Hot-rolled seamless tube on-line accelerated cooling device and method

A seamless steel pipe, accelerated cooling technology, applied in the direction of cooling bed, metal rolling, metal rolling, etc., can solve the problems of uneven temperature distribution, bending of steel pipe, and failure to effectively implement hot-rolled seamless steel pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

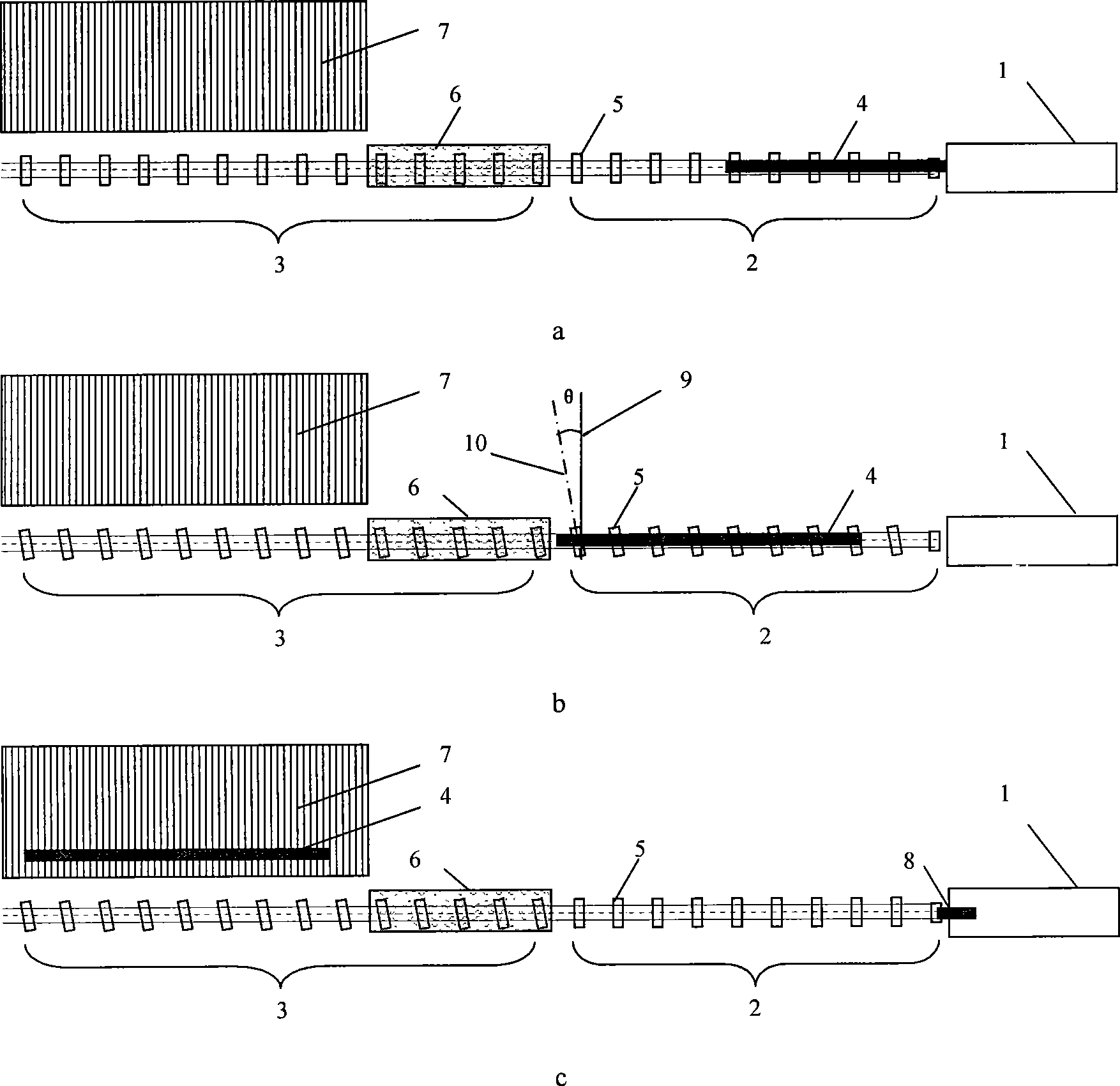

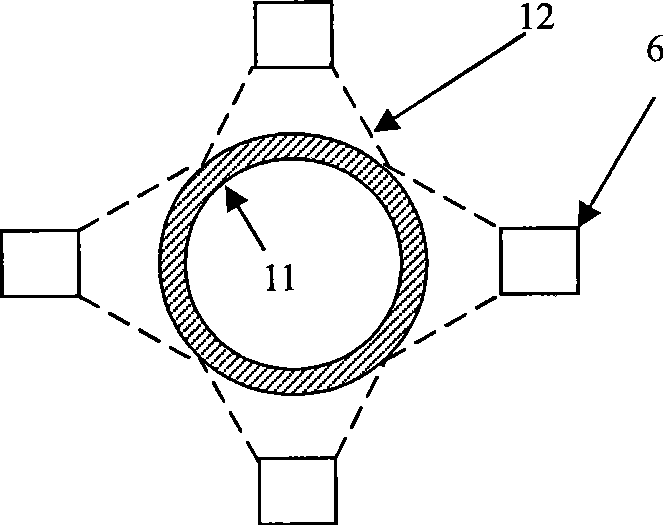

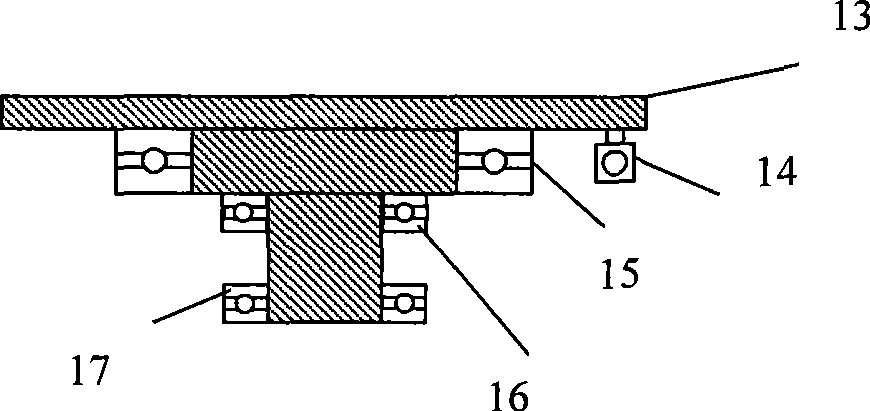

[0022] The hot-rolled seamless steel pipe online accelerated cooling device of the present invention is such as figure 1 , image 3 with Figure 4 As shown, a horizontal rotation mechanism is added to the bottom of the conventional conical roller table to make the conventional conical roller table form a variable-angle roller table group, and the change of its rotation angle is controlled by electrical components. The range of the variable angle is As follows: the angle θ between the roller table centerline 10 when the angle of the variable-angle roller table changes and the roller table centerline 9 at the initial position of the variable-angle roller table is between 10°~45°; set the sizing machine 1 to cold The roller table of bed 7 is divided into two sets of variable angle roller table groups, namely variable angle roller table I group 2 and variable angle roller table II group 3.

[0023] The lengths of the two sets of variable-angle roller sets are greater than or equal to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com