Patents

Literature

32 results about "Stability Model" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stability Model (SM) is a method of designing and modelling software. It is an extension of Object Oriented Software Design (OOSD) methodology, like UML, but adds its own set of rules, guidelines, procedures, and heuristics to achieve a more advanced Object Oriented software.

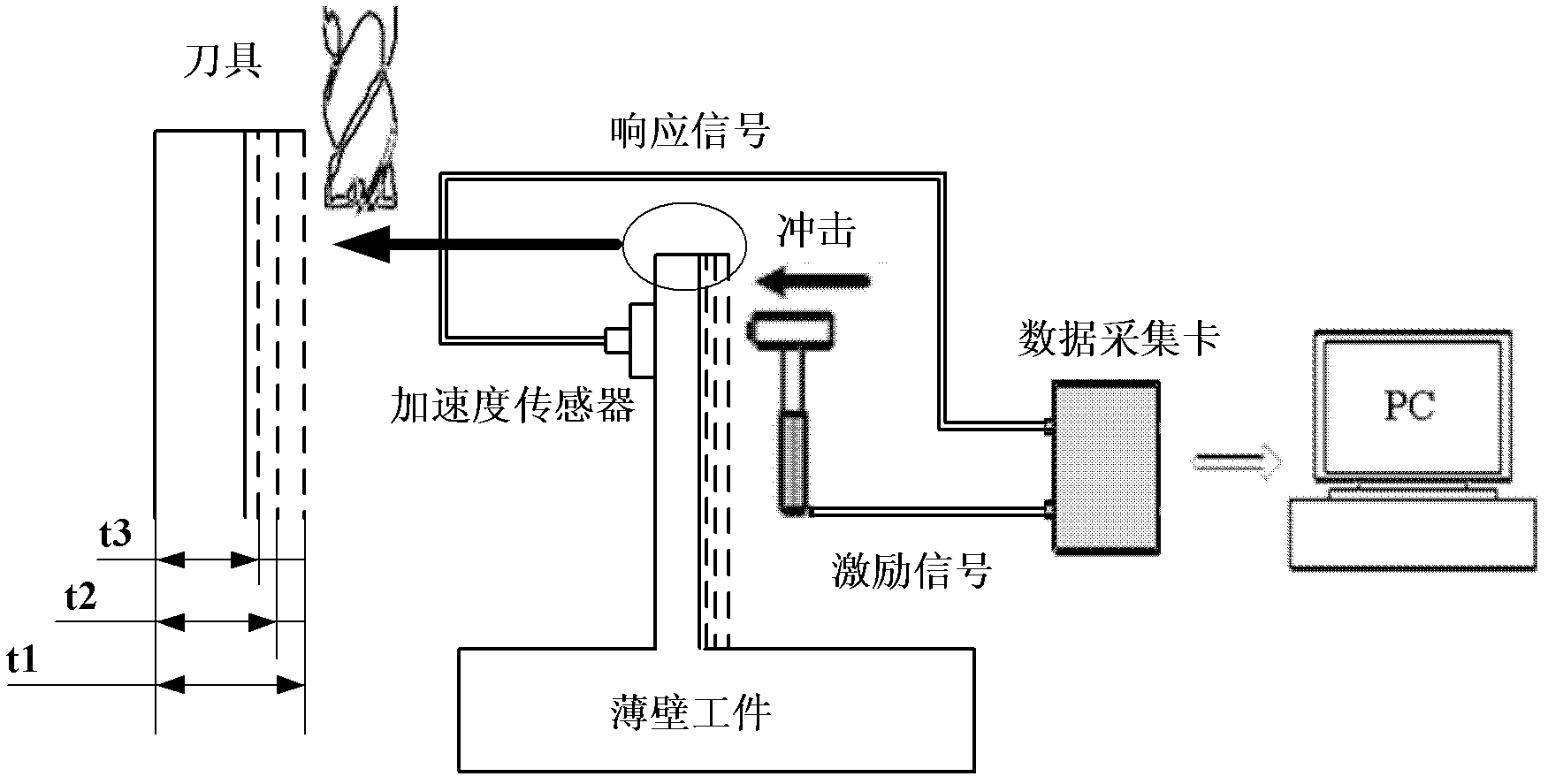

Milling finish machining method based on dynamic rigidity of impeller blade

ActiveCN102554326ASolve the problem of cutting chatterImprove processing stabilityMilling equipment detailsSpecial data processing applicationsImpellerDiagnostic Radiology Modality

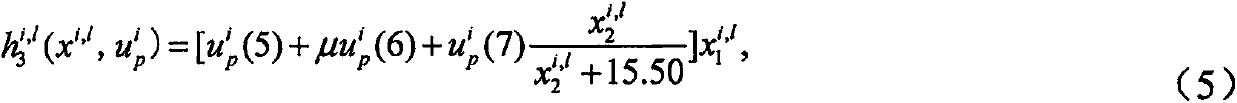

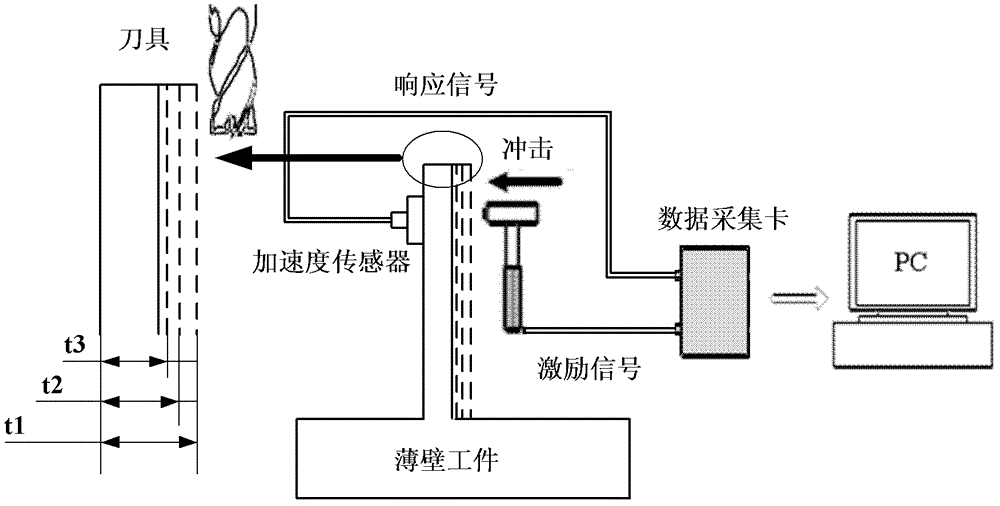

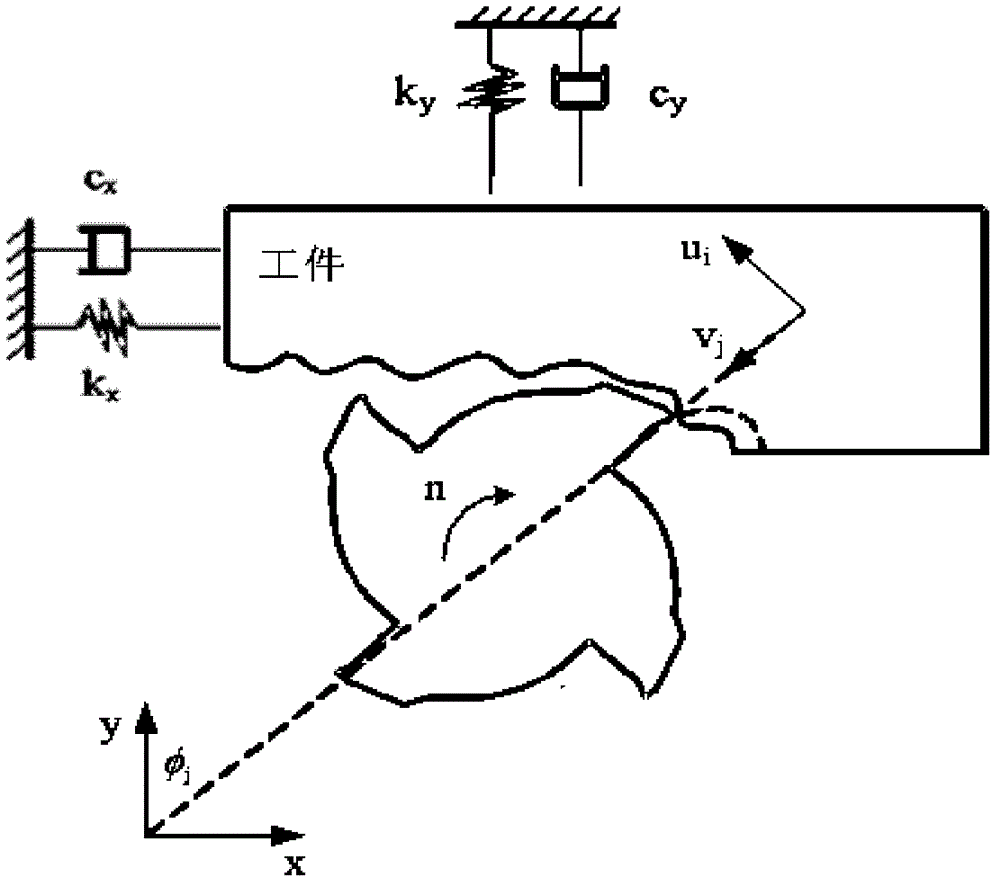

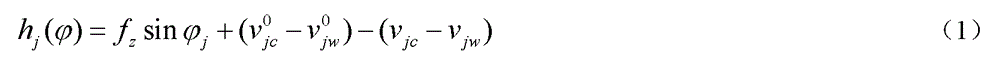

The invention discloses a milling finish machining method based on the dynamic rigidity of an impeller blade. The dynamic modality of the impeller blade is obtained through a standard modal test, a flutter model is introduced to obtain a stability criterion, and reasonable machining parameters are acquired. The method comprises the followings steps of: 1, performing the modal test to measure the dynamic modality of the impeller blade; 2, building a milling stability model of the impeller blade; 3, studying the dynamic rigidity stability of the impeller blade; 4, obtaining a cutting stability condition under the dynamic rigidity of the impeller blade; and 5, verifying the cutting stability condition and adopting the finally optimized cutting parameters to machine. The problem of cutting flutter caused by milling of thin-walled parts such as the blade is solved by the method, and the machining stability is obviously improved by optimizing the cutting parameters. The method is suitable for finish machining of various thin-walled parts.

Owner:SHANGHAI JIAO TONG UNIV

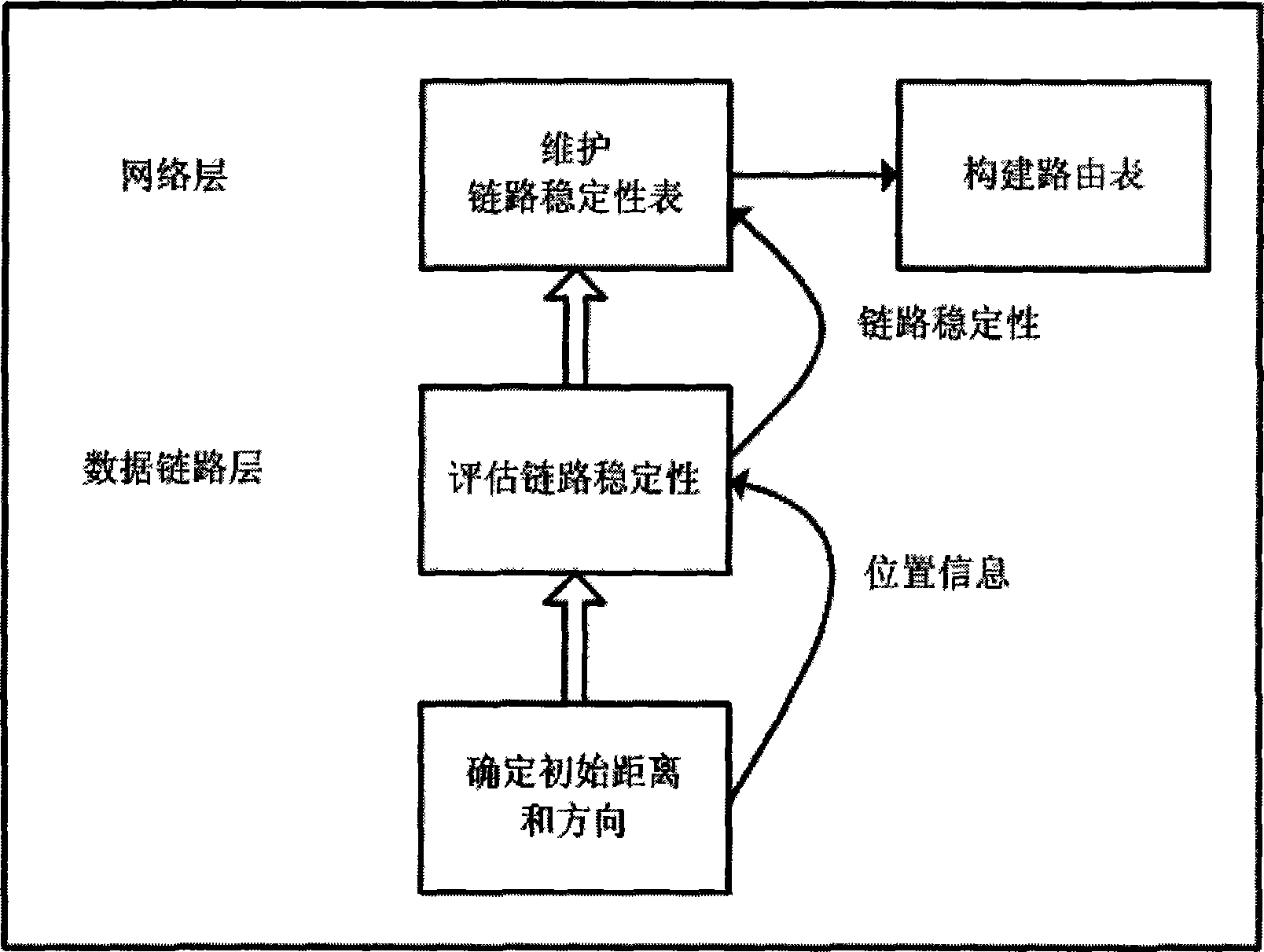

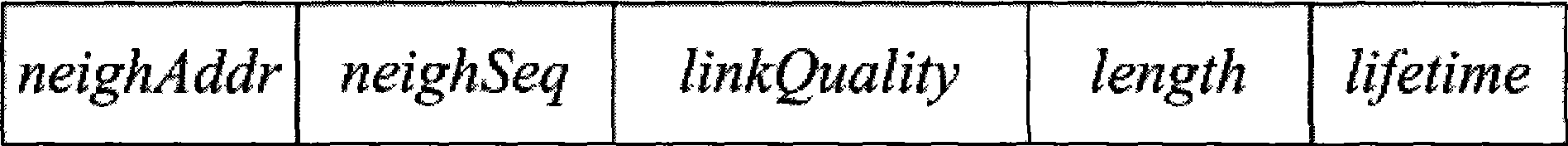

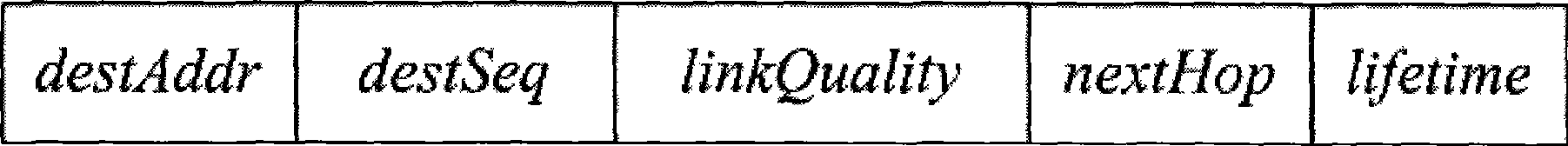

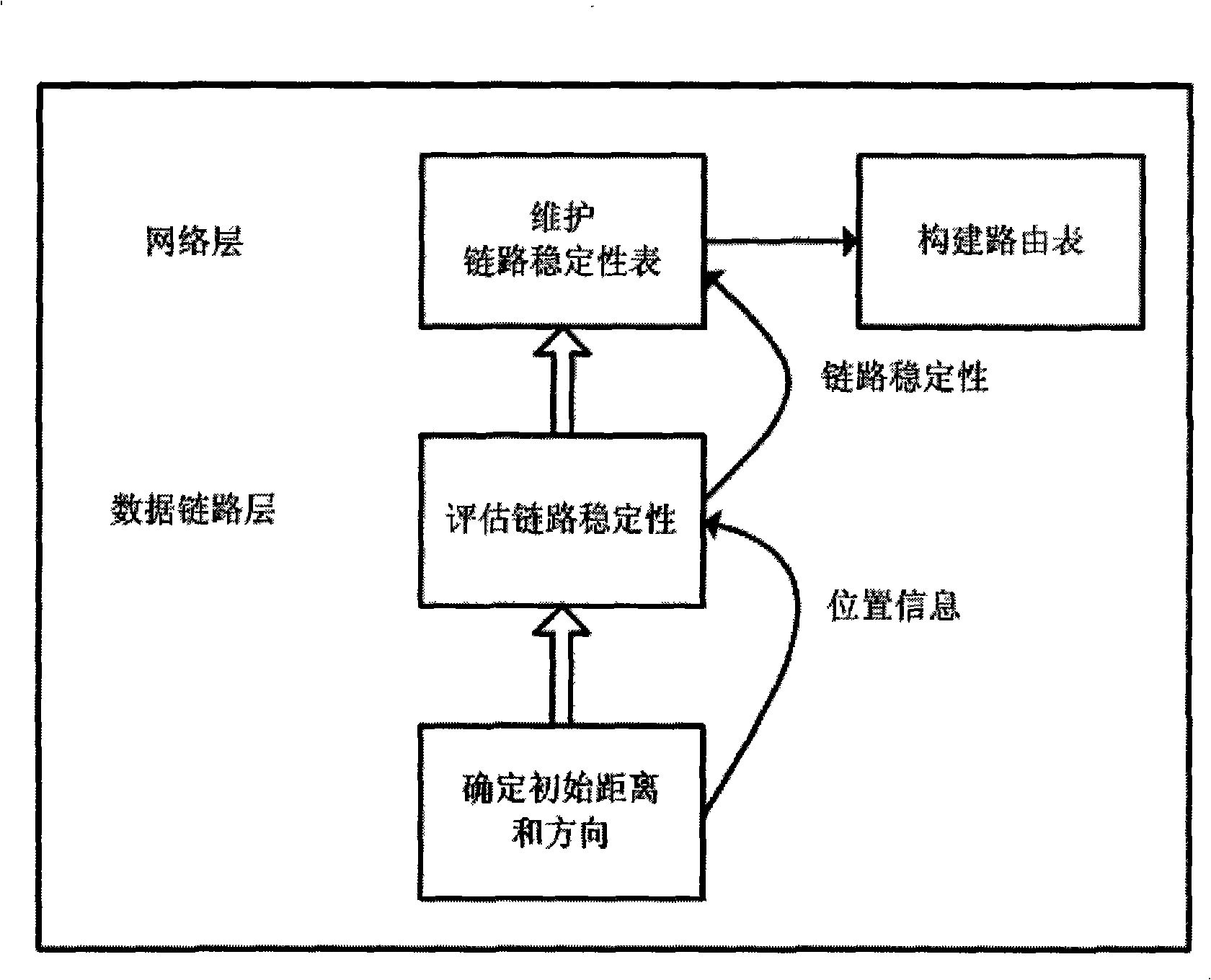

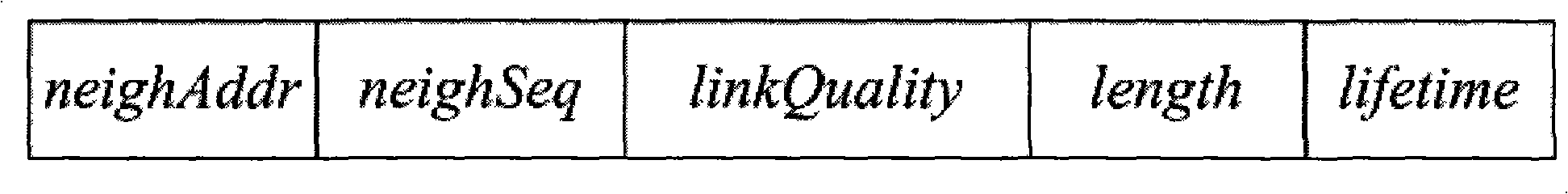

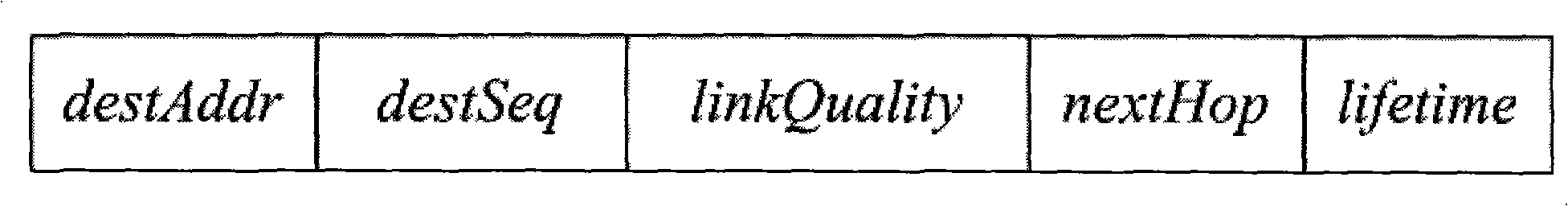

Reliable routing method of mobile Ad hoc network

InactiveCN101534520AGuaranteed reliabilityImprove reliabilityNetwork traffic/resource managementNetwork topologiesInformation controlDependability

The invention relates to a reliable routing method in the context of a mobile Ad hoc network. The method aims to improve effectiveness of data transmission, takes combination of link stability and route selection as the core concept and solves the problem of reliable routing in the context of the Ad hoc network. In the method, data link layer design is closely linked with network layer design; the data link layer generates the newest link stability information for each node according to a link stability model; the network layer configures a link stability form according to the information; the nodes establish routings according to needs when needing to transmit data; the network layer takes the link stability form as a basis, the link stability as a standard for weighing on route selection to establish a reliable routing between the source nodes and the target nodes; a redundancy link is established for unstable links in routing paths to further improve reliability of the routing; advantages of active routing protocol and source-initiated protocol are integrated, routing reliability is ensured in that the link stability form needs to be updated in time; routing information in the routing form only needs to be updated when transmission begins, thus reducing extra expenditure for information control.

Owner:BEIHANG UNIV

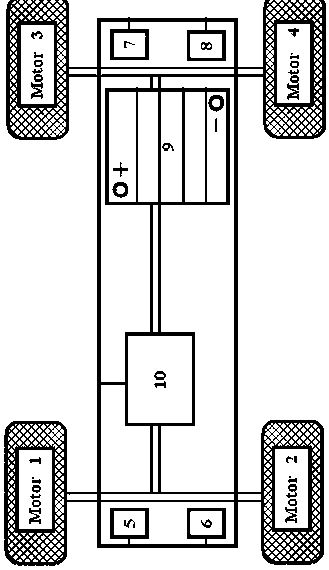

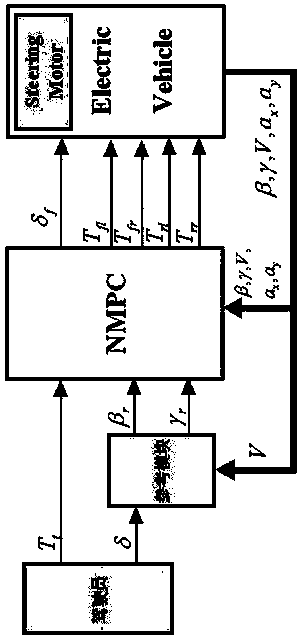

Vehicle stability model predictive control method

InactiveCN109552312AImproved yaw stabilityImprove comfortSpeed controllerElectric energy managementRolloverRoad surface

A vehicle stability model predictive control method belongs to the technical field of control. The object of the vehicle stability model predictive control method is to establish a vehicle yaw kineticmodel in consideration of road unevenness and design a yaw stability controller by a model predictive control algorithm so as to prevent an electric vehicle against rollover and drift in a poor working condition and a sharp turn. The method comprises steps of establishing a mechanical and kinetic model and a yaw stability controller of an electric vehicle in consideration of road unevenness. In aprocess of formulating a torque distribution strategy, the method considers vehicle safety (preventing skid or lock, rollover or drift), vehicle performance (acceleration and braking performance), and driving comfort (torque change cannot be too large and the vertical force change value cannot be too high), saves control energy (saving energy under the premise of satisfying performance), and improves the kinetic performance of the vehicle.

Owner:JILIN UNIV

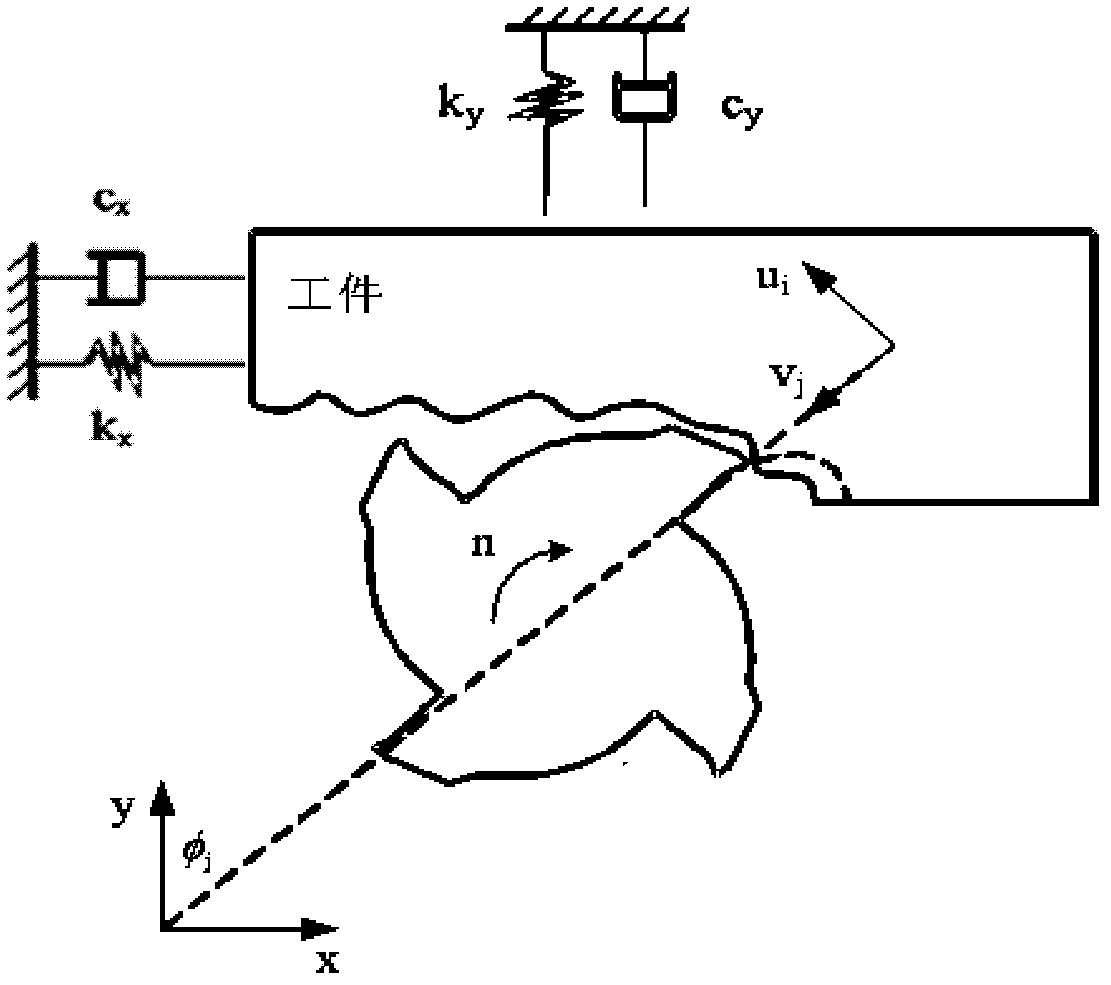

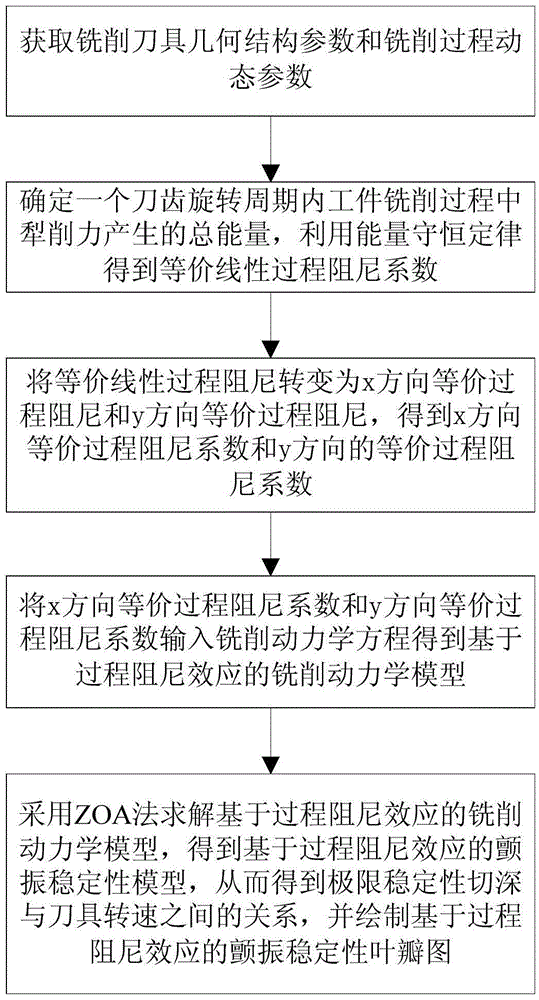

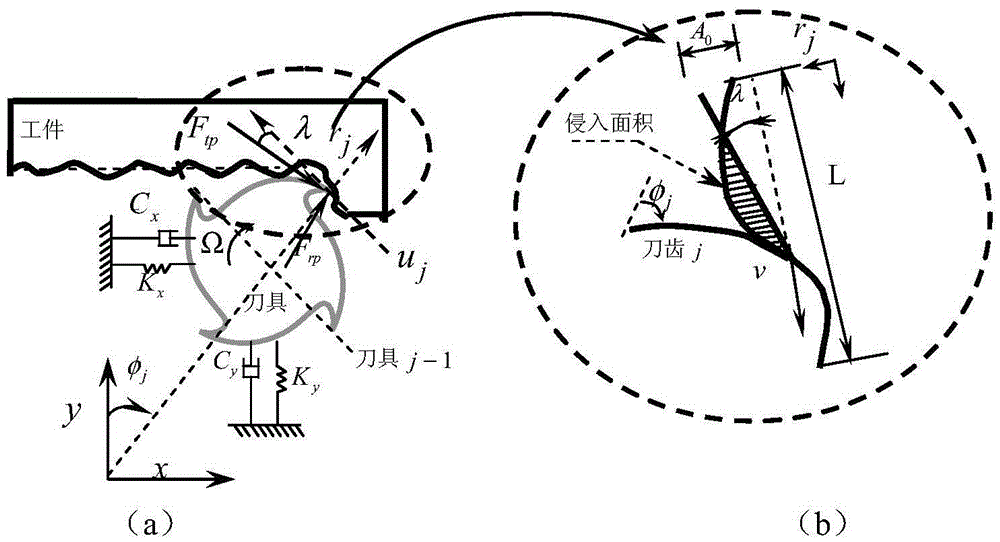

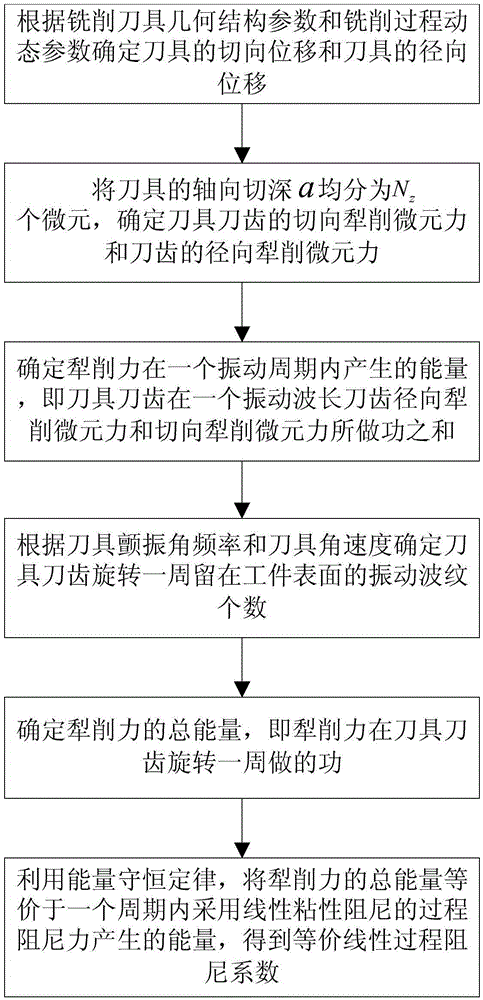

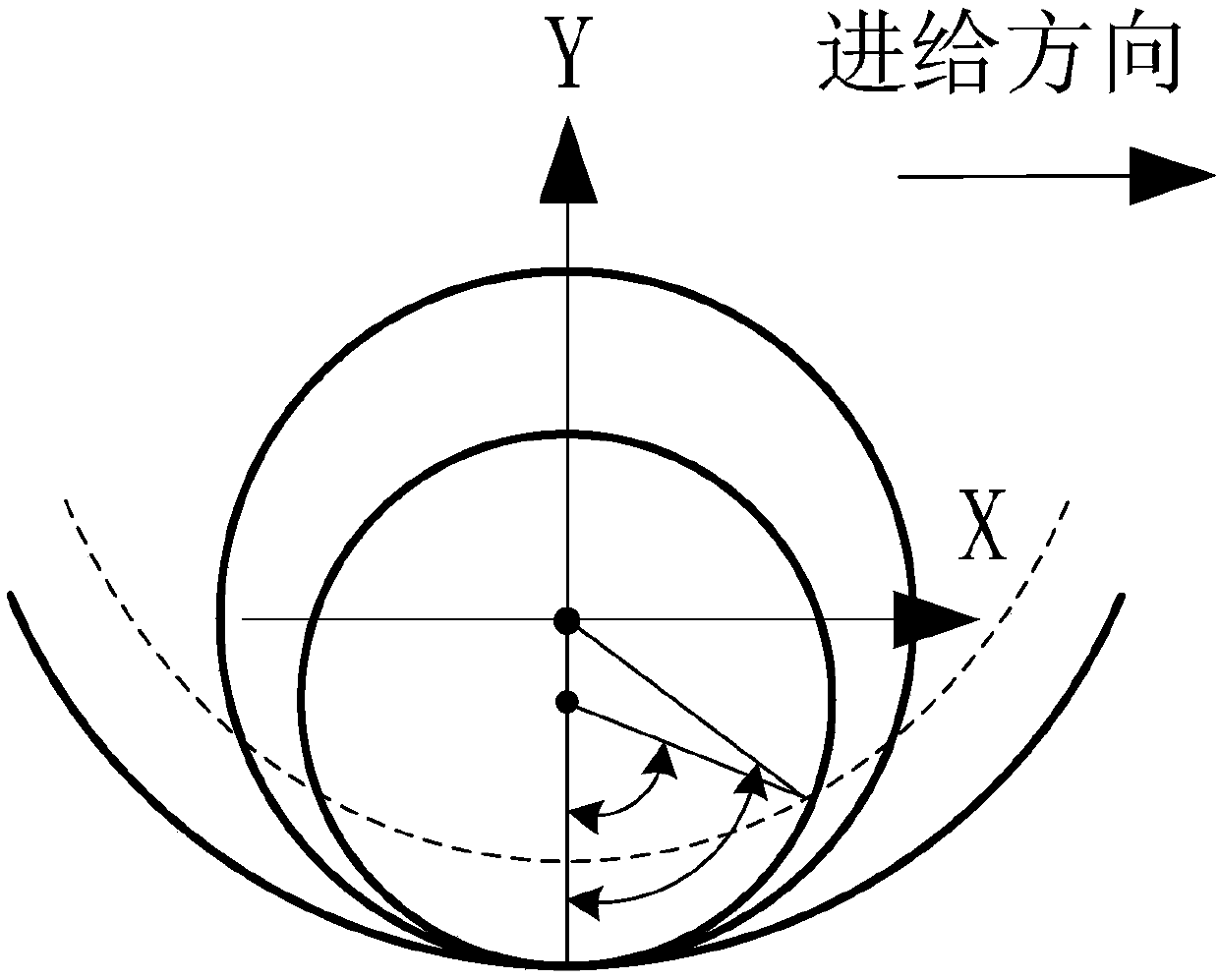

Milling vibration stability predicating method based on process damping effect

ActiveCN105608288AImprove accuracySolve the problem that the cutting parameters cannot be selected using the stable domainProgramme controlComputer controlDamping factorDynamic models

The invention provides a milling vibration stability predicating method based on the process damping effect. According to the method, in the milling process of a workpiece, the geometric structure parameter of a milling tool and the dynamic parameter in the milling process are obtained, the total energy generated by ploughing and milling force in the workpiece milling process in one cutter tooth rotation cycle is determined, the damping coefficient of the equivalent linear process is obtained through the law of conservation of energy, equivalent linear process damping is converted into equivalent process damping in the x direction and equivalent process damping in the y direction, the equivalent process damping coefficient in the x direction and equivalent process damping coefficient in the y direction are input into a milling dynamics equation, a milling dynamics model based on the process damping effect is obtained, a ZOA method is adopted to solve the milling dynamics model based on the process damping effect, and a vibration stability model based on the process damping effect is obtained, so that relation between extreme stability cutting depth and the cutter rotation speed is obtained, and a vibration stability steel lobe diagram based on the process damping effect is drawn.

Owner:NORTHEASTERN UNIV

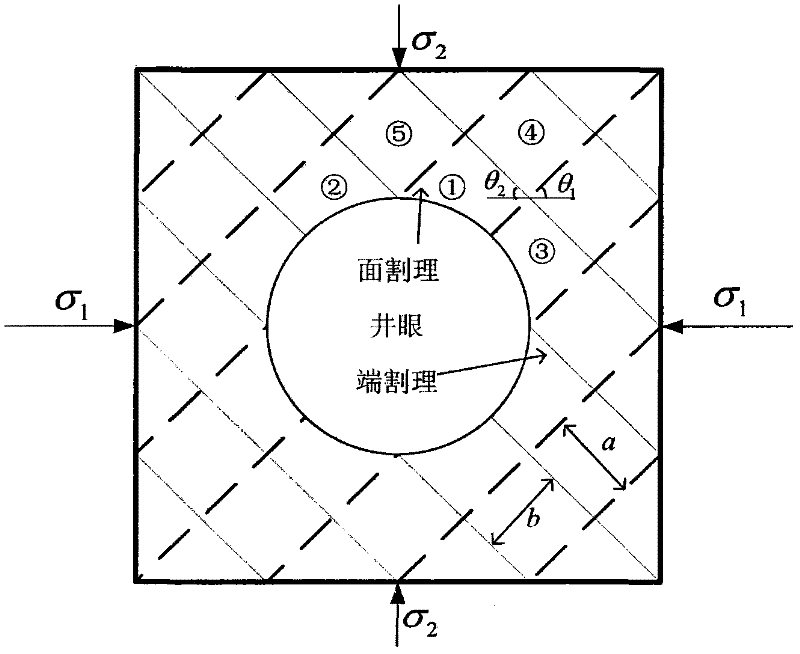

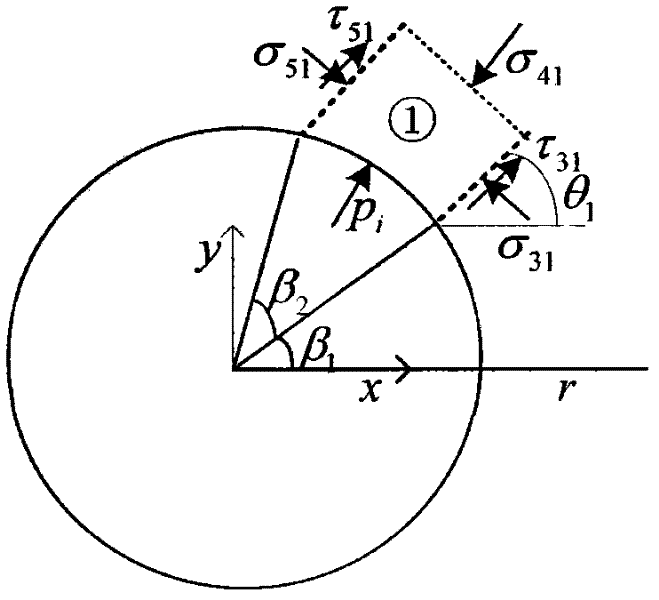

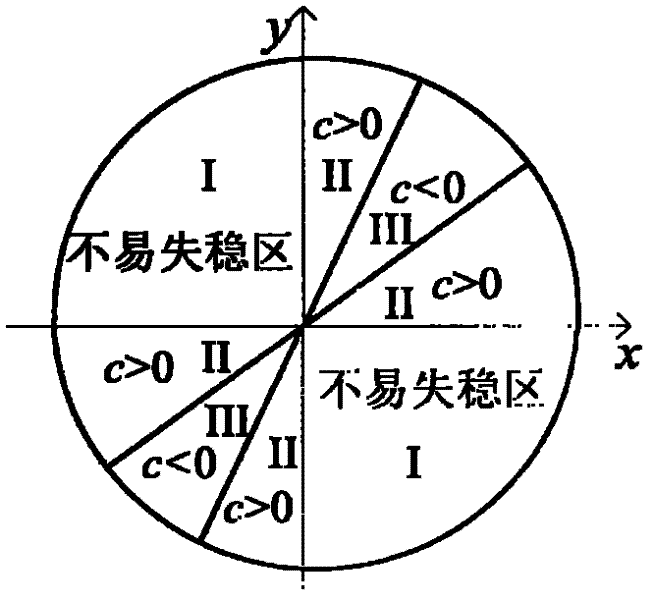

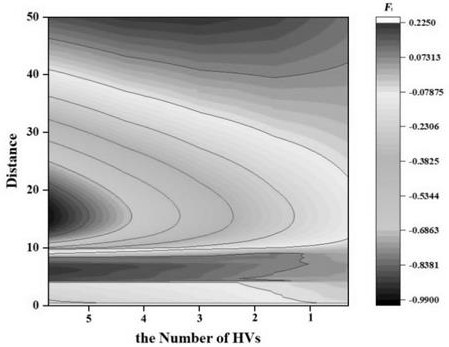

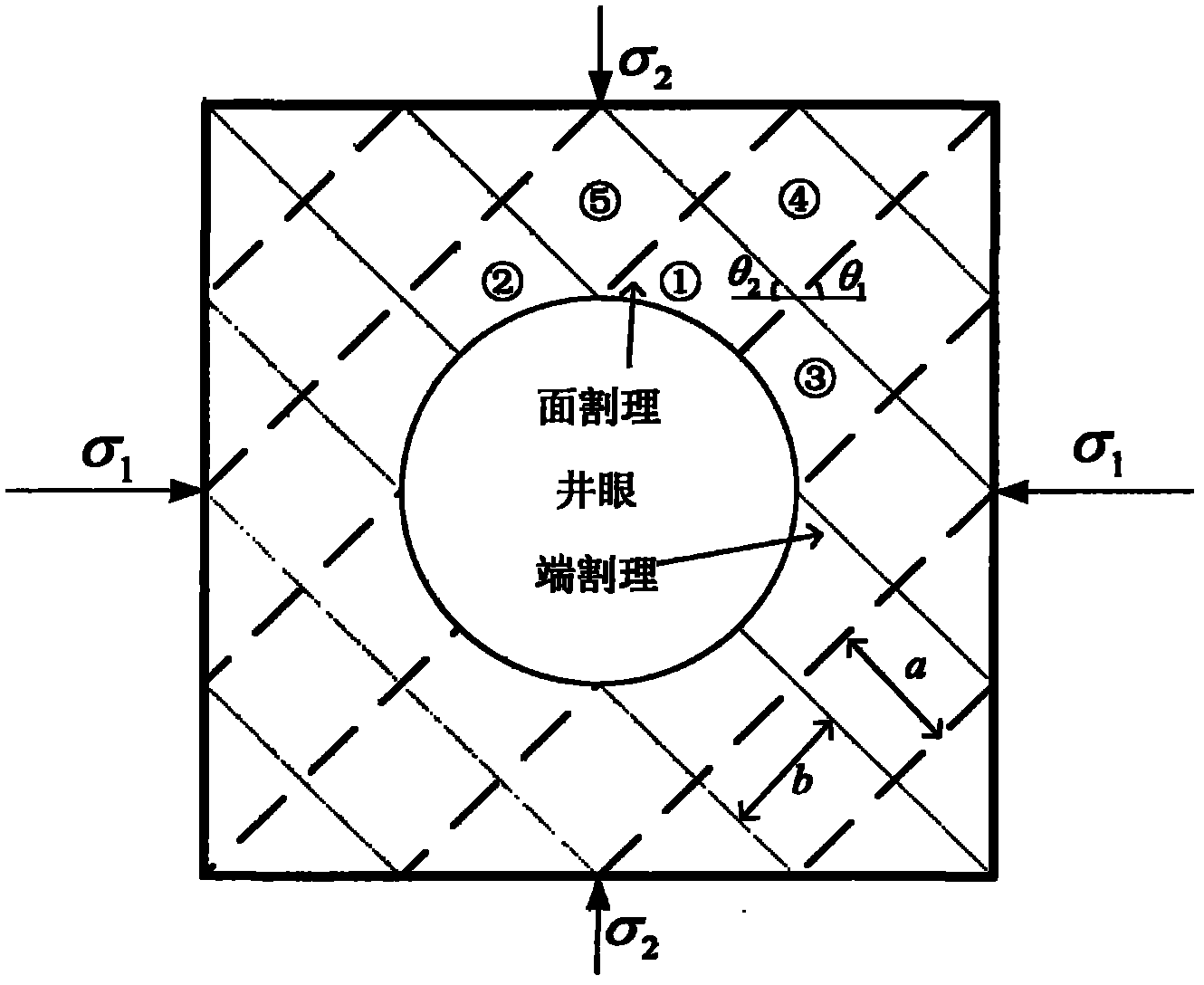

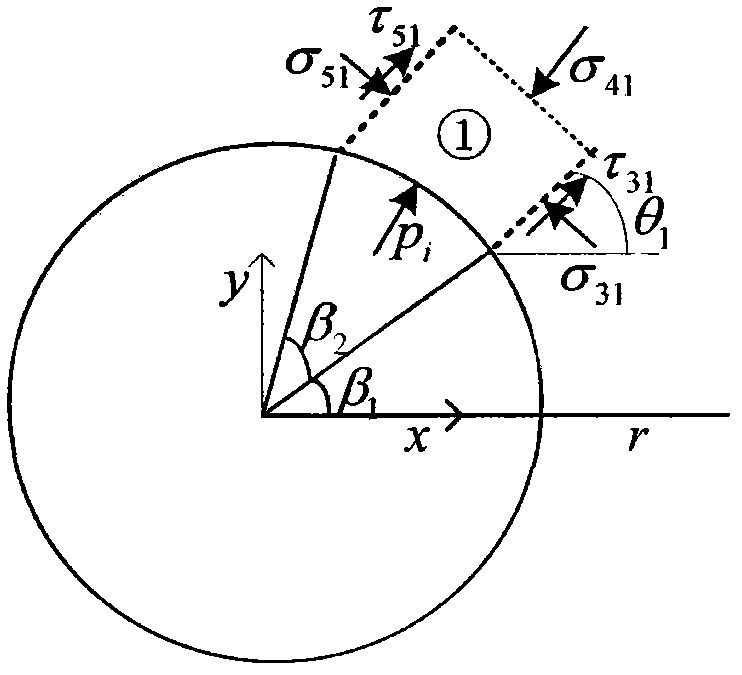

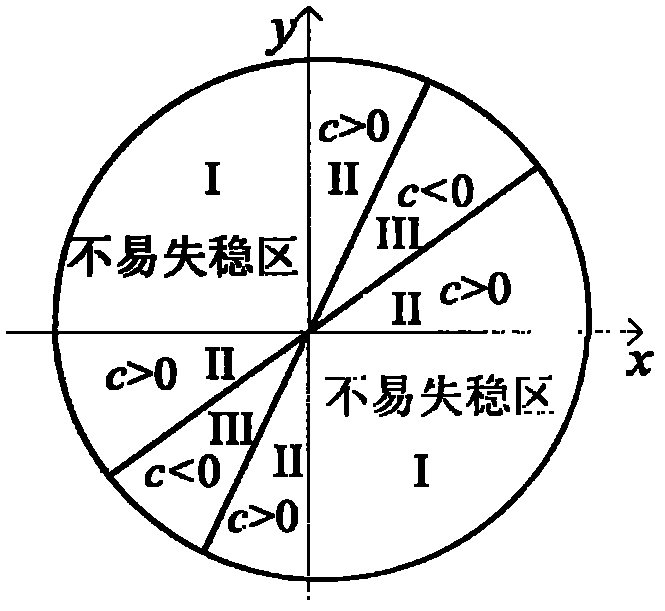

Method for determining safe drilling fluid density of coal bed based on structural element analysis model

InactiveCN102230373ASurveySpecific gravity by measuring pressure differencesCoal briquetteInstability

The invention discloses a method for determining the safe drilling fluid density of a coal bed based on a structural element analysis model. The method has the advantages of coal bed cleat and fracture development, big rock brittleness, low strength and obvious anisotropy and discontinuity. The borehole wall instability characteristics of the method are different from those of the common sandstone stratum. The phenomenon that the traditional borehole wall stability model based on the mechanics of continuous media is difficult to be successful for solving coal bed instability problems can be eliminated. In the method, the coal bed is composed of discrete blocks. A coal briquette which has the biggest possibility of generating spallation between surface cleats is analyzed to carry out force analysis. A structural element model of collapse pressure is built by the stressed balance condition among pressure stress, shearing strength and shaft pressure. A coefficient c is introduced to judge the stable relationship of borehole pressure and borehole wall so as to judge the range of the safe drilling fluid density.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

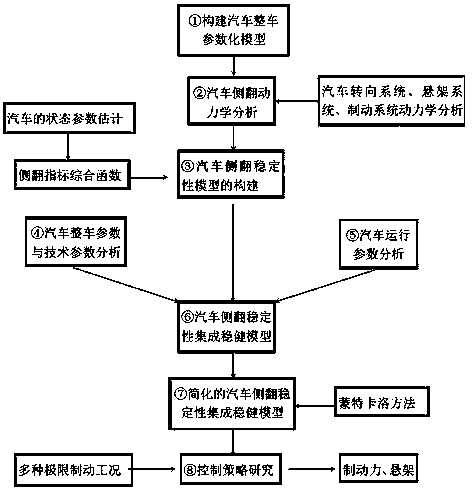

Automobile rollover stability integrated control method for limit braking working conditions

ActiveCN108146431AImproved rollover stabilityImplementing Adaptive Vehicle Rollover Stability ControlGeometric CADDesign optimisation/simulationRolloverEngineering

The invention provides an automobile rollover stability integrated control method for limit braking working conditions. The correlation of various uncertain factors such as automobile parameters, chassis technical parameters and operating parameters which affect automobile rollover stability is analyzed by applying the robust design theory, the affect of the initial value and the variation of theparameters on the automobile rollover stability is analyzed, a whole preference aggregate function is applied to integrate the variables of the automobile parameters, the technical parameters and theoperating parameters into an automobile integrated robust model by layers, a simplified automobile rollover stability model for the limit braking working conditions is established through a monte carlo method, and self-adaptive automobile rollover stability control for the various limit braking working conditions is achieved, so that the automobile stability for the limit braking working conditions is improved in the aspects of the initial design stage, the manufacturing process and the using process.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

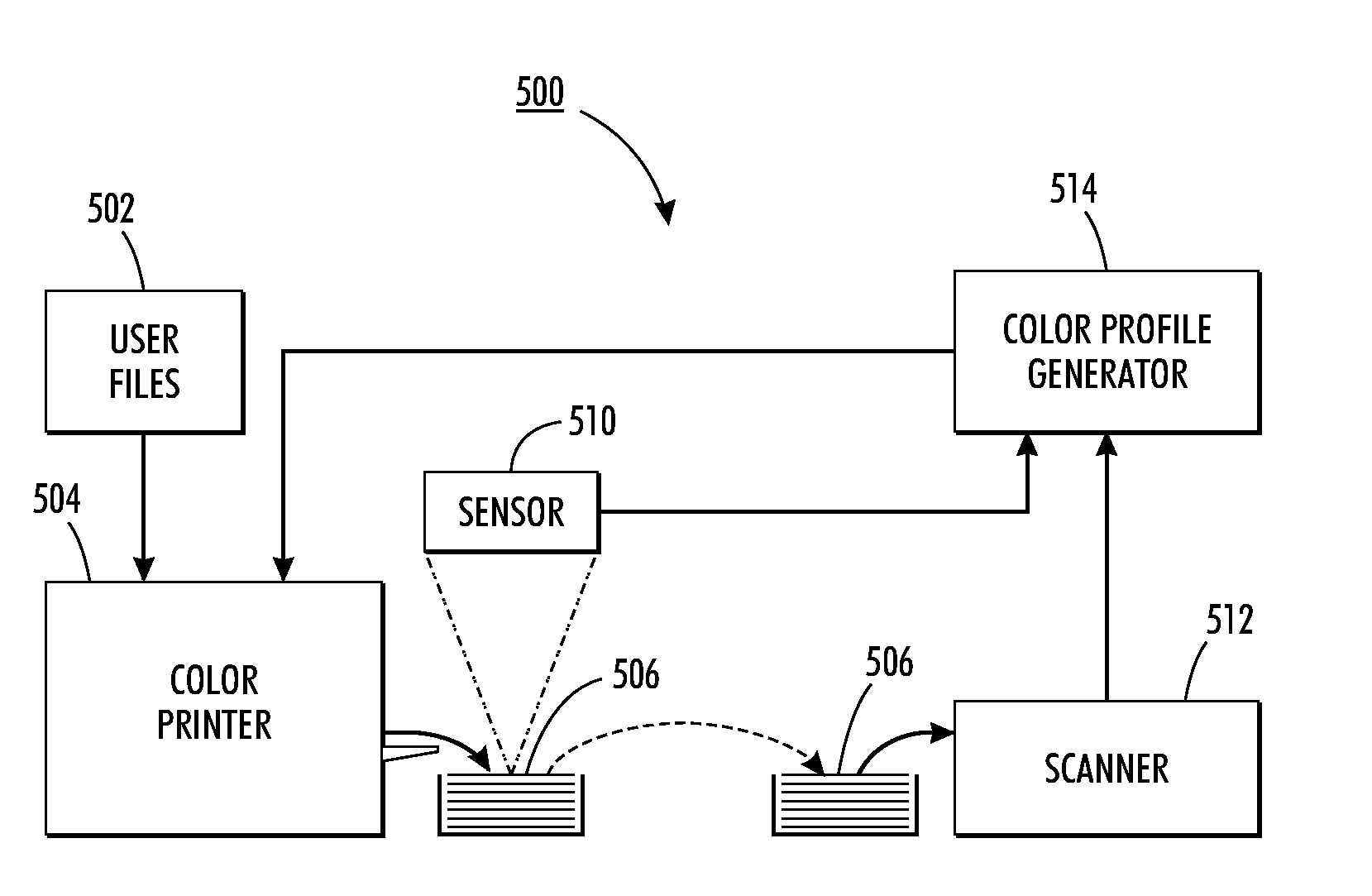

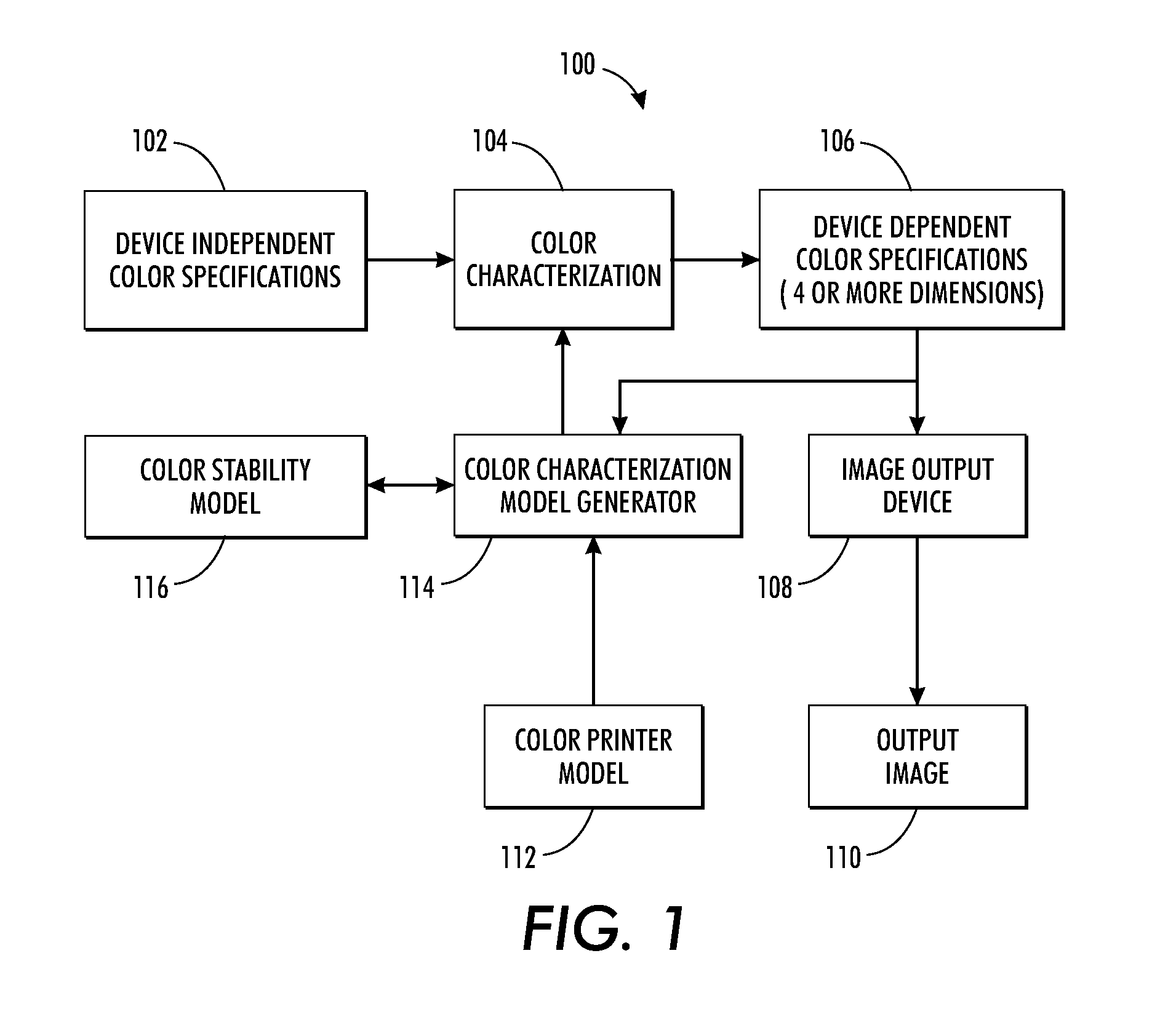

Color mapping determination for an n-color marking device based upon color stability

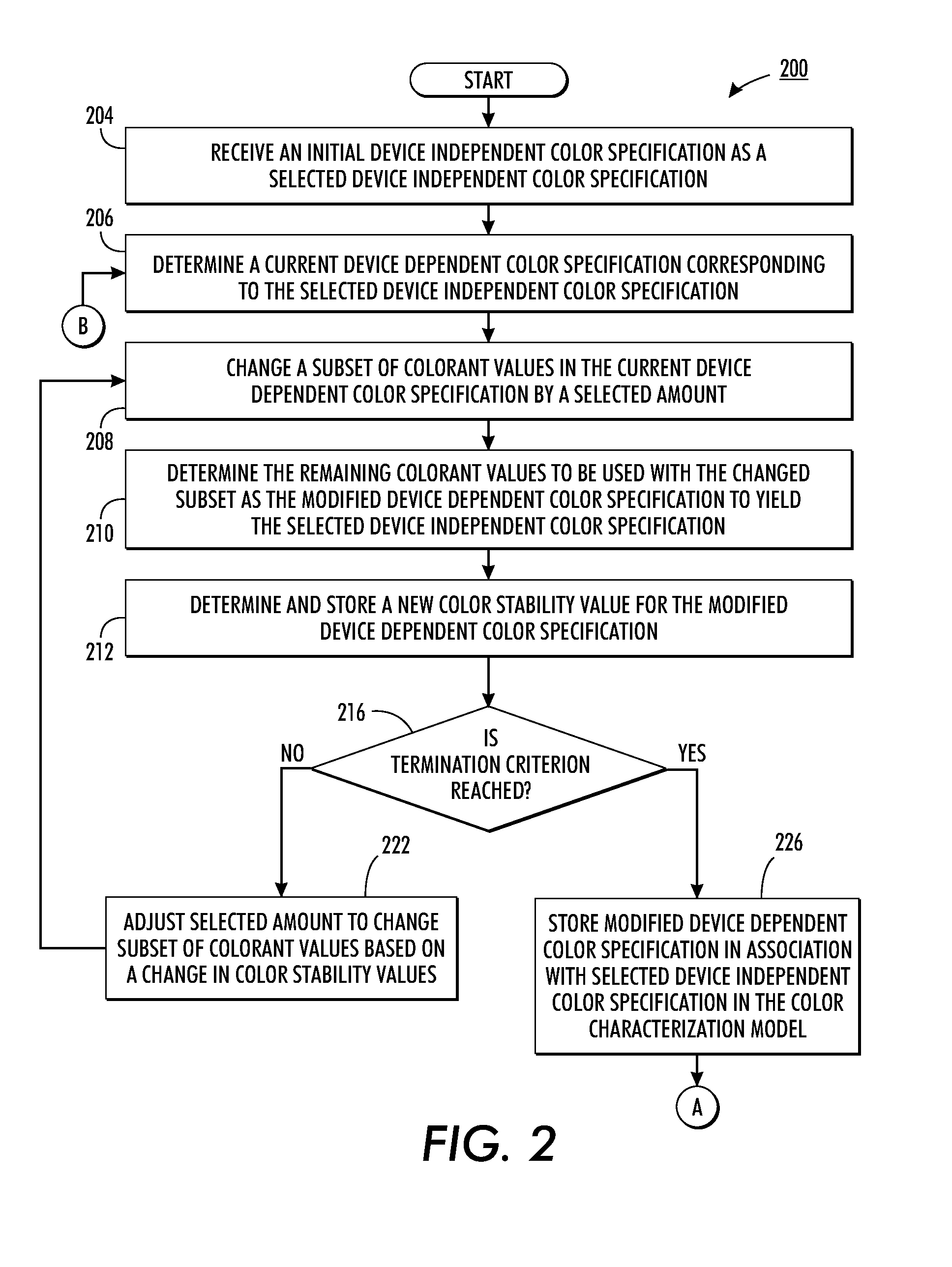

InactiveUS20110228290A1Improve color stability valueImprove device performanceDigitally marking record carriersDigital computer detailsPattern recognitionColor mapping

What is disclosed is a novel system and method for determining color profiles based upon optimizing image output color stability. For each of a number of selected output colors, color stability values for a set of device-dependent color specifications that produce the selected output color are iteratively determined. The set of device-dependent color specifications is generated by varying a subset of colorants in the device-dependent color specifications while changing the remaining colorants to maintain the selected output color. The iterative process improves the color stability value, as determined by a color stability model, of the device-dependent color specifications that correspond to the selected output color. When an optimum color stability value is found, the device-dependent color specification having that color stability value is selected as the mapping for the selected device-independent color specification. Various embodiments are disclosed.

Owner:XEROX CORP

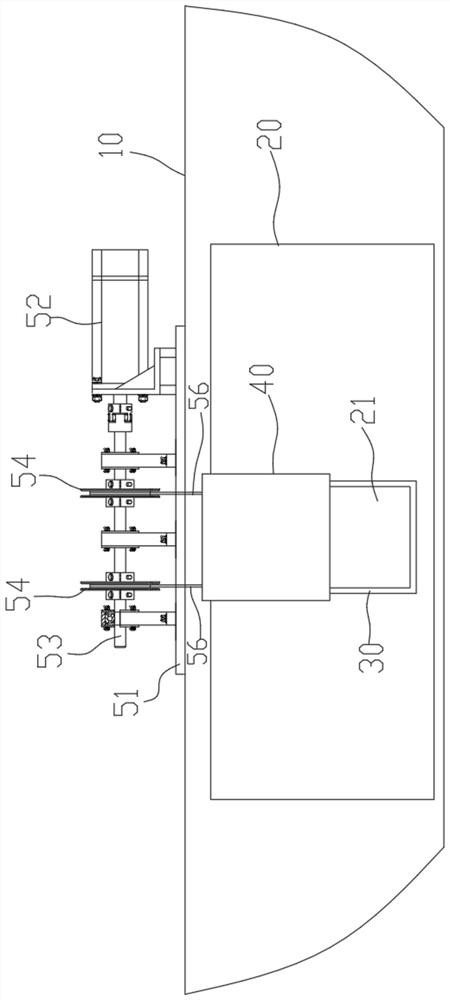

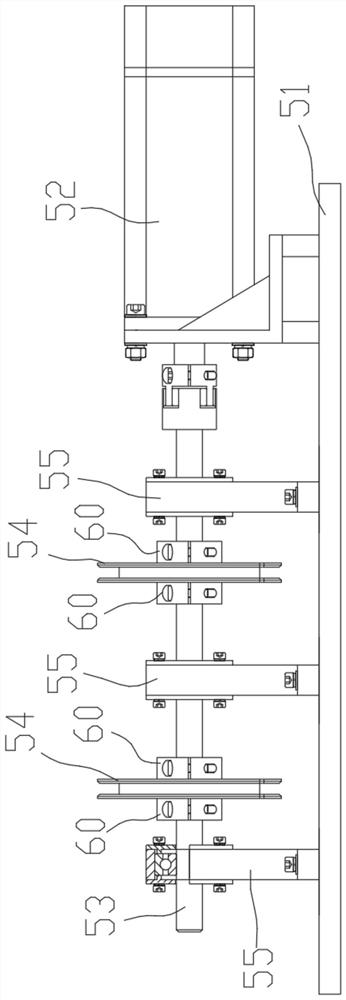

Active control device for ship damage stability model tests

ActiveCN113335476AEasy to controlRealize active controlWaterborne vesselsClimate change adaptationModel testMechanical engineering

The invention relates to the technical field of ship damage stability model tests, in particular to an active control device for ship damage stability model tests, which comprises a ship body model and a driving mechanism, a transparent organic window plate is embedded in the broadside of the ship body model, a damage opening is formed in the transparent organic window plate, and a magnetic steel frame is adhered to the outer end face of the periphery of the damage opening. A magnetic cover plate covers the damage opening, the magnetic cover plate and the magnetic steel frame attract each other, and the driving mechanism pulls the magnetic cover plate to move so that the damage opening can be opened. According to the active control device, active control to multiple damage opening plans can be realized; and according to damage stable model test characteristics and test research contents, real-time switching of various damage opening schemes in waves is realized.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

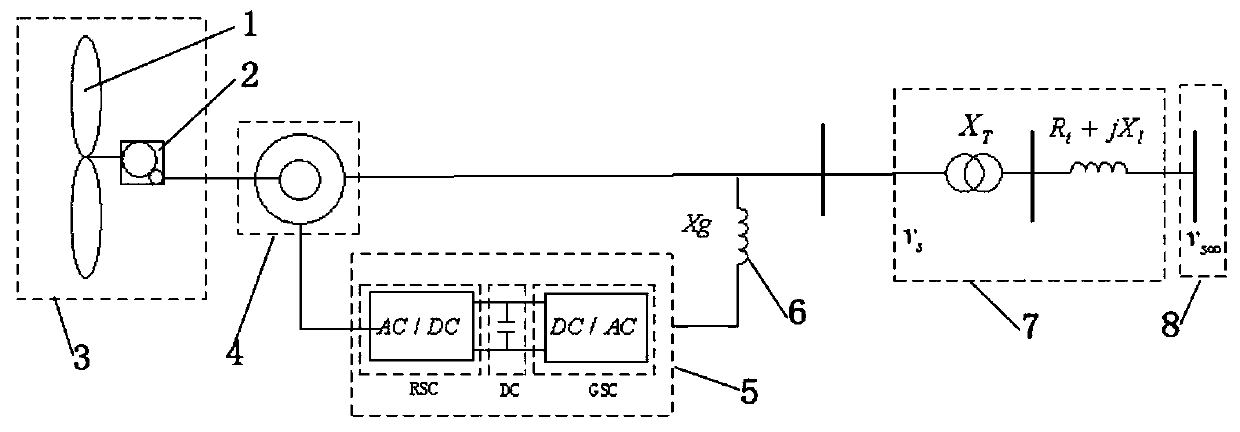

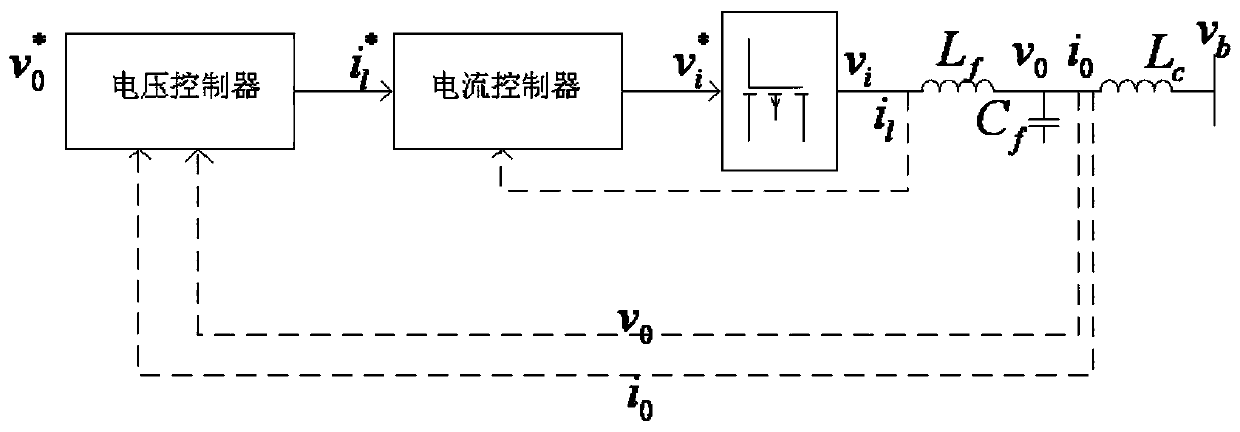

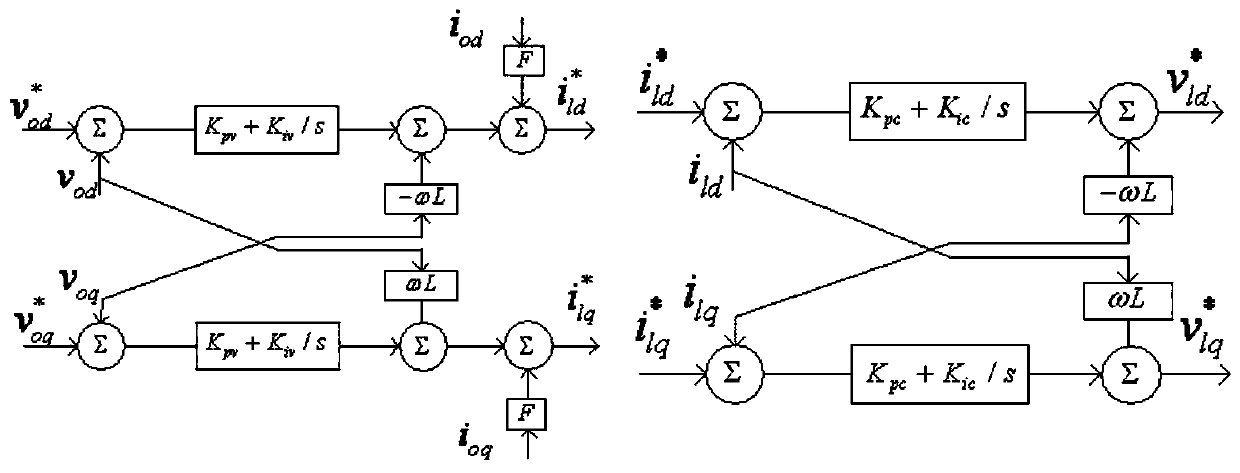

Distribution network reconstruction method by considering small signal stability of comprehensive energy system

PendingCN110336299ARun economyPower oscillations reduction/preventionElectricityReconstruction method

The present invention discloses a distribution network reconstruction method by considering the small signal stability of a comprehensive energy system. The method mainly comprises the steps that: ina region-class comprehensive energy system, the influence of the distribution network reconstruction of various power sources and the small signal stability of the system is considered, a respective small signal stability model is established for various types of power sources in the comprehensive energy system, a final comprehensive energy system model is formed through transformation of coordinates, the small signal stability is added into the distribution network reconstruction constraint, and wind power and photovoltaic output is arranged in a situation when the system operation is the most unstable, so that it is ensured that the comprehensive energy system is more economically operated on the basis of meeting the small signal stability.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

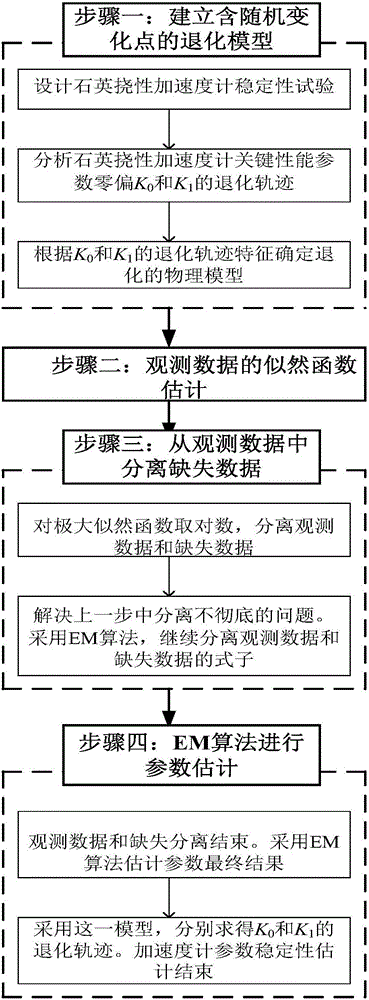

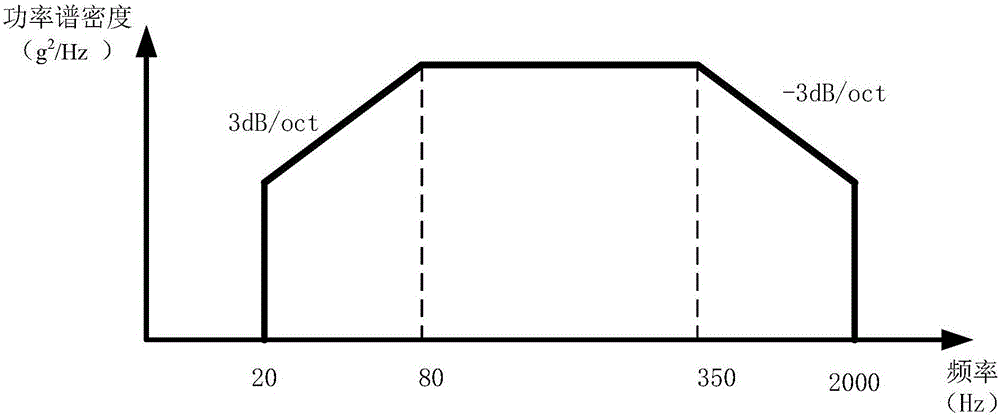

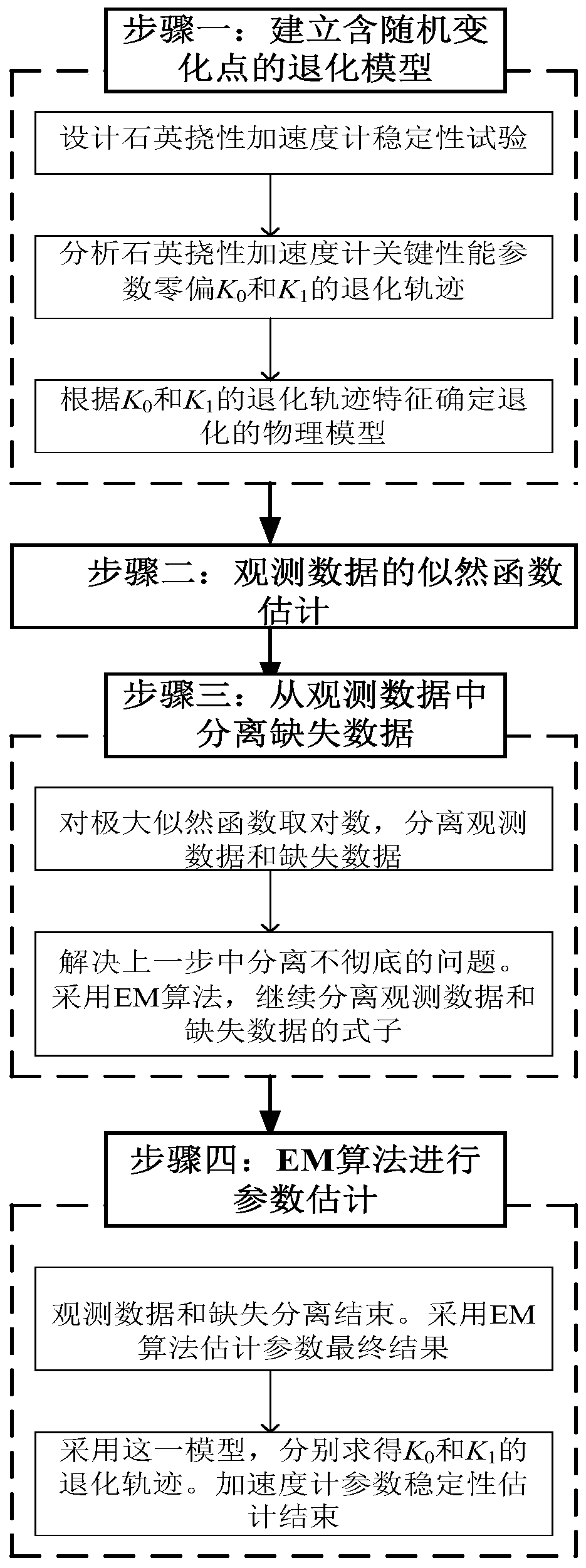

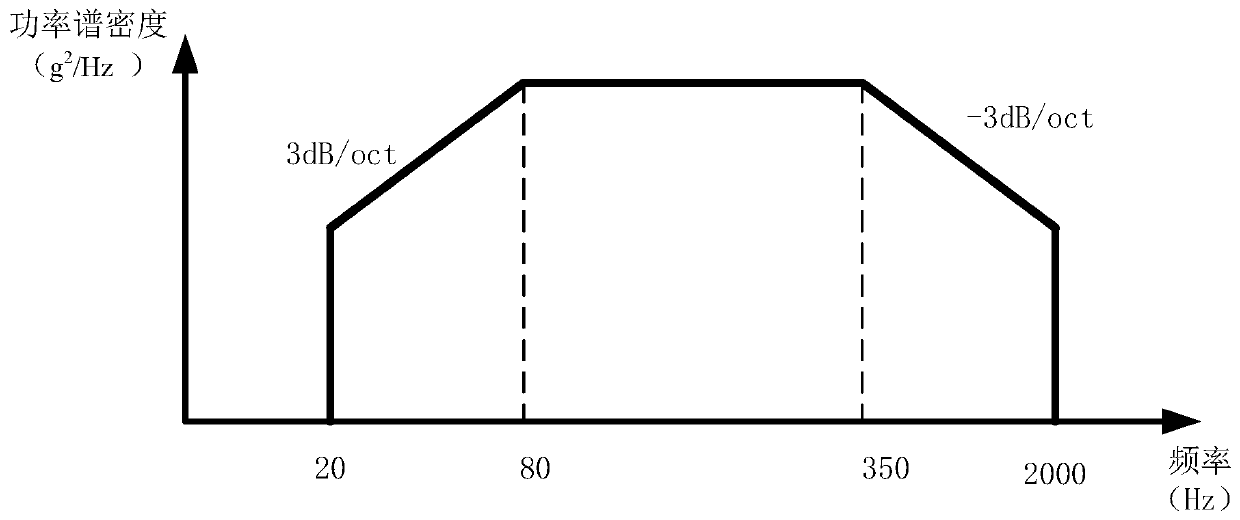

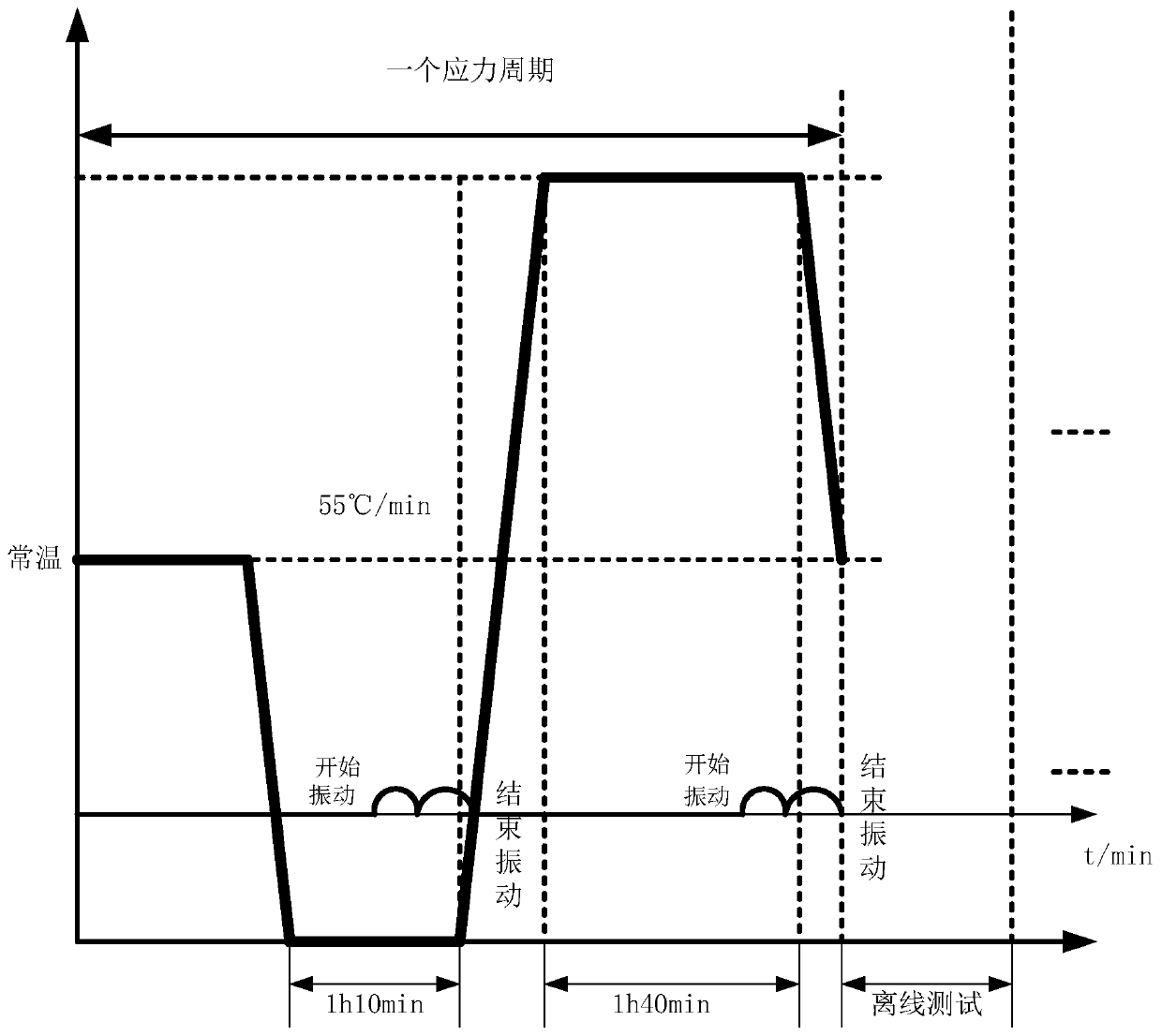

Quartz flexure accelerometer parameter stability modeling method

ActiveCN106844836AGood repeatabilityGeometric CADSpecial data processing applicationsAccelerometerObservation data

The invention discloses a quartz flexure accelerometer parameter stability modeling method, namely a parameter stability modeling method for a quartz flexure accelerometer based on a random point degradation model. The method comprises the steps that first, the degradation model containing random change points is established; second, a likelihood function of observation data is estimated; third, a deficient number is separated from the observation data; and fourth, parameter estimation is performed through an EM algorithm. Through the steps, the degradation model is established through product main performance parameters, test cost and test time are saved for products with high construction cost, high reliability and long service life, and the method has practical significance; an accelerometer parameter stability model is established and the random change points are estimated mainly targeting the problem of poor parameter repeatability of the quartz flexure accelerometer to make sure accelerometer parameters gets into a stable profile cycle number, and the method has huge practical significance in practical engineering application.

Owner:BEIHANG UNIV

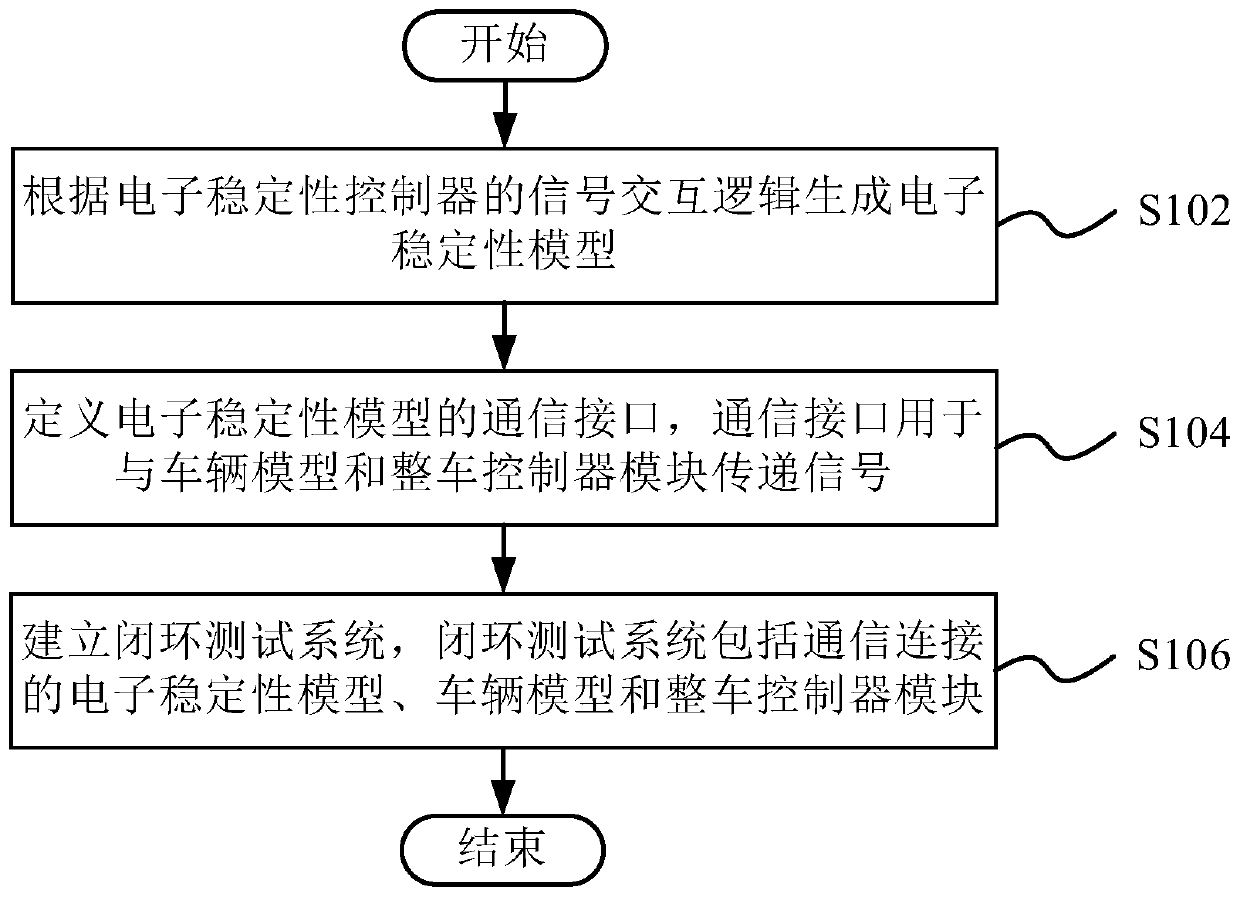

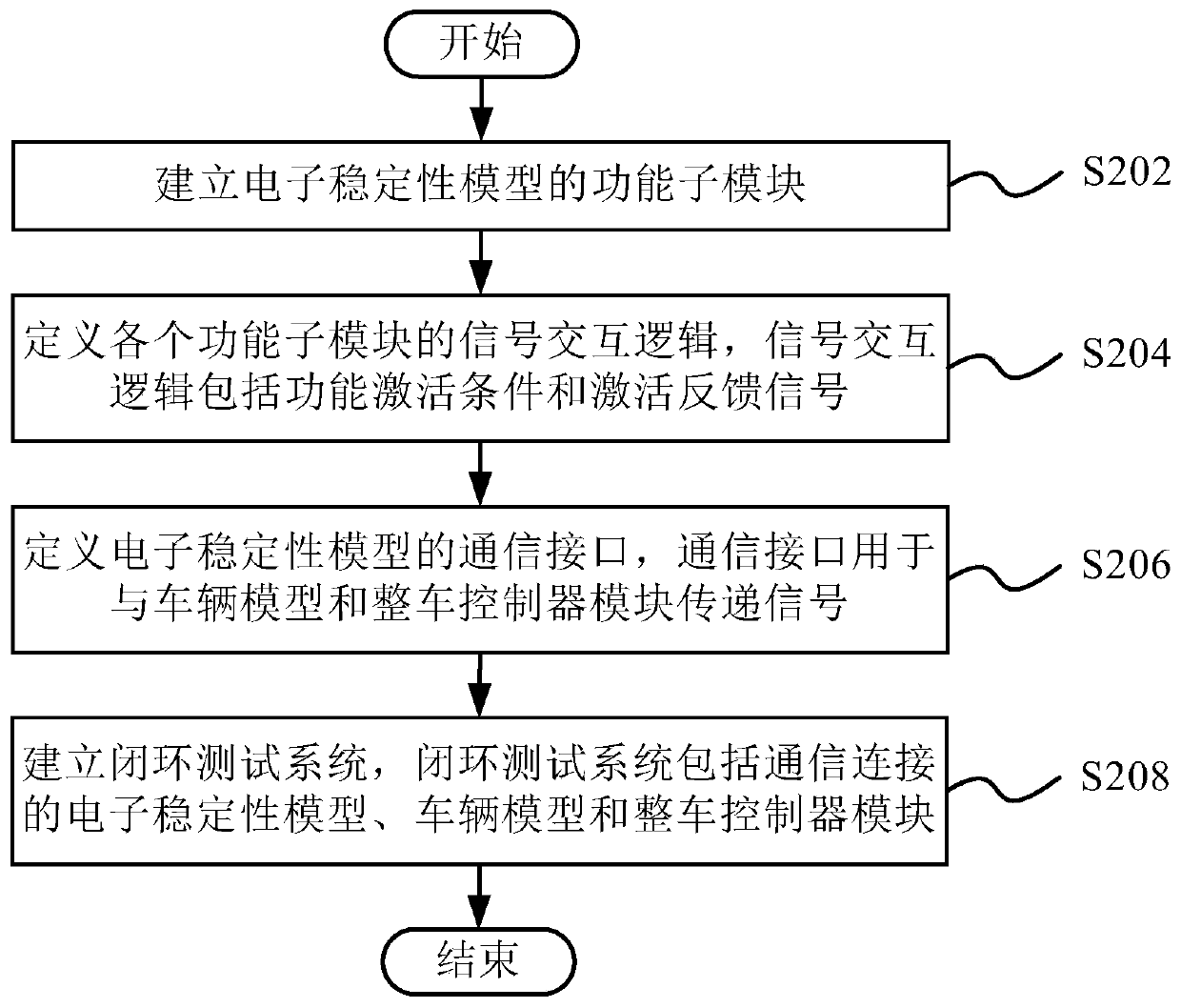

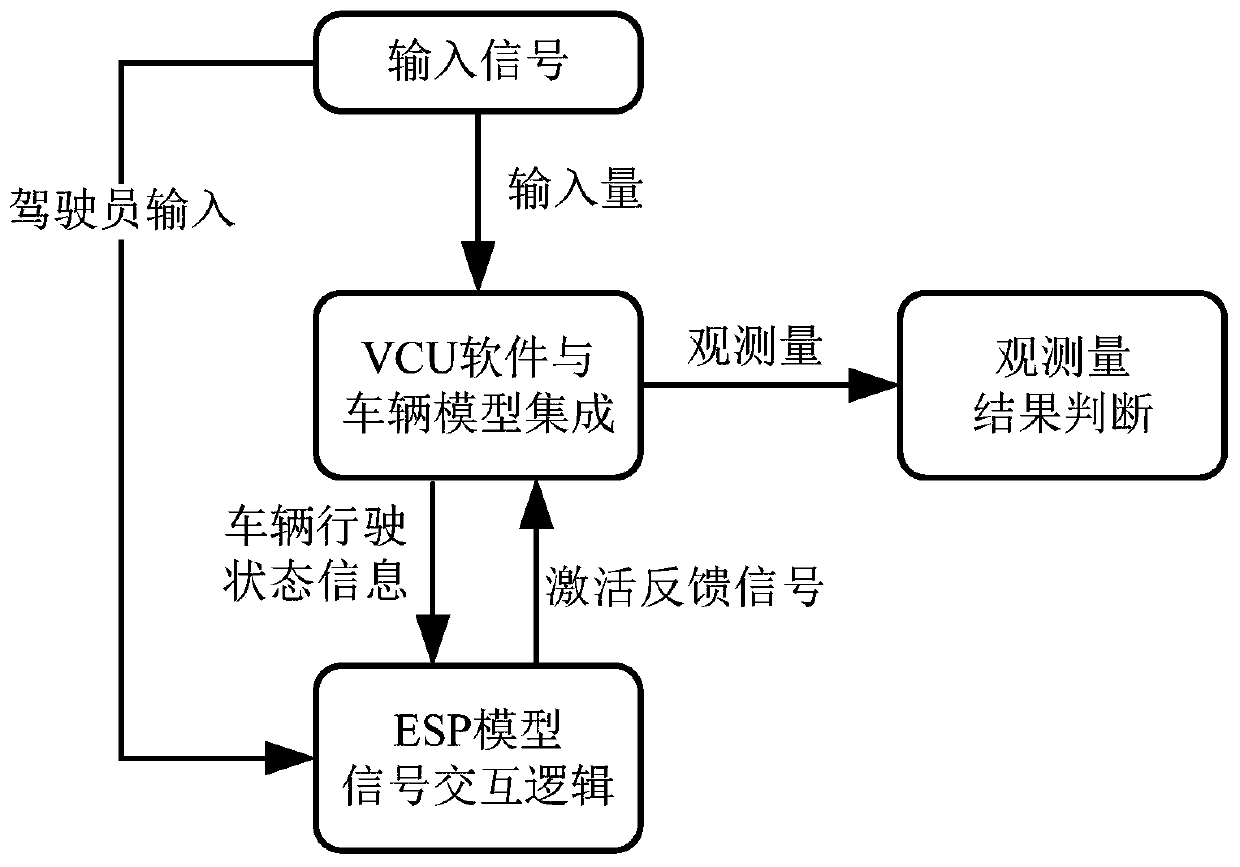

Vehicle controller closed loop test system building method, device and equipment

ActiveCN110109437AQuick buildGuaranteed validityElectric testing/monitoringTest efficiencyCommunication interface

The embodiment of the invention discloses a vehicle controller closed loop test system building method, device, equipment and a computer readable storage medium. The method comprises steps: an electronic stability model is generated according to a signal interaction logic of an electronic stability controller; a communication interface of the electronic stability model is defined, wherein the communication interface is used for transmitting signals with a vehicle model and a vehicle controller module; and a closed loop test system is built, wherein the closed loop test system comprises the electronic stability model, the vehicle model and the vehicle controller module in communication connection. According to the method, on the basis of integration of the traditional vehicle controller software and the vehicle model, the electronic stability model can be quickly integrated, the SIL closed-loop automatic test function of the vehicle controller, the electronic stability controller and the vehicle model can be realized, the functions related to the vehicle controller and the electronic stability controller can be quickly verified, and while complex logic function test is met, the testscene effectiveness is ensured, and the test efficiency is improved.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

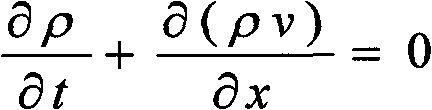

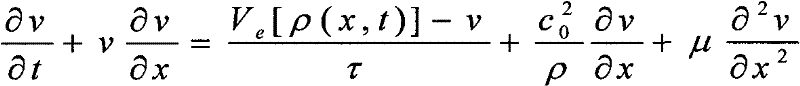

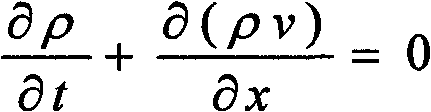

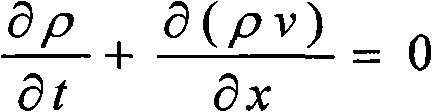

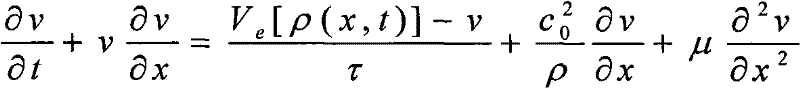

Stability modeling method for macroscopic traffic flow viscous model

The invention discloses a stability modeling method of a macroscopic traffic flow viscosity model, which is used to solve the technical problem that the existing models are difficult to directly deal with the problem of traffic congestion. The technical solution is to establish a new traffic model on the basis of the existing model to obtain the relationship between traffic congestion and system stability, so as to determine whether there will be traffic congestion or other abnormal phenomena from a macro perspective by using the perspective of global stability , provide a basic basis for traffic control and decision-making, and be directly applied to deal with traffic congestion problems.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Stability modeling method of macroscopic traffic flow velocity gradient viscous model

The invention discloses a stability modeling method for a macroscopic traffic flow velocity gradient viscosity model, which is used to solve the technical problem that the existing model is difficult to directly deal with the traffic congestion problem. The technical solution is to obtain the relationship between the traffic congestion problem and the system stability by establishing a new traffic model on the basis of the existing model, so as to use the global stability perspective to determine whether traffic congestion or other abnormal phenomena will occur macroscopically. , provides the basic basis for traffic control and decision-making, and is directly applied to deal with the problem of traffic congestion.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

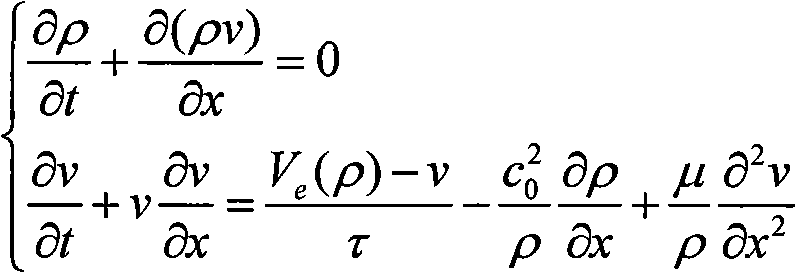

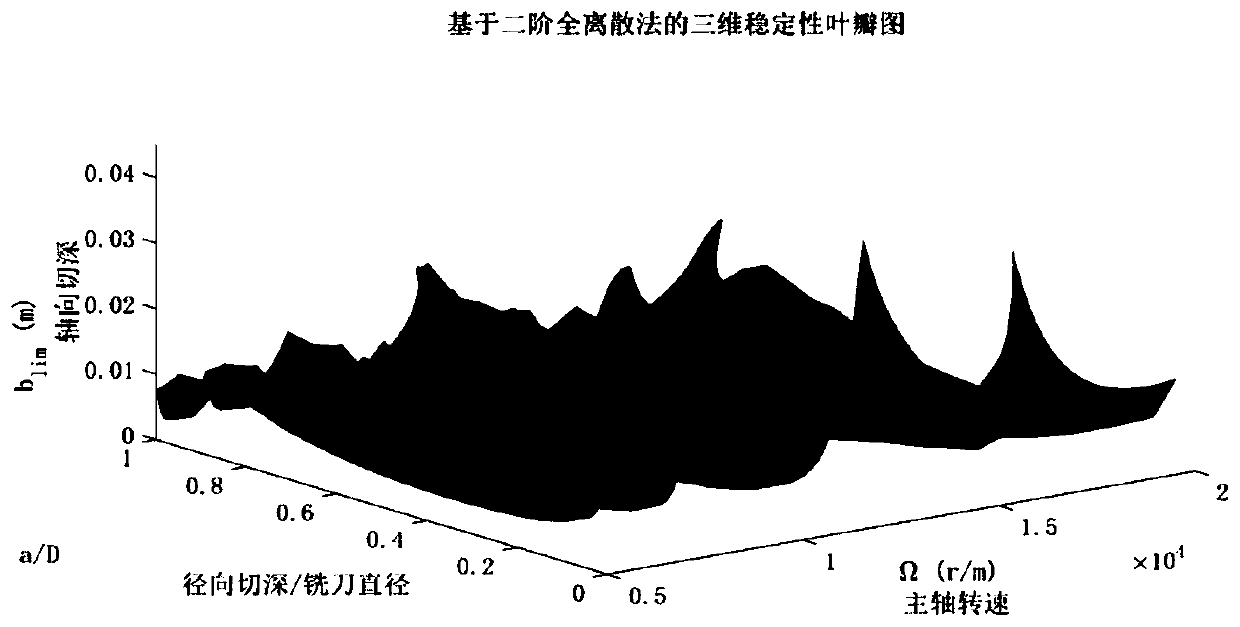

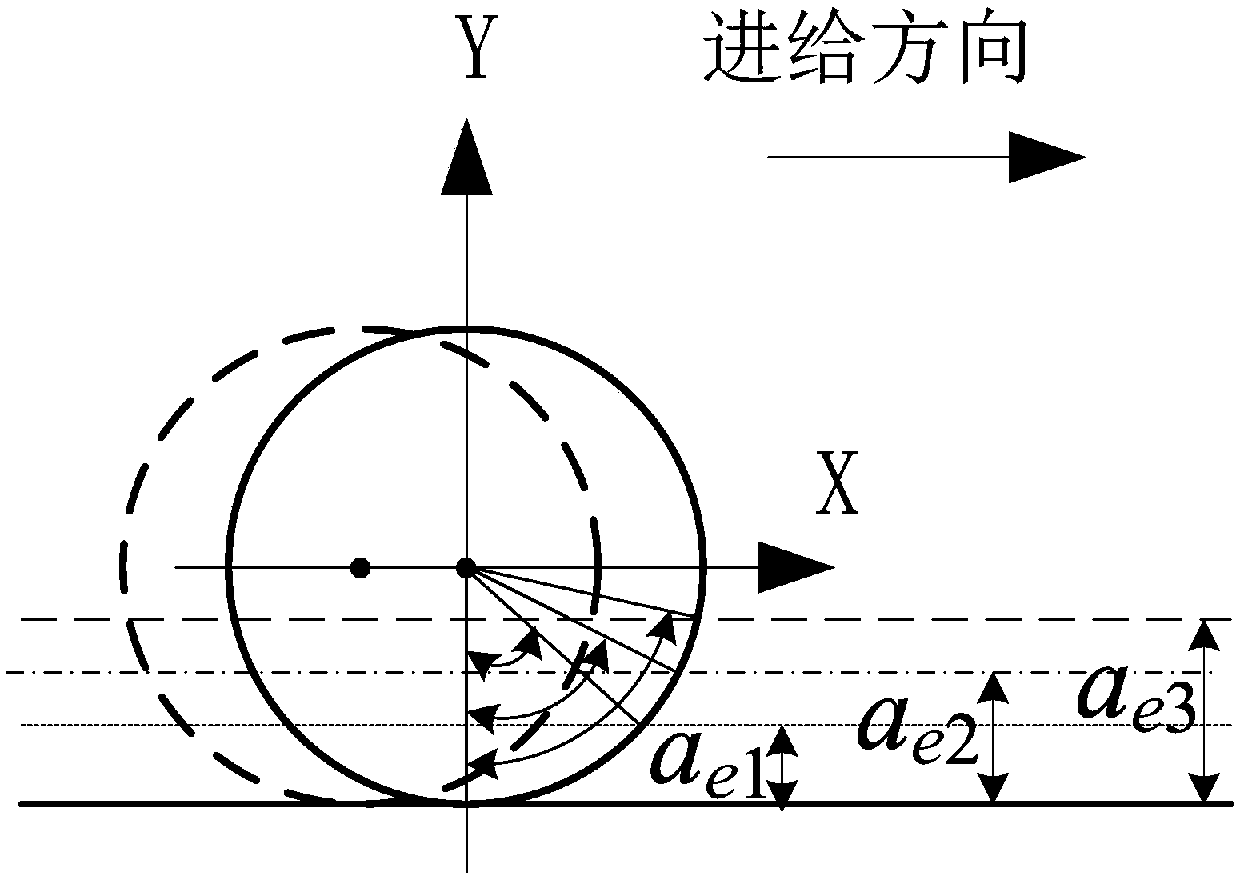

Milling multi-objective optimization decision-making method introducing three-dimensional stability constraint

ActiveCN110162841AIncrease profit marginsHave diversityGeometric CADArtificial lifeEngineeringStability constraints

The invention discloses a milling multi-objective optimization decision-making method introducing three-dimensional stability constraint. The method comprises the following steps: constructing a three-dimensional stability model about the rotating speed, the axial cutting depth and the radial cutting depth of a milling main shaft; establishing a milling parameter optimization model which takes high efficiency, low cost and high profit as objective functions and takes machine tool performance, cutter performance, workpiece performance, stability requirements and machining requirements as constraint conditions; and solving the milling parameter optimization model by using a multi-objective firefly optimization algorithm based on a clustering principle to obtain a plurality of groups of optimal process parameters. The invention provides a more reasonable optimization decision-making method for multi-objective optimization of the milling process parameters, and provides an effective and practical technology for optimization selection of the multi-feed high-speed milling process parameters.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

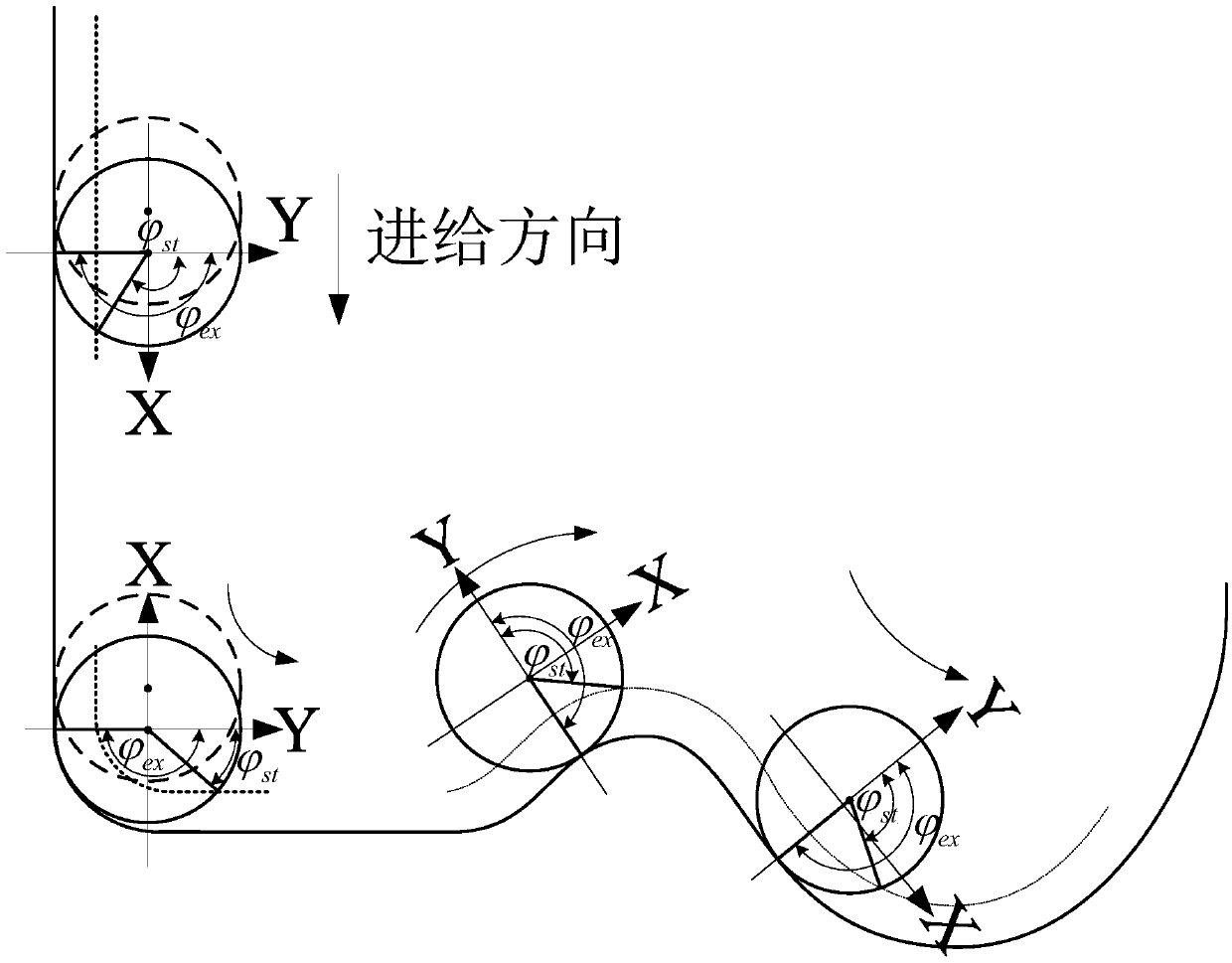

Method for prediction of flutter in numerical-control milling of mold cavities

InactiveCN108746795AFlutter predictions are accurateGuarantee processing qualityMilling equipment detailsNumerical controlMilling cutter

The invention relates to a method for prediction of flutter in numerical-control milling of mold cavities, aiming to solve problems that conventional methods for predicting stability in milling utilizing single tool path are low in applicability, which causes low accuracy of flutter prediction, accelerates failure of tools and affects processing quality of mold cavities. The method for predictionof flutter in numerical-control milling of mold cavities includes the step 1, building the relative transfer function of a tool-workpiece system; the step 2, introducing the relative transfer function of the tool-workpiece system to a three-dimensional milling stability model to obtain a critical axial cutting depth at the milling flutter frequency of a milling cutter; the step 3, judging whetherthe mold cavities flutter in numerical-control milling according to the critical axial cutting depth obtained in the step 2. The method is applied to the field of numerical-control milling of the mold cavities.

Owner:HARBIN UNIV OF SCI & TECH

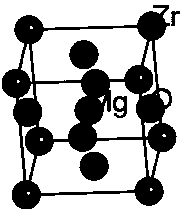

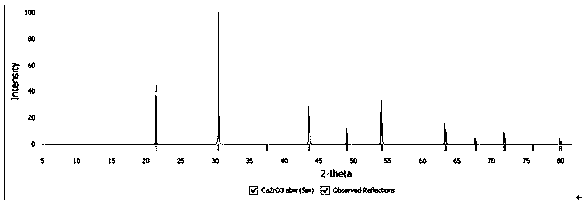

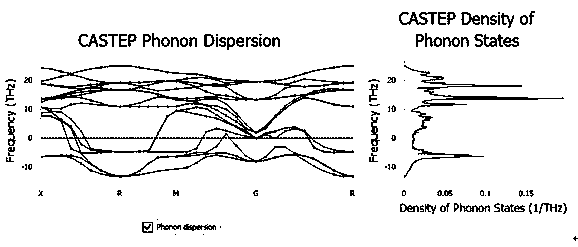

Calculation method for calculating ABO3 perovskite stable structure and performance

ActiveCN110277142AStable structureChemical property predictionAnalysing solids using sonic/ultrasonic/infrasonic wavesElectronic structureFirst principle

The invention discloses a calculation method for calculating ABO3 perovskite stable structure and performance. The method comprises the following steps: firstly, constructing an ABO3 perovskite type material stability model for selected elements at specific positions in the periodic table of elements according to certain method steps; calculating, analyzing and comparing different ABO3 structure formation energy and phonon spectrums, wherein the stability of the structure can be obtained from the thermodynamic direction and the thermokinetic direction, and then calculating the electronic structure thereof to obtain the photoelectric basic performance of the structure. The invention provides a method for judging whether a stable perovskite structure can be formed or not, and the method comprises the following steps: selecting any element (except a radioactive element Ra) from a second main group in the periodic table of elements, and adding a + 4-valent transition metal element (defined as Zr and Ha) and an O element to form a stable perovskite ABO3 structure. If a compound with a stable perovskite structure can be formed, the general performance of the compound can be calculated and predicted through a first principle.

Owner:YANGEN UNIV

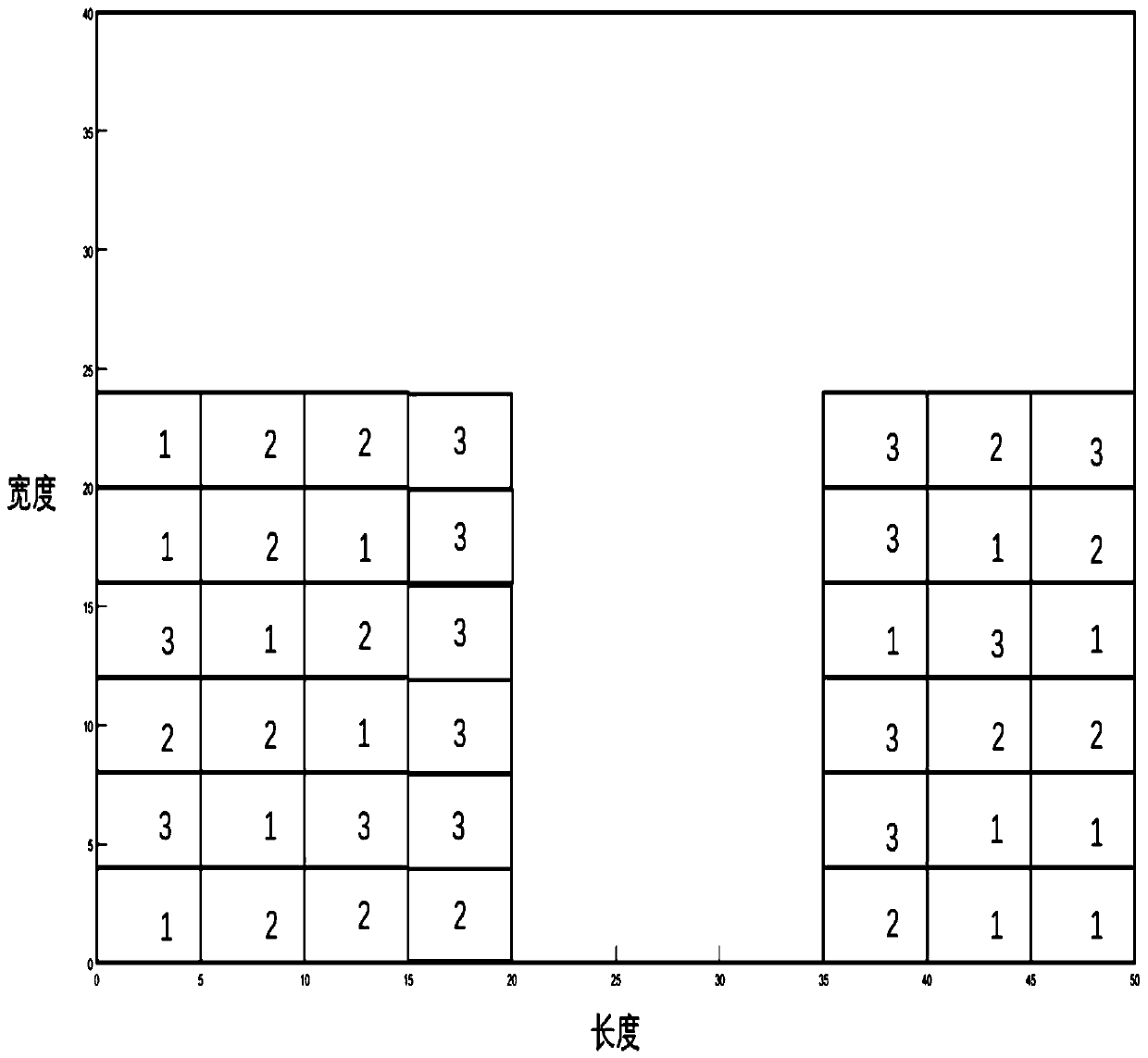

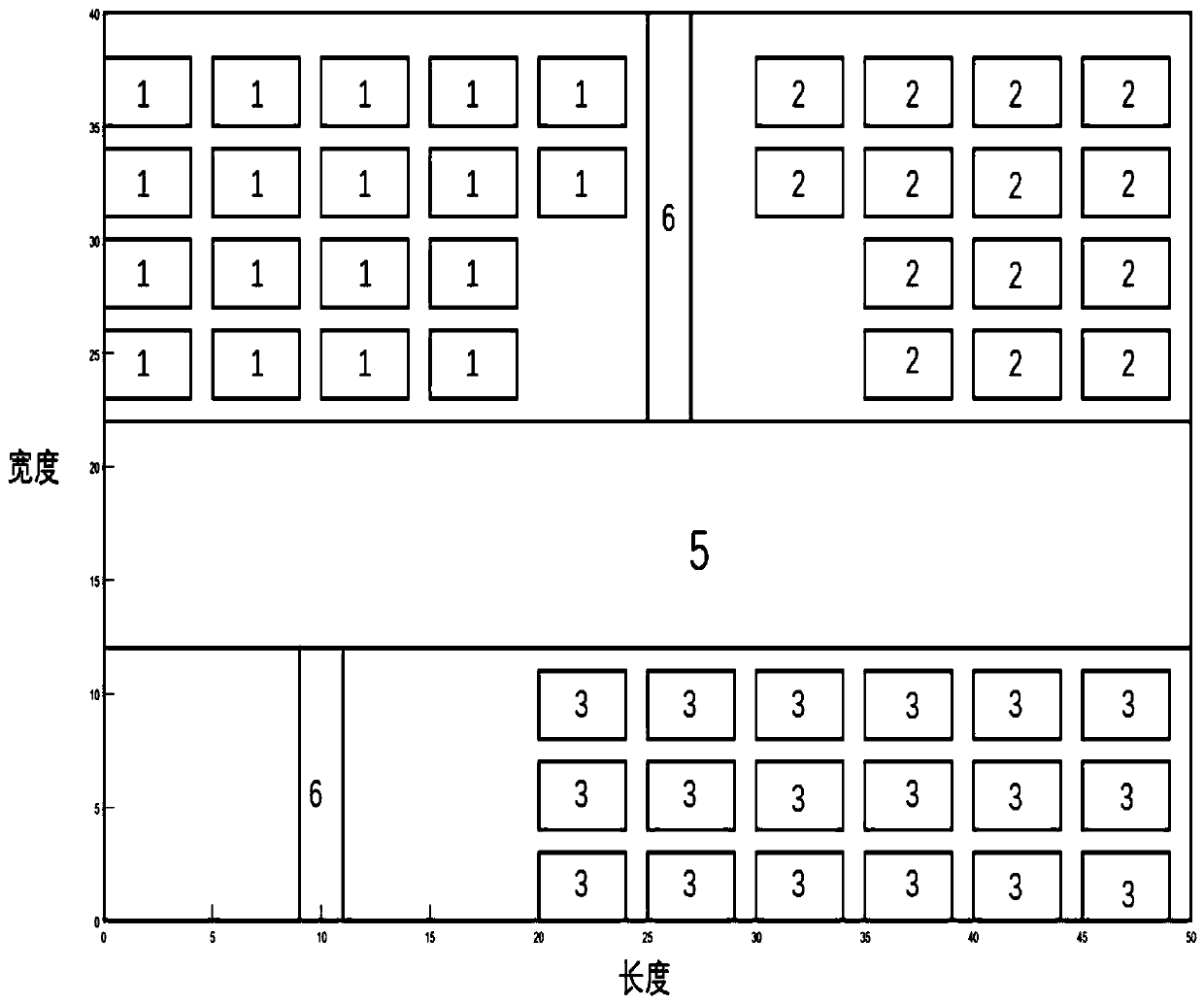

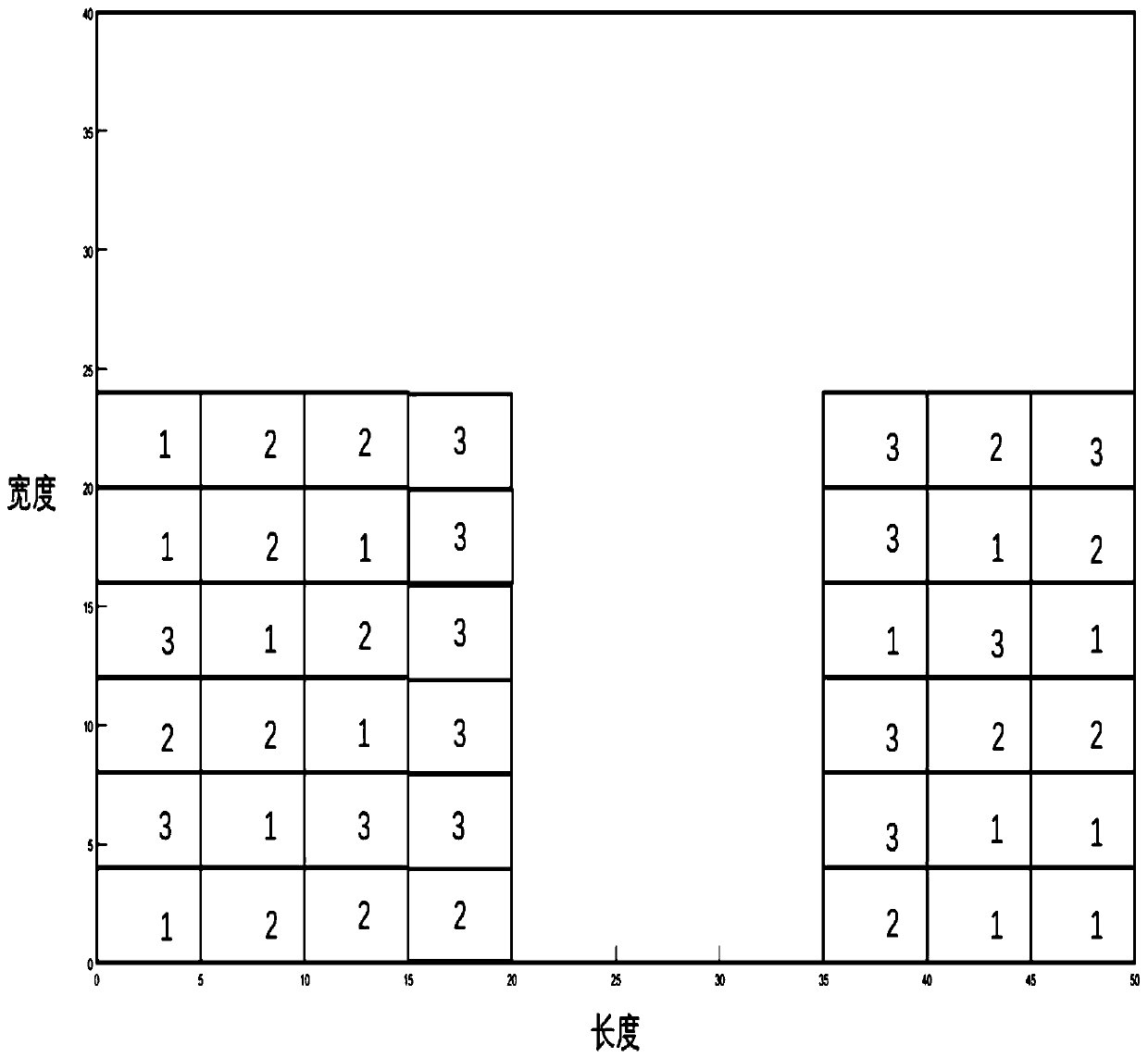

Three-acid chemical warehouse goods location layout method based on particle swarm optimization algorithm

InactiveCN110009138ASolve the problem of security layout optimizationImprove storage efficiencyForecastingLogisticsProcess engineeringGravity center

The invention provides a three-acid chemical warehouse goods location layout method based on a particle swarm optimization algorithm, and aims to realize scientific goods layout of a three-acid chemical warehouse aiming at the characteristics that the three-acid chemical warehouse is difficult in layout and easy to cause potential safety hazards due to errors. According to the goods location layout method, a three-acid chemical warehouse safety layout model consisting of a goods location longitudinal stability model and a goods location transverse gravity center stability model is establishedas an optimization objective function, an objective function is optimized through a multi-objective particle swarm optimization algorithm to obtain a three-acid chemical warehouse optimal storage scheme of the storage area length, the storage area width and the storage area chemical stacking number. The warehousing safety can be improved, the cargo warehousing efficiency can be improved, and efficient and stable operation of chemical enterprises is guaranteed.

Owner:BEIJING UNIV OF TECH

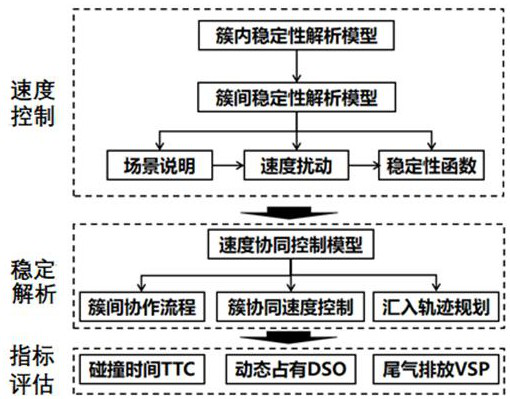

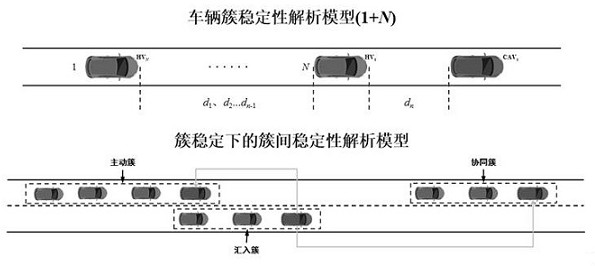

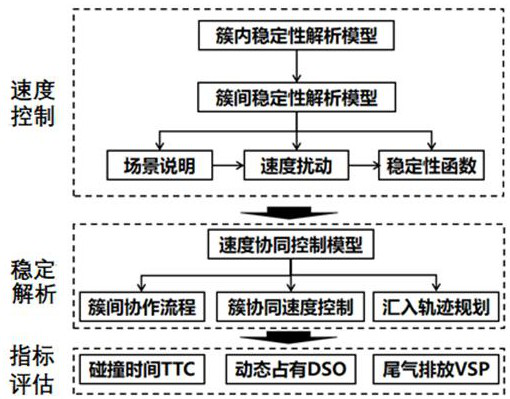

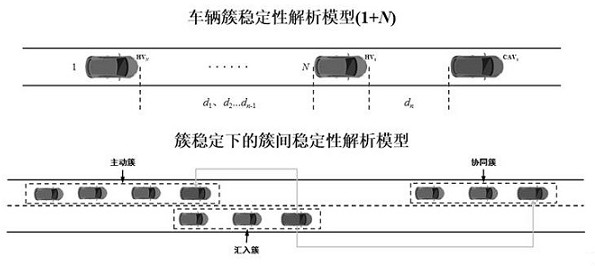

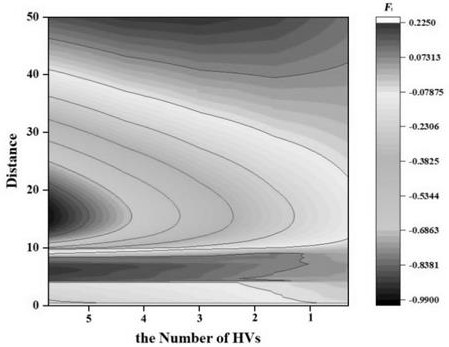

Confluence area mixed traffic speed cooperative control method based on stability analysis

ActiveCN113256988AEase traffic congestionEmission reductionDetection of traffic movementSimulationTraffic flow

The invention discloses a confluence area mixed traffic speed cooperative control method based on stability analysis, and the method specifically comprises the steps: forming a vehicle cluster in the form of '1 + N', the '1' representing one intelligent automatic driving vehicle (CAV), and 'N' representing a plurality of following artificial vehicles (HV); constructing an intra-cluster stability analysis model, and analyzing intra-cluster stability conditions; on the premise that the intra-cluster stability condition is met, constructing an inter-cluster stability model and analyzing the inter-cluster stability condition; based on intra-cluster and inter-cluster stability conditions, establishing a cluster cooperation speed control model, and under the condition that the intra-cluster and inter-cluster stability conditions are met, introducing the confluence cluster to smoothly enter the confluence area by controlling the CAV speed. According to the method, the highway confluence area is used as a research object, the speed cooperative control model is constructed on the premise of stability, the accuracy is improved, the traffic flow risk is effectively reduced, the dynamic space occupancy is improved, and tail gas emission is reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for determining safe drilling fluid density of coal bed based on structural element analysis model

InactiveCN102230373BSpecific gravity by measuring pressure differencesDrilling compositionCoal briquetteInstability

The invention discloses a method for determining the safe drilling fluid density of a coal bed based on a structural element analysis model. The method has the advantages of coal bed cleat and fracture development, big rock brittleness, low strength and obvious anisotropy and discontinuity. The borehole wall instability characteristics of the method are different from those of the common sandstone stratum. The phenomenon that the traditional borehole wall stability model based on the mechanics of continuous media is difficult to be successful for solving coal bed instability problems can be eliminated. In the method, the coal bed is composed of discrete blocks. A coal briquette which has the biggest possibility of generating spallation between surface cleats is analyzed to carry out force analysis. A structural element model of collapse pressure is built by the stressed balance condition among pressure stress, shearing strength and shaft pressure. A coefficient c is introduced to judge the stable relationship of borehole pressure and borehole wall so as to judge the range of the safe drilling fluid density.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

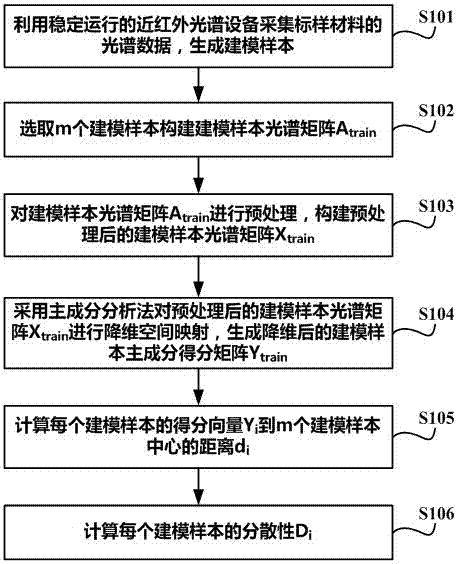

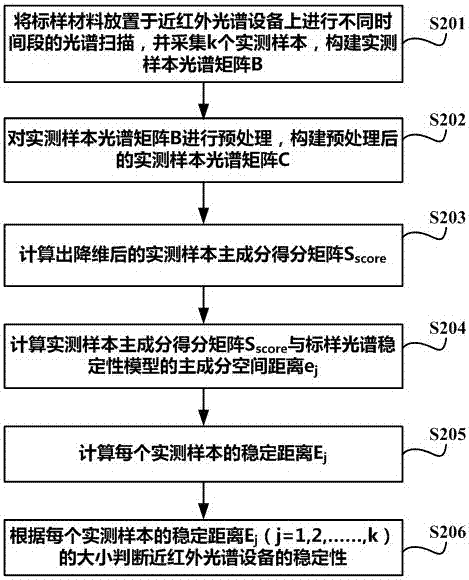

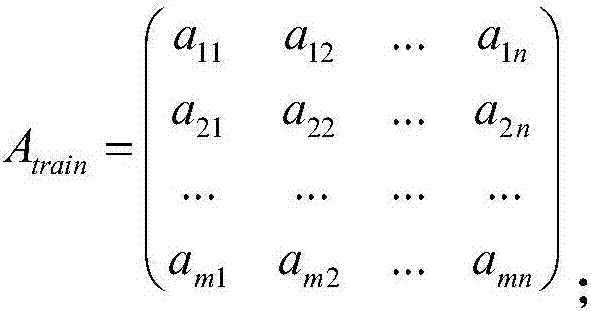

Method for discriminating stability of near-infrared spectroscopy device

ActiveCN108009569AGuaranteed stabilityImprove consistencyMaterial analysis by optical meansCharacter and pattern recognitionStable stateStability index

The invention discloses a method for discriminating the stability of a near-infrared spectroscopy device. The method comprises a construction process of a standard sample spectrum stability model anda discriminating process of the measured spectrum stability, can be objectively discriminate the stability of an unknown scanning spectrum by constructing a stability model and calculating a stabilityindex of the scanning spectrum, and further can judge, based on the stability of the scanning spectrum, whether or not a near-infrared spectroscopy device that generates the scanning spectrum is operating at a stable state at this moment to achieve the objective judgment of the stability of the near-infrared spectroscopy device. The method has a high discriminating speed, quantifies the judgmentresult, and ensures the stability and high consistency of the operation of all near-infrared spectroscopy devices under a network state.

Owner:OCEAN UNIV OF CHINA

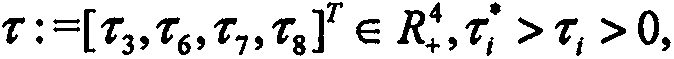

High-stability model for non-linear time-lag power system

ActiveCN108333942AEasy to solveProof of existenceAdaptive controlIntracellular substancePerformance index

The invention relates to a high-stability model for a non-linear time-lag power system. According to the model, the concentration of extracellular 1,3-propylene glycol is taken as a performance index,the approximate stability of the non-linear time-lag power system and an intermittent fermentation system, relative errors of the concentration of intracellular and extracellular substances, the stability of the concentration of intracellular substances and the like are taken as main constraint conditions, and the high-stability model is established. According to the high-stability model, the non-linear time-lag power system is established and converted into a linear variational equation, a method for linearly processing a non-linear problem is established, the non-linear time-lag power system is better solved, the condition of the high-stability model for the non-linear time-lag power system is provided, and the existence solution method of the high-stability model is given.

Owner:HUZHOU TEACHERS COLLEGE

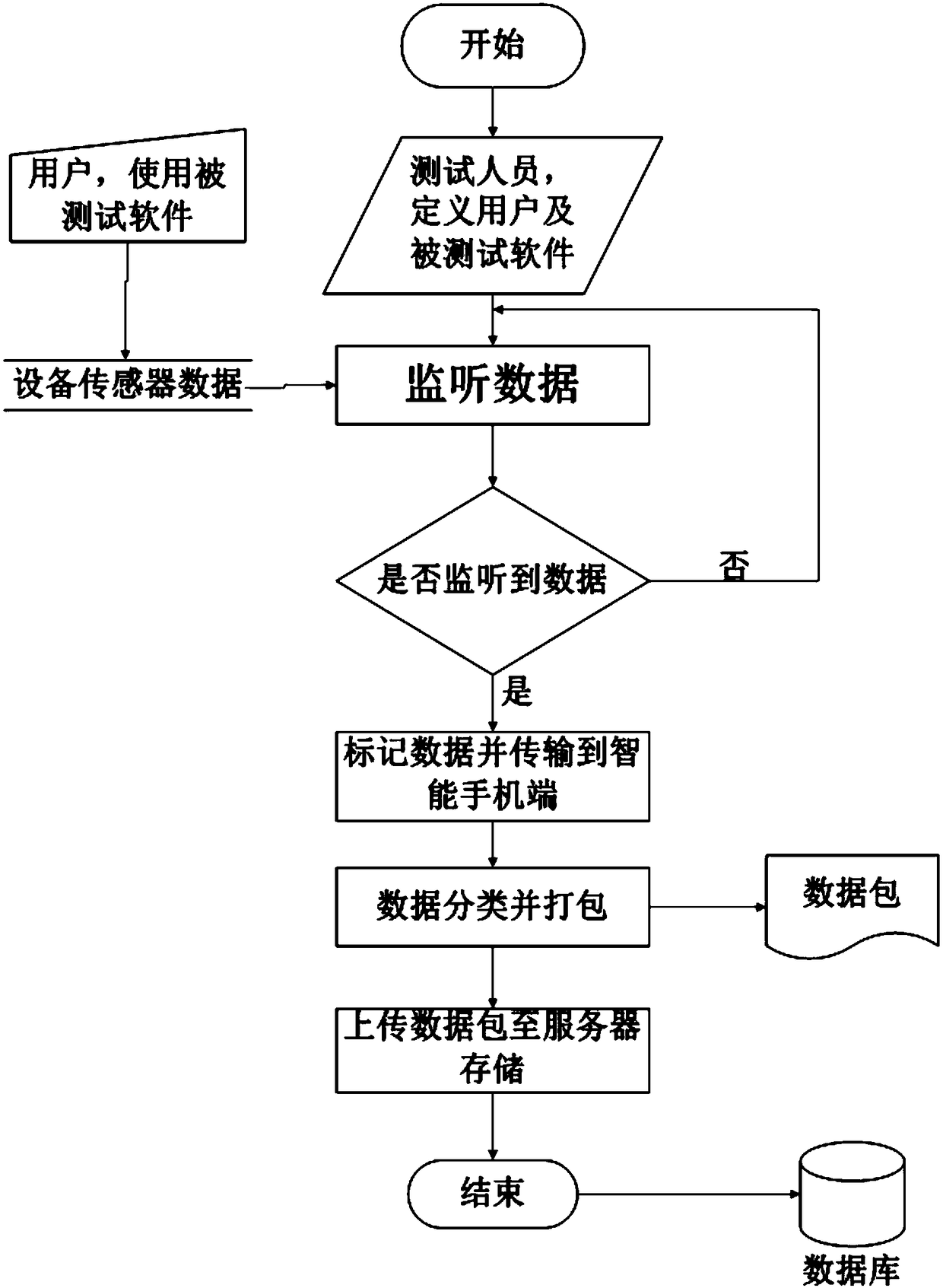

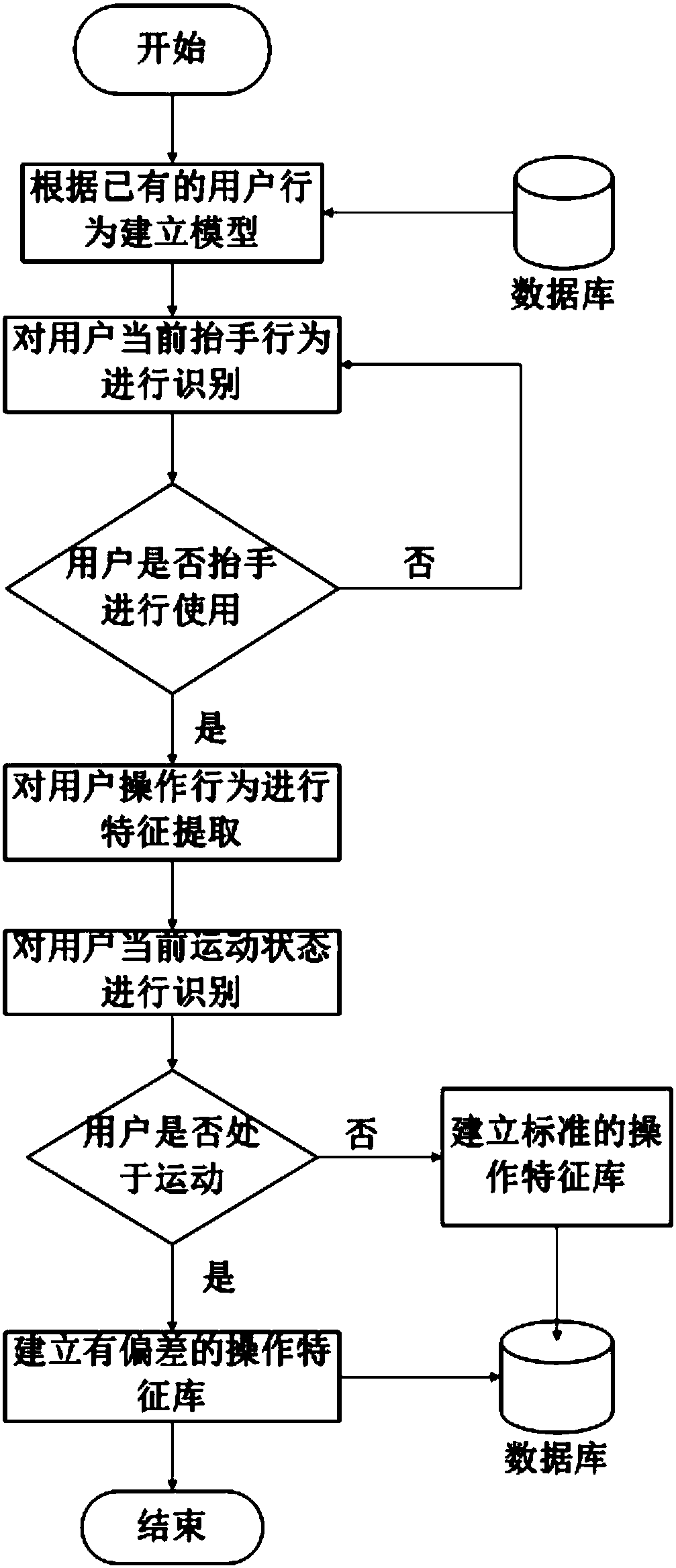

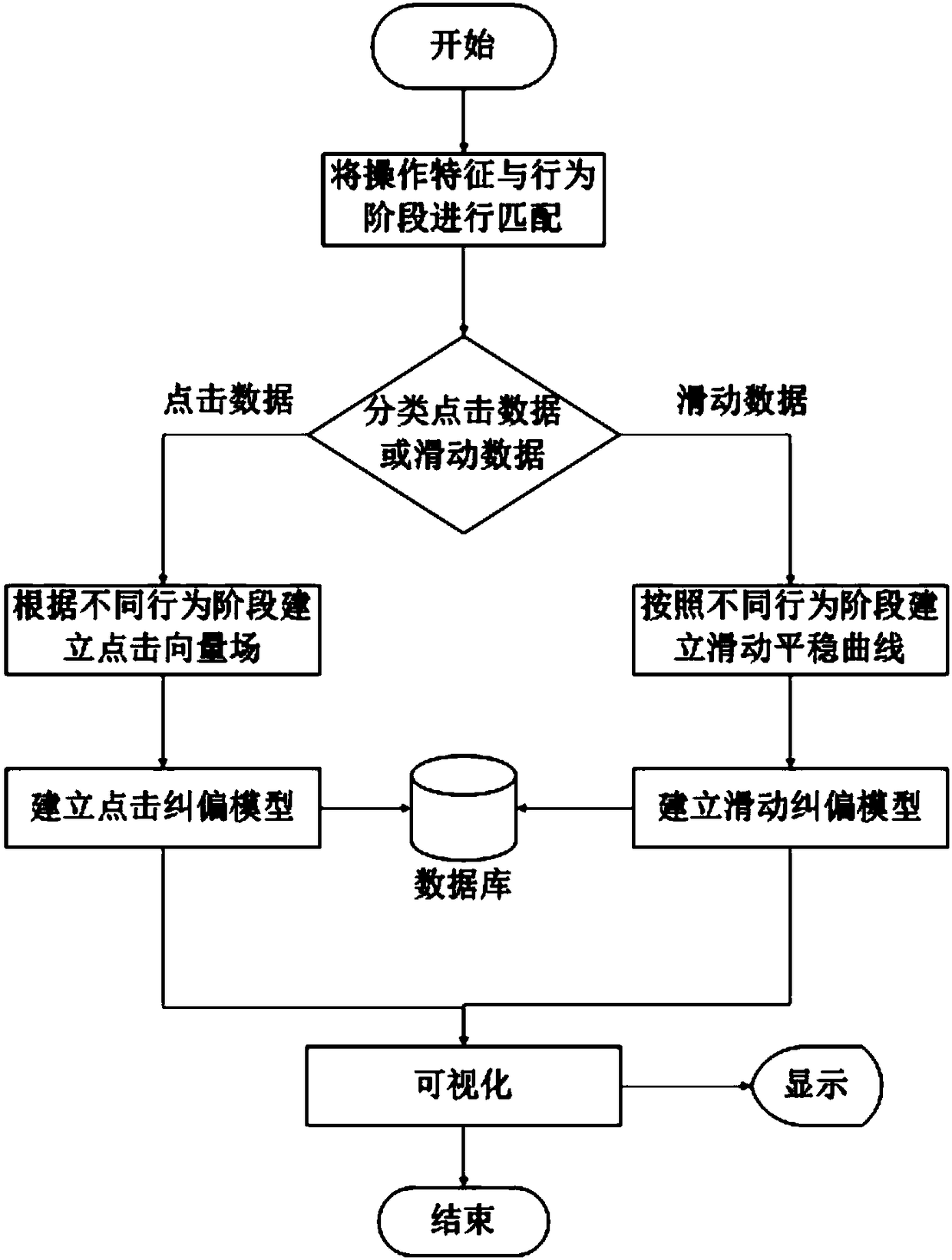

Wearable device sensor technology-based user behavior measurement method and operation deviation rectification model

ActiveCN108446019AExtensive and pervasive collectionInput/output for user-computer interactionParticular environment based servicesTest analysisData acquisition

The invention discloses a wearable device sensor technology-based user behavior measurement method and an operation deviation rectification model. The method mainly comprises the following steps of 1)performing data collection; 2) performing data uploading; 3) performing behavior analysis; 4) judging a current motion state of a user; 5) building the interface operation deviation rectification model; and 6) according to the deviation rectification model and a sliding stability model, rectifying a deviation of user operation. The invention aims to provide the wearable device sensor technology-based user behavior measurement method and the operation deviation rectification model. The user behavior data can be widely and popularly collected; the collected data can be uploaded to a shared platform for quick visualization and subsequent test analysis; and the user-based operation deviation rectification model can be built.

Owner:CHONGQING UNIV

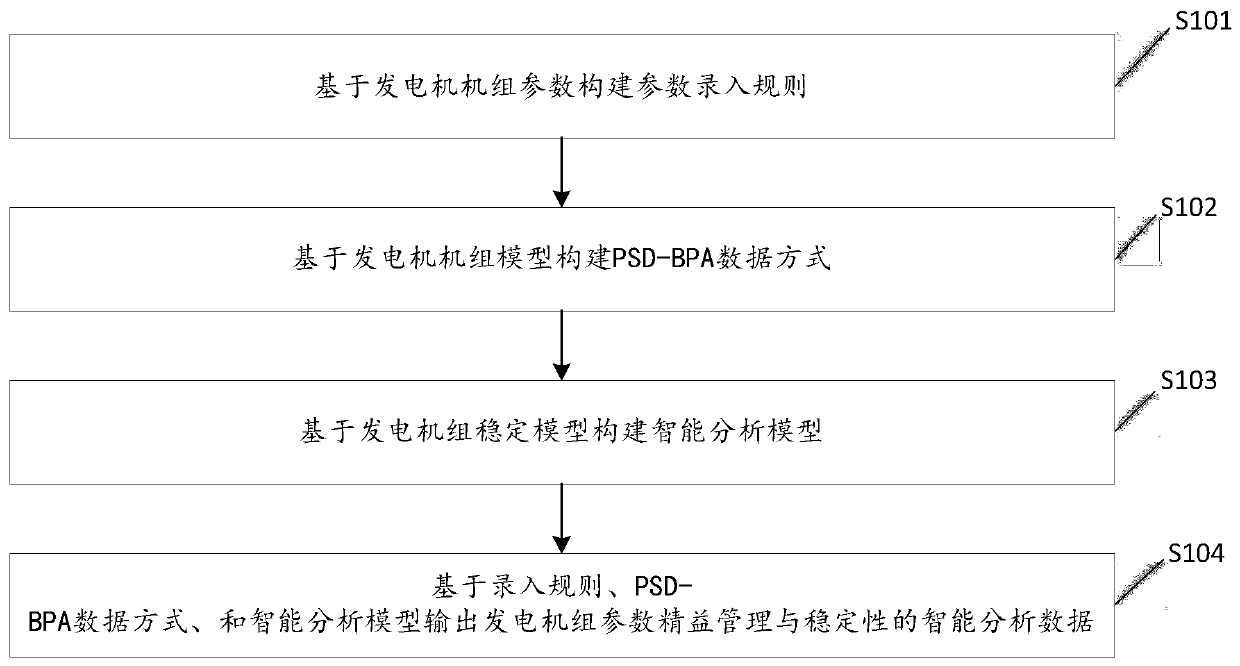

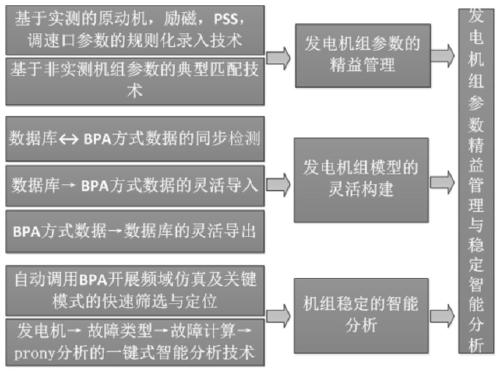

Method for lean management and stable intelligent calculation of parameters of generator set

ActiveCN111506987AStable intelligent analysisIntelligent analysis of generator set parameters integrating stable and intelligent analysisData processing applicationsDesign optimisation/simulationAnalysis dataControl engineering

The invention discloses a method for lean management and stable intelligent calculation of parameters of a generator set. The method comprises the following steps: constructing a parameter input rulebased on the parameters of the generator set; constructing a PSD-BPA data mode based on the generator set model; constructing an intelligent analysis model based on the generator set stability model;and outputting intelligent analysis data of generator set parameter lean management and stability based on the input rule, the PSD-BPA data mode and the intelligent analysis model. According to the generator set parameter intelligent analysis method integrating parameter lean management and stable intelligent analysis, the completeness of data is guaranteed, the accuracy of the data is improved, and the management level of generator set parameters is effectively improved.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

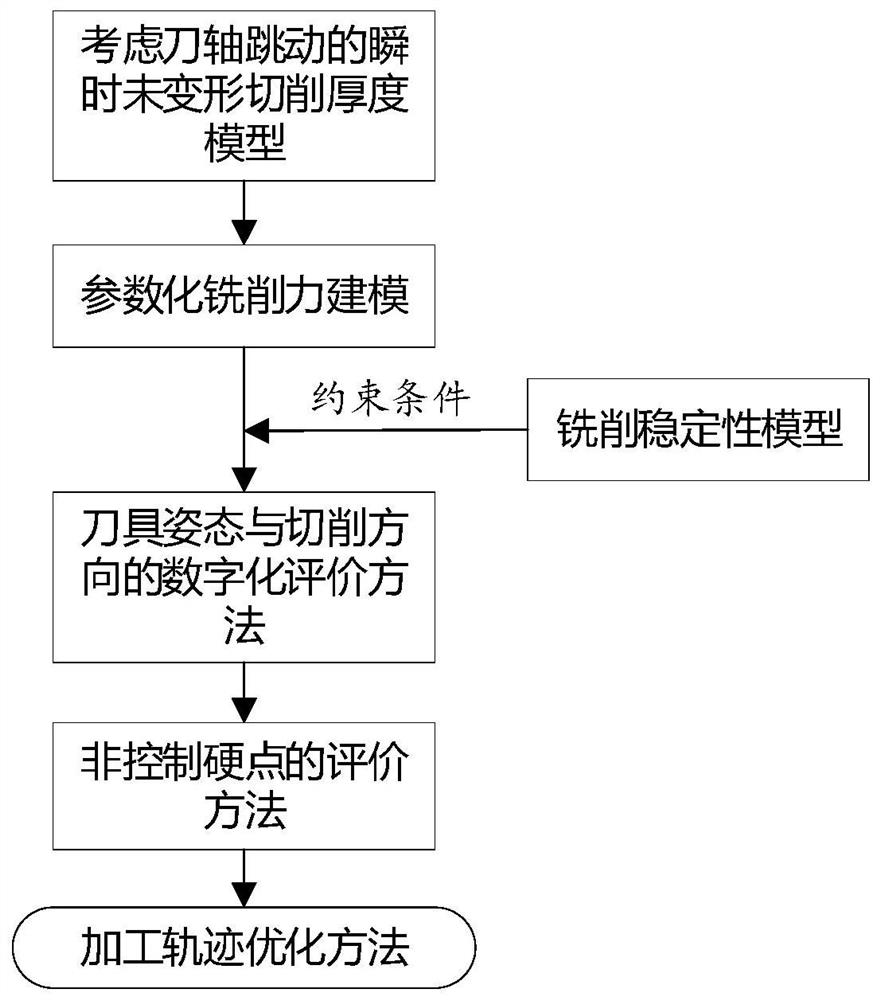

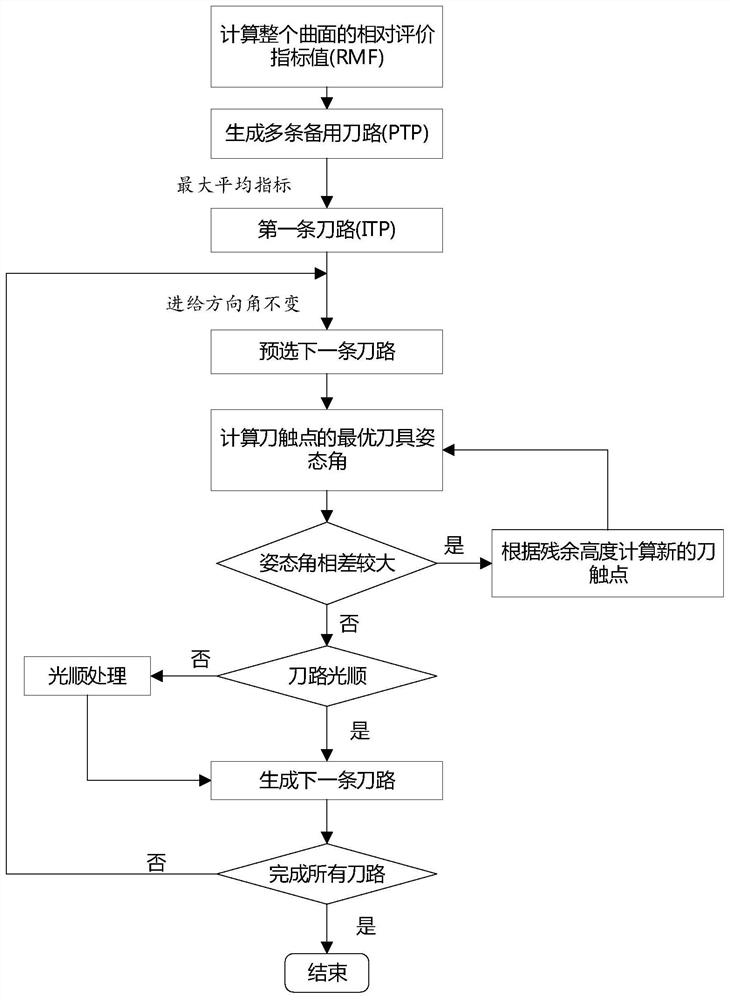

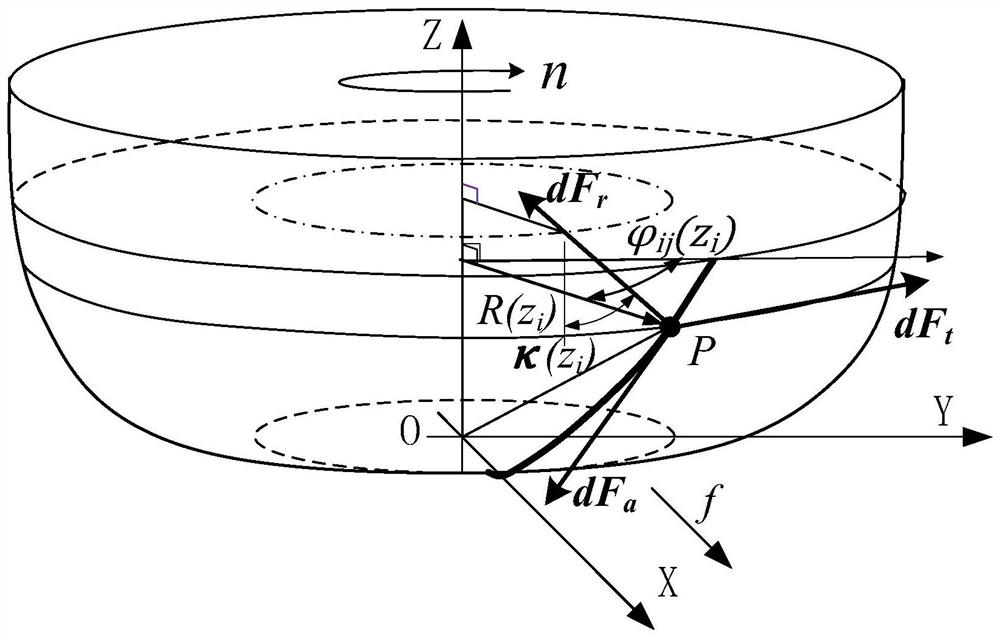

A Machining Trajectory Optimization Method Based on Parameterized Milling Force and Stability Constraints

ActiveCN111008442BImprove processing efficiencyImprove processing qualityGeometric CADDesign optimisation/simulationControl engineeringProcess engineering

The invention belongs to the field of milling processing, and specifically discloses a processing trajectory optimization method based on parameterized milling force and stability constraints. Including: considering the tool axis runout and tool attitude changes, constructing the tool cutting force model, and at the same time building the milling stability model; taking the stability model as a constraint, according to the tool cutting force model to obtain the control hard point in different tool attitudes and feeds The cutting force value of the tool under the direction, and use this to classify the angle parameters of the tool attitude, so as to construct the angle parameter classification model of the non-control hard point on the parametric surface; according to the digital angle parameter classification table of a control hard point corresponding to An ideal tool path is induced by the optimal tool pose of ; with the residual height as a constraint, all tool paths on the parametric surface are obtained. The method of the invention can plan a tool path with relatively small cutting force, which is beneficial to improving the surface quality of the workpiece, processing efficiency, tool durability and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

A speed cooperative control method for mixed traffic in merge areas based on stability analysis

ActiveCN113256988BEase traffic congestionEmission reductionDetection of traffic movementSimulationTraffic flow

The invention discloses a method for synergistic control of speed of mixed traffic in a merge area based on stability analysis, specifically: with "1+ N "The form constitutes a vehicle cluster, "1" represents an intelligent self-driving vehicle CAV," N "Represents the following multiple artificial vehicles HV; build an intra-cluster stability analysis model, and analyze the intra-cluster stability conditions; under the premise of satisfying the intra-cluster stability conditions, build an inter-cluster stability model, and analyze the inter-cluster stability conditions; based on Cluster and inter-cluster stability conditions, build cluster synergy speed control model, under satisfying cluster and inter-cluster stability conditions, guide the incoming cluster to enter the confluence area smoothly by controlling the CAV speed. The present invention takes the expressway confluence area as research Object, the speed cooperative control model is built on the premise of stability, which improves the accuracy, effectively reduces the risk of traffic flow, improves the dynamic space occupancy rate and reduces exhaust emissions.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Reliable routing method of mobile Ad hoc network

InactiveCN101534520BGuaranteed reliabilityImprove reliabilityNetwork traffic/resource managementNetwork topologiesInformation controlDependability

The invention relates to a reliable routing method in the context of a mobile Ad hoc network. The method aims to improve effectiveness of data transmission, takes combination of link stability and route selection as the core concept and solves the problem of reliable routing in the context of the Ad hoc network. In the method, data link layer design is closely linked with network layer design; the data link layer generates the newest link stability information for each node according to a link stability model; the network layer configures a link stability form according to the information; the nodes establish routings according to needs when needing to transmit data; the network layer takes the link stability form as a basis, the link stability as a standard for weighing on route selection to establish a reliable routing between the source nodes and the target nodes; a redundancy link is established for unstable links in routing paths to further improve reliability of the routing; advantages of active routing protocol and source-initiated protocol are integrated, routing reliability is ensured in that the link stability form needs to be updated in time; routing information in the routing form only needs to be updated when transmission begins, thus reducing extra expenditure for information control.

Owner:BEIHANG UNIV

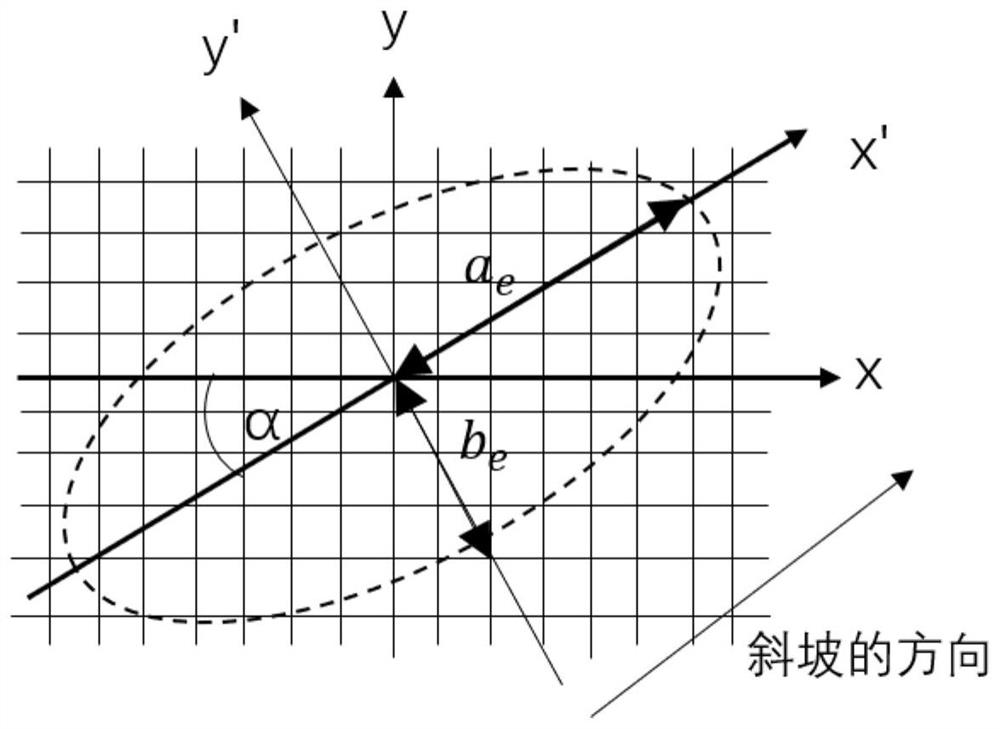

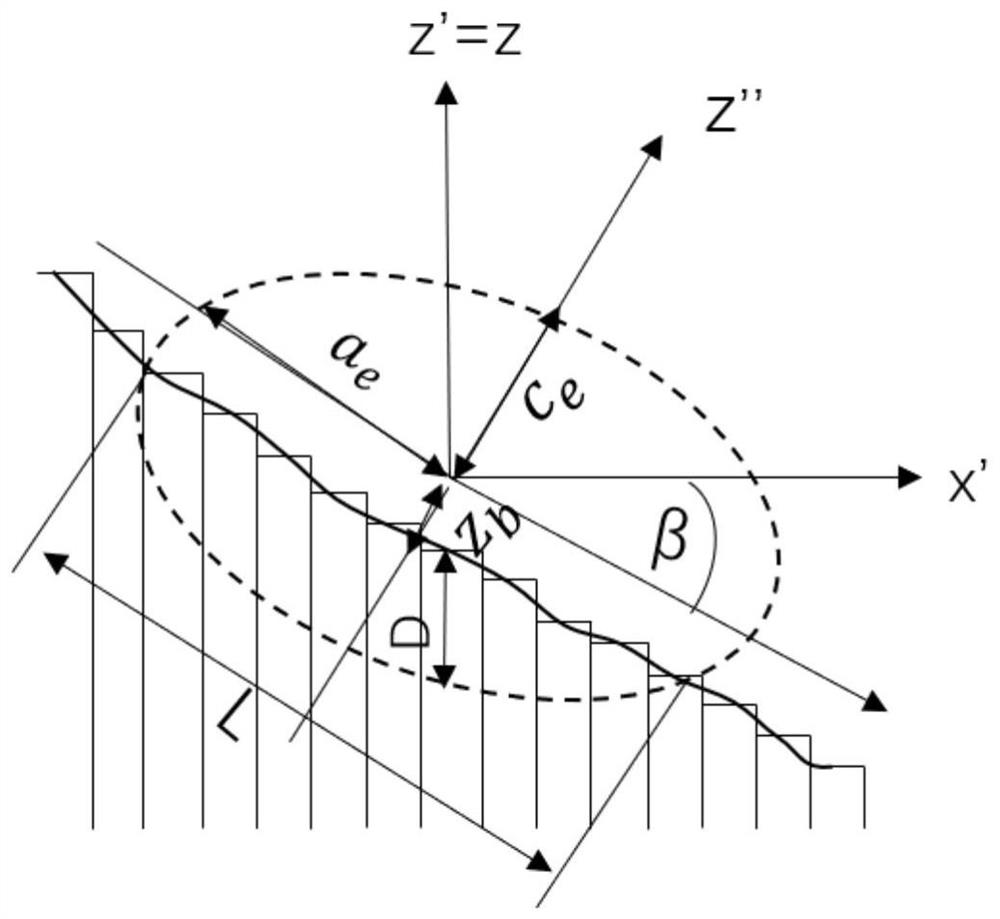

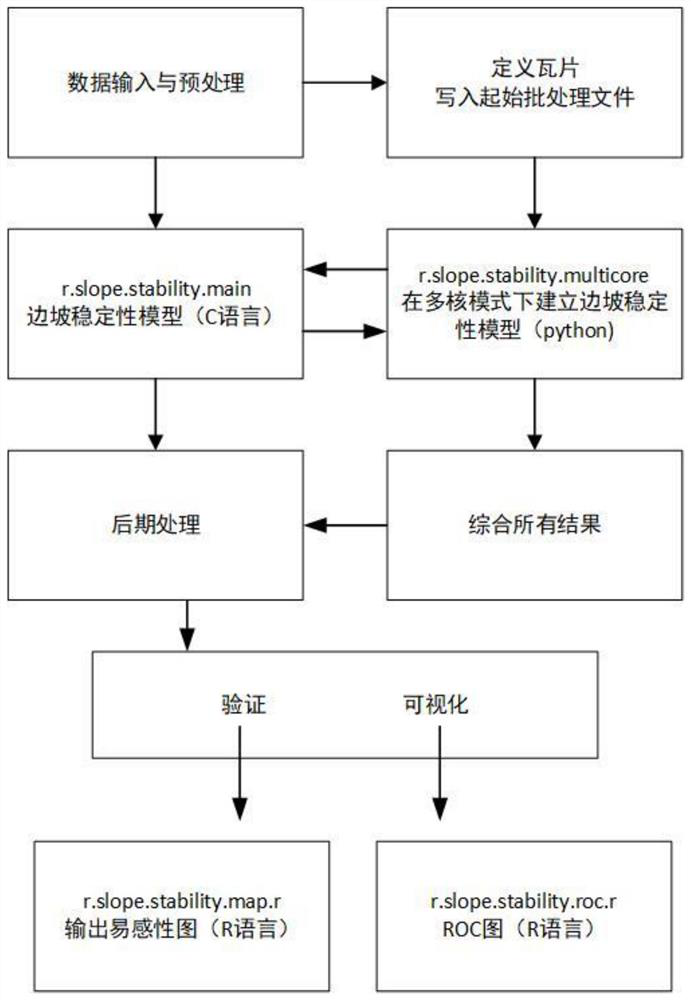

Large-area three-dimensional slope stability modeling method based on GIS

PendingCN114861285AFix memory issuesFast and efficient accessGeometric CADClimate change adaptationAlgorithmClassical mechanics

The invention relates to the technical field of landslide prevention and control, in particular to a GIS-based large-area three-dimensional slope stability modeling method, which comprises the following steps: S1, inputting data; s2, an r.slope.stability model is established, and an r.slope.stability model is established; s3, testing the number of the ellipsoids; s4, solving the problems of computer memory and operation time; s5, parameterizing the model; s6, result verification and model visualization are carried out; according to the technical scheme of the method, the calculation time and the model result of the three-dimensional slope stability model r.slope.stability based on the GIS are optimized, the safety coefficient and the slope instability probability are calculated, and the time required for large-area slope stability modeling is greatly shortened.

Owner:CHONGQING INST OF GEOLOGY & MINERAL RESOURCES +1

A Modeling Method for Parameter Stability of Quartz Flexible Accelerometer

ActiveCN106844836BGood repeatabilityGeometric CADSpecial data processing applicationsAccelerometerObservation data

The invention discloses a quartz flexure accelerometer parameter stability modeling method, namely a parameter stability modeling method for a quartz flexure accelerometer based on a random point degradation model. The method comprises the steps that first, the degradation model containing random change points is established; second, a likelihood function of observation data is estimated; third, a deficient number is separated from the observation data; and fourth, parameter estimation is performed through an EM algorithm. Through the steps, the degradation model is established through product main performance parameters, test cost and test time are saved for products with high construction cost, high reliability and long service life, and the method has practical significance; an accelerometer parameter stability model is established and the random change points are estimated mainly targeting the problem of poor parameter repeatability of the quartz flexure accelerometer to make sure accelerometer parameters gets into a stable profile cycle number, and the method has huge practical significance in practical engineering application.

Owner:BEIHANG UNIV

Strong stability model for non-linear multistage enzyme catalysis system

ActiveCN108398882AEasy to solveProof of existenceAdaptive controlBatch fermentationPerformance index

The invention relates to a strong stability model for a non-linear multistage enzyme catalysis system. According to the model, an optimization method is adopted to reveal a problem that a reactant hasdifferent characteristics at different batch fermentation phases. The strong stability model is established in such a way that concentration of extracellular 1, 3-propylene glycol is used as a performance index, and approximate stability of a hybrid nonlinear dynamic system and a batch fermentation system, a relative error of concentration of intracellular and extracellular substances, biologicalrobustness of concentration of the intracellular substances are used as main constraints; research is conducted on a non-linear power system of which a analytical solution cannot be obtained and of which no equilibrium point is available. Via the strong stability model, a non-linear multistage power system is built and converted into a linear variation equation, a linear processing method for non-linear problems is established, the non-linear multistage power system is well solved, conditions for the strong stability model for a non-linear multistage batch enzyme fermentation catalysis powersystem are put forward, and output of the system can be maximized via calculation based on a control model.

Owner:HUZHOU TEACHERS COLLEGE

Milling finish machining method based on dynamic rigidity of impeller blade

ActiveCN102554326BSolve the problem of cutting chatterImprove processing stabilityMilling equipment detailsSpecial data processing applicationsImpellerDiagnostic Radiology Modality

The invention discloses a milling finish machining method based on the dynamic rigidity of an impeller blade. The dynamic modality of the impeller blade is obtained through a standard modal test, a flutter model is introduced to obtain a stability criterion, and reasonable machining parameters are acquired. The method comprises the followings steps of: 1, performing the modal test to measure the dynamic modality of the impeller blade; 2, building a milling stability model of the impeller blade; 3, studying the dynamic rigidity stability of the impeller blade; 4, obtaining a cutting stability condition under the dynamic rigidity of the impeller blade; and 5, verifying the cutting stability condition and adopting the finally optimized cutting parameters to machine. The problem of cutting flutter caused by milling of thin-walled parts such as the blade is solved by the method, and the machining stability is obviously improved by optimizing the cutting parameters. The method is suitable for finish machining of various thin-walled parts.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com