Method for determining safe drilling fluid density of coal bed based on structural element analysis model

A technology of drilling fluid density and analysis model, applied in drilling composition, chemical instruments and methods, by measuring the pressure difference to determine the specific gravity and other directions, can solve the problem of significant anisotropy and discontinuity, ineffectiveness, and low strength And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, specific implementations of the present invention will now be described with examples.

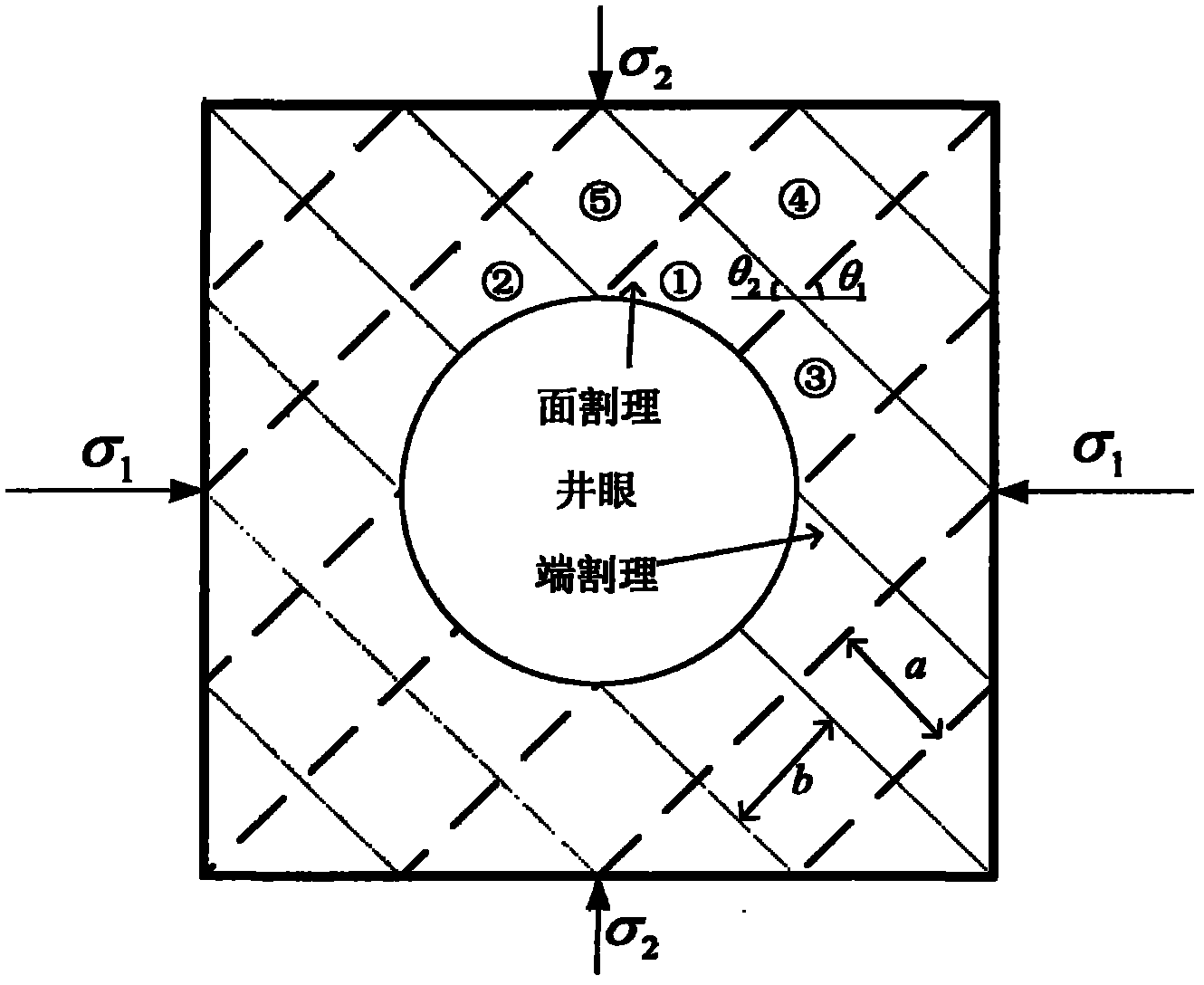

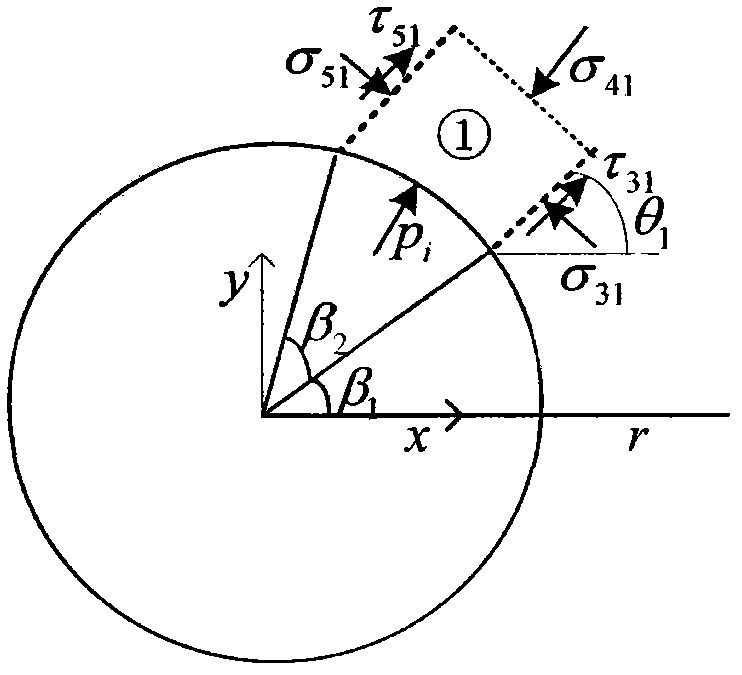

[0047] 1. Determine the relevant geological parameters of the target coal seam, such as the distance between cleats a / r i =0.1, end cleat spacing b / r i =0.1, cleat dip angle θ 1 = θ 2 =45°, ground stress σ 2 / σ 1 =0.9, cleat surface friction angle

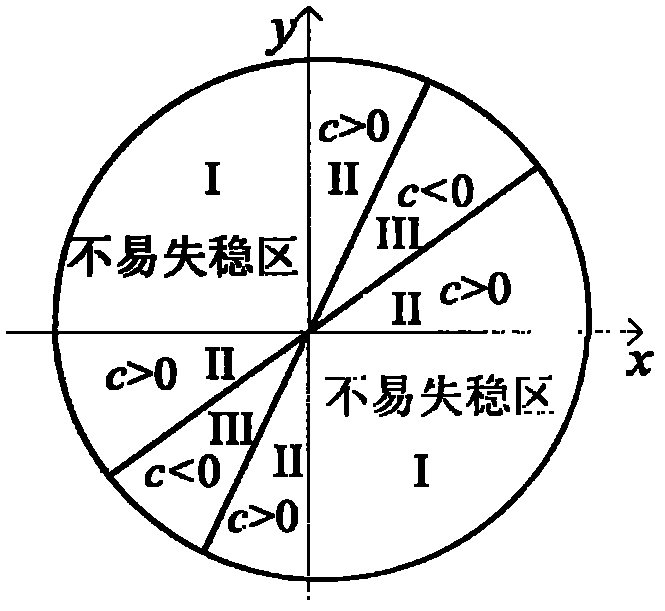

[0048] 2. p in judgment formula (10) c The sign of the coefficient c. E.g Corresponding to c>0, Corresponding to c The corresponding value of c changes to a plus or minus sign.

[0049] 3. Determine safe drilling fluid density. Figure 4 middle Corresponding to c>0, the safe mud pressure should be greater than the critical value (maximum value of the curve); Corresponding to c Figure 5 Medium beta 1 In the intervals of 11-20 degrees and 63-78 degrees, the value of c is close to 0, indicating that the stabil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com