Method for processing ceramic wall and floor tiles

A processing method and technology for wall and floor tiles, which are applied in the field of building decoration materials, can solve the problems of affecting the health of operators, damage and scratches of bricks, and increase in production costs, and achieve the advantages of leveling and decoration, high yield and process. Convert convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

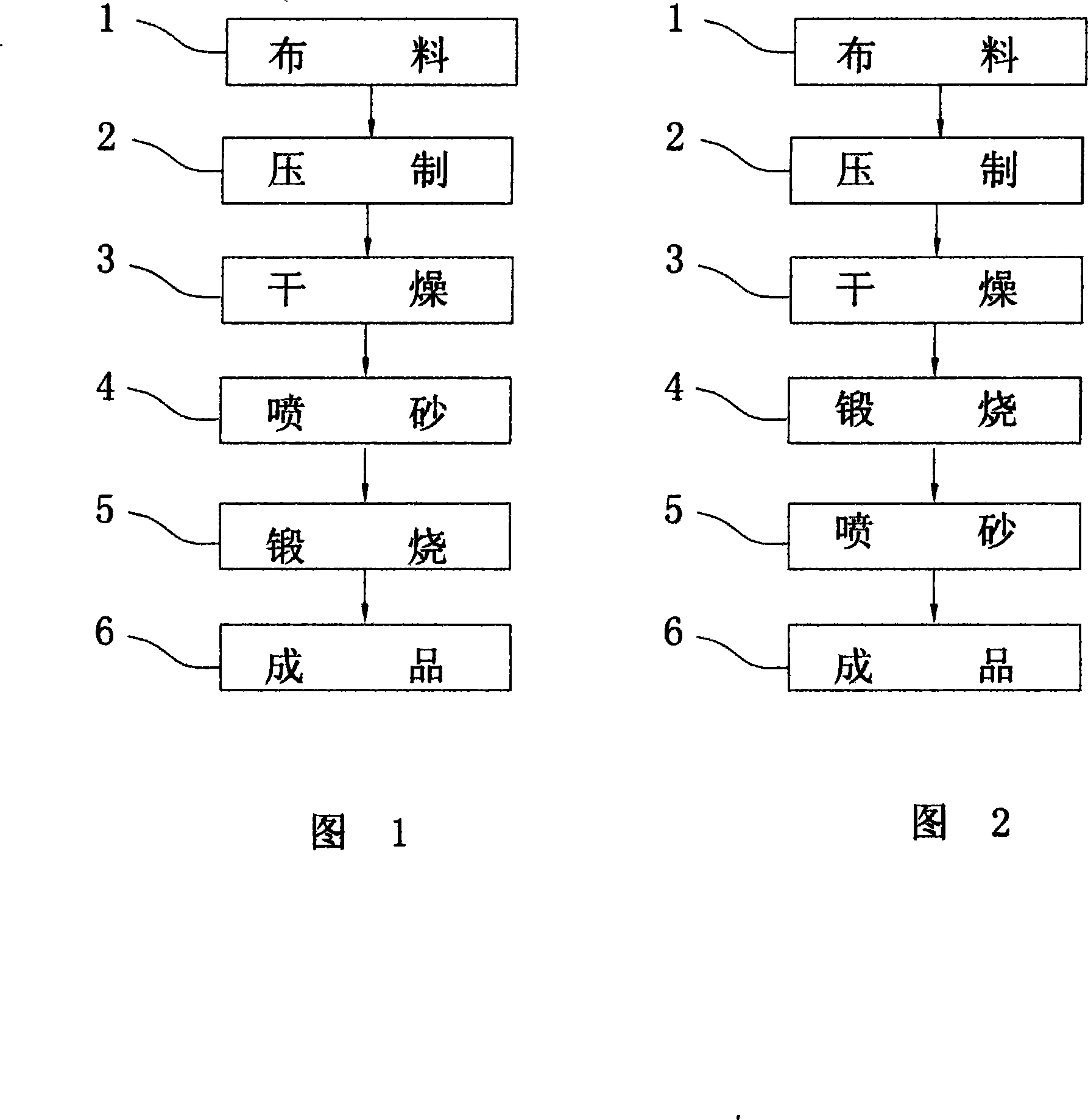

[0043] As shown in Figure 1, firstly, the ceramic base material and various components of the fabric are distributed through the distributing machine as required, and then the distributed material is placed in the pressed mold cavity to be pressed into the required specification and dried, and then implemented. For the sand blasting treatment on the surface of the brick adobe, for the production of matte floor tiles, the range of sand blasting treatment should at least cover the entire upper surface of the floor tiles. Partial deep blasting treatment is carried out on the brick surface, so that the finished product has a more concave-convex layered feeling. After sandblasting, it can be calcined to finally produce the finished product. It should be noted that in the sandblasting process adopted, the operation can be a single operation or an airborne operation. It can be implemented by a single station using a sandblasting gun, or it can be set up as a special machine and multip...

Embodiment 2

[0045] As shown in Figure 2, the whole process is roughly the same as that of Example 1. The key is to switch back and forth between the sandblasting and calcination processes during the implementation. The purpose is mainly for smooth bricks.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com