Vacuum extruder adjustable mud speed machine head

A technology of vacuum extruder and machine head, applied in the direction of ceramic extrusion die, etc., can solve problems such as mud strip collapse, and achieve the effect of ensuring quality and balancing section speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

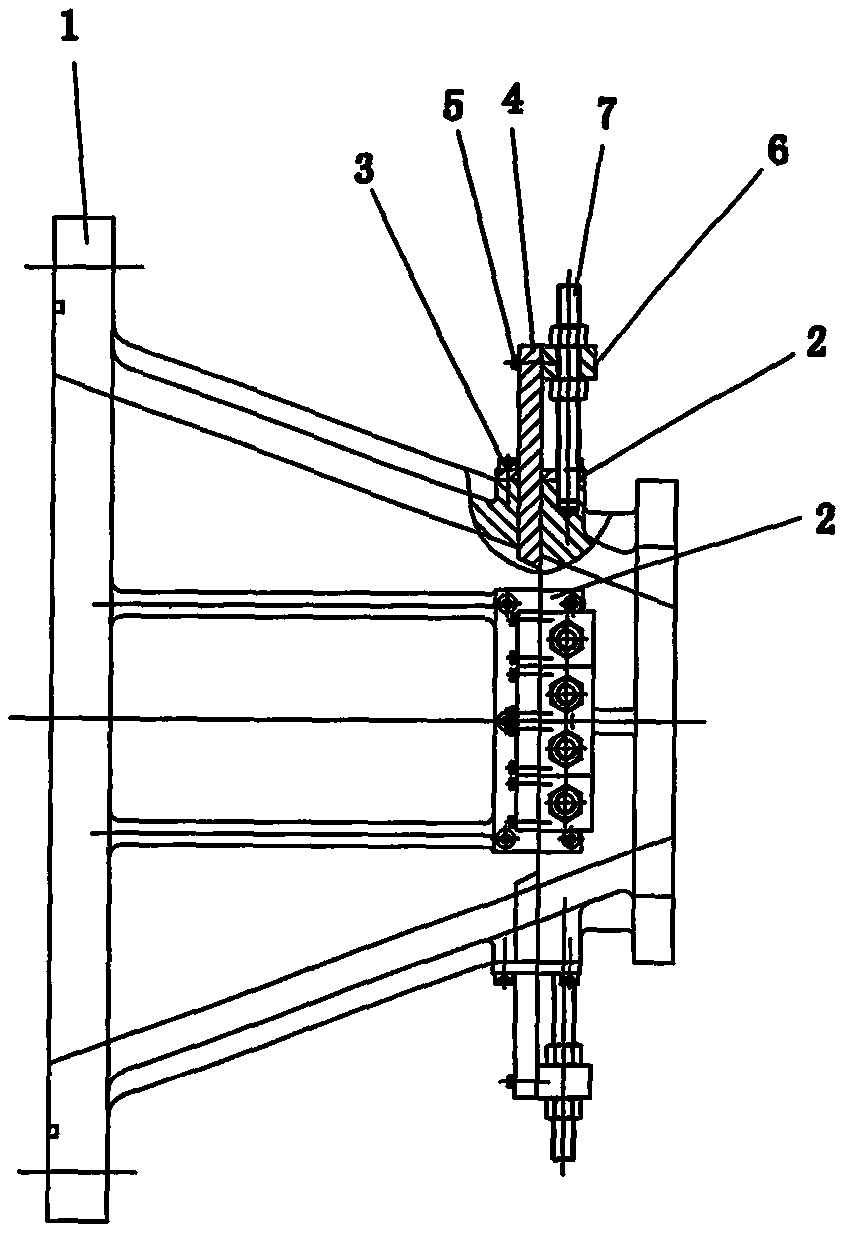

[0011] Such as figure 1 The vacuum extruder shown in the adjustable mud speed head has a head 1, the mouth of the head 1 is provided with a cover plate 2, the cover plate 2 is fixedly connected with the head 1 through the fixing bolt A3, and the mud blocking plate 4 Extend through the cover plate 2 and the side wall of the machine head 1 to the inside of the machine head, one end of the mud block 4 outside the machine head is fixedly connected with the adjustment plate 6 through the fixing bolt B5, and the fixing screw 7 passes through the adjustment plate 6 to connect the adjustment plate 6 and the adjustment plate 6. The cover plate 2 is fixedly connected with the side wall of the machine head 1 .

[0012] The mud-repelling plate 4 can be arranged in multiple groups to meet the requirement of adjusting the mud-repelling speed for machine hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com