A method for dynamic stiffness control of hot rolling mill finishing mill stand

A technology of finishing rolling unit and control method, which is applied in the direction of rolling force/roll gap control, etc., can solve the problems affecting the surface quality control of hot-rolled strip, large rolling force of the front stand, and peeling of oxide film on the roll surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0165] Combined with this technical solution, taking a hot-rolled F2 stand of Baosteel as an example, the implementation of each step of the process is as follows:

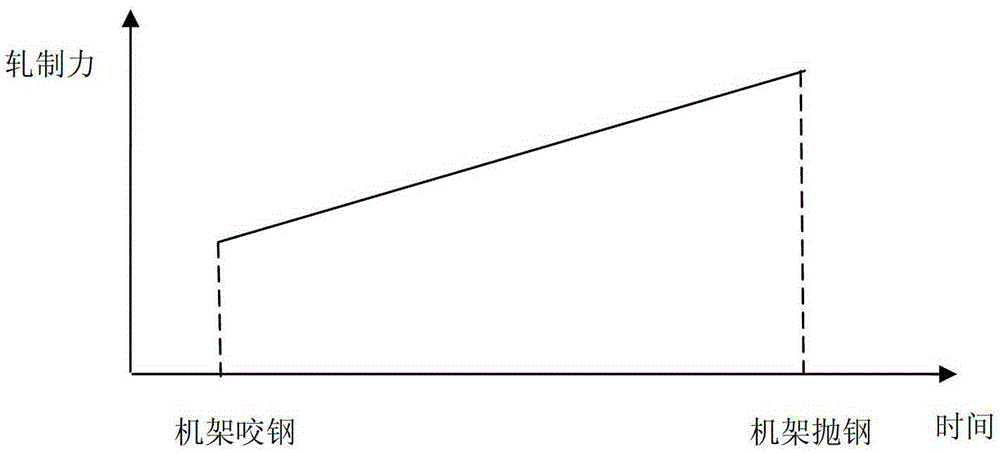

[0166] 1. Use the process control computer to set the initial rigidity of the F2 frame to 500KN / mm, and the roll gap to 3mm, then when the actual rolling force after the frame bites the steel is 1800KN, combine step 1P SET = M SET ×S SET , the actual stiffness of the frame is 600KN / mm

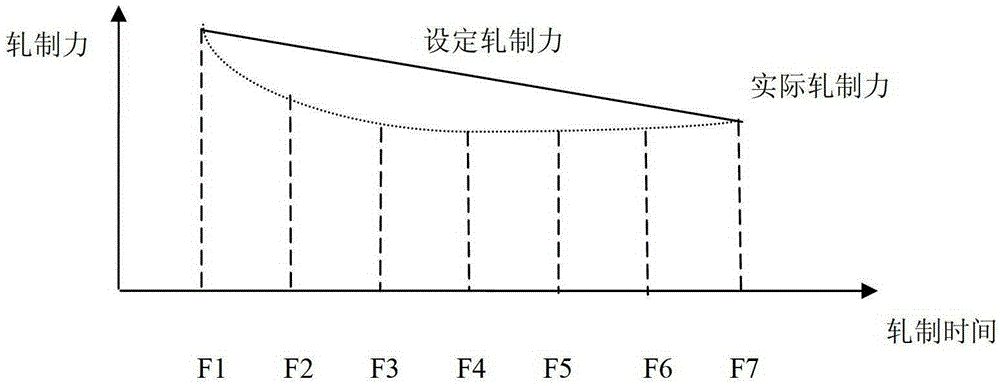

[0167] 2. According to the actual position of the strip head, calculate from 0 to reach 10% of the strip length, and combine the actual length of the strip on the intermediate roller table, the thickness of the intermediate billet and the thickness of the finished strip to obtain the calculation of the finished strip Length, when the length of the intermediate billet is 58 meters, the thickness of the intermediate billet is 40 mm, and the thickness of the finished product is 4 mm, the length of the finished strip steel product is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com