A kind of high friction coefficient wear-resistant composite material and preparation method thereof

A high friction coefficient, composite material technology, applied in the field of wear-resistant materials, can solve problems such as difficulty in large-scale promotion, large structure size, complex structure, etc., and achieve the effect of reducing cost, improving wear resistance, and high dynamic friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

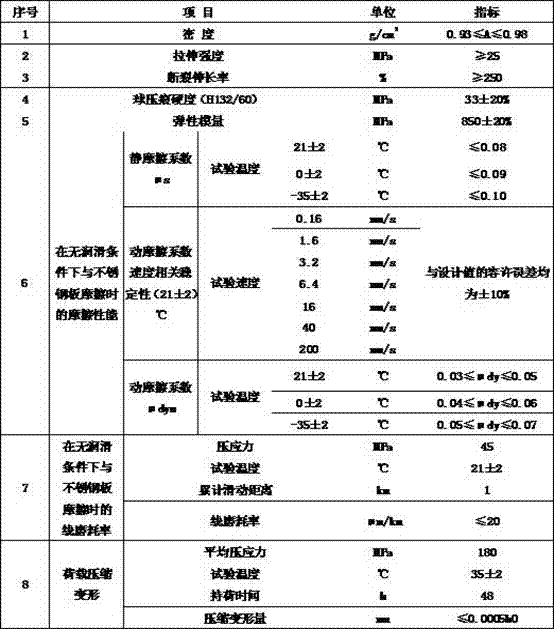

Image

Examples

Embodiment 1

[0027] The preparation method of the high friction coefficient wear-resistant composite material of the present invention comprises the following steps:

[0028] step one

[0029] Put 10 parts by weight of high-density polyethylene, 30 parts by weight of ultra-high molecular weight polyethylene, 10 parts by weight of cross-linked rubber powder, 0.1 part by weight of antioxidant 1010, 5 parts by weight of inorganic powder, and 1 part by weight of carbon black in a mixer Stir at 900 rpm and normal temperature for 8 minutes, then add it to a banbury mixer, and banbury at 175°C for 8 minutes to obtain a lumpy polymer complex;

[0030] step two

[0031] Put the lumpy polymer composite obtained in step 1 into a mold at 180° C. for 10 minutes while hot, and then cool to shape.

Embodiment 2

[0033] The preparation method of the high friction coefficient wear-resistant composite material of the present invention comprises the following steps:

[0034] step one

[0035] Put 20 parts by weight of high-density polyethylene, 40 parts by weight of ultra-high molecular weight polyethylene, 15 parts by weight of cross-linked rubber powder, 0.3 parts by weight of antioxidant 1010, 12.5 parts by weight of inorganic powder, and 3 parts by weight of carbon black in a mixer Stir at 1050 rpm and normal temperature for 8 minutes, then add it to an internal mixer, and banbury at 185°C for 11.5 minutes to obtain a lumpy polymer complex;

[0036] step two

[0037] Put the lumpy polymer composite obtained in step 1 into a mold at 190° C. for 20 minutes while hot, and then cool to shape.

Embodiment 3

[0039] The preparation method of the high friction coefficient wear-resistant composite material of the present invention comprises the following steps:

[0040] step one

[0041] Put 30 parts by weight of high-density polyethylene, 50 parts by weight of ultra-high molecular weight polyethylene, 20 parts by weight of cross-linked rubber powder, 0.5 parts by weight of antioxidant 1010, 20 parts by weight of inorganic powder, and 5 parts by weight of carbon black in a mixer Stir at 1200 rpm at room temperature for 8 minutes, then add it to an internal mixer, and banbury at 195°C for 15 minutes to obtain a lumpy polymer complex;

[0042] step two

[0043] Put the lumpy polymer composite obtained in step 1 into a mold at 200° C. for 30 minutes while it is hot, and then cool to shape.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com