Milling vibration stability predicating method based on process damping effect

A technology of stability prediction and milling chatter, which is applied in special data processing applications, program control, instruments, etc., can solve the problems of less research and achieve the effect of improving accuracy and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

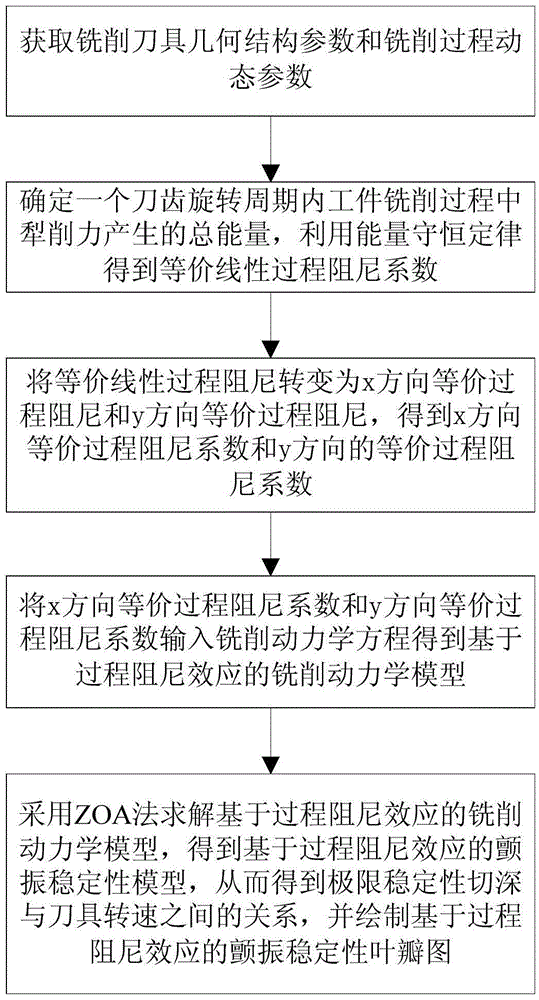

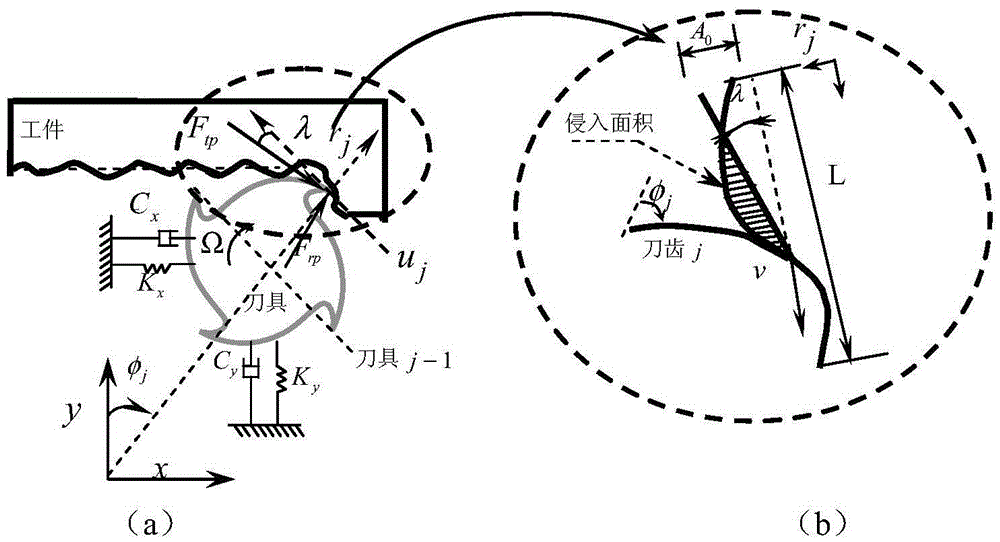

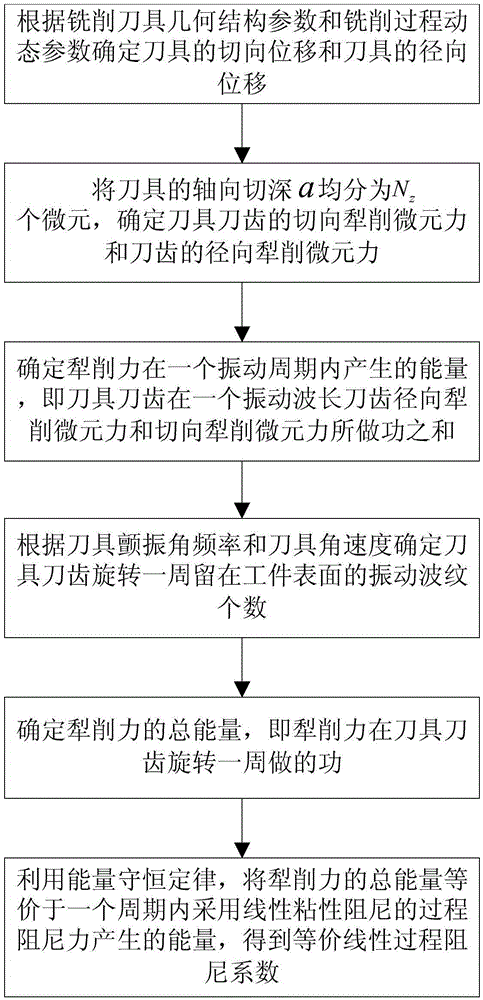

[0036] The present invention provides a milling chatter stability prediction method based on the over-damping effect, which decomposes the vibration of the tool into radial reciprocating vibration and tangential linear motion, and calculates within one vibration period of the cutter tooth. The work done by the intrusion force that intrudes into the machined surface of the workpiece is then multiplied by the number of complete vibration ripples in one rotation cycle of the tool, and the nonlinear damping is equivalent to linear damping by using the principle of energy equivalence, and the frequency domain method is used to solve the chatter stability The lobe map enables efficient and accurate prediction of depth-of-cut limits for chatter stability during low-speed milling. Therefore, it provides theoretical guidance for optimizing cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com