Aluminium section bar panel frame and method for manufacturing the same

A technology of processing and manufacturing aluminum profiles, which is applied in the field of aluminum profile panel frames and processing and manufacturing, can solve the problems that aluminum alloy frames cannot be stamped and formed, and achieve the effects of simple structure, good effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

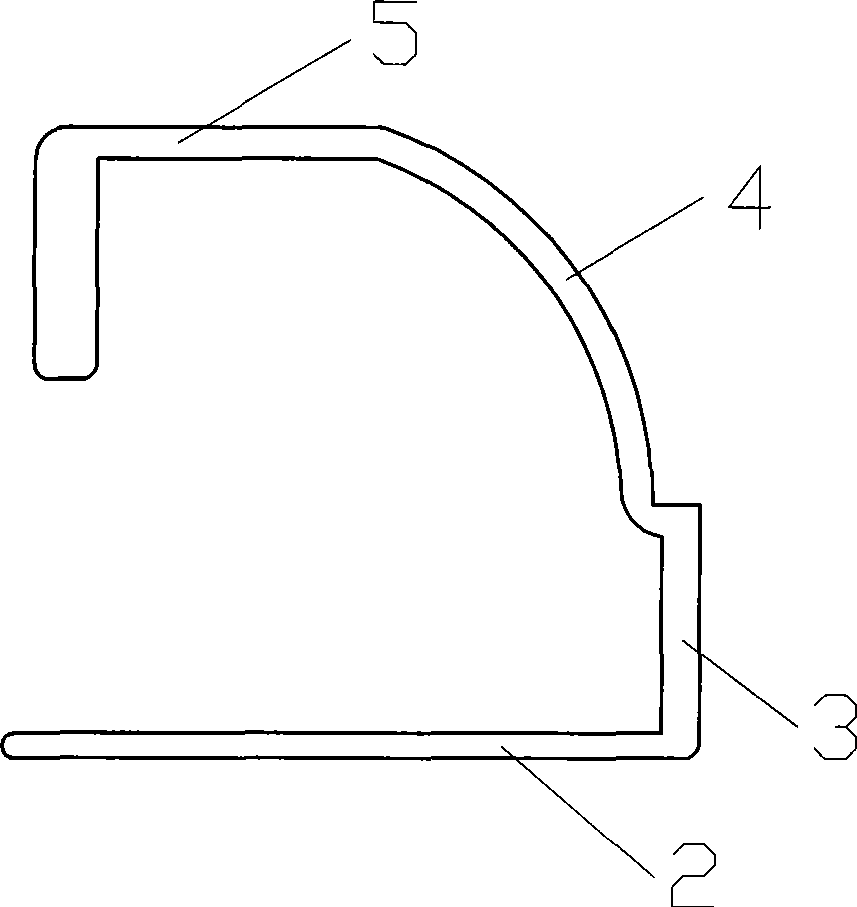

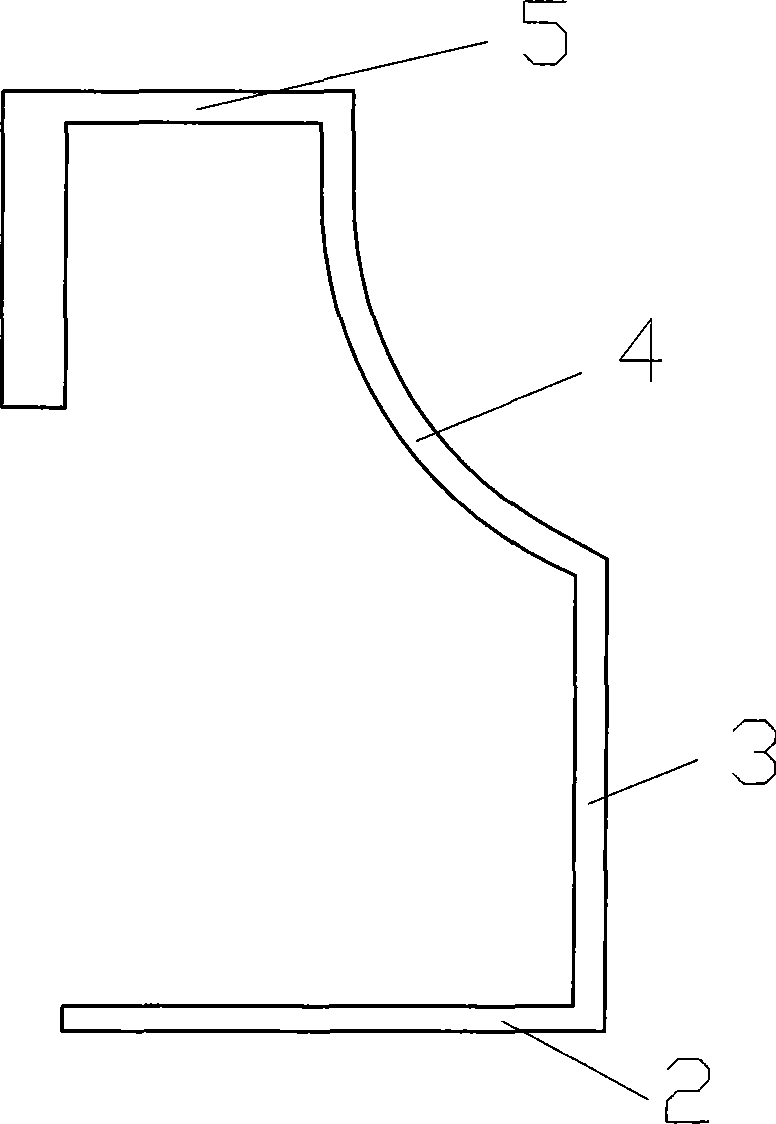

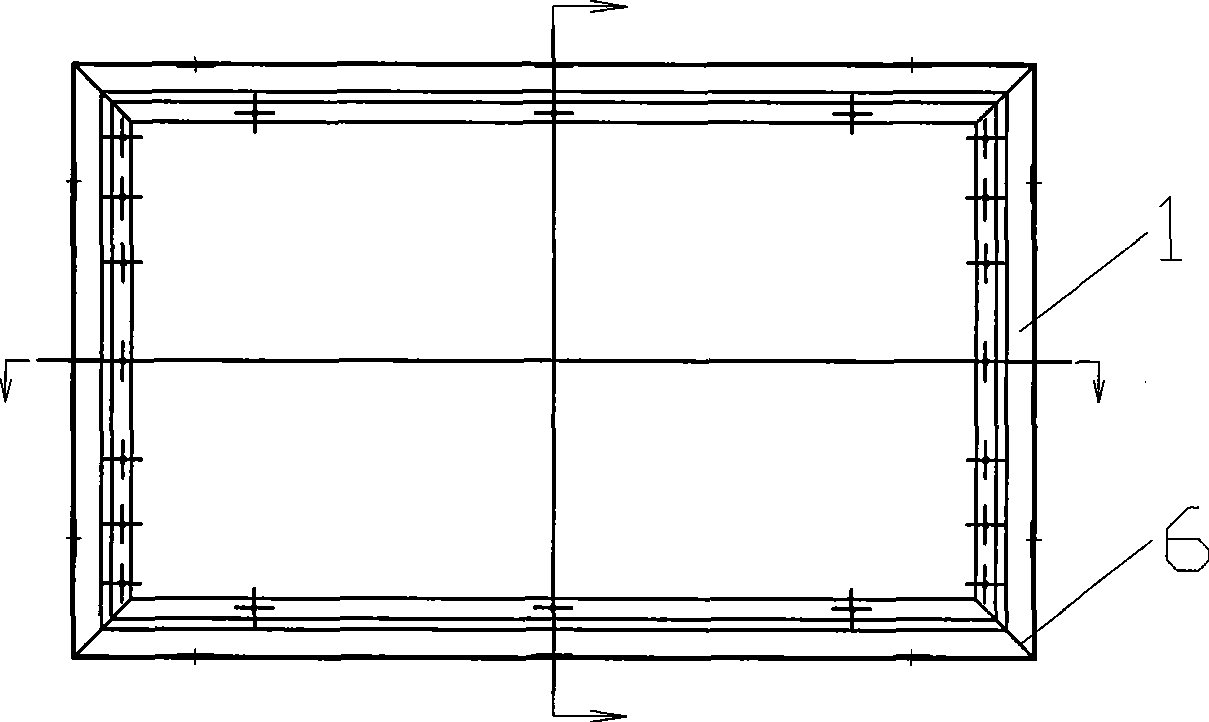

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings: the aluminum profile frame of the present invention is a quadrilateral frame formed by connecting four frame bars in pairs, and the frame bar 1 is an extruded profile bar with a special shape in cross section constitute, such as figure 1 , 2 shown. combined with image 3 , 4 As shown, the frame strip edge 2 around the quadrangular frame is an inlay edge that can be buckled to the ceiling keel, and the inlay edge is perpendicular to the upper surface of the quadrangular frame 3; the frame strip 1 is opposite to the frame The inner side of the strip edge 2 is provided with a special-shaped connecting edge 4 that shrinks inwardly relative to the upper surface, and the special-shaped connecting edge 4 is connected to the inner side 5 parallel to the frame strip edge 2 .

[0014] Both ends of the four frame strips 1 are obliquely cut into 45-degree hypotenuse 6 and spli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com