Linear electric motor driven four-shaft linkage numerical control machine

A technology of linear motors and CNC machine tools, which is applied in the direction of drive devices, metal processing machinery parts, large fixed members, etc., can solve the problems of feed movement lag, affecting machining accuracy, and increasing inertial mass, etc., to achieve fast feed speed, The effect of simple and compact structure and large deflection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings.

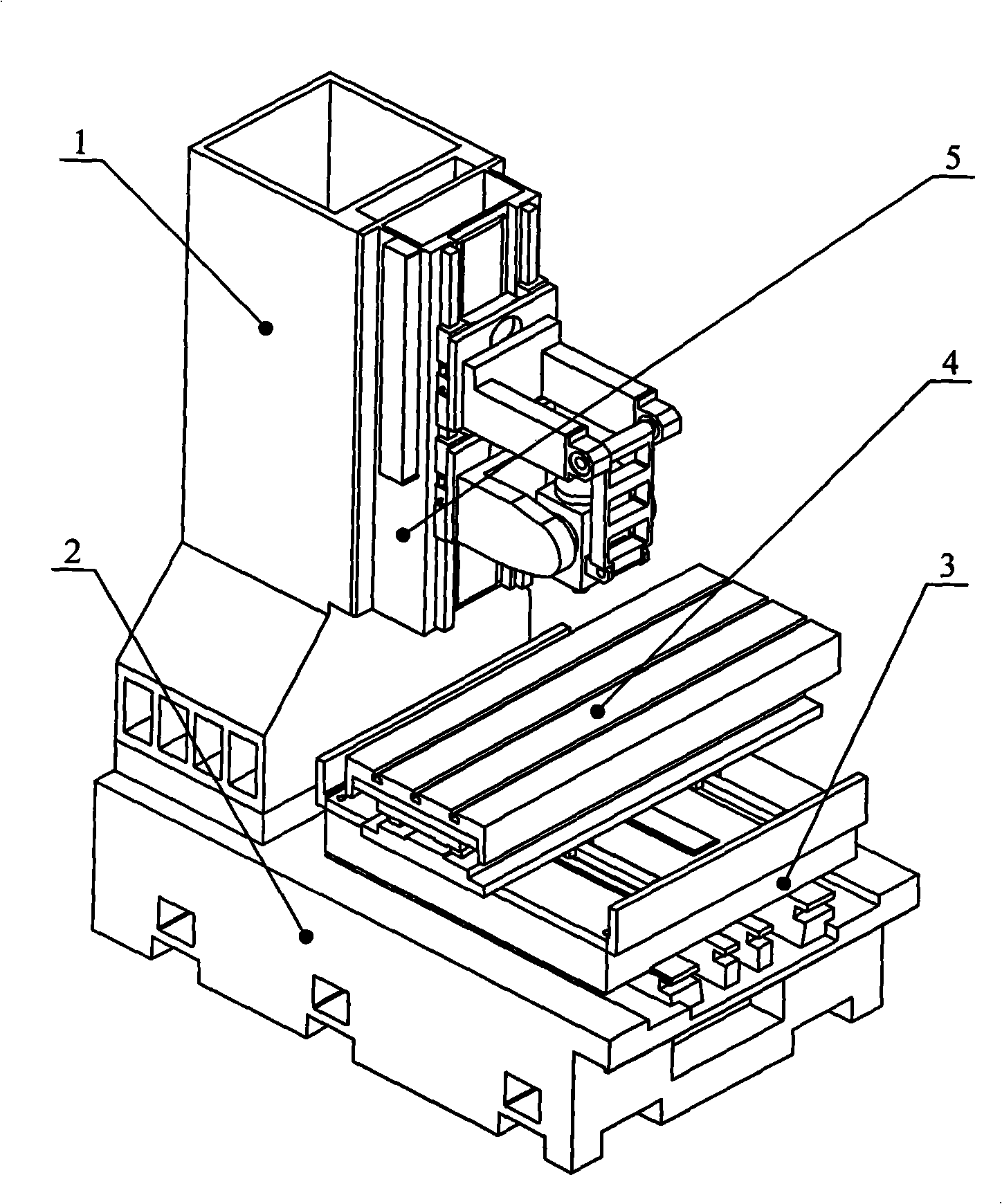

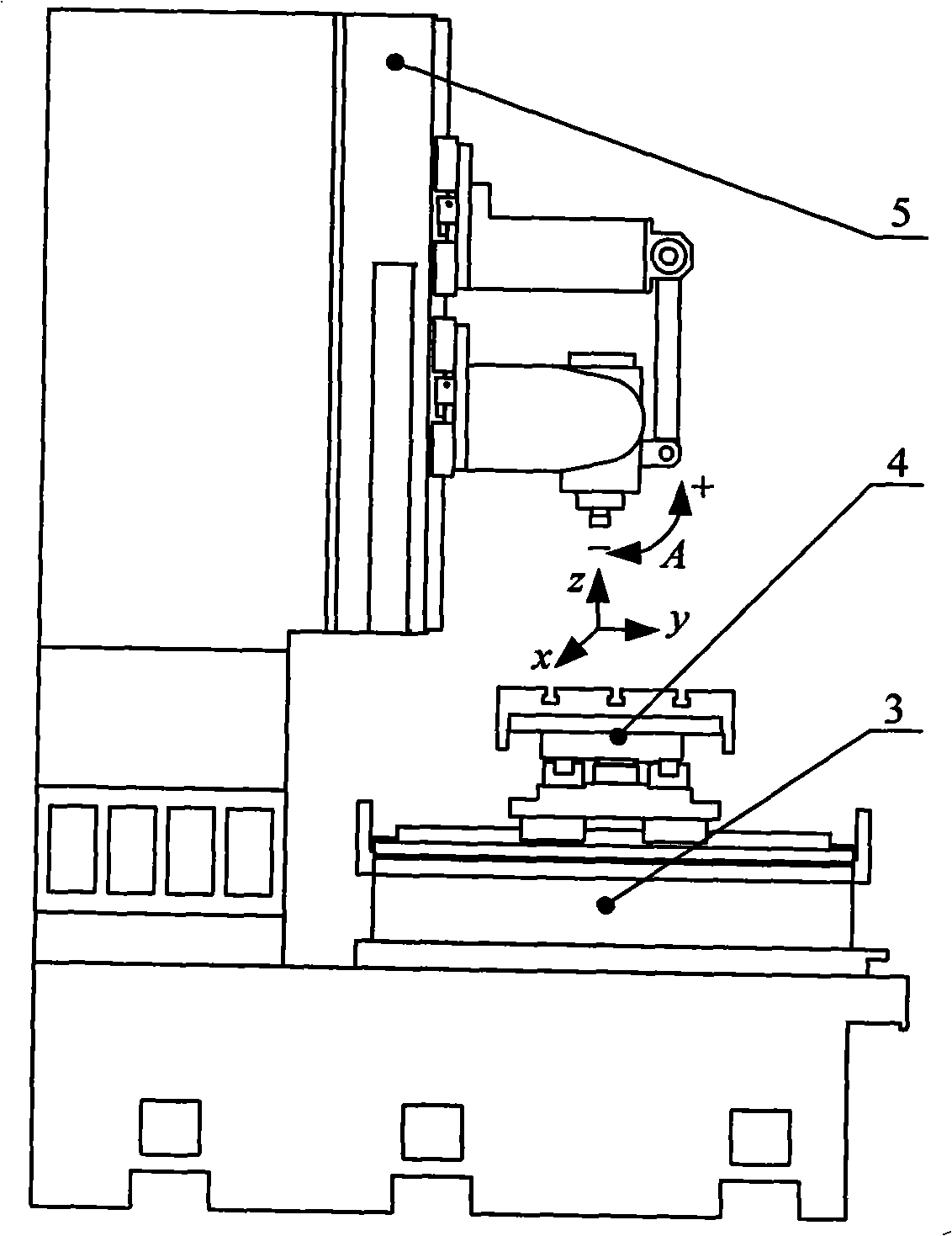

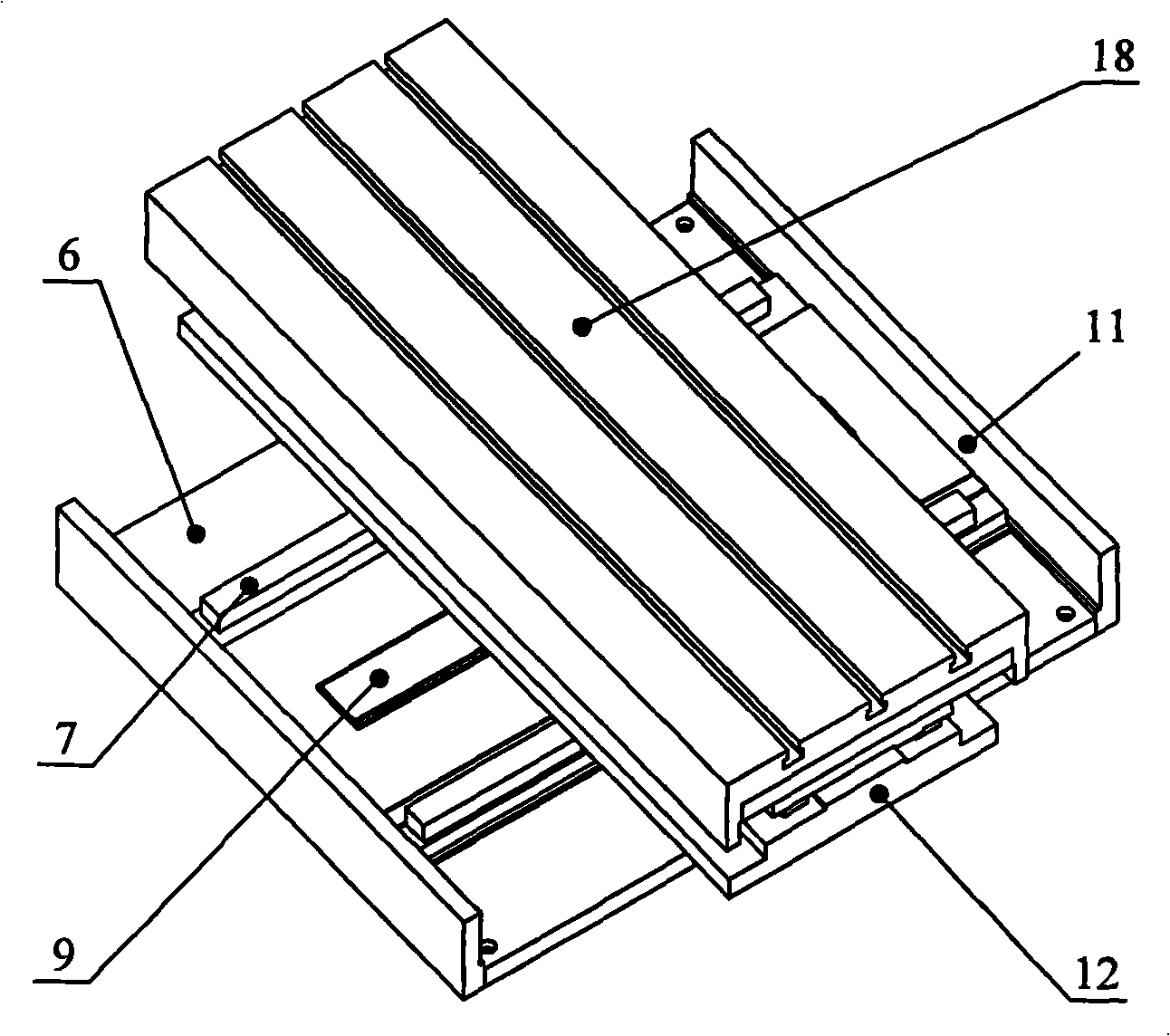

[0046] Such as figure 1 with 2 As shown, the four-axis linkage CNC machine tool driven by a linear motor according to the present invention is composed of a bed column 1, a bed base 2, a workbench mounting seat 3, an XY workbench module 4 and an asymmetrical parallel spindle module 5. .

[0047] The bed column 1 is an integral casting with mounting holes on its lower end surface; the bed base 2 is also an integral casting with bosses and mounting holes on it; the bed column 1 is fixed on the bed by bolts On the base 2, the end faces are placed flush with each other in an L-shaped structure; the parallel spindle head module 5 is vertically installed on the bed column 1 through the mounting hole on the side of the bed column 1 . The workbench mounting seat 3 is a cuboid intermediate connecting part, which is fixedly installed on the boss of the bed base 2 by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com