Chain wheel tooth form precision processing technology

A precision machining and tooth shape technology, applied in the field of mechanical processing, can solve the problems of poor machining accuracy and low machining efficiency, and achieve the effect of better machining accuracy and higher machining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

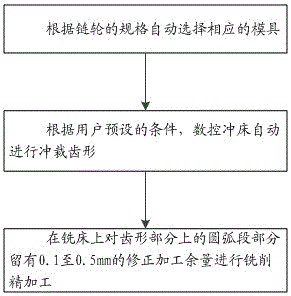

[0022] In the first embodiment, a sprocket tooth shape precision machining process is provided, please refer to figure 1 , the process includes:

[0023] Automatically select the corresponding mold according to the specifications of the sprocket;

[0024] According to the preset conditions of the user, the CNC punching machine automatically punches the tooth profile;

[0025] On the milling machine, a correction machining allowance of 0.1-0.5 mm is left on the arc section of the tooth portion for milling finishing.

[0026] Wherein, in the embodiment of the present application, the mold includes: a spring-tooth tooth-shaped arc segment mold and a multi-tooth tooth-shaped arc segment mold.

[0027] Wherein, in the embodiment of the present application, a correction machining allowance of 0.1-0.5 mm is left on the arc section of the toothed portion that is in contact with the chain rollers.

[0028] Wherein, in the embodiment of the present application, the turned sprocket bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com