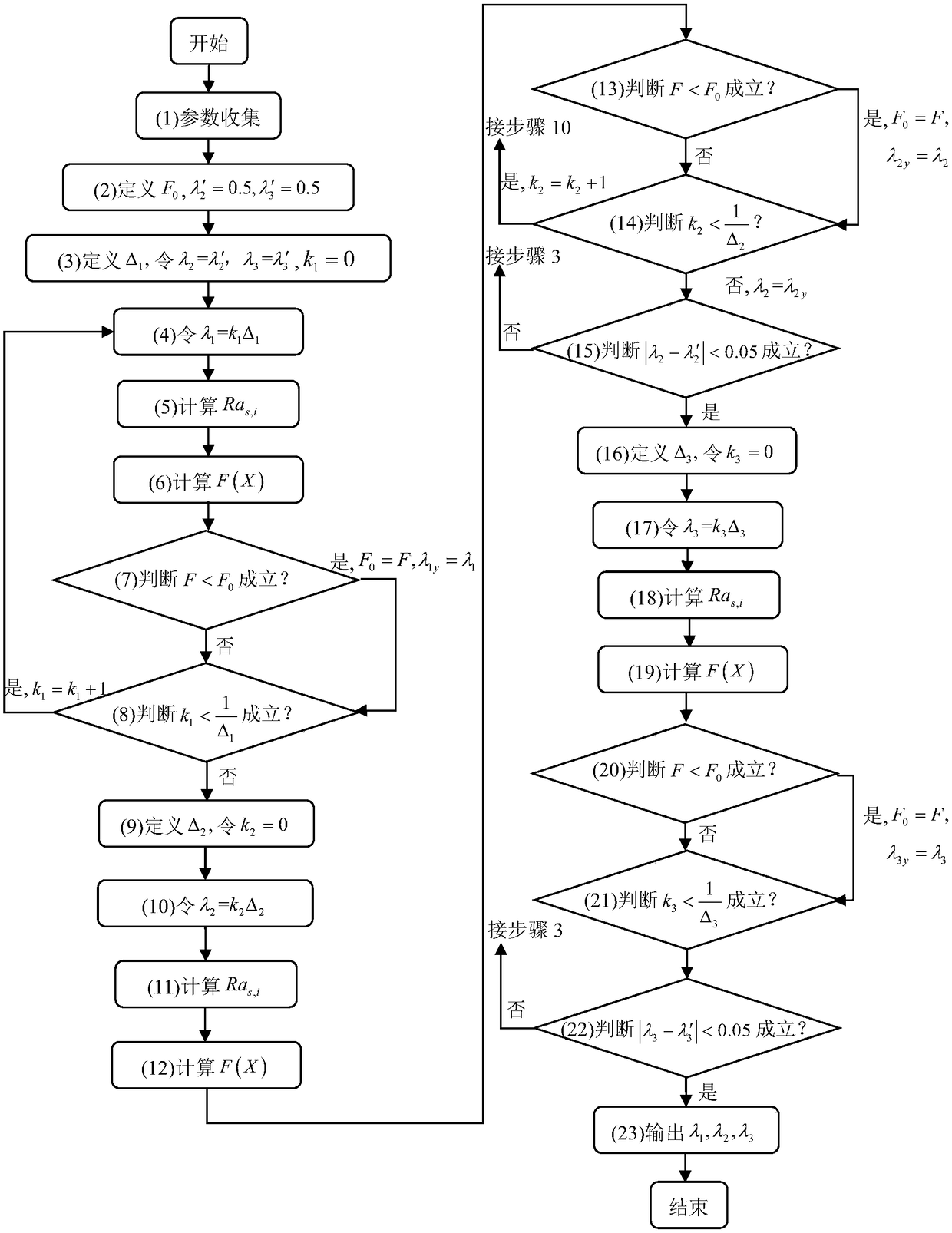

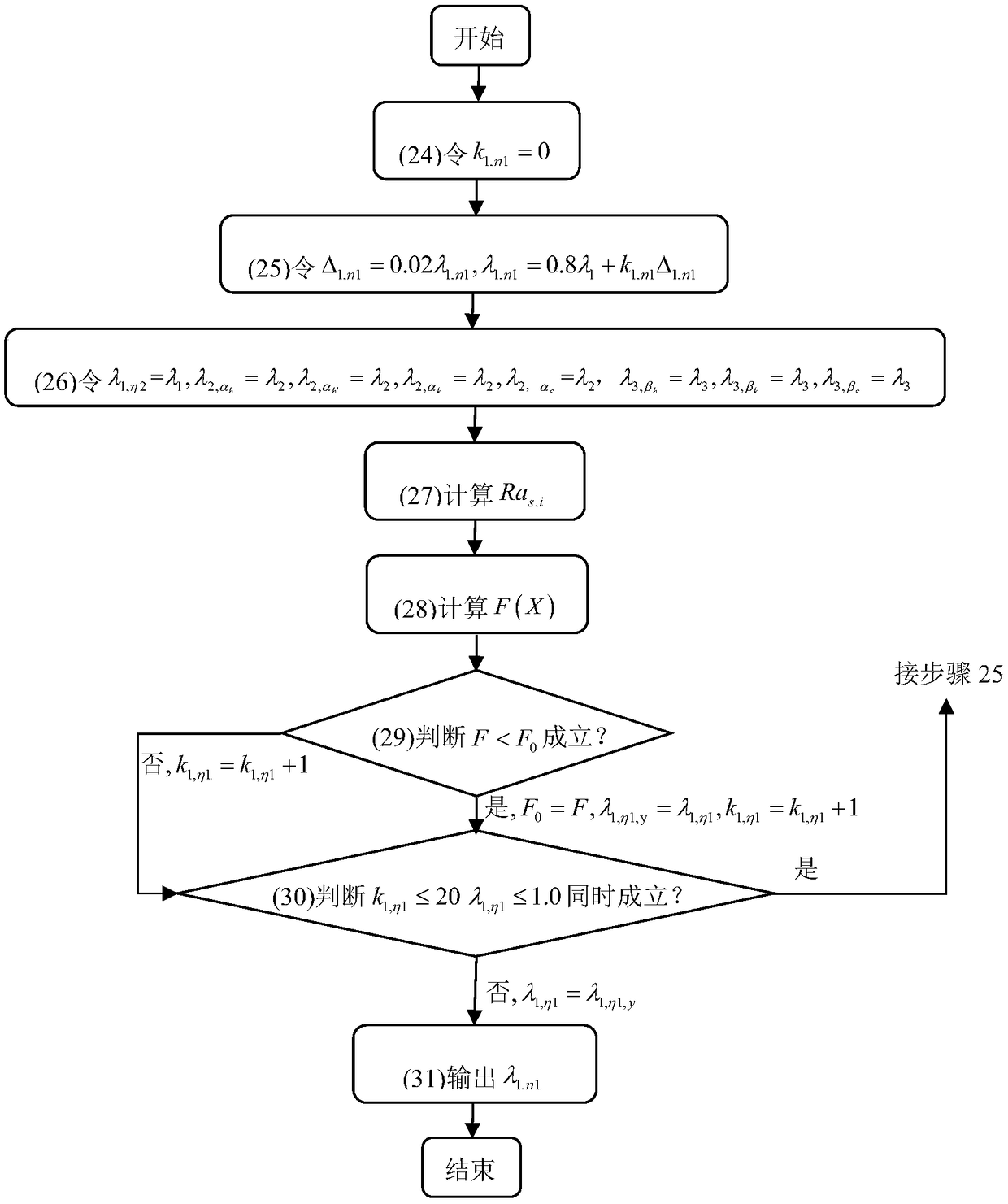

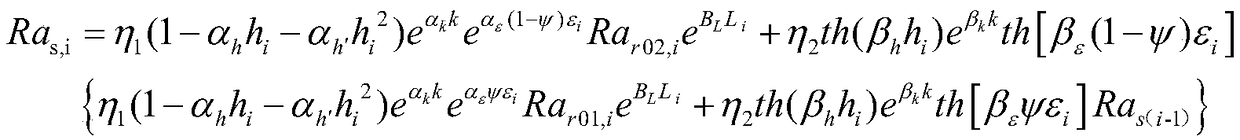

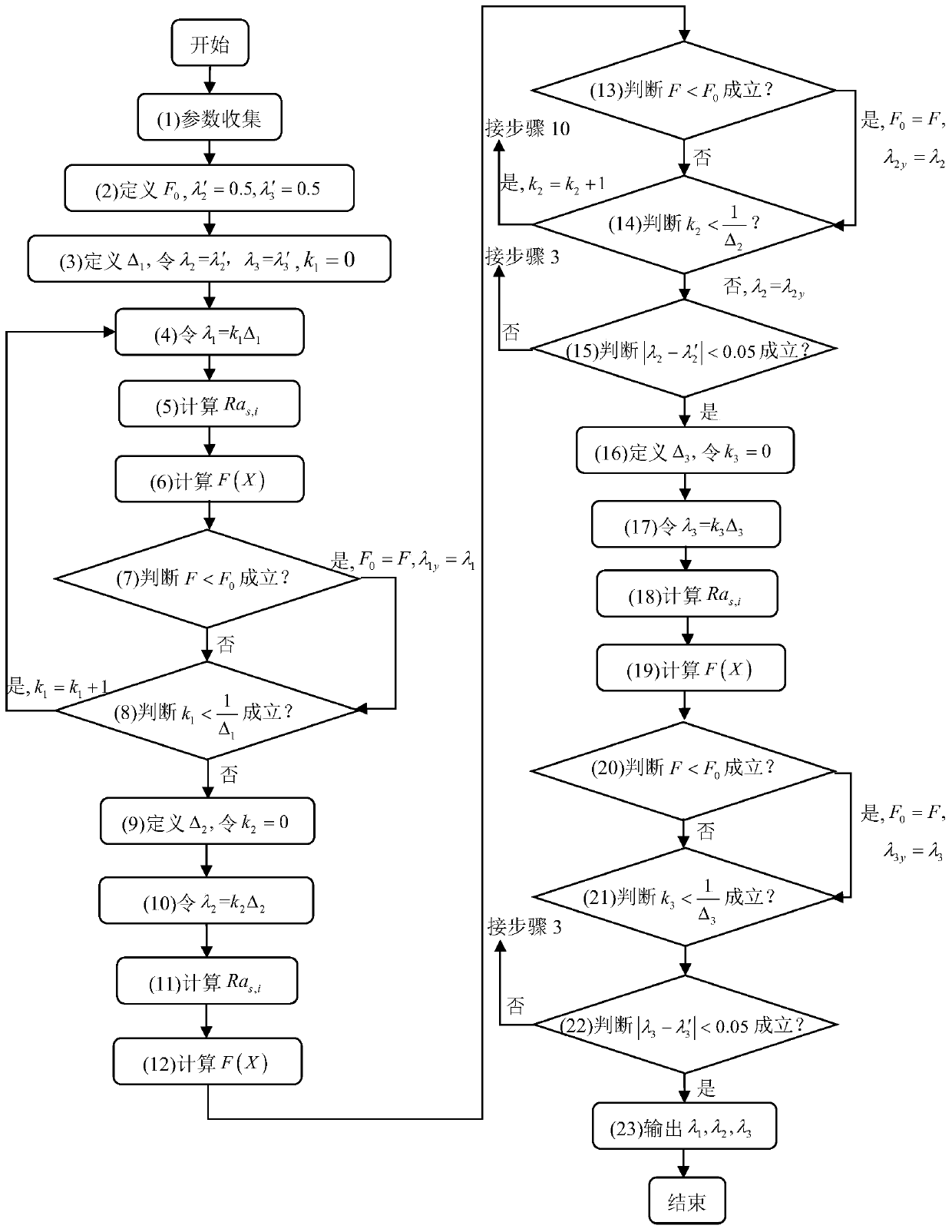

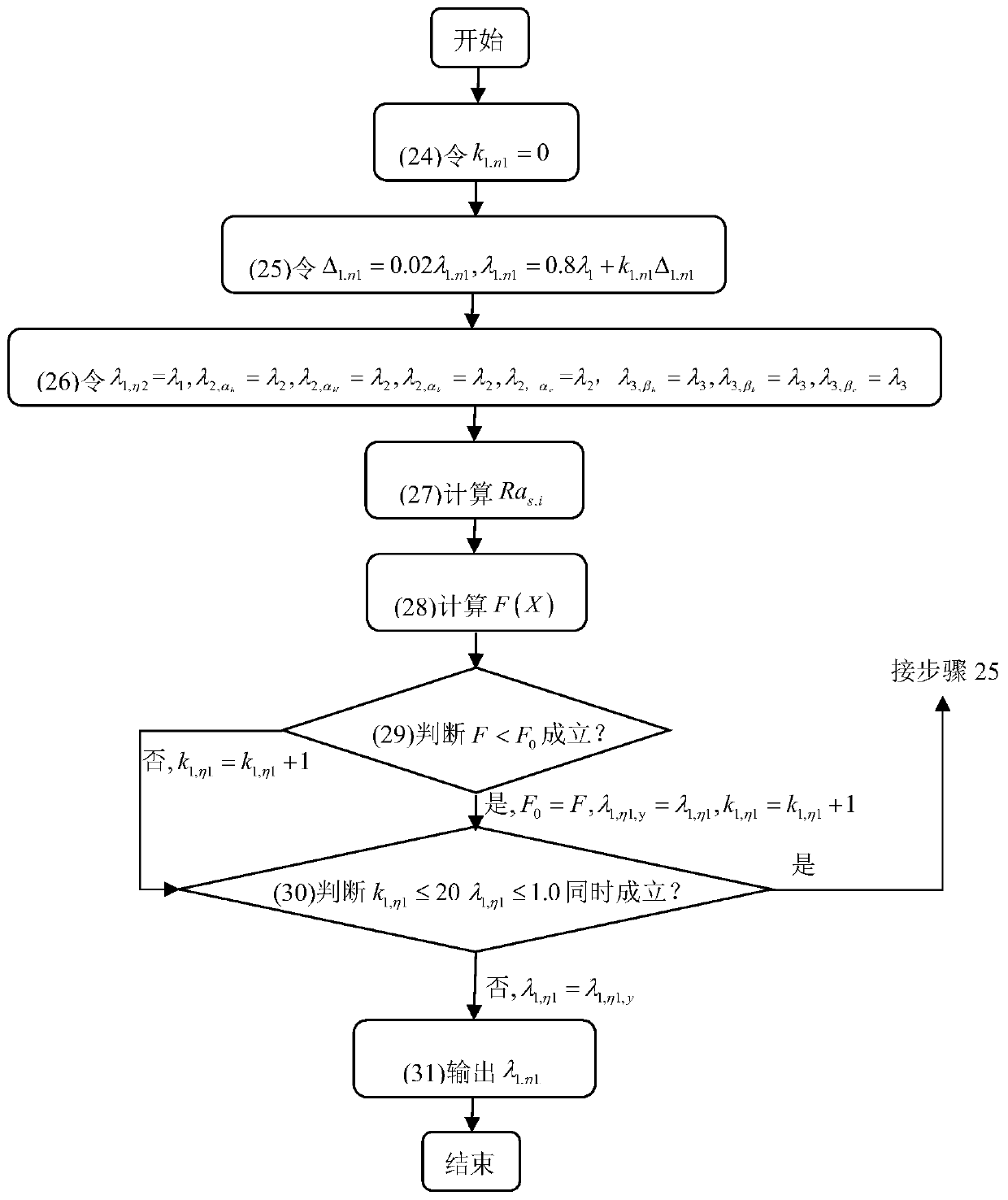

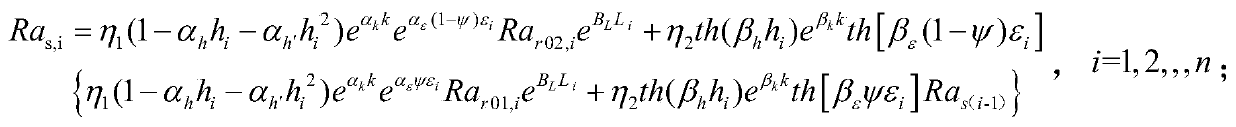

Calculation method for two-stand temper mill finished plate surface roughness characteristic parameters

The invention discloses a calculation method for two-stand temper mill finished plate surface roughness characteristic parameters. The calculation method comprises the following steps that (1) parameters are collected; (2) a target function initial value F0 is set; (3) lambda2 is set to be equal to lambda2', and lambda3 is set to be equal to lambda3'; (4) lambda1 is set to be equal to k1delta1; (5) the finished product strip steel surface roughness Ras,i under the current state is calculated; (6) a target function F(X) is calculated; (7) whether an inequality F<F0 is met or not is judged; (8)whether an inequality k1<1 / delta1 is met or not is judged; (9) a comprehensive imprinting rate influence coefficient adjustment factor optimization step size delta2 is defined; (10) lambda2 is set tobe equal to k2delta2; (11) the finished product strip steel surface roughness Ras,i under the current state is calculated; (12) the target function F(X) is calculated; (13) whether the inequality F<F0is met or not is judged; and (14) an inequality k2<1 / delta2 is met or not is judged; and other steps are carried out. According to the calculation method, on the basis of deeply researching the stripsteel surface roughness forming mechanism in temper rolling process, the calculation method for the two-stand temper mill finished plate surface roughness characteristic parameters is established, and the foundation is laid for the development of the strip steel surface roughness control technology.

Owner:YANSHAN UNIV

A semi-final grinding system

ActiveCN105498927BImprove grinding efficiencyReduce energy consumptionGrain treatmentsWork in processBall mill

A semi-finished milling system is characterized by comprising a raw material warehouse (1), a first raw material conveying belt (201), a second raw material conveying belt (202), a third raw material conveying belt (203), a first iron remover (301), a second iron remover (302), a first lifter (4), a vertical mill (5), a semi-finished product conveyor belt (601), a semi-finished product conveying air chute (602), a ball mill (7), a second lifter (8), a powder concentrator (9), a cyclone dust collector (10), a first fan (11), a bag type dust collector (12), a second fan (13), a vertical mill finished product conveying air chute (1401), a ball mill finished product conveying air chute (1402), a third lifter (15) and a finished product storage warehouse (16). Through regulating the fineness and the feed quantity of coarse particle products entering the ball mill, the milling efficiency and the power consumption of the ball mill are controlled, and the high milling efficiency and low energy consumption characteristics of the novel vertical mill are exerted to an utmost extent. Finally, the milling efficiency of the whole milling system is increased, and the energy consumption of the whole milling system is reduced.

Owner:LOESCHE (SHANGHAI) CO LTD +1

A method for controlling the variable speed at the finish rolling entrance of hot continuous rolling mill

ActiveCN103934276BRealize multi-level controlSave shipping timeRoll mill control devicesMetal rolling arrangementsStrip steelContinuous rolling

The invention provides a hot continuous rolling mill finish rolling inlet variable speed control method which is especially suitable for metal rolling mills or control devices for machining products, and particularly relates to a method for controlling entrance speed of finish rolling strip steel of a hot continuous rolling mill through computer programs. According to four sets of compensation factors, feature parameters of the entering strip steel are determined; according to the feature parameters of the strip steel, speed reducing point correction of the strip steel is determined; according to the speed reducing point correction, a target speed reducing point of the strip steel is determined, and a dynamic speed reducing point is controlled; according to the target speed reducing point of the strip steel, a tracking start point of the head of the strip steel is determined; according to the feature parameters of the strip steel, the shear front-arranging rate of a flying shear is determined; according to the entrance speed of the strip steel and the shear front-arranging rate of the flying shear, the shearing speed of the flying shear is determined. Speed change points are determined according to the types and specifications of steel, the speed of the strip steel before flying shear is controlled in a multilevel mode, conveying time of the strip steel in an intermediate roller way is saved, the rolling efficiency of different strip steel can be maximized, and the rolling efficiency of the strip steel in the hot rolling process is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

A Calculation Method of Characteristic Parameters of Surface Roughness of Finished Board of Double-frame Skin-passing Unit

The invention discloses a calculation method for two-stand temper mill finished plate surface roughness characteristic parameters. The calculation method comprises the following steps that (1) parameters are collected; (2) a target function initial value F0 is set; (3) lambda2 is set to be equal to lambda2', and lambda3 is set to be equal to lambda3'; (4) lambda1 is set to be equal to k1delta1; (5) the finished product strip steel surface roughness Ras,i under the current state is calculated; (6) a target function F(X) is calculated; (7) whether an inequality F<F0 is met or not is judged; (8)whether an inequality k1<1 / delta1 is met or not is judged; (9) a comprehensive imprinting rate influence coefficient adjustment factor optimization step size delta2 is defined; (10) lambda2 is set tobe equal to k2delta2; (11) the finished product strip steel surface roughness Ras,i under the current state is calculated; (12) the target function F(X) is calculated; (13) whether the inequality F<F0is met or not is judged; and (14) an inequality k2<1 / delta2 is met or not is judged; and other steps are carried out. According to the calculation method, on the basis of deeply researching the stripsteel surface roughness forming mechanism in temper rolling process, the calculation method for the two-stand temper mill finished plate surface roughness characteristic parameters is established, and the foundation is laid for the development of the strip steel surface roughness control technology.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com