A Calculation Method of Characteristic Parameters of Surface Roughness of Finished Board of Double-frame Skin-passing Unit

A calculation method and technology of surface roughness, which are applied in the field of calculation of surface roughness characteristic parameters of finished panels of double-rack leveling units, and can solve the problems of not being proposed and the model not being able to be applied specifically.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

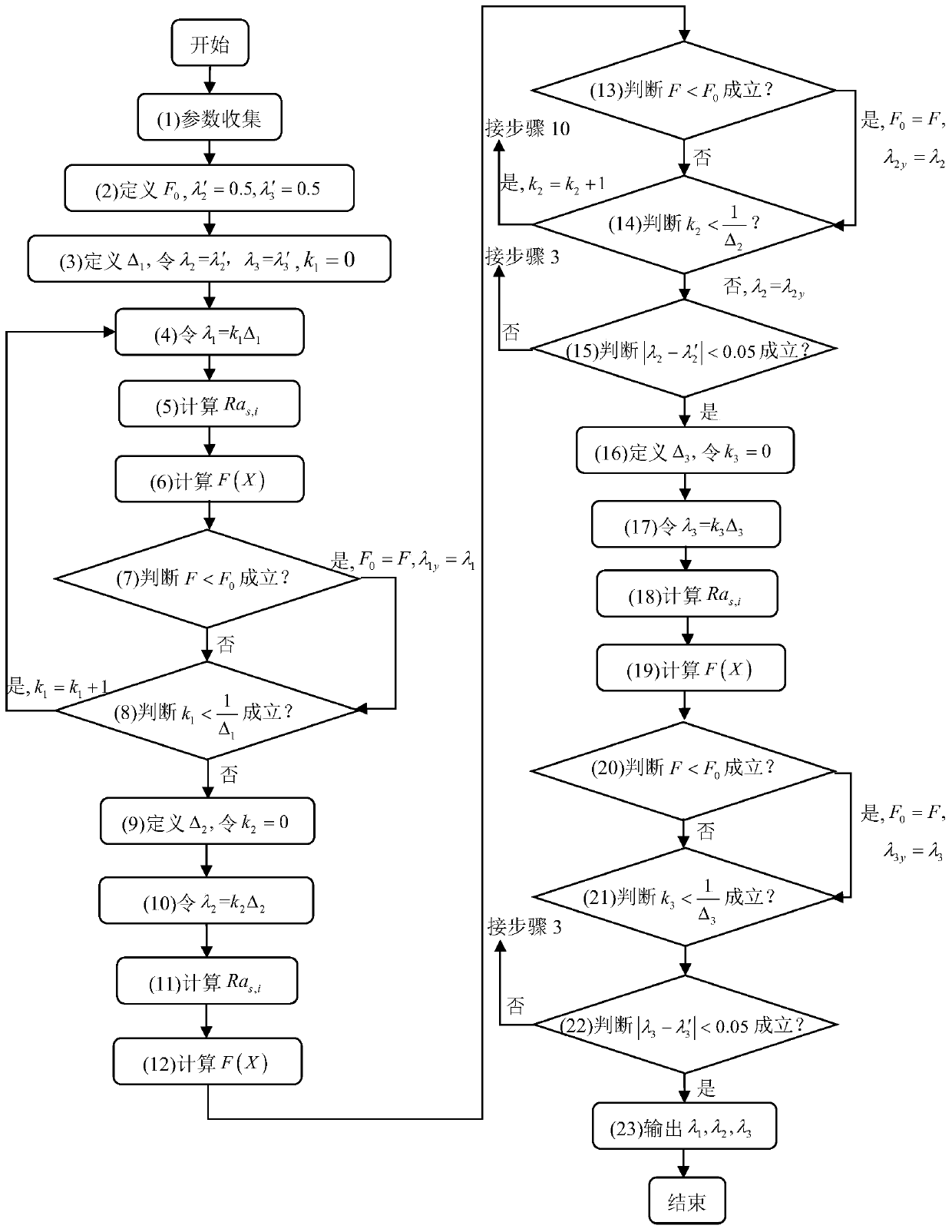

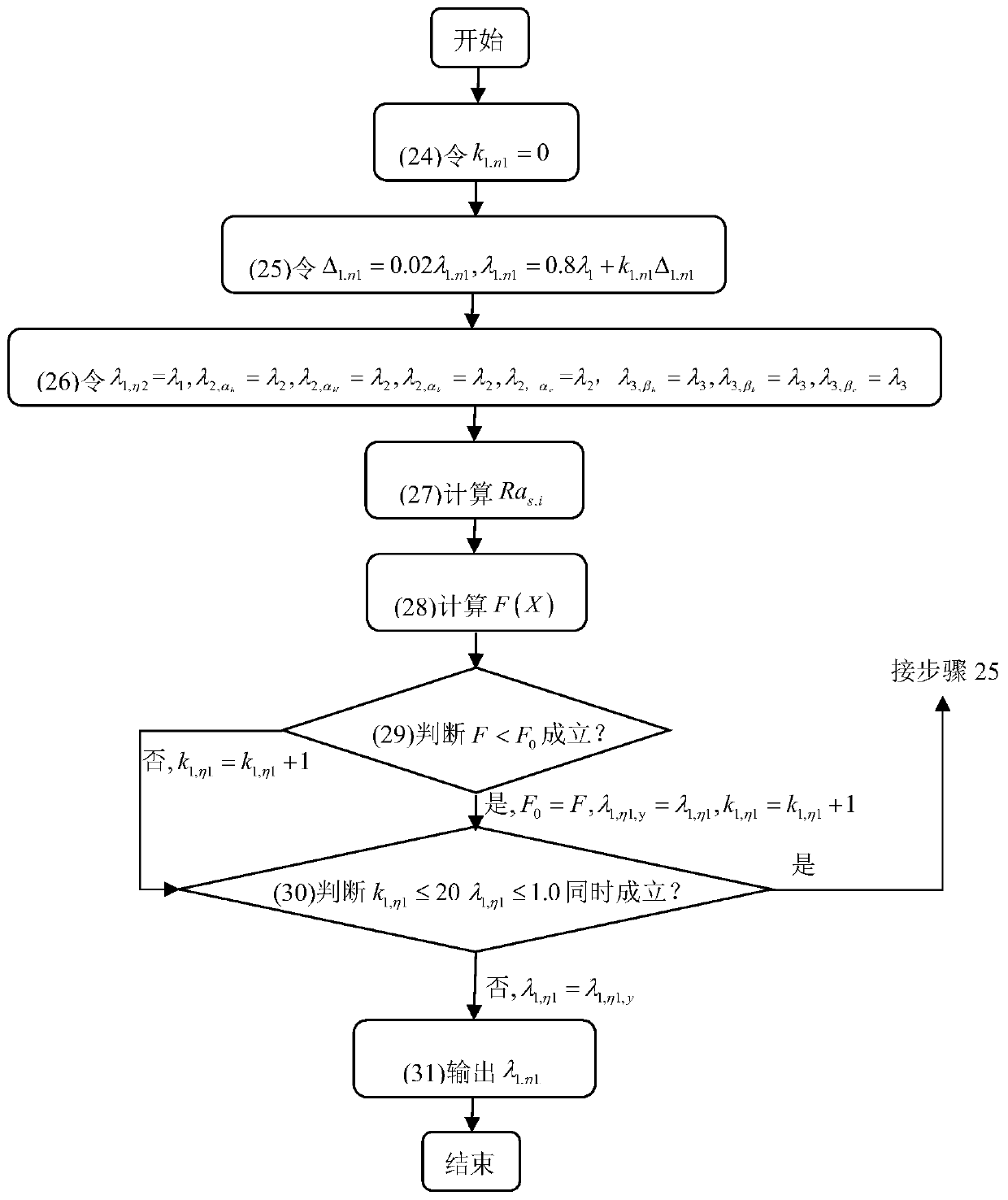

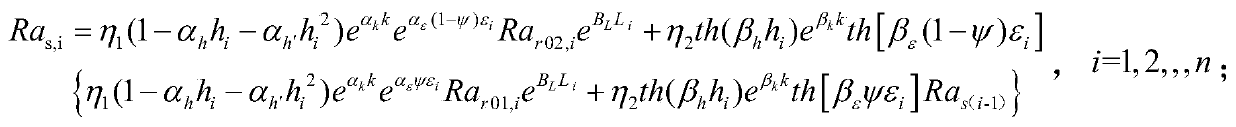

Method used

Image

Examples

Embodiment 1

[0045] (1) Parameter collection, mainly including: surface roughness of finished strip steel

[0046] Ra′ s,i ={0.544,0.493; 0.523, 0.485; 0.516, 0.490; 0.595, 0.454; 0.446, 0.460; 0.476, 0.444; 1.538, 1.408; 1.486, 1.436; 0.744, 0.730; 0.706, 0.677} μm, the original surface roughness of the strip Ra s0,i ={0.864,0.544,0.818,0.818,0.552,0.552,0.568,0.568,0.478,0.478}μm, strip thickness h i ={0.18,0.17,0.17,0.18,0.18,0.18,0.354,0.354,0.199,0.21}mm, strip deformation resistance k i ={460,460,390,390,460,460,270,270,390,390}Mpa,

[0047] Total elongation ε i ={0.73,0.75,0.96,0.95,0.81,0.80,1.55,1.51,0.98,1.15}, the original surface roughness of 1# roll Ra r01,i ={1.63,1.63,1.63,1.63,1.63,1.63,1.64,1.64,1.63,1.63}μm, 1# rolling kilometers L 1,i ={651.64,710,750.81,870.65,810.23,862.56,13.093,26.326,14.439,24}km, 2# original surface roughness of the roll Ra r02,i ={0.42,0.42,0.42,0.42,0.42,0.42,2.97,2.97,0.70,0.70}μm, 2# rolling kilometers

[0048] L 2,i ={651.64,710,750.81,870.65,810.2...

Embodiment 2

[0079] (1) Parameter collection, mainly including: surface roughness Ra' of finished strip steel s,i = {0.644, 0.646; 0.677, 0.687; 0.546, 0.574; 0.523, 0.485; 0.516, 0.490; 0.595, 0.454; 0.446, 0.460; 0.476, 0.444; 0.465, 0.475; 0.526, 0.574} μm, the original surface roughness of the strip Ra s0,i ={0.864,0.864,0.818,0.818,0.552,0.552,0.568,0.568,0.678,0.678}μm, strip thickness h i ={0.17,0.17,0.18,0.18,0.17,0.18,0.35,0.34,0.159,0.21}mm, strip steel deformation resistance k i = {460,460,390,390,460,460,270,270,390,390}Mpa, total elongation ε i ={0.63,0.77,0.86,0.92,0.83,0.80,1.15,1.21,0.78,0.95}, the original surface roughness of the 1# roll Ra r01,i ={1.63,1.63,1.63,1.63,1.63,1.63,1.64,1.64,1.63,1.63}μm, 1# rolling kilometers L 1,i ={551.64,510,650,820.65,710.23,862.55,23.093,26.326,16.439,24}km, 2# original surface roughness of the roll Ra r02,i ={0.42,0.42,0.42,0.42,0.42,0.42,2.97,2.97,0.70,0.70}μm, 2# rolling kilometers L 2,i ={551.64,510,650,820.65,710.23,862.55,23.093,26....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com