Three-acid chemical warehouse goods location layout method based on particle swarm optimization algorithm

A technology of particle swarm optimization and layout method, which is applied in computing, instruments, data processing applications, etc., to achieve the effect of improving storage safety and storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

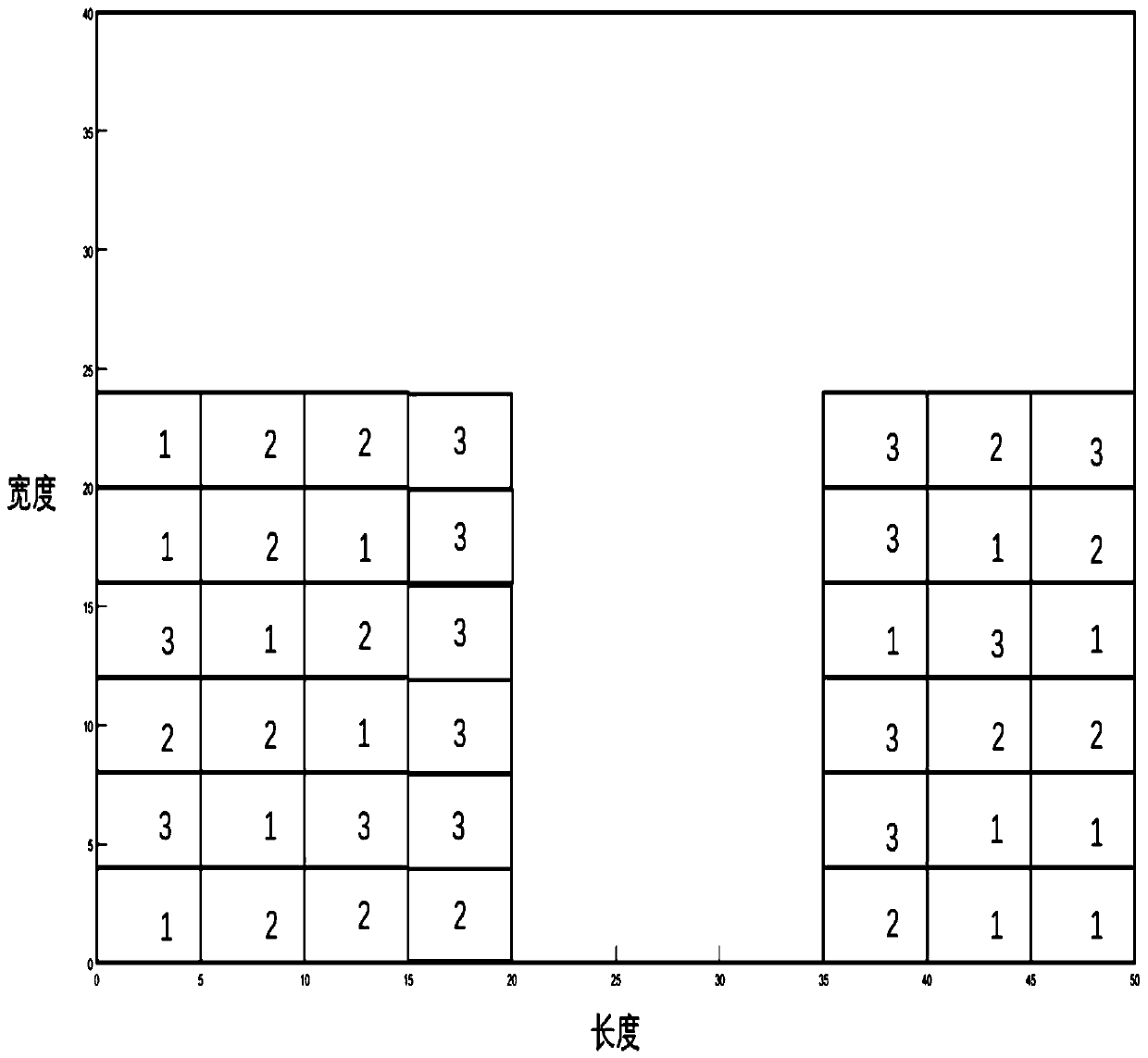

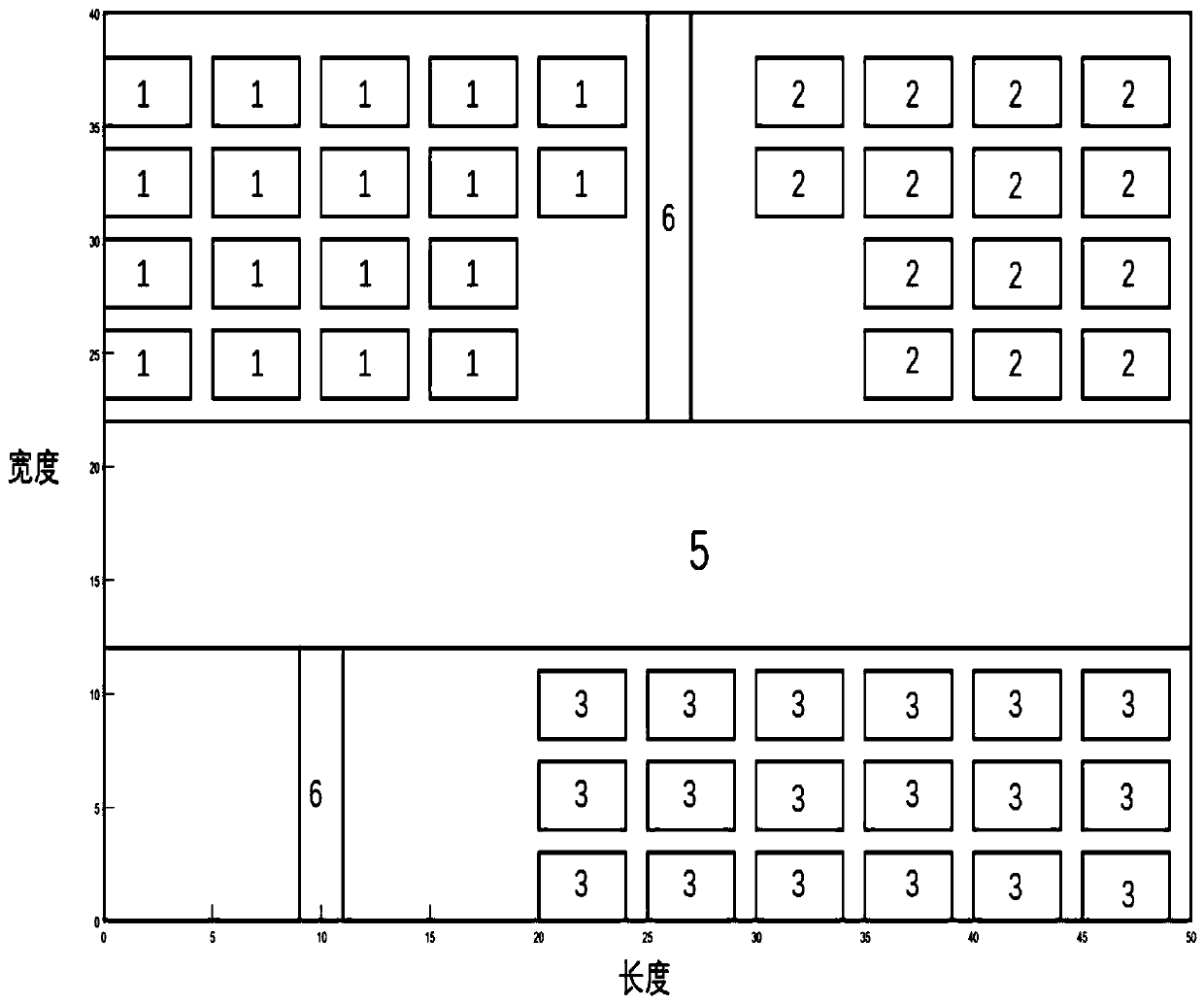

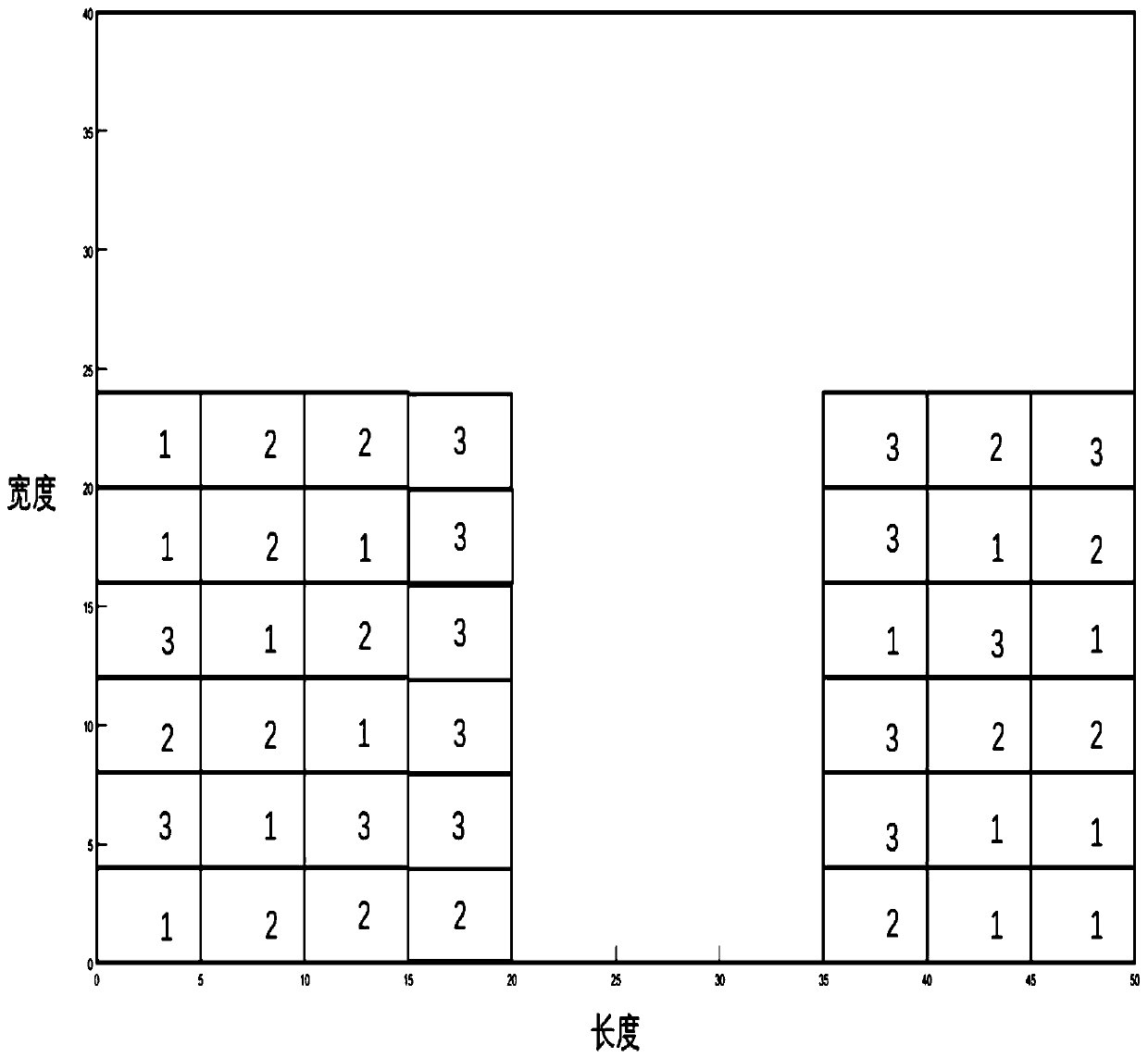

[0040] The present invention adopts following technical scheme and implementation steps:

[0041] (1) Select the variables related to the safety model of the storage space of the Sanacid Chemical Warehouse, specifically: the length L of the first storage area of the Sanacid Chemical Warehouse 1 , the length L of the second storage area 2 , the length L of the third storage area 3 , the length L of the fourth storage area 4 ;Width W of the first memory area 1 , the width W of the second storage area 2 , the width of the third memory area W 3 , the width W of the fourth storage area 4 ;Number of chemical stacks in the first storage area N 1 , the number of chemical stacks N in the second storage area 2 , the number of chemical stacks N in the third storage area 3 , the number of chemical units in the fourth storage area N 4 ;

[0042] (2) Establish a safety model for the storage space of the three-acid chemical warehouse:

[0043]

[0044]

[0045] Restriction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com