Ram of electric spark forming machine suitable for C-axis mounting

A shaft installation and forming machine technology, applied in the direction of attachments, electric processing equipment, metal processing equipment, etc., can solve the problems of non-common equipment parts, low processing efficiency, difficult assembly operation, etc., to prevent infiltration, ensure universality, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

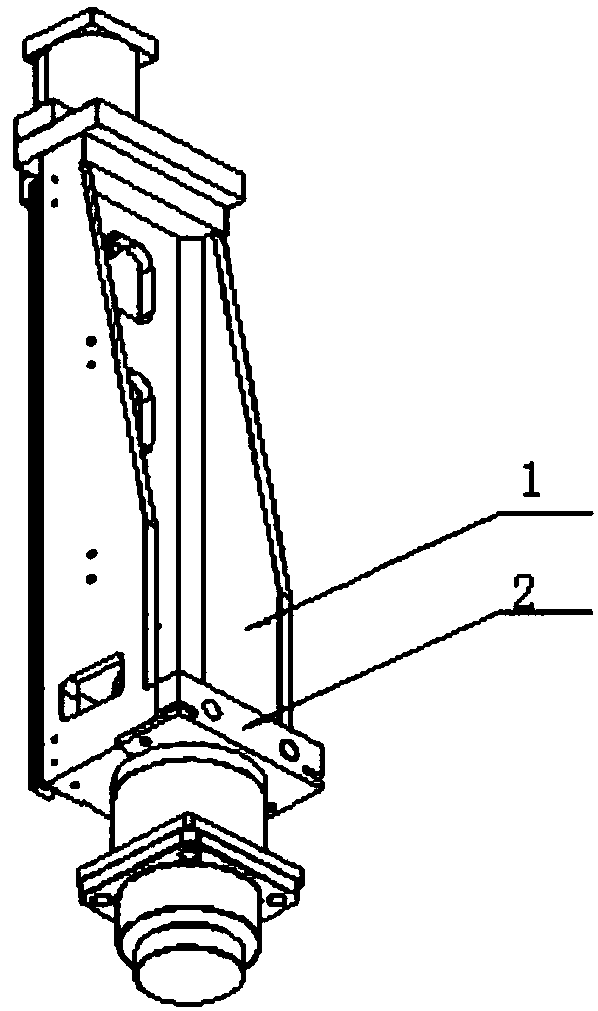

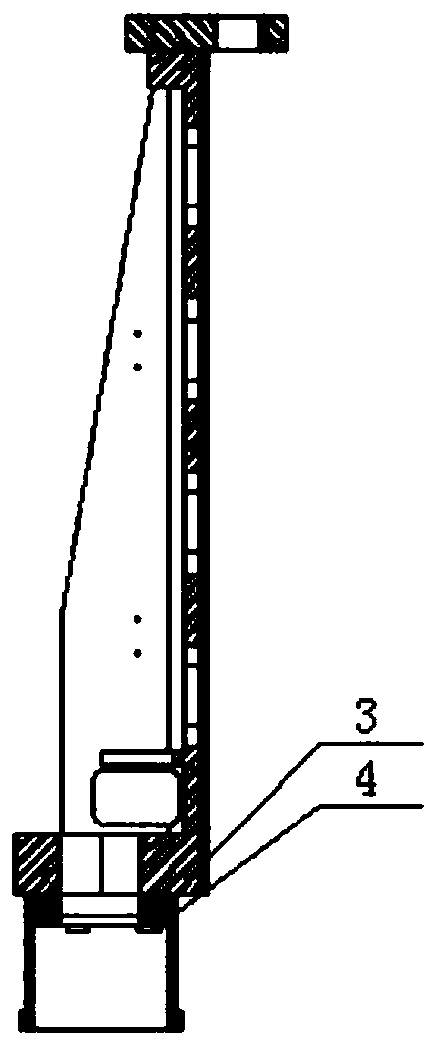

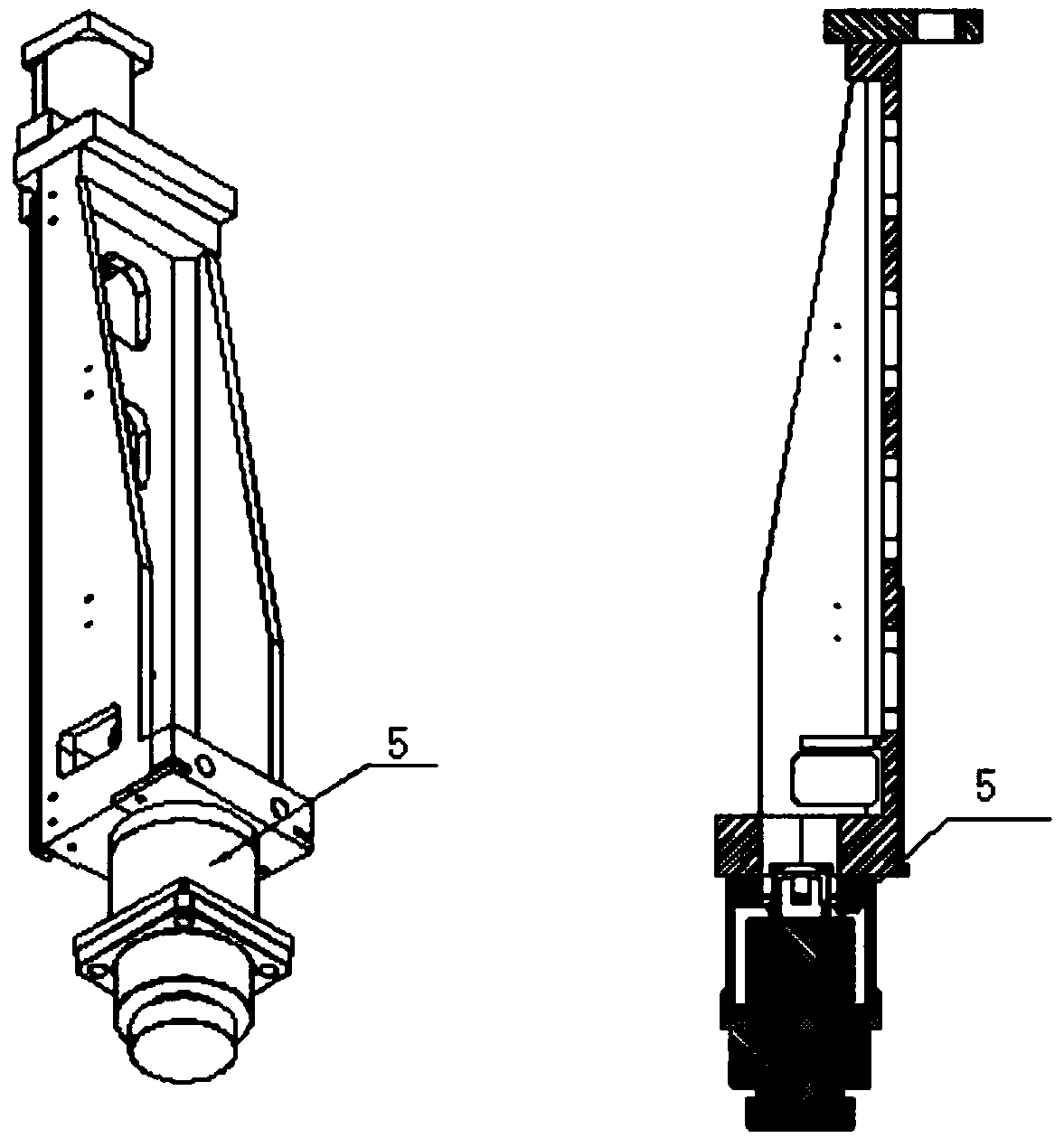

[0019] Such as Figure 1-4 As shown, an EDM ram suitable for C-axis installation includes a split structure of the Z-axis lifting pallet and clamping plate, an insulation mechanism and a split structure of the C-axis mounting seat, wherein:

[0020] Z-axis lifting pallet and clamping plate split structure: Z-axis lifting pallet 1 and clamping plate 2 are separated, and the bottom of Z-axis lifting pallet 1 is cast with a semi-circular hole, which is matched with the semi-circular hole of clamping plate 2, through contact The Z-axis lift plate 1 and the clamping plate 2 are locked by two hexagon socket screws in the direction of the contact surface, which is easy to process and easy to disassemble and maintain; at the same time, to ensure the assembly accuracy, the bottom of the clamping plate and the semicircle hole After the rough machining is completed, it can be installed on the Z-axis lifting pallet, and it will be milled and finished together to ensure the verticality of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com