Method for fast cooling low-carbon hot-rolling small H-shaped steel

A rapid cooling, H-shaped steel technology, applied in the direction of cooling bed, metal rolling, metal rolling, etc., can solve the problems of restricting the production of small H-shaped steel, uneven structure, low mechanical properties of waist and leg joints, etc., to improve the comprehensive Mechanical properties, improving product yield, improving the effect of cross-section uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

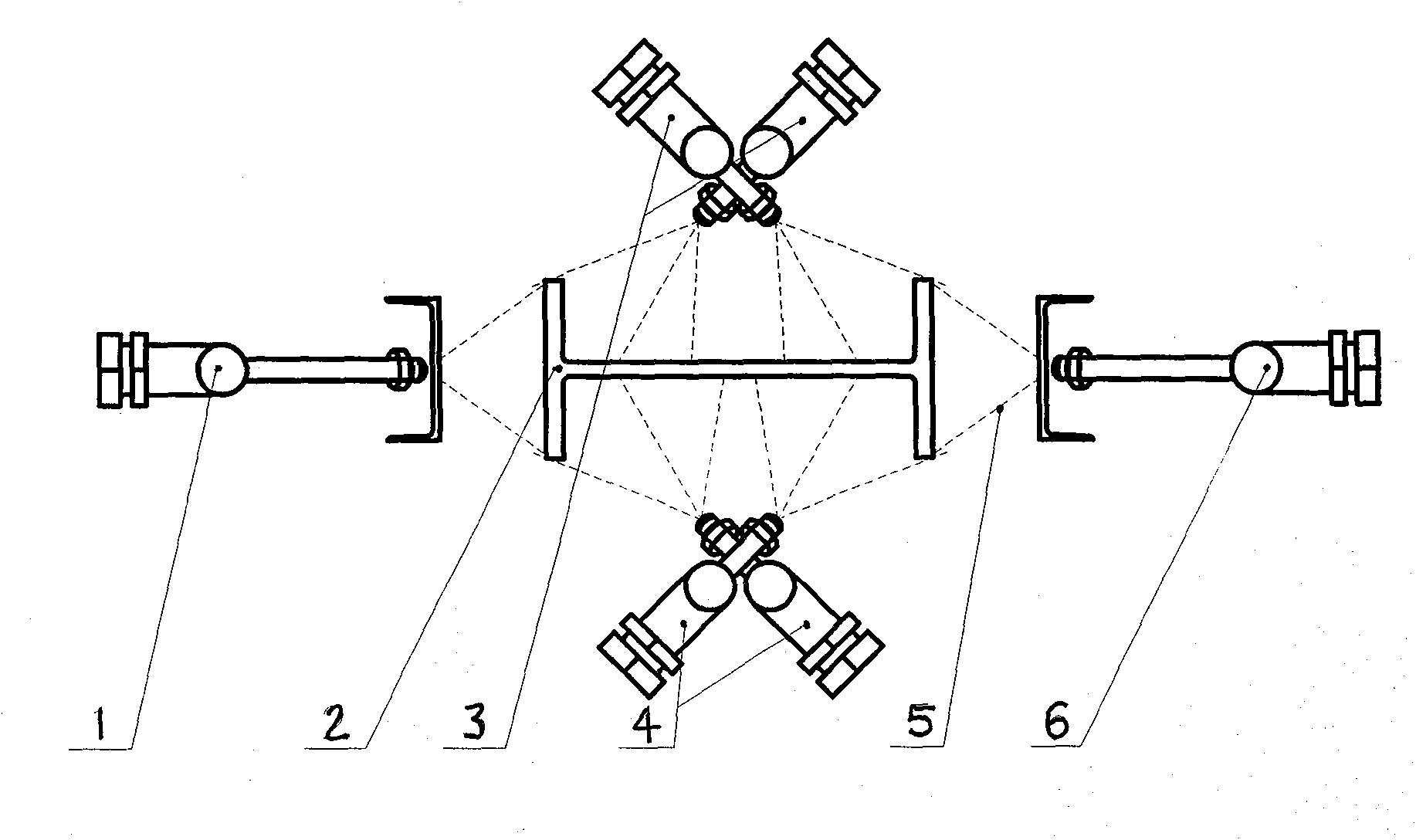

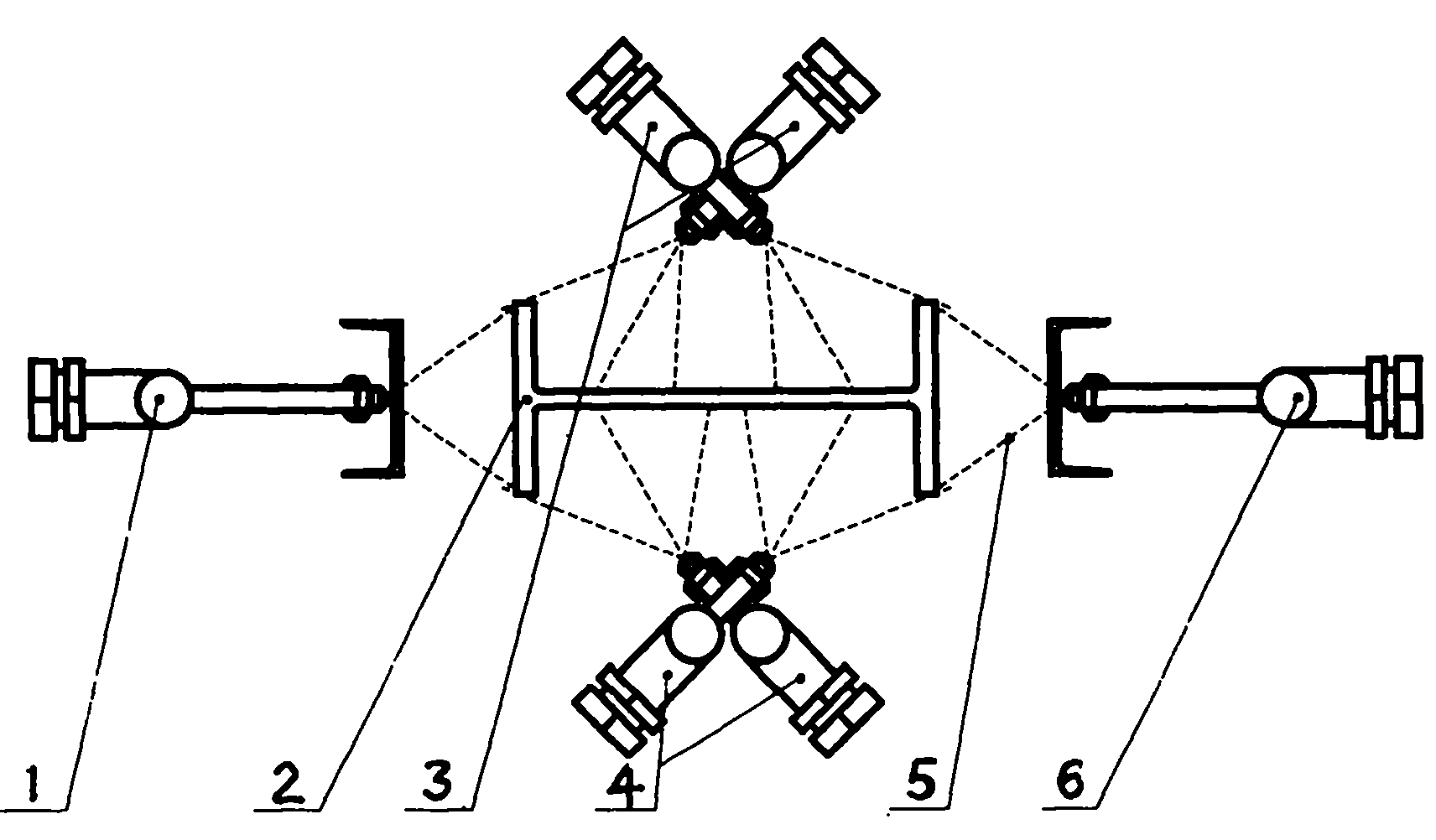

Image

Examples

Embodiment 1

[0014] Example 1: For Q235B and Q345B, the specifications are: 300×150×6.5×9mm, with six sections of side spray and bottom spray fully open, the water pressure is 0.65MPa, and the air pressure is 0.5MPa. The running speed of the rolled piece in the controlled cooling zone is 2.5m / s, the running time of the section steel in the controlled cooling zone is about 11.5s, and the average cooling speed of the rolled piece is 24.2~29.1℃ / s. The cooling method adopts regional cooling control, and adopts different cooling strategies for the cooling parts, so that the temperature drop of the flange part and the R part is relatively large, and the temperature drop is 278 ~ 335 ° C, which meets the requirements of rapid cooling, and the H-shaped steel products are different. The temperature tends to be the same at all places, and the temperature difference between all places is obviously reduced.

[0015] Due to the full opening of the six-stage side spray and the bottom spray, the temperat...

Embodiment 2

[0016] Example 2: For Q235B and Q345B, the specifications are: 300×150×6.5×9mm, the 1st, 2nd, 3rd, 4th stage side spray and bottom spray of the cooling device are fully opened, and the 5th and 6th stage side spray and bottom spray are fully opened Off, the water pressure is 0.65MPa, and the air pressure is 0.5MPa. The running speed of the rolled piece in the controlled cooling zone is 2.5m / s, and the running time of the section steel in the controlled cooling zone is about 7.7s. The designed cooling control mode fully considers the temperature field distribution after H-beam rolling, adopts regional cooling control, and adopts different cooling strategies for the cooled parts, so that the temperature drop of the flange part and the R part is relatively large, and the temperature drop is 227~ 282°C, the average cooling rate of the rolled piece is 29.5-36.6°C / s. The lower flange and R part of the H-beam are kept warm for a long time in a higher temperature zone, the transformat...

Embodiment 3

[0018] Example 3: For Q235B and Q345B, the specifications are: 300×150×6.5×9mm, the 1st, 2nd and 3rd stages of side spray and bottom spray of the cooling device are fully opened, and the 4th, 5th and 6th stage of side spray and bottom spray are fully opened Off, the water pressure is 0.65MPa, and the air pressure is 0.5MPa. The running speed of the rolled piece in the controlled cooling zone is 2.5m / s, and the running time of the section steel in the controlled cooling zone is about 5.8s. The designed cooling control mode takes full account of the temperature field distribution after H-beam rolling, adopts zone cooling control, the temperature drop is 175-231°C, and the average cooling rate of the rolled piece is 30.2-39.8°C / s. Although the cooling rate is high, the cooling time is limited, resulting in a higher temperature in the center of the R part, which makes the self-tempering more severe, and the ferrite structure in the R part is only coarser, with a grain size of 8.0-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com