Passing type gang drill online production system and production method thereof

A production system and control system technology, applied to fixed drilling machines, etc., can solve problems such as increased labor costs and lower profit margins, and achieve the effects of increasing profit margins, saving labor costs, and realizing automatic operation of the entire process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Examples of the embodiments are shown in the accompanying drawings, and the specific embodiments described in the following embodiments of the present invention are only illustrative illustrations of specific embodiments of the present invention, and are intended to explain the present invention, rather than constituting a limitation of the invention.

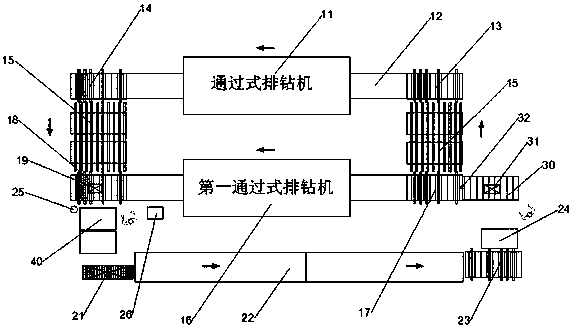

[0027] The through-type row drill production system provided by the present invention, such as figure 1 As shown, it is electrically connected with the control system (not shown in the figure) and is controlled by the control system, including the panel drilling part and the panel turning part set on the side of the panel drilling part, for loading materials to be processed The unpowered roller 30 of the panel is arranged at the feed end of the panel drill section, and the plate receivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com