Cooling-bed hydraulic stepping and tread control device and control method thereof

A technology of control devices and electric control devices, applied in the direction of fluid pressure actuators, cooling beds, metal rolling, etc., can solve the problems of uneconomical, large investment, and high price of proportional valves, and achieve convenient electrical control and maintenance, and system The structure is simple and the effect of meeting the stability requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

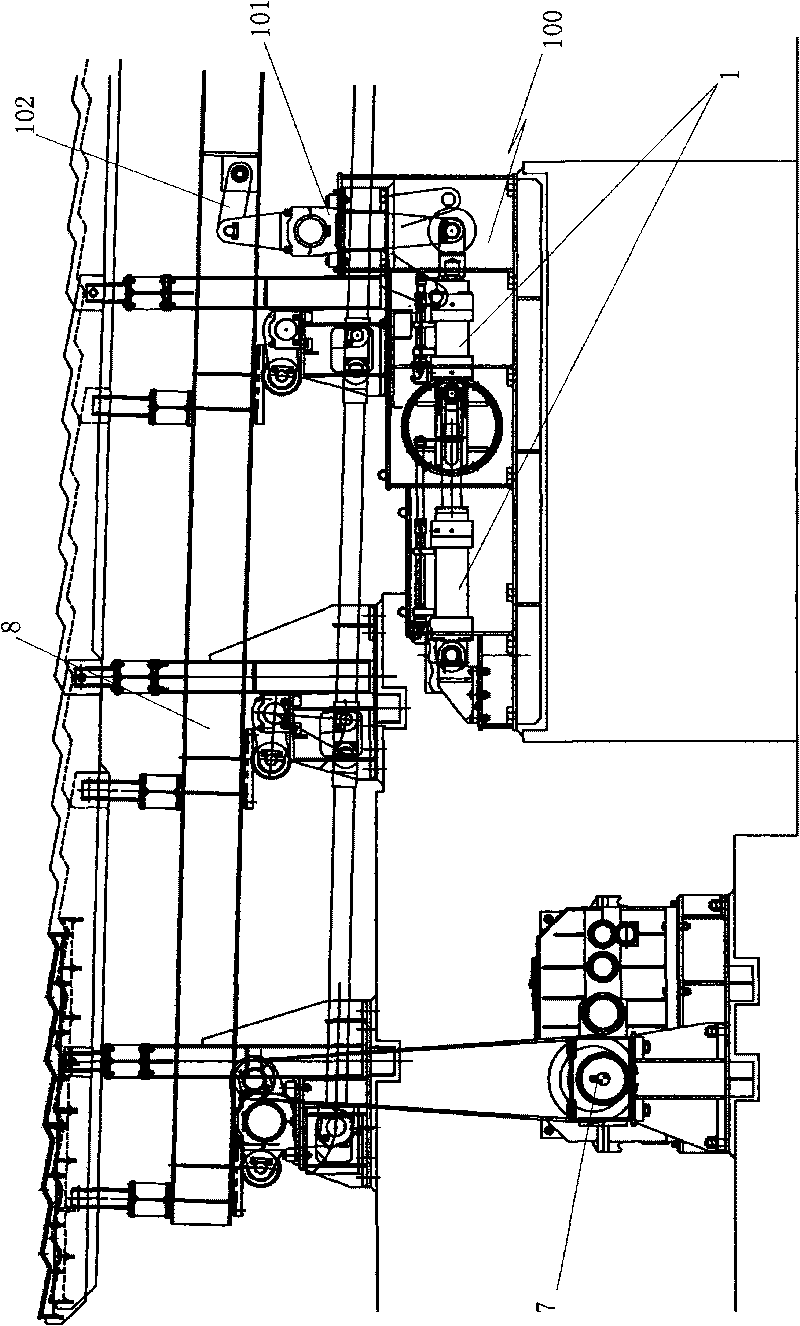

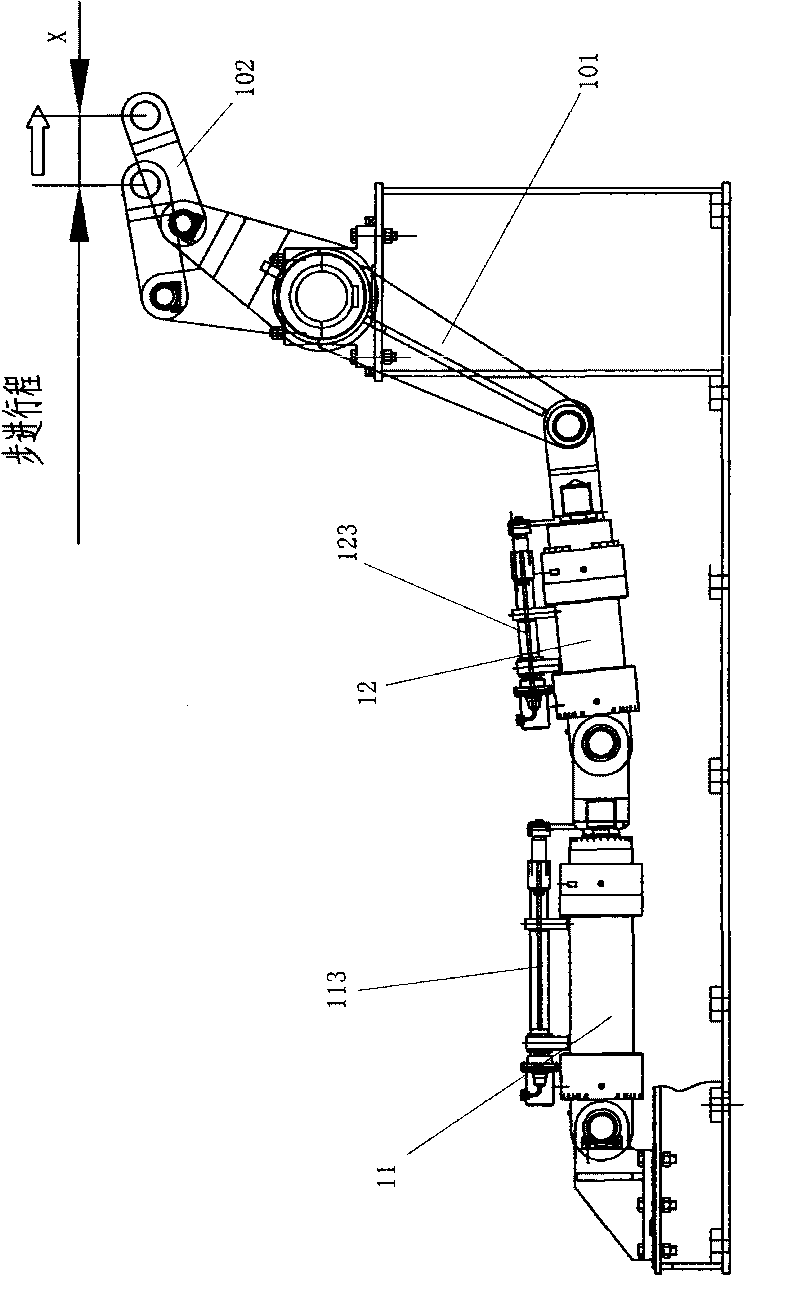

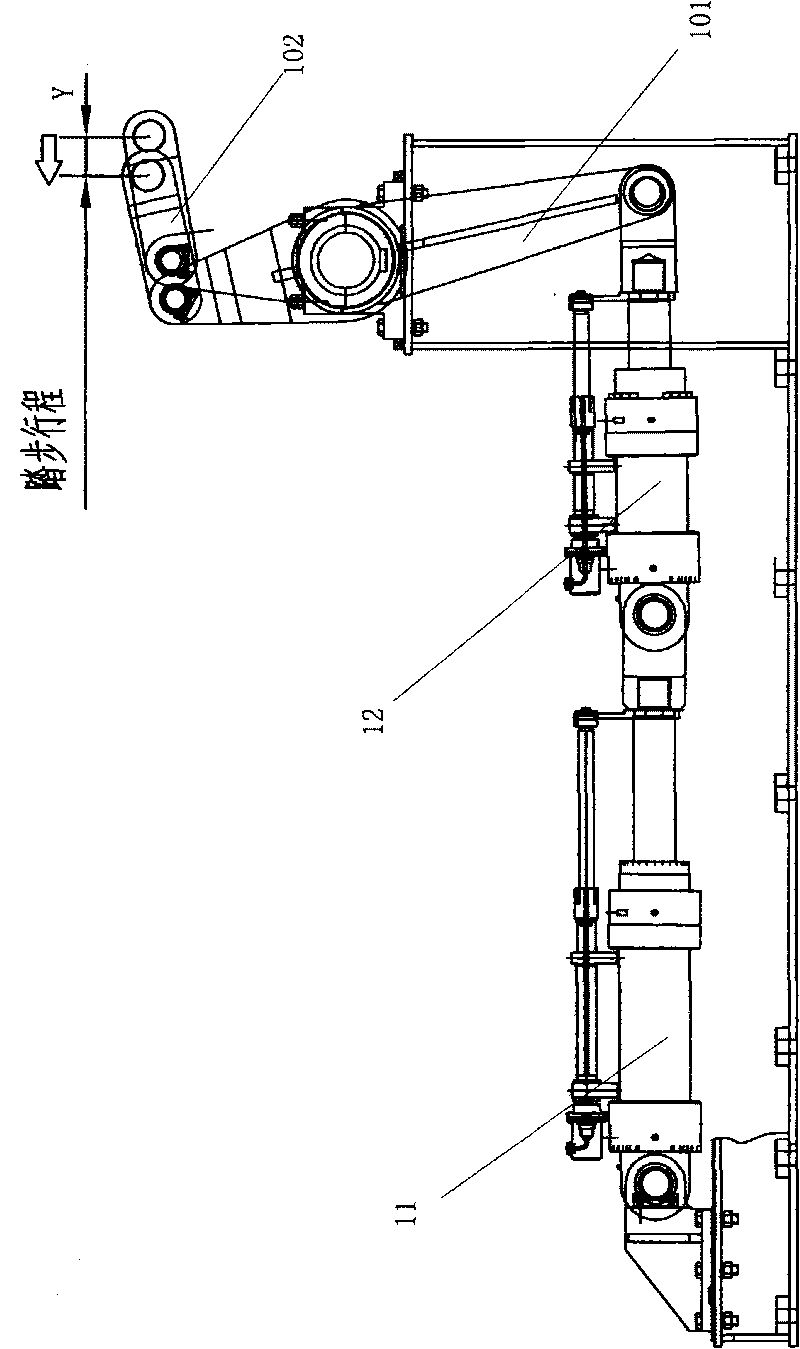

[0032] Such as figure 1 , figure 2 and image 3 As shown, the cooling bed includes a cooling bed moving rack beam 8, a cooling bed lifting device 7 and a cooling bed hydraulic stepping and stepping control device 100; the action of the cooling bed is composed of two parts: lifting action and lateral movement; The lifting action of the bed is realized by the rotation of the crank shaft of the cooling bed lifting device 7 to drive the connecting rod up and down to lift the swing shaft or lower the moving rack beam 8; the lateral movement of the cooling bed is achieved by hydraulic stepping and stepping of the cooling bed Two hydraulic cylinders connected end to end in the control device 100 drive the lever 101 to swing to drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com