Milling multi-objective optimization decision-making method introducing three-dimensional stability constraint

A multi-objective optimization and milling processing technology, applied in the field of mechanical processing technology, can solve problems such as cumbersome operations, large limitations, and inaccurate predictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0117] The drawings constituting a part of the present invention are used to provide a further understanding of the present invention, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, and do not constitute an improper limitation of the present invention.

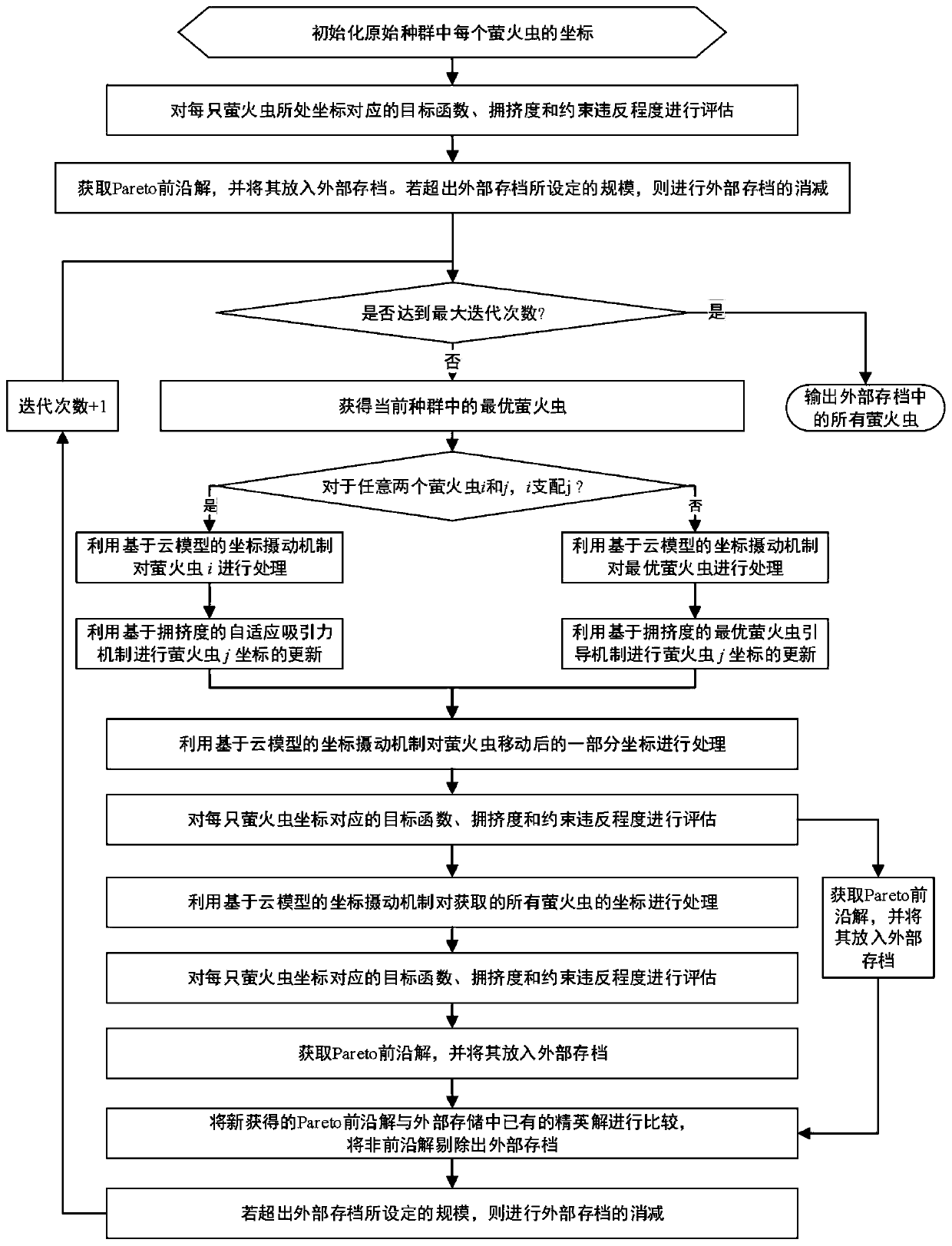

[0118] This embodiment provides a milling multi-objective optimization decision-making method that introduces three-dimensional stability constraints, including the following steps

[0119] Step 1: Identify and acquire the modal parameters of the milling system through the hammer excitation method;

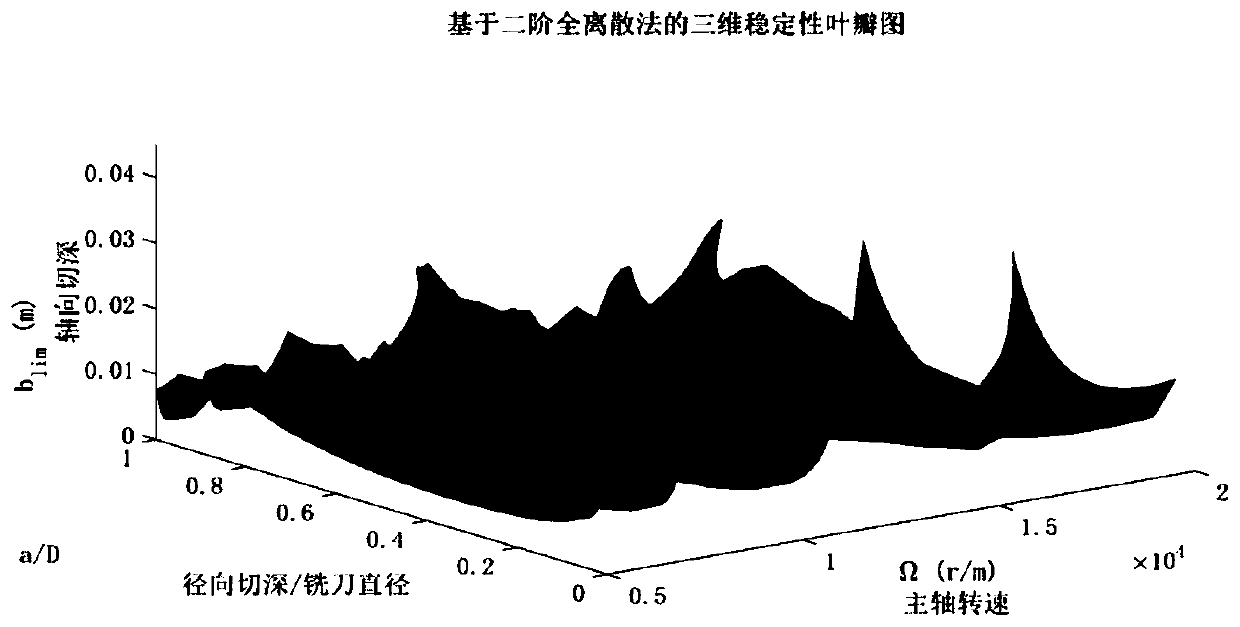

[0120] Step 2: and use the modal parameters and the second-order full discrete method to construct a milling three-dimensional stability model about the spindle speed Ω, the axial depth of cut d and the radial depth of cut a;

[0121] Step 3: According to the milling process of the CNC machine tool, the objective function of the milling process parameter optimizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com