Technique of hot rolled plate and linear cooling bed for manufacturing trolley track girder

A technology of trolley track and manufacturing process, applied in the direction of manufacturing tools, cooling beds, metal rolling, etc., can solve the problems of prolonging the manufacturing cycle and increasing manufacturing costs, and achieve the effects of shortening the manufacturing cycle, improving production efficiency, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

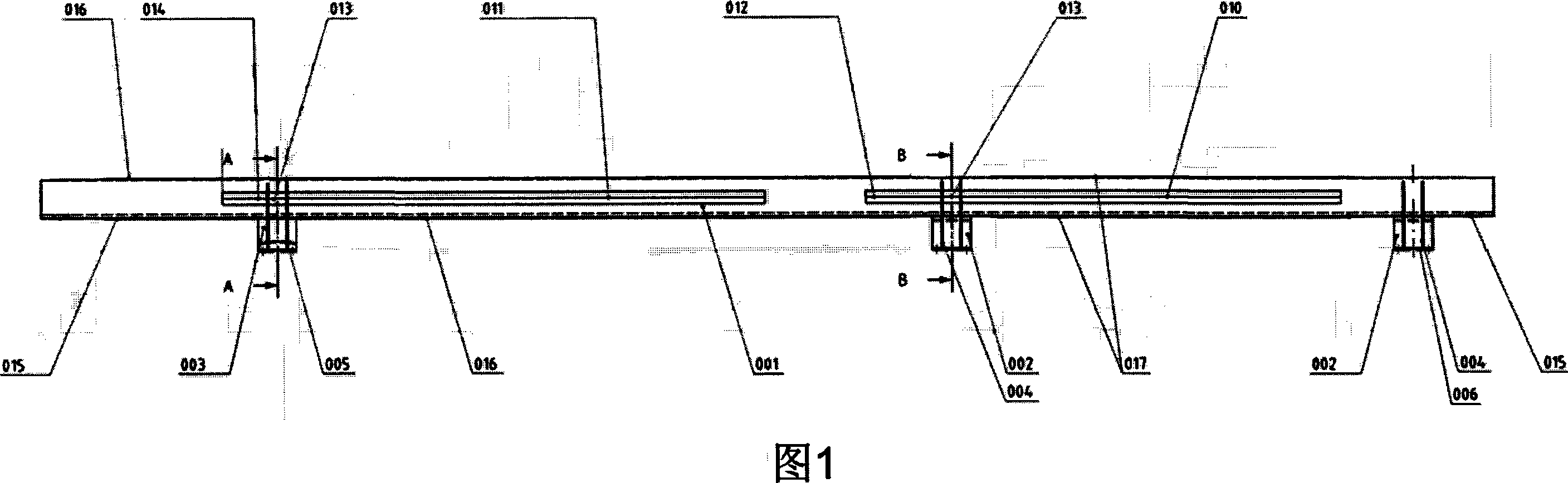

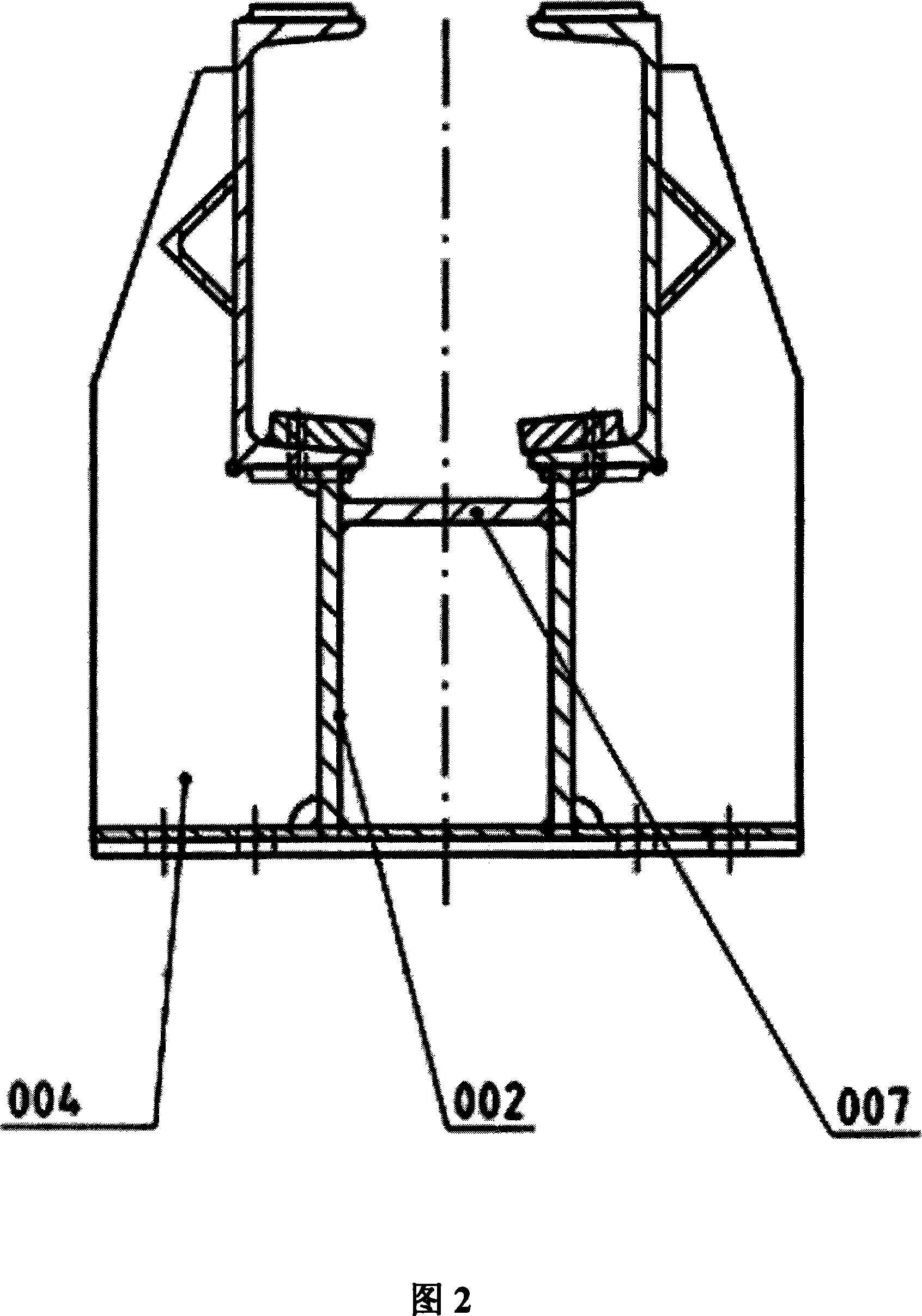

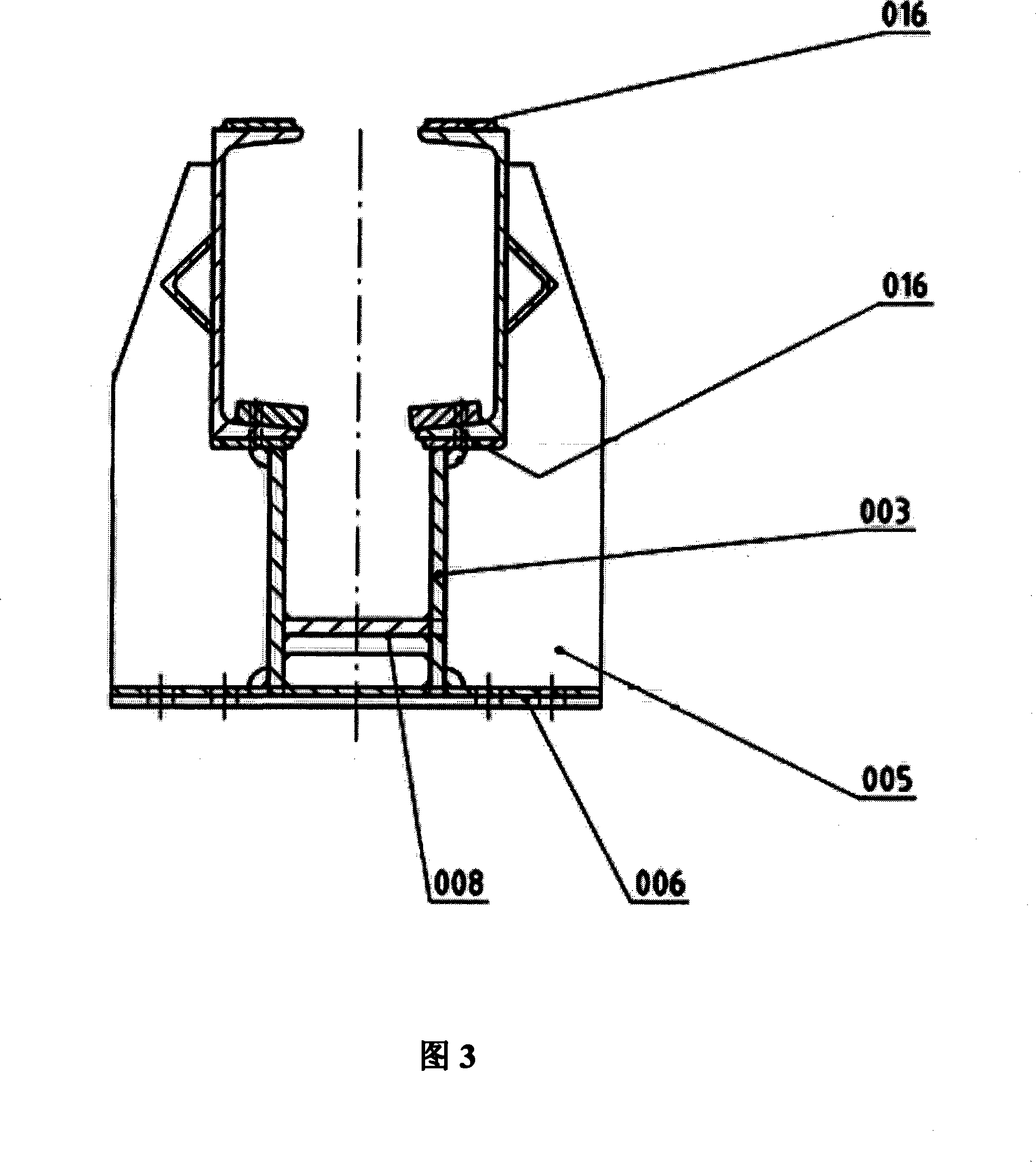

[0020] See Figures 1 through 7.

[0021] The present invention includes a welding process and a machining process, the welding process is to weld parts according to the structure, adjust the shape individually after welding, and then assemble and weld to form; the machining process is segmental processing before welding of the track plate, leaving Expansion joints, alignment, and grinding; After the track beams are welded and formed, the shape is adjusted and corrected, and after aging treatment, the bottom surface and key grooves are processed as a whole.

[0022] Please refer to Figure 4 to Figure 6. Track plate 009 is cut into 6 sections, 1 piece in the first section, 4 pieces in the middle section, and 1 piece in the tail section, about 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com