Method for guaranteeing hot continuous rolling mill finish rolling outlet temperature

A technology of outlet temperature and hot continuous rolling mill, applied in the direction of temperature control, etc., can solve problems such as outlet temperature lag, and achieve the effect of improving temperature regulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

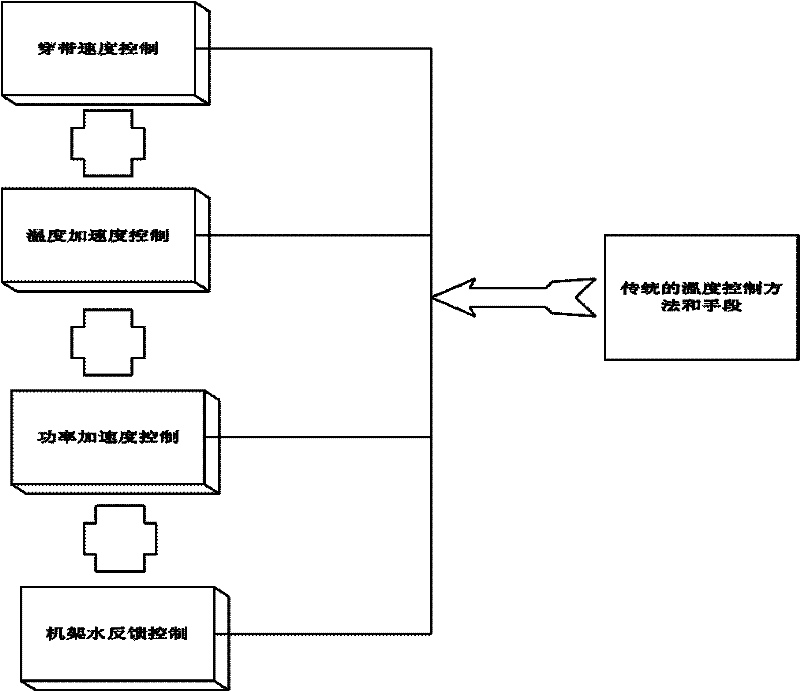

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Such as figure 2 As shown in the schematic diagram, the method for ensuring the finish rolling exit temperature of the hot continuous rolling mill is based on the prediction and control of the full-length finish rolling temperature of the strip, and carries out temperature feedforward control on the control unit with the section as the unit; its technical scheme is given by It consists of three parts:

[0064] 1. Strip steel section

[0065] Divide the strip into logical segments of a certain length. The logic segment is the basic unit of calculation and control;

[0066] 2. Predict the final rolling temperature of each logic section according to the load distribution and speed system of the rolled piece.

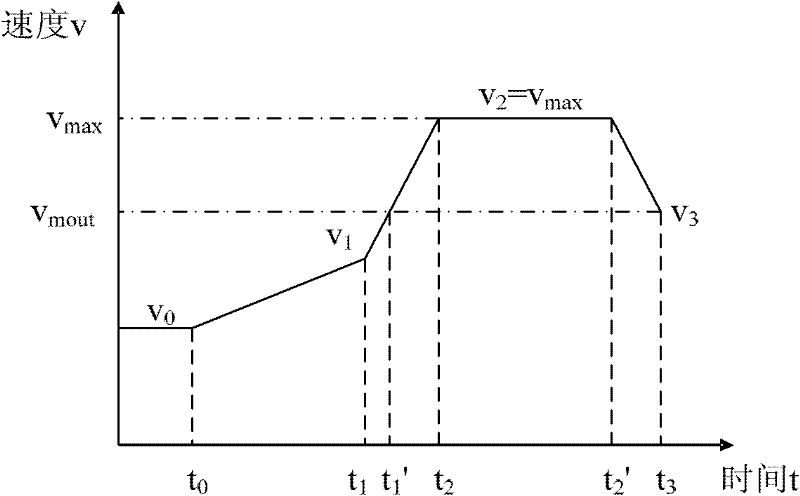

[0067] First, the calculation of the exit speed of the rolling mill for each section of the strip's full length:

[0068] The segmentation principles are as follows:

[0069] The realization of this scheme is based on the calculation and control of the strip st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com