Low helical abrasion-proof drill rod for mash gas pumping drilling construction and machining process thereof

A technology for gas extraction and processing technology, applied in drill pipe, gas discharge, metal material coating technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

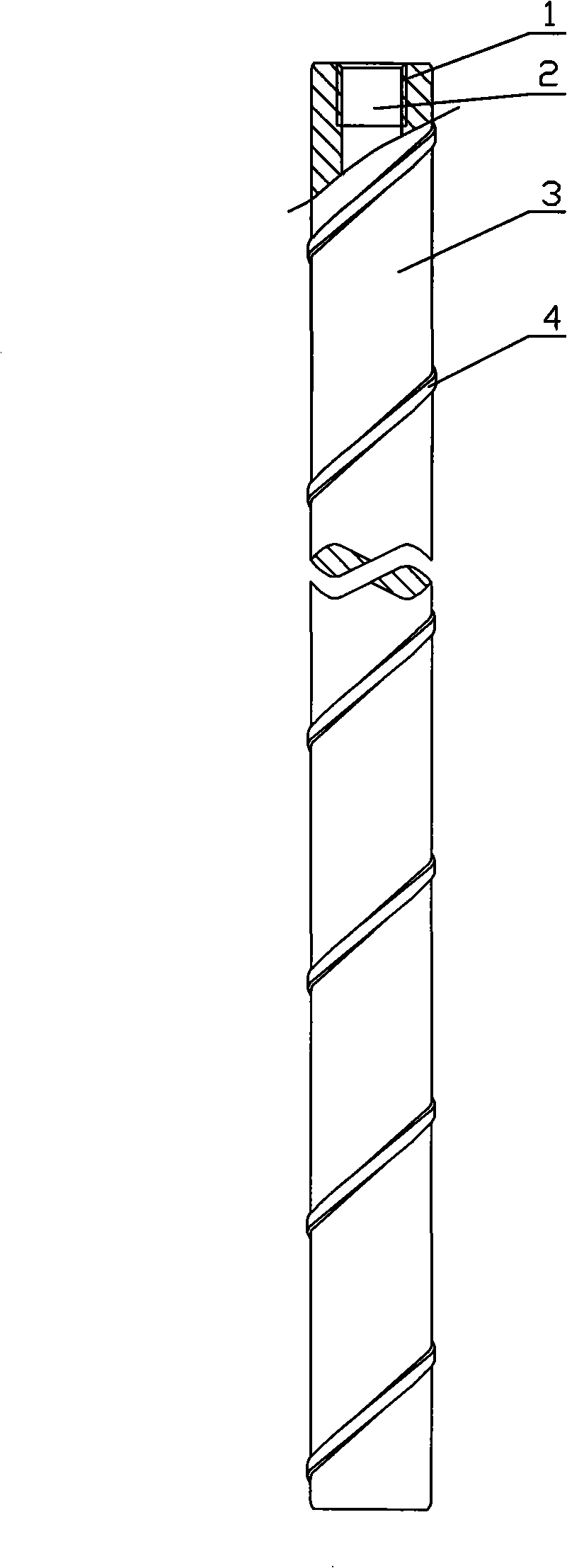

[0014] As shown in the figure, the main body of the drill rod of the present invention is a smooth round drill rod 3, the center of the drill rod 3 is provided with an inner hole 2, the two ends of the inner hole 2 are provided with connecting threads 1, and the outer surface of the smooth round drill rod 3 is provided with Alloy-coated convex ribs 4 with low density regular helical shape.

[0015] The processing technology of drill pipe of the present invention is carried out by following steps operation:

[0016] The first step, at first be processed into common round drill pipe 3 by conventional method.

[0017] In the second step, the plasma beam surface metallurgy equipment is used, and the hollow smooth round drill pipe 3 is placed on the special additional screw propulsion device of the plasma beam surface metallurgy equipment, and the nozzle of the plasma beam surface metallurgy equipment faces the hollow smooth round drill On the outer surface of the rod 3, the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com