Soil scarifying harvester

A technology of machine tools and picking devices, which is applied to harvesters, digging harvesters, excavators, etc., can solve problems such as crop damage, sweet potato rot, and farmer loss, and achieve integrity protection, work efficiency, and multiple benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

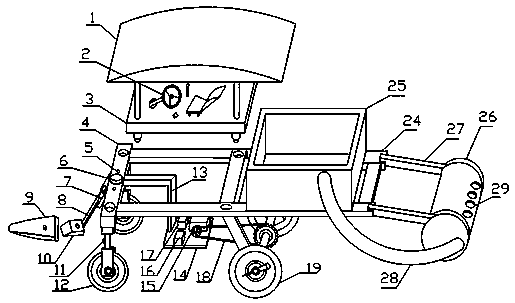

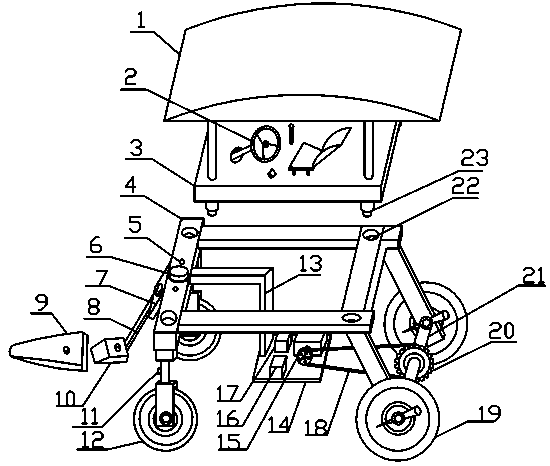

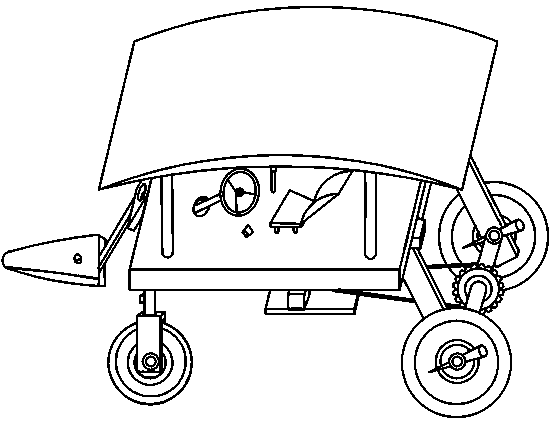

[0028] Embodiment one: a kind of tillage collecting machine, comprises support 4, machine tool, container 25, front wheel 12, rear wheel 19, power unit 15; Supported with the rear wheel 19; the machine tool includes a base plate I3, a thin-film solar cell ceiling 1 above the base plate I3, and a controller 2, and the base plate I3 is fixed above the bracket 4 through the bottom fixing feet 23 and fixing holes 22; the cargo box 25 Connect with the discharge port 26.2 of pick-up device 26 by traditional delivery device 28; Also comprise pillar 6, bottom plate II fixed bracket 13, wheel rotating shaft 21, pick-up device 26; Described pillar 6 is arranged on the support 4, and pillar 6 below is provided with The control box 7 is provided with a power-assisted tripod 8 below the control box 7, and the power-assisted tripod 8 is connected to the sliding disc support 10, and the sliding disc 9 is fixed on the sliding disc support 10 by bolts; the bottom plate II fixing bracket 13 ...

Embodiment approach 2

[0029] Embodiment two: a kind of tillage collecting machine, comprises support 4, machine tool, container 25, front wheel 12, rear wheel 19, power unit 15; Supported with the rear wheel 19; the machine tool includes a base plate I3, a thin-film solar cell ceiling 1 above the base plate I3, and a controller 2, and the base plate I3 is fixed above the bracket 4 through the bottom fixing feet 23 and fixing holes 22; the cargo box 25 Connect with the discharge port 26.2 of pick-up device 26 by traditional delivery device 28; Also comprise pillar 6, base plate II fixed bracket 13, wheel rotating shaft 21, pick-up device 26; Described pillar 6 is arranged on the support 4, and pillar 6 below is provided with The control box 7 is provided with a power-assisted tripod 8 below the control box 7, and the power-assisted tripod 8 is connected with the sliding disc support 10, and the sliding disc 9 is fixed on the sliding disc support 10 by bolts; the bottom plate II fixing bracket 13 ...

Embodiment approach 3

[0033] Embodiment three: a kind of tillage collecting machine, comprises support 4, machine tool, container 25, front wheel 12, rear wheel 19, power unit 15; Supported with the rear wheel 19; the machine tool includes a base plate I3, a thin-film solar cell ceiling 1 above the base plate I3, and a controller 2, and the base plate I3 is fixed above the bracket 4 through the bottom fixing feet 23 and fixing holes 22; the cargo box 25 Connect with the discharge port 26.2 of pick-up device 26 by traditional delivery device 28; Also comprise pillar 6, bottom plate II fixed bracket 13, wheel rotating shaft 21, pick-up device 26; Described pillar 6 is arranged on the support 4, and pillar 6 below is provided with The control box 7 is provided with a power-assisted tripod 8 below the control box 7, and the power-assisted tripod 8 is connected to the sliding disc support 10, and the sliding disc 9 is fixed on the sliding disc support 10 by bolts; the bottom plate II fixing bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com