Method and device for testing dynamic stiffness of high-speed main shaft

A technology of high-speed spindle and test method, applied in the direction of mechanical bearing testing, etc., can solve the problems of prone to friction, low rigidity of air bearing, non-uniform spindle cross-section, etc., to reduce heat generation and wear, small rolling friction coefficient, Simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

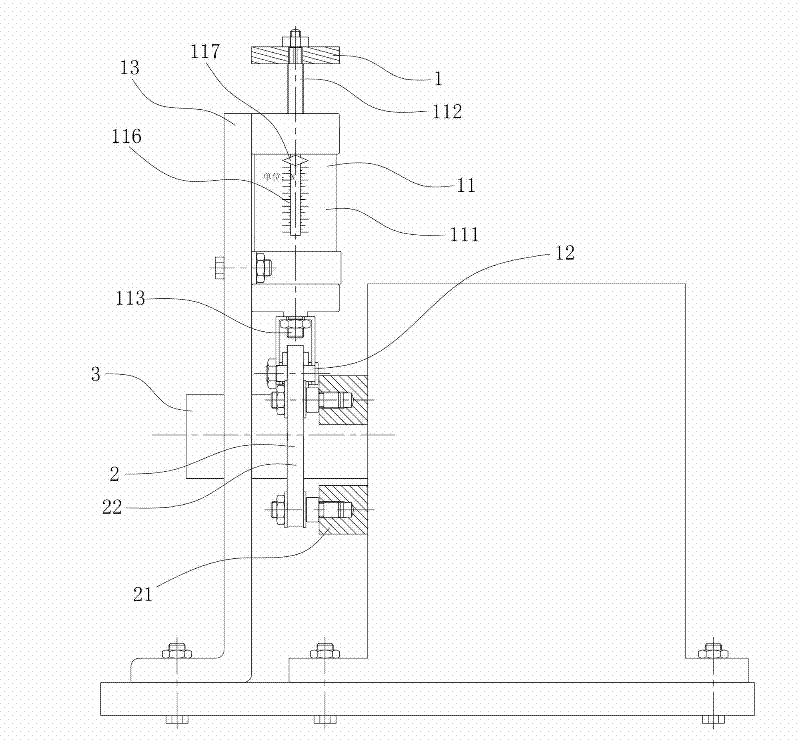

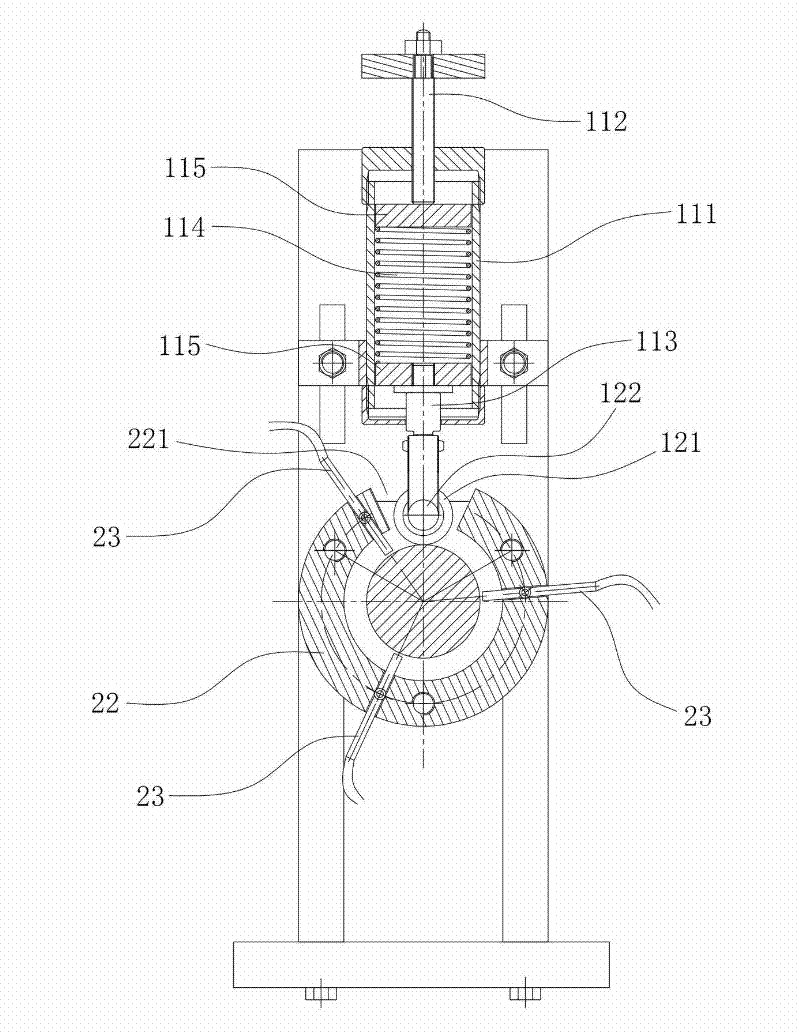

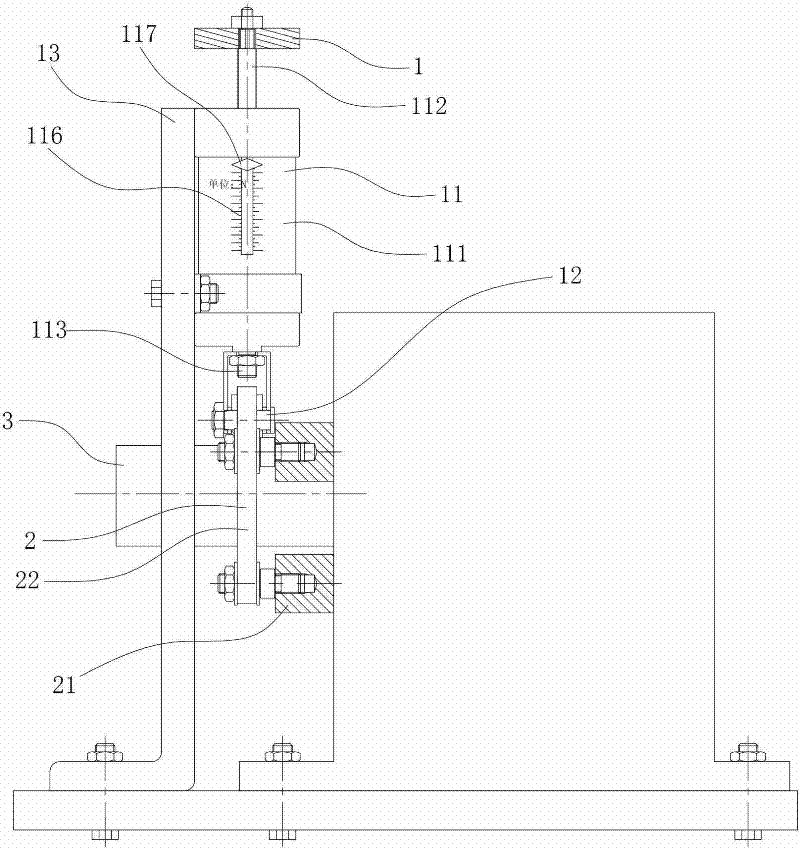

[0030] This embodiment provides a method for testing the dynamic stiffness of a high-speed main shaft, which includes a step of radial loading, a step of measuring the displacement of the shaft center, and a step of calculating the dynamic stiffness value, such as figure 1 and figure 2 As shown, when carrying out the radial loading step, the loading element 11 with a readable loading force pushes a rotatable rolling member 12 to contact the circumferential surface of the tested high-speed spindle 3, and makes the direction of the loading force point to the tested high-speed spindle 3 When the tested high-speed main shaft 3 rotates, the rolling element 12 rotates synchronously under the friction force provided by the circumferential surface. The wear of the component 12 is small, which can effectively avoid the heat and wear caused by the traditional loading method, and at the same time has little impact on the measurement accuracy; the loading force can be obtained by reading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com