Milling finish machining method based on dynamic rigidity of impeller blade

An impeller blade, dynamic stiffness technology, applied in the field of machining, can solve problems such as the importance of suppression not involved, achieve the effect of improving machining stability and solving cutting chatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

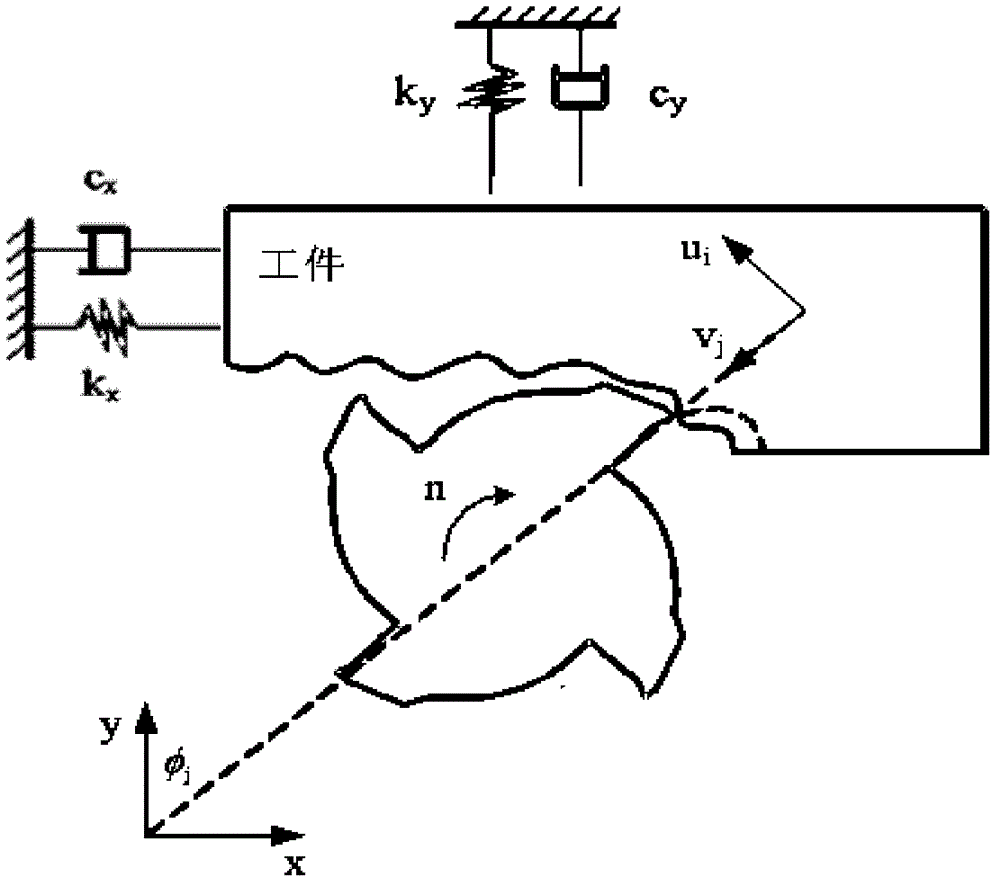

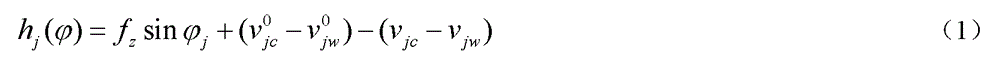

[0017] The content of the milling finishing method based on the dynamic stiffness of the impeller blade according to the present invention is to obtain the dynamic mode (damping ratio, stiffness, natural frequency, effective mass) of the impeller blade through the standard modal test, and then introduce flutter The model can be used to obtain the stability criterion, so as to obtain reasonable processing parameters.

[0018] The present invention will be further described below in conjunction with the accompanying drawings, and the details of each step will be set forth.

[0019] Processing method of the present invention comprises the steps:

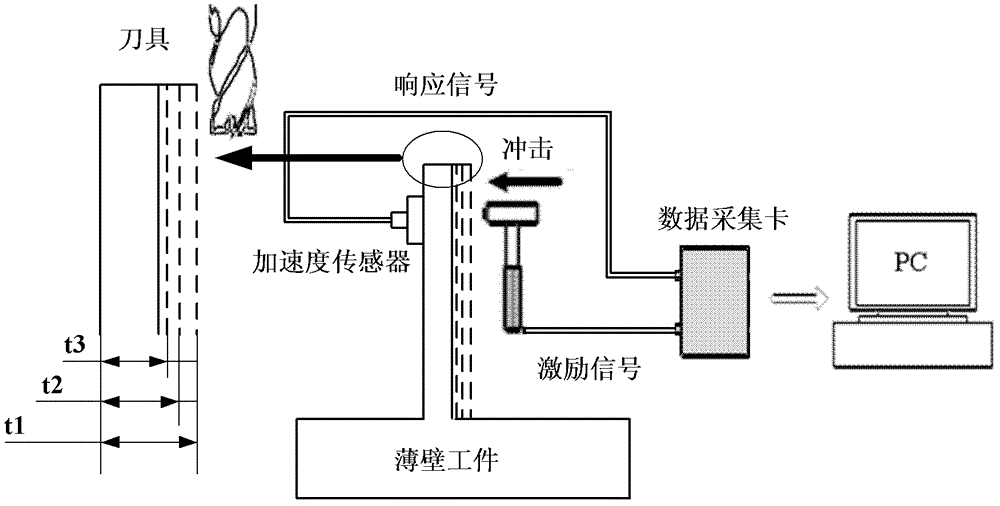

[0020] Step 1: Modal test to determine the dynamic mode of the impeller blade: the principle is as follows figure 1 As shown in , the standard hammer impact test is adopted, by collecting the impact excitation signal of the hammer and the response signal of the acceleration sensor, aiming at the changing wall thickness t 1 , t 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com