Three-dimensional vibration isolation device applicable to low-frequency vibration

A low-frequency vibration, three-dimensional technology, applied in the direction of non-rotational vibration suppression, etc., can solve the problems that the static balance position of the structure cannot be adjusted, the static bearing capacity of the rubber sheet is poor, and the linear bearing capacity is poor. The effect of avoiding aging fracture and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

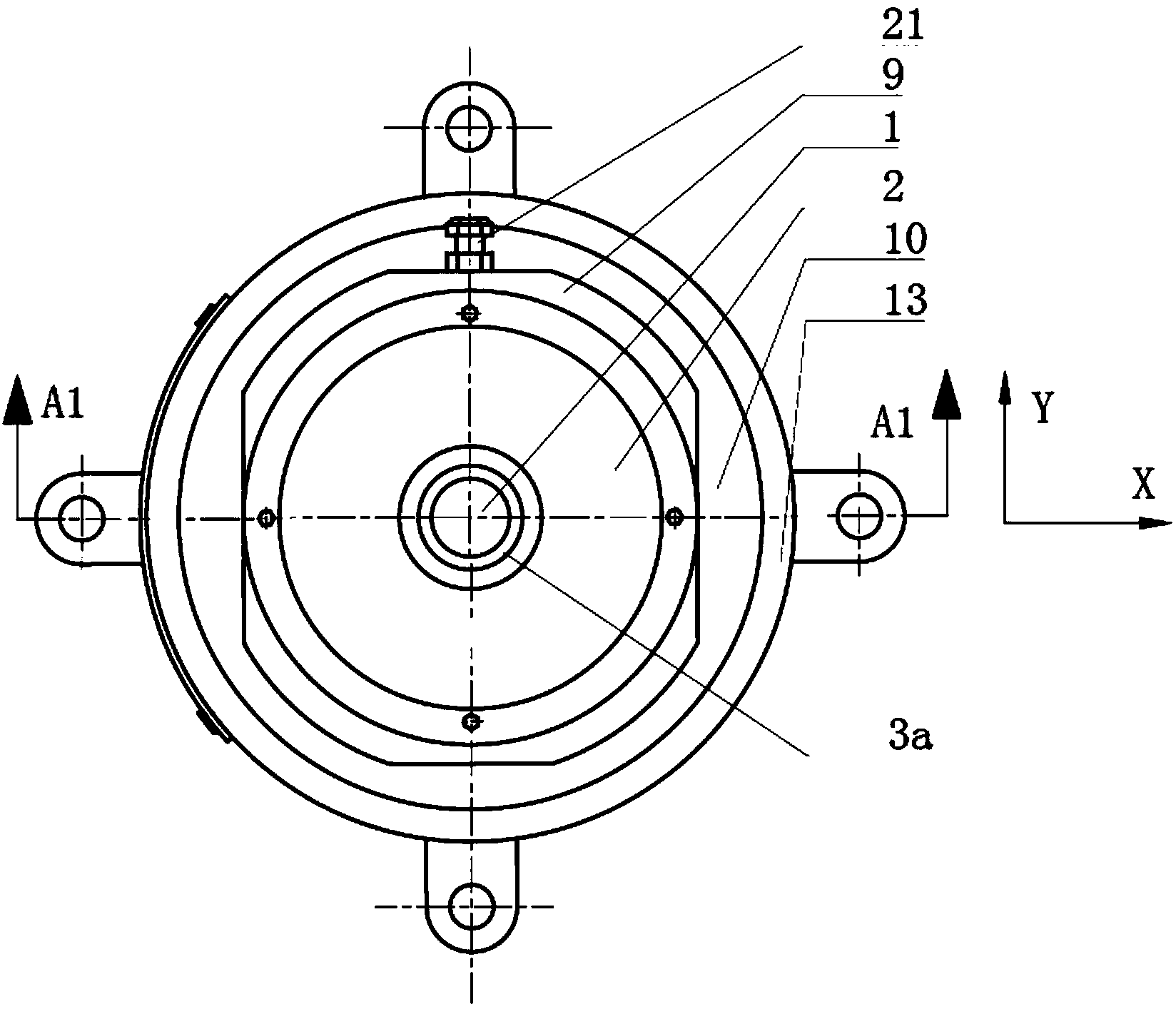

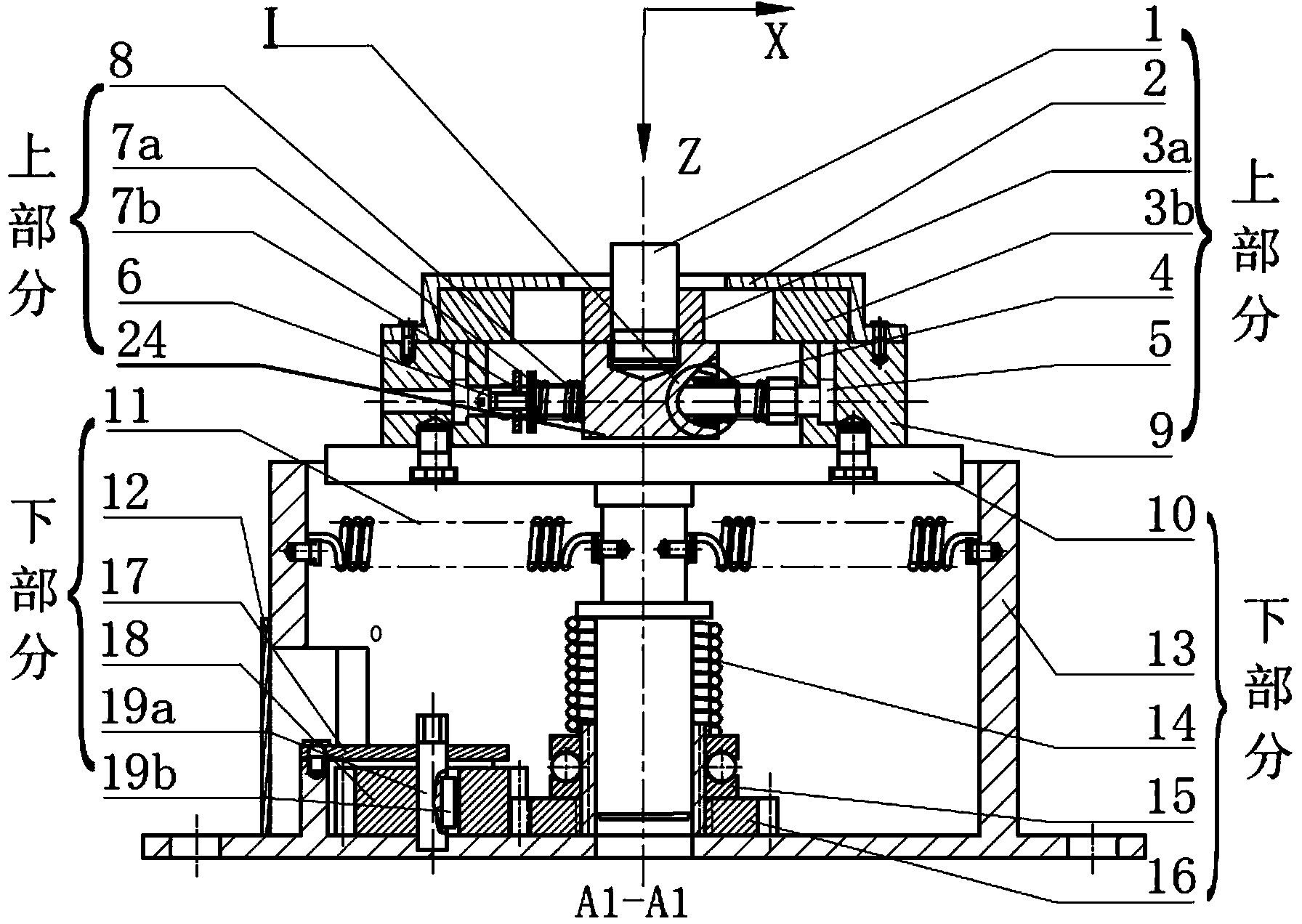

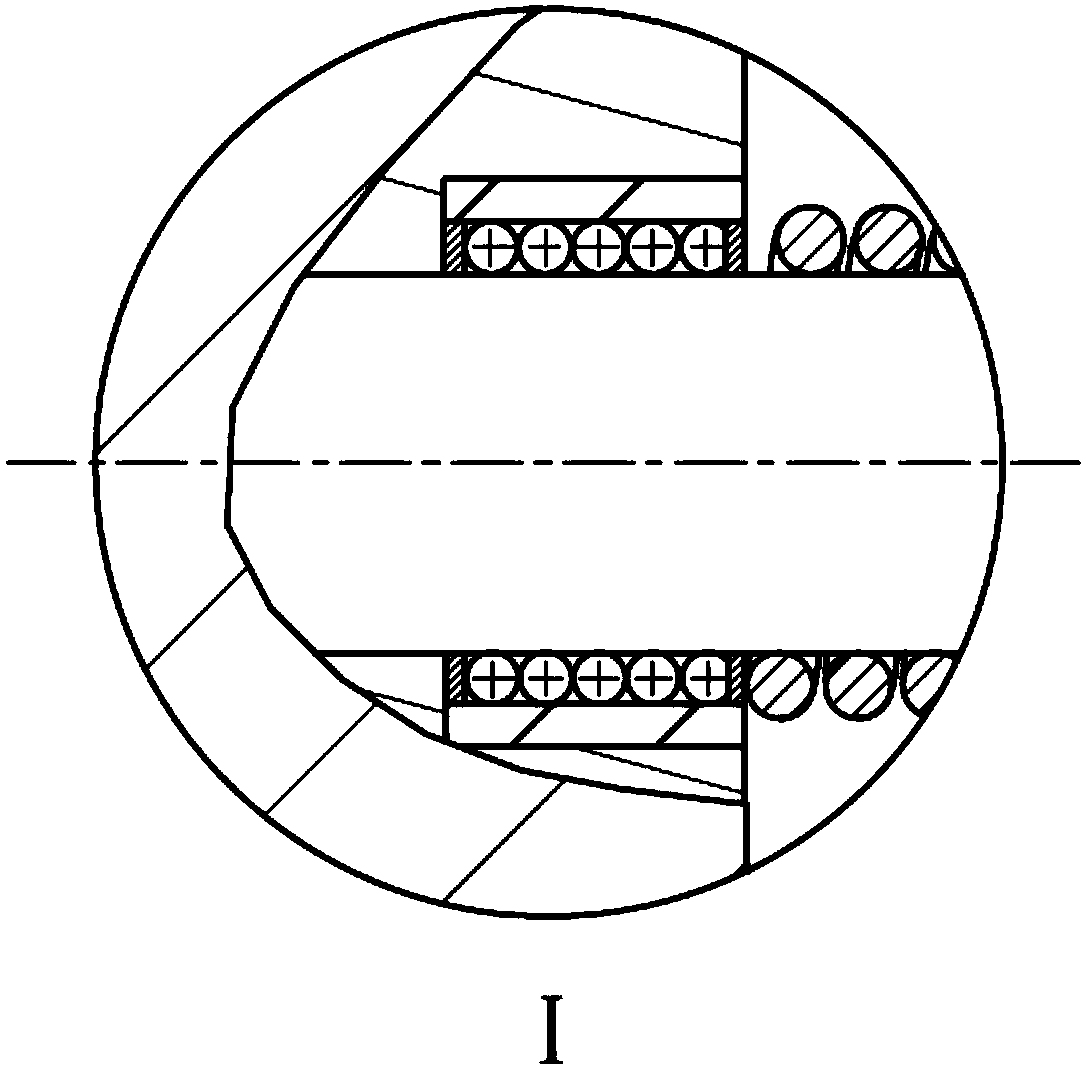

[0018] combine figure 1 ~5, a three-dimensional vibration isolator suitable for low-frequency vibration includes: aluminum vibration isolation table 1, aluminum magnet fixing cover 2, small round permanent magnet 3a, large round permanent magnet 3b, wire bearing 4, support Bearing 5, aluminum fixed adjustment block 7a in X direction, aluminum moving adjustment block 7a in X direction, aluminum adjustment block 21 in Y direction, aluminum XY surface decoupling bracket 9, vibration table 10 in Z direction, aluminum Made of housing 13, gear retaining ring 17, adjustment handle 19, steel shaft 22, aluminum sliding block 24; sliding block 24 can slide along the X direction on two supporting shafts 22, as shown in Figure 2, supporting shaft 22 Supported by the support bearing 5, it can move in the Y direction. The support bearing is located in the bearing groove of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com