Foam floating body core circular bead milling finishing device

A technology of rounded corners and floating bodies, which is applied in the direction of milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve the problems of poor crash resistance of floating bodies, corrosion of steel floating bodies, and affecting the continuity of observation, etc., to achieve regular appearance and good surface quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

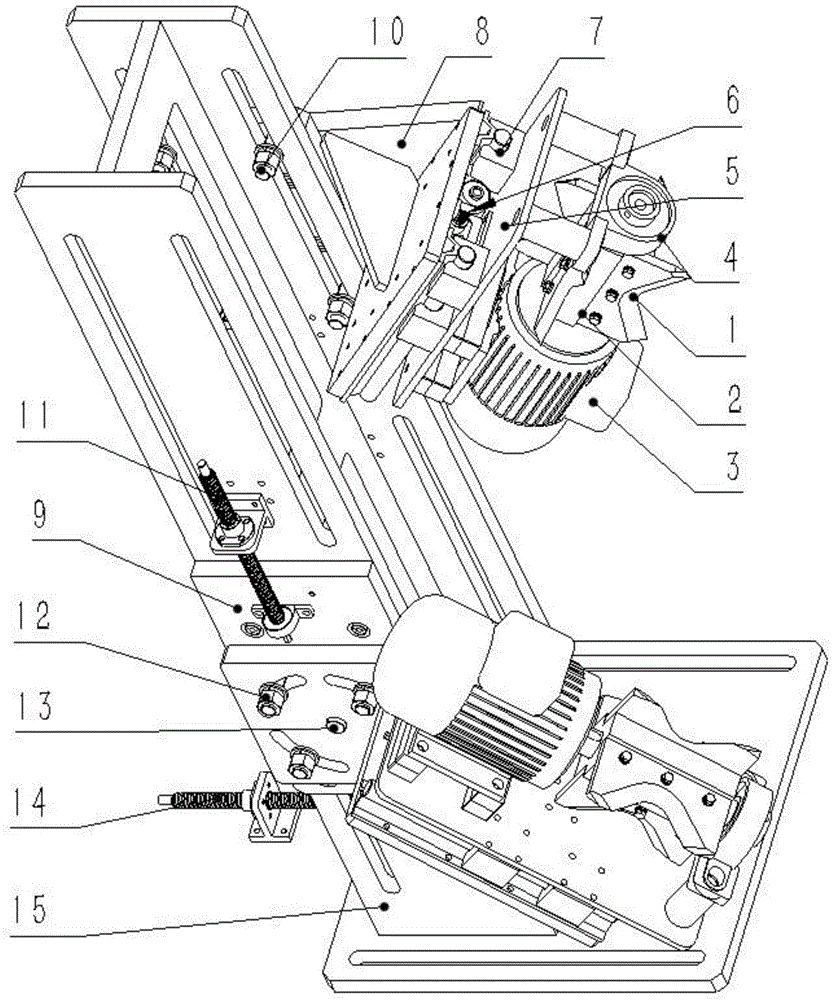

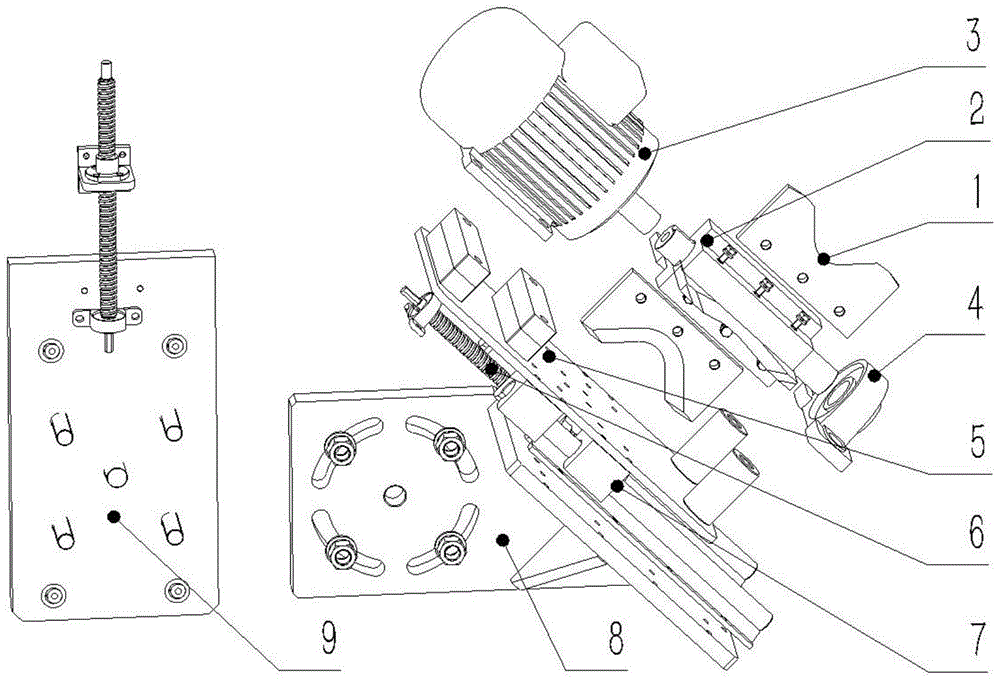

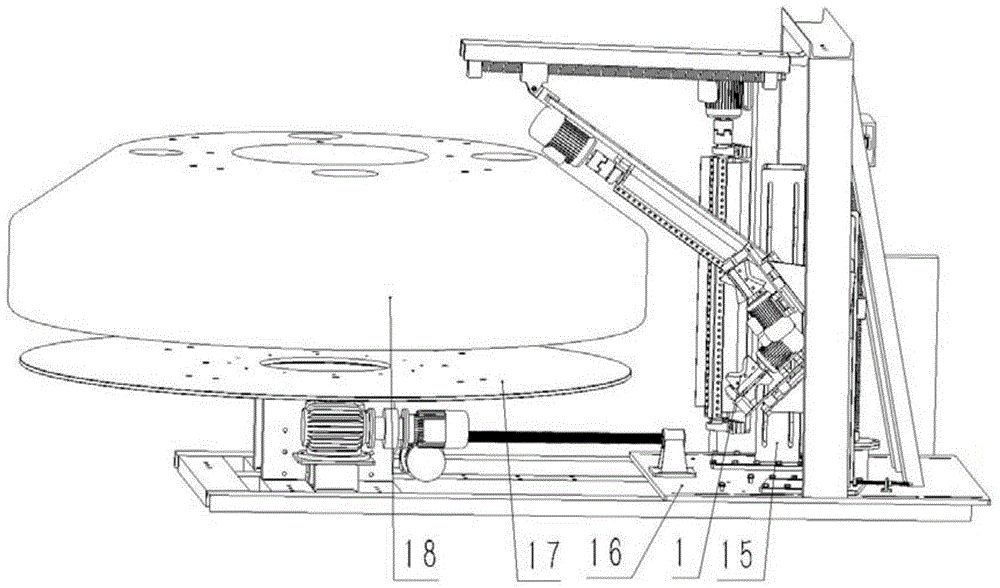

[0016] Example: such as figure 1 As shown, a foam floating core fillet milling and finishing equipment includes a fillet blade 1, a cutter body 2, a motor 3, a bearing 4, a cutter mounting plate 5, a cutter ball screw adjustment mechanism 6, a slide rail 7, a cutter holder 8, Vertically adjust the mounting plate 9, the rotating pin shaft 13, the system support 15 and the system support ball screw adjustment mechanism 14. Such as figure 1 , figure 2 As shown, the four rounded corner blades 1 are installed on the cutter body 2 and fastened with screws, and the cutter body 2, the motor 3, and the bearing 4 are coaxially installed on the cutter mounting plate 5 to form a rounded corner cutter subsystem; the cutter subsystem The two rows of slide rails 7 are connected to the tool bracket 8, the slider is connected to the tool mounting plate 5, the slide bar is connected to the tool bracket 8, the bearings at both ends of the tool ball screw mechanism 6 are assembled on the tool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com