Patents

Literature

30results about How to "Good resistance to environmental stress cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multistep separation of plastics

InactiveCN1659225AGood resistance to environmental stress crackingIncrease dosageElectrostatic separationPlastic recyclingEngineeringPolymer

Techniques for creating recycled plastic materials from waste plastic materials are described. A recycled plastic material contains at least a primary polymer, a secondary polymer, and residual additives. Predetermined properties of the recycled plastic material can be controlled by selecting the types of waste plastic materials used in the recycling feed, determining the types and amounts of recycled plastic material recovered from a separation process and blending the recycled plastic material with other materials.

Owner:MBA POLYMERS INC

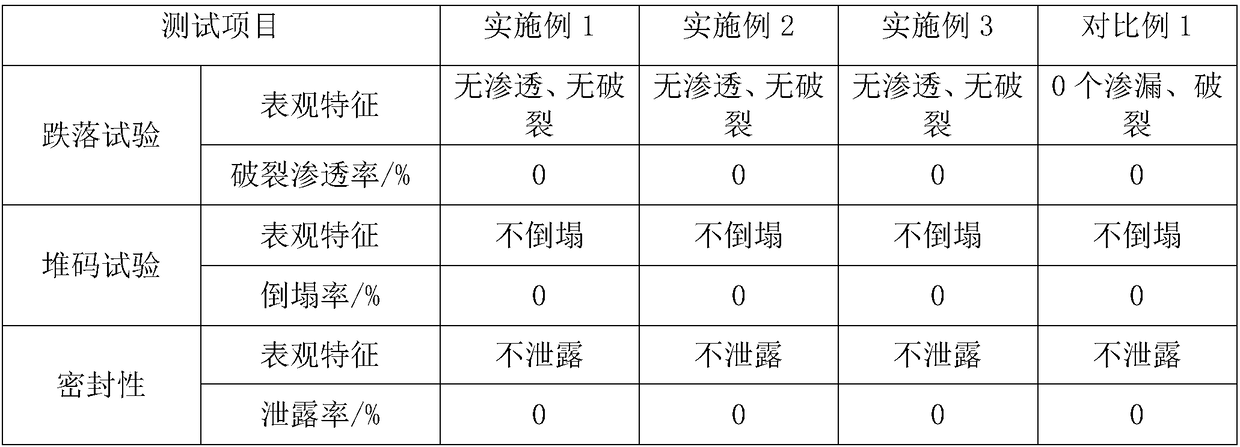

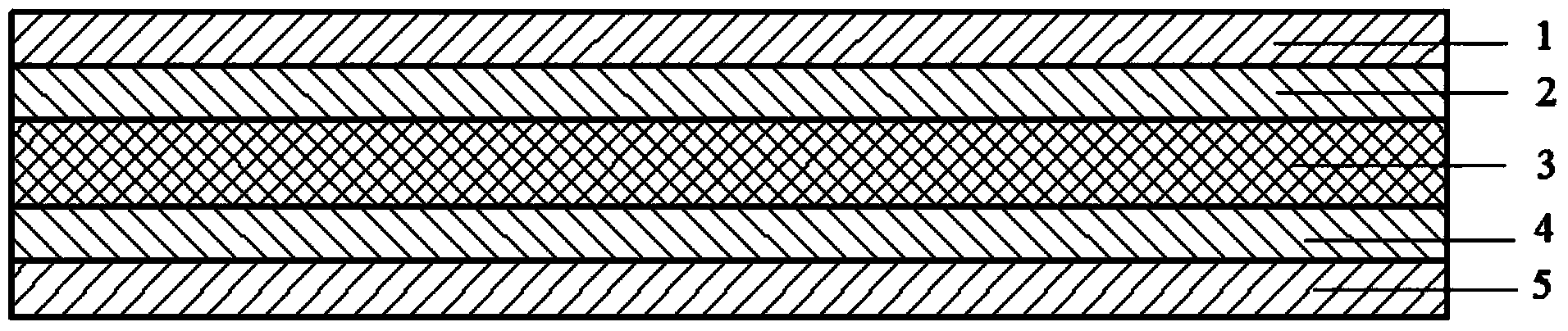

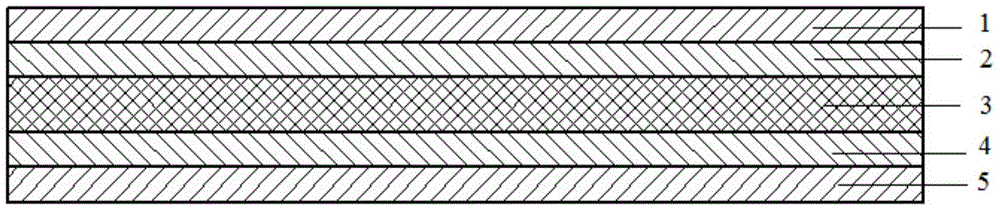

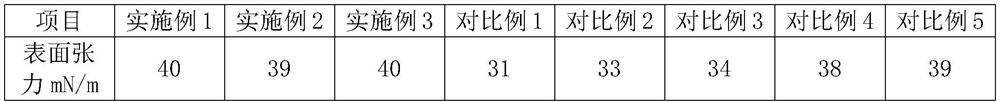

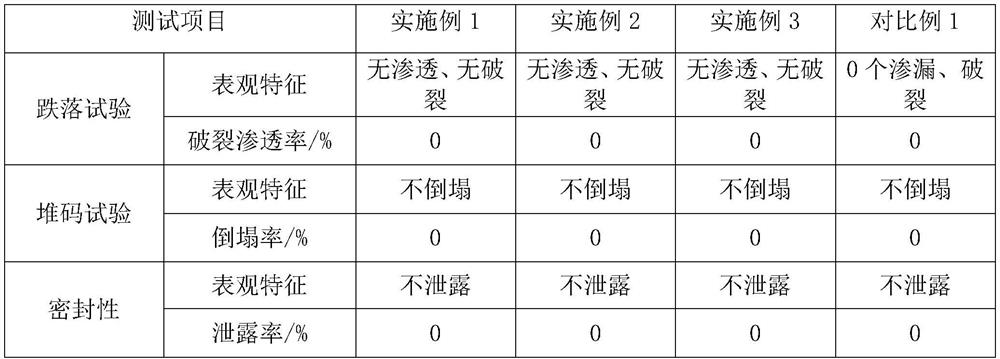

Liquid package composite membrane and preparation method thereof

ActiveCN102673882AHigh heat sealing strengthExcellent drop resistance and pressure resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a liquid package composite membrane and a preparation method thereof and belongs to the technical field of plastic package. The composite membrane comprises a surface layer, an obstruction layer, a reinforced layer and a heat seal layer, wherein the surface layer is a polyethylene terephthalate film layer; the obstruction layer is an aluminum foil layer; the reinforced layer is a polyethylene terephthalate film layer; and the heat seal layer consists of the following materials: 40-60wt% of eight-carbon linear low-density polyethylene, 35-50wt% of polyvinyl acetate and 5-10wt% of low-density polyethylene. The liquid package composite membrane provided by the invention has excellent break-resistant and pressure-resistant performances; break-resistant performance test shows that the liquid package composite membrane does not break while falling to a cement floor from a height of 10 meters once; and pressure-resistant performance test shows that the liquid package composite membrane has no leakage within 24 hours when the static pressure is 20MPa.

Owner:ZHEJIANG GOLDSTONE PACKING

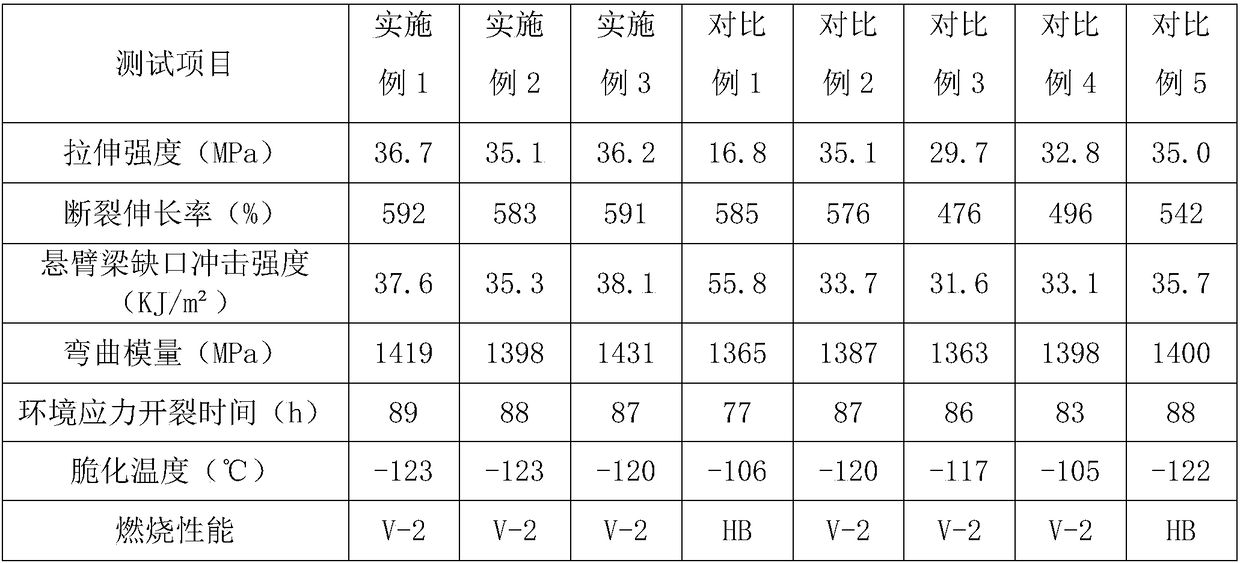

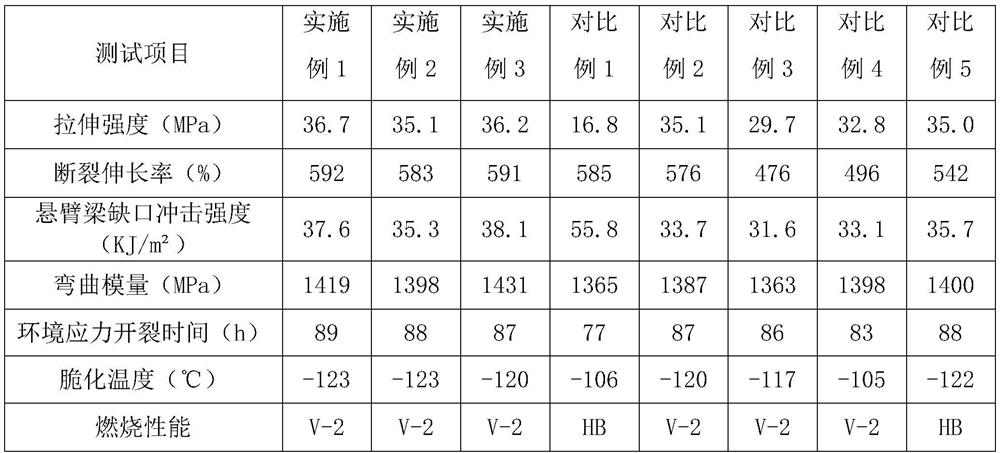

Cold-resistant plastic bucket and preparation method thereof

ActiveCN108822385AImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

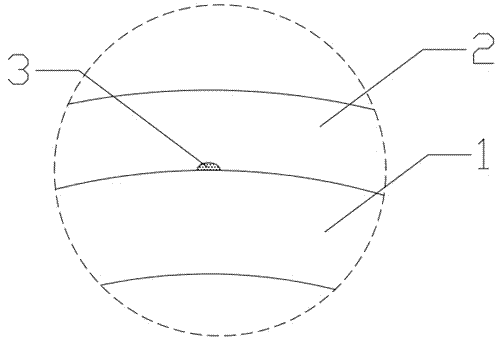

Method for producing silane crosslinked polyethylene hot water flexible tubes through one-step process of single screw extruder

The invention relates to hot water flexible tubes, and concretely relates to a method for producing silane crosslinked polyethylene hot water flexible tubes through a one-step process of a single screw extruder. The method for producing silane crosslinked polyethylene hot water flexible tubes through a one-step process of a single screw extruder has the advantages of obvious reduction of the equipment investment, reduction of the technological difficulty, and increase of the product competitiveness. The method comprises the following steps: adding raw materials to the single screw extruder, carrying out a grafting reaction and mixing of the raw materials through a fusing segment and a homogenizing segment, carrying out extrusion molding through a head grinding mouth, carrying out vacuum sizing, cooling, drawing and curling of the obtained extruded tubes to obtain grafted polyethylene tubes, and crosslinking the grafted polyethylene tubes in hot water to obtain the silane crosslinked polyethylene hot water flexible tubes, wherein the raw materials are composed of 100 parts by mass of a matrix resin, 0.5-5 parts by mass of a silane crosslinking agent, 0.05-0.5 parts by mass of a grafting initiator, 0.02-0.4 parts by mass of a crosslinking catalyst and 0.05-0.5 parts by mass of an antioxidant.

Owner:XIAMEN UNIV

High-performance barrier environmental-friendly package material of inner bag of flexible freight bag and preparation method of package material

ActiveCN103862772AImprove barrier propertiesGood film transparencyFlexible coversWrappersComposite filmEngineering

The invention relates to a high-performance barrier environmental-friendly package material of an inner bag of a flexible freight bag and a preparation method of the package material, which belong to the technical field of flexible package materials. The environmental-friendly package material structurally sequentially comprises a first polyethylene layer, a first adhesive layer, an ethylene-vinyl alcohol (EVOH) layer, a second adhesive layer and a second polyethylene layer from top to bottom; a composite thin film is prepared via a five-layer co-extrusion casting process. The package material of the inner bag of the flexible freight bag has good barrier performance, an environmental-friendly effect and an excellent appearance effect, saves resources and energy, enables packaged goods to not deteriorate easily, and is excellent in thin film transparency, thickness tolerance and heat sealing performance; the environmental-friendly package material prepared via the multiple-layer co-extrusion casting process has the advantages of being easy to recover, generating no harmful gas after burning, and the like, thereby having very high practical value and good market prospects.

Owner:JRB PACKING CO LTD

Modified weather-resistant high-density polyethylene sheathing compound for bridge cables and method for preparing modified weather-resistant high-density polyethylene sheathing compound

ActiveCN105086079AGood resistance to environmental stress crackingUniform colorCarbon blackPOLYETHYLENE WAX

The invention discloses a modified weather-resistant high-density polyethylene sheathing compound for bridge cables. A method for preparing the modified weather-resistant high-density polyethylene sheathing compound includes mixing ultrahigh-molecular-weight polyethylene, high-density polyethylene, linear low-density polyethylene, low-density polyethylene, antioxidants and polyethylene wax with one another in high-speed mixers at normal temperatures to obtain mixtures, discharging the mixtures into parallel double-screw granulation units, melting and extruding the mixtures, granulating the mixtures under underwater conditions to obtain particles, dehydrating the particles, and then drying the particles to obtain modified high-density polyethylene particles; mixing the obtained modified high-density polyethylene particles, high-density polyethylene, carbon black parent materials, antioxidants and silicone parent materials with one another in the high-speed mixers at normal temperatures to obtain mixtures, discharging the mixtures into the parallel double-screw granulation units, melting and extruding the mixtures, granulating the mixtures under underwater conditions to obtain particles, dehydrating the particles, and drying the particles to obtain the modified weather-resistant high-density polyethylene black sheathing compound for the bridge cables. The modified weather-resistant high-density polyethylene sheathing compound and the method have the advantages that the sheathing compound is excellent in physical and mechanical properties, in particular, the ultraviolet resistance property and the environmental stress cracking resistance property, and various indexes of manufactured products conform to requirements of standards CJ / T297-2008 of housing construction departments.

Owner:HUBEI YANGTIAN PLASTIC PROD CO LTD

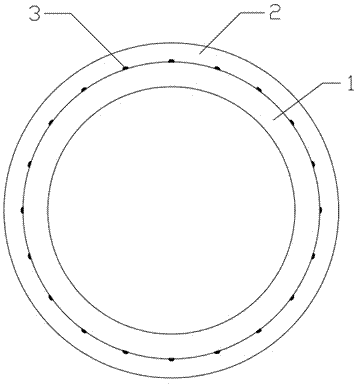

Flexible pipe for water purifying equipment

InactiveCN103939684AHigh strengthGood resistance to environmental stress crackingFlexible pipesEngineeringFiber

The invention relates to a flexible pipe, in particular to a flexible pipe for water purifying equipment. The flexible pipe comprises an inner layer pipe and an outer layer pipe. The inner layer pipe is placed inside the outer layer pipe in a sleeved mode. A braiding layer is formed between the inner layer pipe and the outer layer pipe. The braiding layer forms a net shape through a plurality of strands of wire-shaped bodies in a crossing mode and is wound on the outer wall of the inner layer pipe. Wire filaments are made of reinforcing fibers. The wire-shaped bodies are formed by a plurality of wire filament bundles in a combined mode, and each bundle comprises 200-250 wire filaments. The flexible pipe is good in tenacity and high in impact-resisting strength, pipeline breaking cannot be caused when a heavy object runs over a pipeline directly, PE intensity is high, environment-stress-cracking-resisting performance is good, and creep resistance is good.

Owner:余月华

Preparation method of special sheath material for bridge cable

InactiveCN108239321AGood resistance to environmental stress crackingImprove aging resistanceLow-density polyethyleneSilanes

The invention belongs to the technical field of high molecular materials and relates to a preparation method of a special sheath material for a bridge cable. The special sheath material for the bridgecable is prepared from the following raw materials in parts by weight: 50-80 parts of high density polyethylene, 10-40 parts of low density polyethylene, 5-10 parts of vinyl trimethoxy silane, 1.0-10parts of color master batch, 0.5-1.0 part of an antioxidant, 0.5-1.0 part of a compound ultraviolet absorbent and 0.5-1.0 part of a compound plastic modifier. The special sheath material for the bridge cable has excellent environmental stress cracking resistance, ageing resistance and good stability, and the indexes of the material meet the standard CJ / T297-2008 demand of Ministry of Housing andUrban-Rural Development. The preparation process of the special sheath material for the bridge cable is simple and easy to control, and the raw materials and equipment are easily available, so that the special sheath material for the bridge cable is quite conveniently produced on a large scale industrially.

Owner:SHANGHAI BANGZHONG NEW MATERIAL

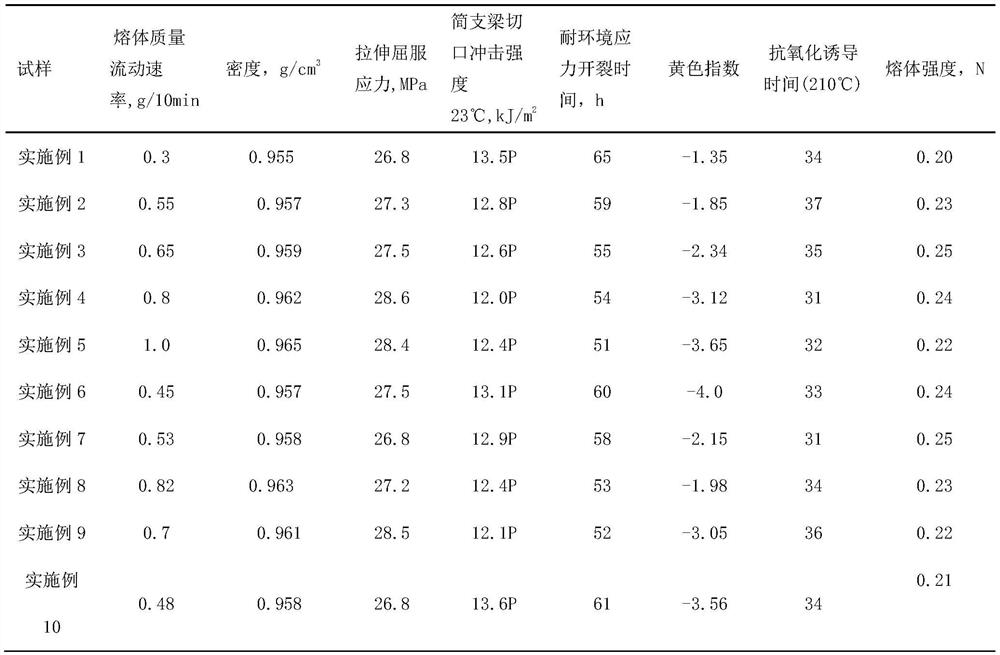

Modified small hollow high-density polyethylene resin for blow molding and preparation method thereof

InactiveCN112280158AAvoid crosslinkingGood resistance to environmental stress crackingPolymer sciencePtru catalyst

The invention discloses modified small hollow high-density polyethylene resin for blow molding and a preparation method thereof. The melt flow rate of the resin is 0.3-1.0 g / 10min, the density is 0.955-0.965 g / cm<3>, the yellow index is -4-0, the environmental stress cracking resistance time exceeds 50h, the oxidation induction resistance time t is more than or equal to 30min (210 DEG C), and themelt strength value tested under the same condition is 0.20 N or above. A chromium catalyst EP30X is adopted to produce the high-density polyethylene resin for small hollow blow molding on an InnoveneS process double-loop high-density polyethylene device. The high-density polyethylene small hollow special resin for blow molding comprises ethylene-hexene copolymerized high-density polyethylene powder, a main antioxidant, an auxiliary antioxidant, a light stabilizer and an antistatic agent. The resin has high mechanical strength and good processability, can meet the requirement of independentlyprocessing small hollow products, and can be used for manufacturing packaging bottles of various milk products and beverages.

Owner:CHINA PETROLEUM & CHEM CORP

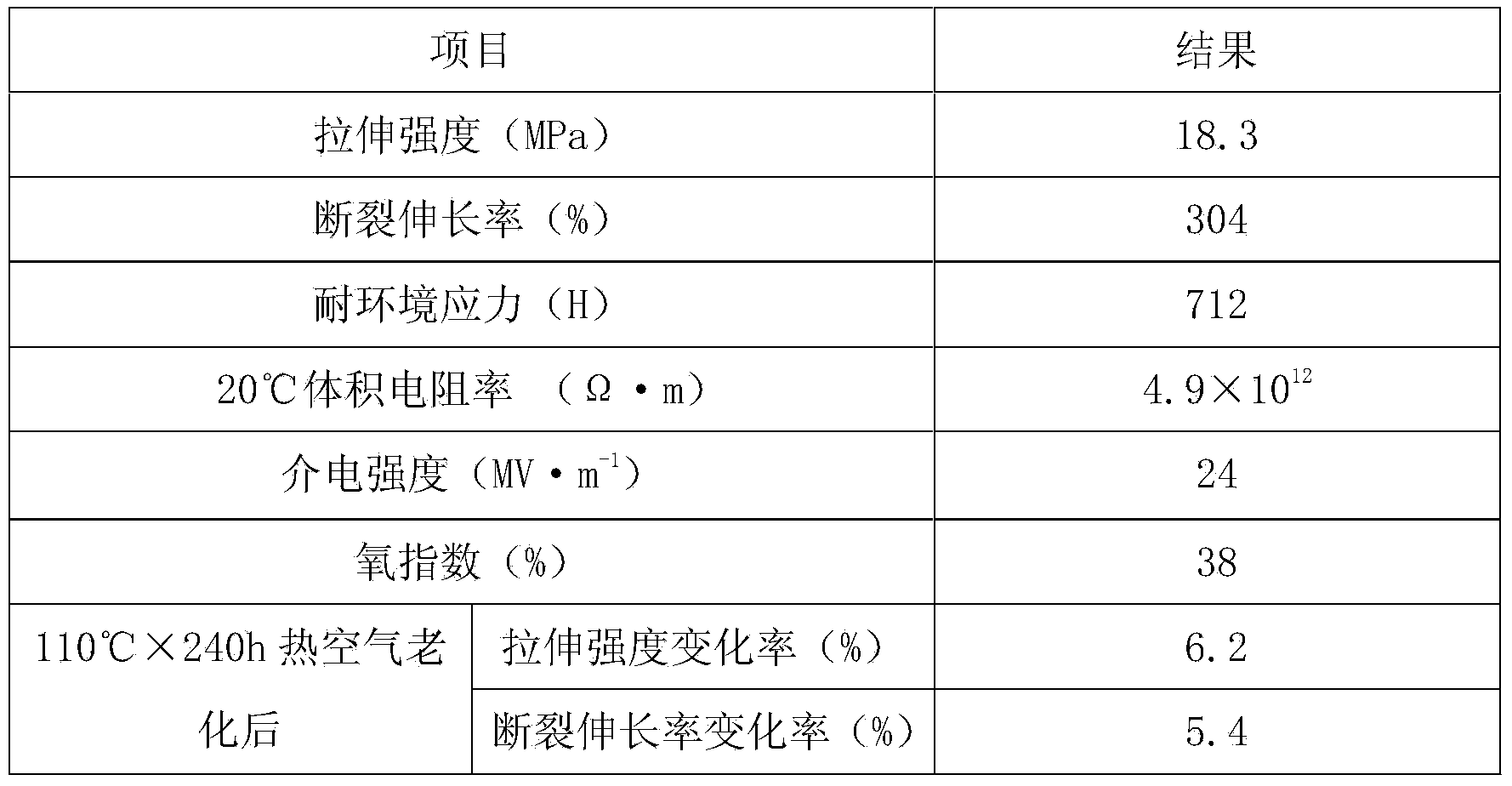

Ultraviolet irradiation cross-linked cable material

InactiveCN109485961ADielectric strength High crystallinityGood heat and cold resistancePlastic/resin/waxes insulatorsLow-density polyethyleneCross-link

The invention discloses an ultraviolet irradiation cross-linked cable material. The ultraviolet irradiation cross-linked cable material comprises, by weight, 20-50 parts of high-density polyethylene,80-100 parts of low-density polyethylene, 30-50 parts of flame retardants, 6-8 parts of melamine cyanurate, 2-4 parts of epoxidized soybean oil, 0.5-5 parts of ultraviolet absorbers, 0.2-0.5 part of coupling agents, 1-5 parts of antioxidants and 0.2-0.4 part of stearic acid. The ultraviolet irradiation cross-linked cable material has the advantages that the thermal properties and the temperature resistance of the ultraviolet irradiation cross-linked cable material can be improved, and accordingly the problems of low work environment temperatures and heat intolerance of existing ultraviolet irradiation cross-linked polyethylene insulation materials can be effectively solved by the aid of the ultraviolet irradiation cross-linked cable material.

Owner:上海电缆厂(南京)有限公司

High-performance barrier environment-friendly packaging material for container bag inner bag and preparation method thereof

ActiveCN103862772BImprove barrier propertiesImprove performanceFlexible coversWrappersComposite filmEngineering

Owner:JRB PACKING CO LTD

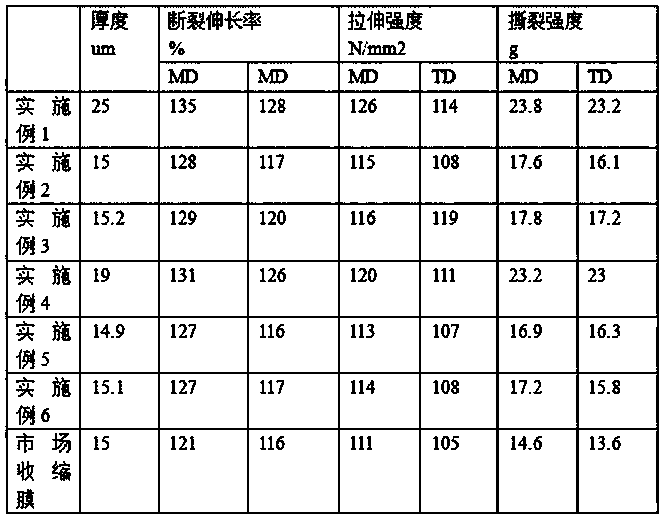

High-flexible environment-friendly shrink film

InactiveCN107759835AGood flexibilitySoft materialSynthetic resin layered productsLaminationLinear low-density polyethyleneTear resistance

The invention discloses a high-flexible environment-friendly shrink film. The shrink film is prepared from, by weight, 5-15 parts of polypropylene, 15-20 parts of polyethylene, 30-40 parts of linear low-density polyethylene, 1-5 parts of high-density polyethylene, 60-80 parts of thermoplastic starch, 5-10 parts of dibutyl phthalate, 1-5 parts of polyethylene wax, 0.5-1 part of antioxidant 168 and1-2 parts of hydrogenated castor oil. The high-flexible environment-friendly shrink film has the advantages of high transparency, high stretching intensity, high tear resistance, good flexibleness andenvironmental friendliness.

Owner:张德发

Compound sound insulation material and preparation method thereof

The invention discloses a compound sound insulation material and a preparation method thereof. The compound sound insulation material contains the following materials by weight percent: 40% of vinyl chloride acetate resin, 10-20% of low-density polyethylene, 20-30% of methyl vinyl silicone rubber, 5-10% of a high molecular compatilizer, 2-3% of a diluent, 1-5% of superfine fiber, and 1-2% of an antioxidant. The preparation method comprises the following steps: S1, weighing and preparing materials: weighing the materials according to weight percentage and marking for storage; S2, feeding and blending; S3, plastifying; and S4, performing extrusion molding. According to the invention, due to the setting of components including vinyl chloride acetate resin, low-density polyethylene, methyl vinyl silicone rubber, high molecular compatilizer, diluent, superfine fiber and antioxidant, so that the sound insulation effect of the compound sound insulation material is improved; and due to the setting of preparation procedures of weighing and preparing materials, feeding and blending, plastifying and performing extrusion molding. Therefore, the quality of the sound insulation material is promoted, and further the market competitiveness of the product is promoted.

Owner:王立菊

Special automobile exterior material prepared from TPO skin reclaimed material and preparation method thereof

PendingCN112048114AGood solvent resistanceAccelerated corrosionSuperstructure subunitsFenderAntioxidant

The invention discloses an automobile exterior trimming special material prepared from a TPO skin reclaimed material and a preparation method thereof. Raw materials comprise: a TPO skin reclaimed material, copolymerized PP, a molecular weight regulator, a flexibilizer, a compatilizer, a weather-resistant agent, a filler, an antioxidant and a colorant. The preparation method comprises the followingsteps: mixing and stirring the TPO skin reclaimed material and the molecular weight regulator, adding the copolymerized PP, the flexibilizer, the weather-resistant agent, the compatilizer, the antioxidant, the filler and the colorant, mixing and stirring the components; and feeding the mixture into a double-screw extruder for perfomring extrusion, cooling, drying and granulation. The TPO skin regenerated material is creatively applied to production of special materials for automobile exterior decorations such as automobile fenders and wheel covers, so that the product can completely meet theworking condition performance requirements of the automobile exterior decorations such as the automobile fenders and the wheel covers, so that high-impact-resistance PP or PE materials are replaced, the problems of resource waste, environmental pollution and the like can be relieved, the production cost can be effectively reduced, and economic benefit is increased.

Owner:广西鑫深科技有限公司

Hard alloy adhesive

InactiveCN105647202AGood compatibilityImprove wettabilityTransportation and packagingMetal-working apparatusParaffin waxAdhesive

The invention discloses a hard alloy adhesive and relates to the field of the powder metallurgy technology. The hard alloy adhesive comprises, by weight, 60-65 parts of solid paraffin, 5-8 parts of liquid paraffin, 10-15 parts of high density polyethylene, 8-12 parts of polypropylene, 5-8 parts of dioctyl phthalate and 5-10 parts of stearic acid. Compared with the prior art, compatibility between the hard alloy adhesive and metal powder is good, environmental stress cracking resisting capacity of a blank formed by injection of feed formed by mixing the adhesive and the metal powder is high, and cracks are prevented from being generated in the solvent degreasing process.

Owner:LIUZHOU ANLONG MACHINERY EQUIP

Stress-resistant plastic part processing technology

ActiveCN112917736AImprove cooling effectQuality improvementMoving filtering element filtersElectric machineryEngineering

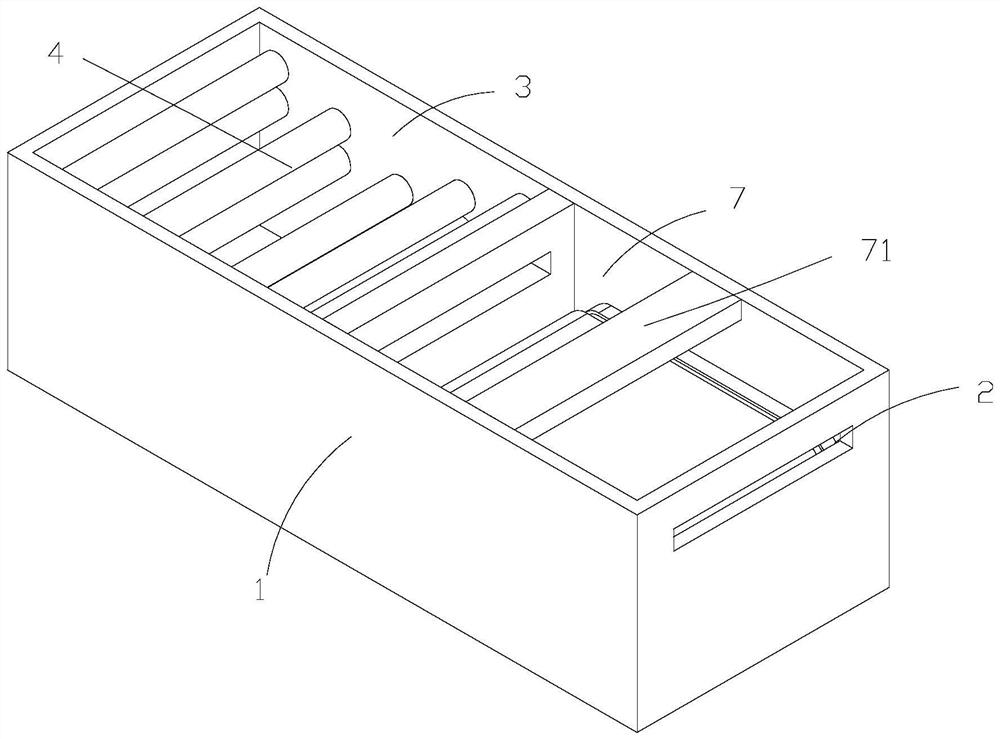

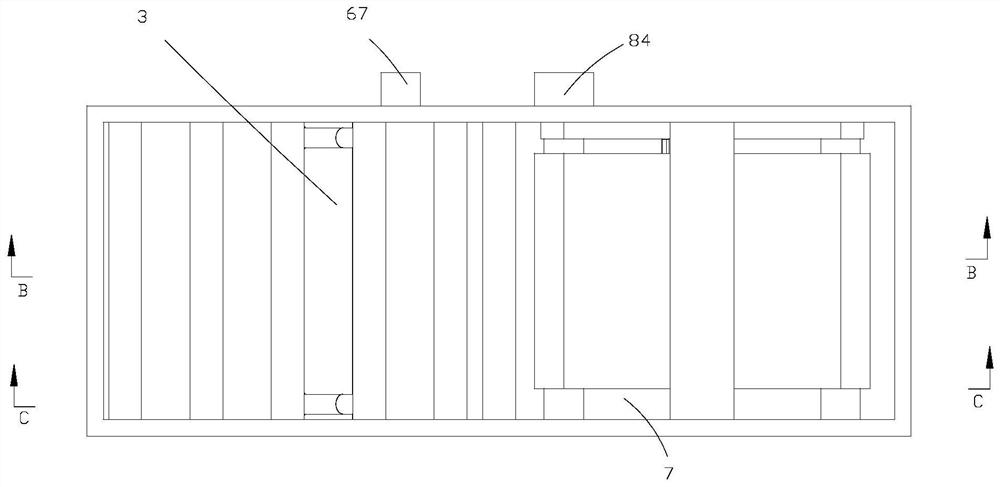

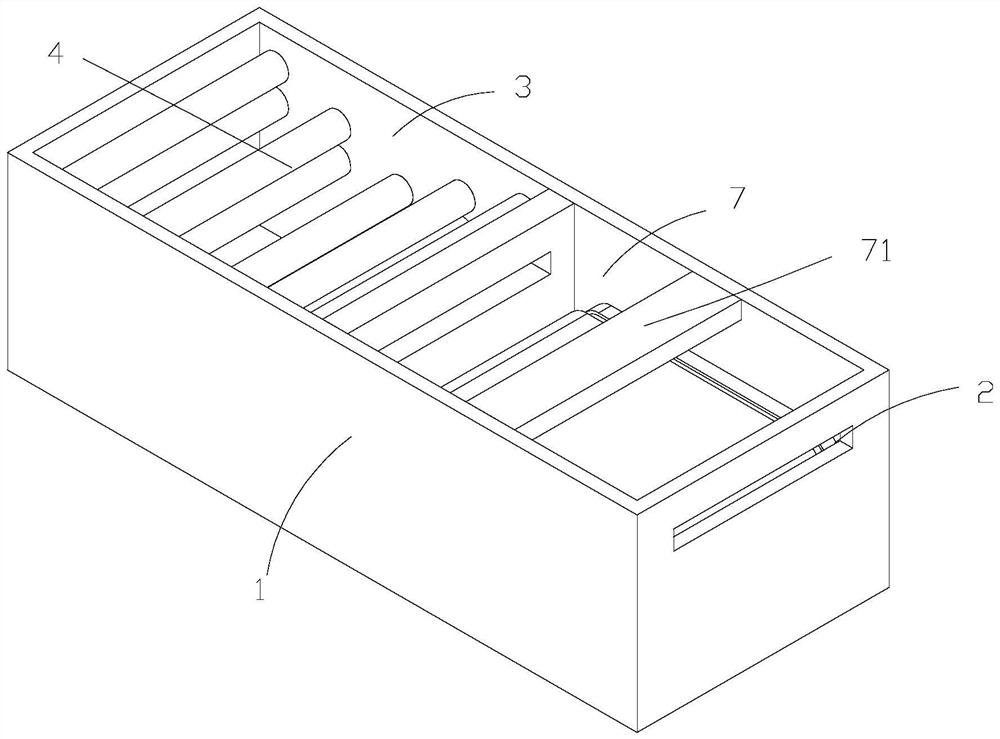

The invention discloses a stress-resistant plastic part machining technology. The stress-resistant plastic part machining technology comprises the following steps of: a, mixing: mixing ethylene-hexene copolymerized polyethylene resin, an antioxidant, an auxiliary antioxidant and a release agent; b, compounding: compounding the mixture in the step a; c, cooling: cooling the mixture extruded in the step b; and d, pelletizing: pelletizing the mixture in the step c. A cooling tank in the step c comprises a main body, a material opening, a cooling cavity, a transfer roller, a transfer spring, a flow guide cylinder, a flow guide device, a drying cavity, a fan, a drying device, a rotating wheel, a first collecting belt, a collecting spring, a second collecting belt, a second motor, a driving cylinder, a scraper blade, an opening and a water removal mechanism. According to the stress-resistant plastic part machining technology, the stress resistance of the plastic can be improved, so that the comprehensive mechanical property of the plastic is higher. The cooled mixture is dried, so that the washed impurities in cooling water can be removed, and the quality of the plastic is improved. Impurities in the drying cavity are automatically cleaned during drying, so that the cooling and drying efficiency is improved.

Owner:KUNSHAN JINLIAN PLASTIC PROD

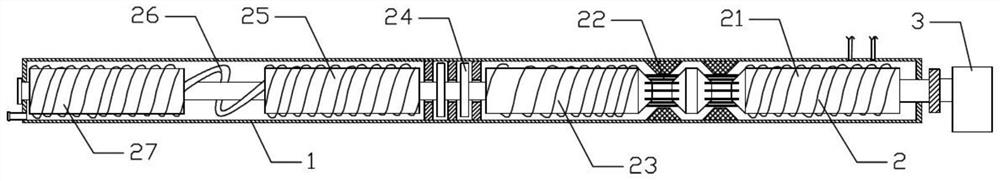

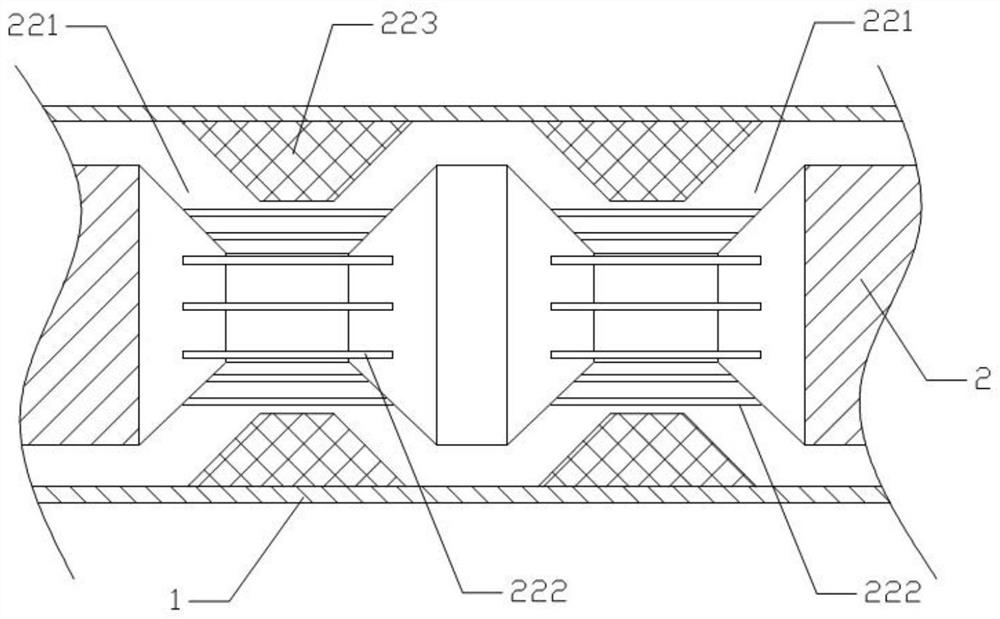

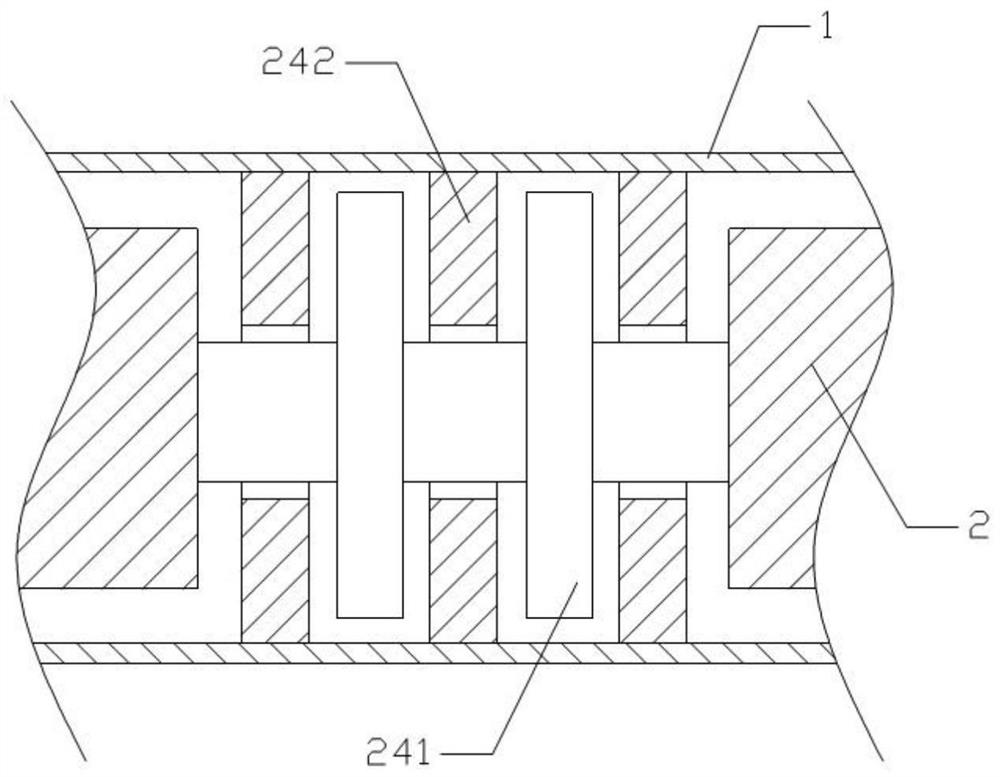

A kneading extrusion device

ActiveCN110948825BAchieve hybridReduce production equipment costsDomestic articlesElectric machineryEngineering

The invention discloses a kneading and extruding device, which comprises a barrel, an extruding screw and a driving motor. The direction is provided with feeding section, primary mixing section, first exhaust feeding section, shear mixing section, second exhaust feeding section, kneading section and discharge extrusion section; the peripheral wall ring of primary mixing section is provided with let There are multiple stirring rods in the recess, the inner wall of the barrel is provided with a guide ring, the shear mixing section is equipped with multiple first dispersing discs, the inner wall of the barrel is provided with a second dispersing disc, and the second dispersing disc is provided on the inner wall of the barrel. The second dispersing discs are arranged alternately with the first dispersing discs. The combination of material mixing and extrusion completely solves the problem of insufficient mixing of traditional mixing devices, improves product quality, and reduces production equipment and production costs. After cross-linking, the material has high structural strength and better mechanical properties. and resistance to environmental stress cracking.

Owner:重庆赛亿高分子材料有限公司

Liquid package composite membrane and preparation method thereof

ActiveCN102673882BHigh heat sealing strengthExcellent drop resistance and pressure resistanceFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention provides a liquid package composite membrane and a preparation method thereof and belongs to the technical field of plastic package. The composite membrane comprises a surface layer, an obstruction layer, a reinforced layer and a heat seal layer, wherein the surface layer is a polyethylene terephthalate film layer; the obstruction layer is an aluminum foil layer; the reinforced layer is a polyethylene terephthalate film layer; and the heat seal layer consists of the following materials: 40-60wt% of eight-carbon linear low-density polyethylene, 35-50wt% of polyvinyl acetate and 5-10wt% of low-density polyethylene. The liquid package composite membrane provided by the invention has excellent break-resistant and pressure-resistant performances; break-resistant performance test shows that the liquid package composite membrane does not break while falling to a cement floor from a height of 10 meters once; and pressure-resistant performance test shows that the liquid package composite membrane has no leakage within 24 hours when the static pressure is 20MPa.

Owner:ZHEJIANG GOLDSTONE PACKING

Metal and polyolefin composite material, preparation method thereof and container

The invention relates to the field of polymer composite materials, in particular to a metal and polyolefin composite material, a preparation method thereof and a container. The composite material of the metal and the polyolefin comprises a metal material and a polyolefin material, the polyolefin material is obtained by performing a cross-linking reaction on a polyolefin composition, the polyolefincomposition comprises polyolefin, a compatilizer, a peroxide cross-linking agent and a silane coupling agent, and relative to 100 parts by weight of polyolefin, the content of the compatilizer is 0.1-20 parts by weight, the content of the peroxide cross-linking agent is 0.01-6 parts by weight, and the content of the silane coupling agent is 0.1-5 parts by weight. The metal and polyolefin composite material provided by the invention is not easy to crack, good in high temperature resistance and longer in service life.

Owner:神华(北京)新材料科技有限公司

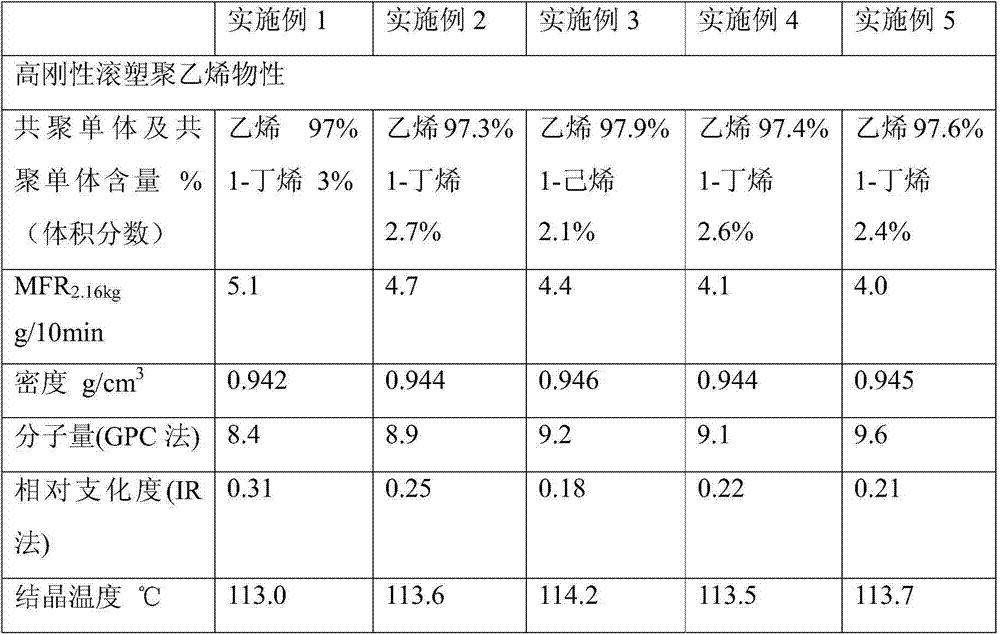

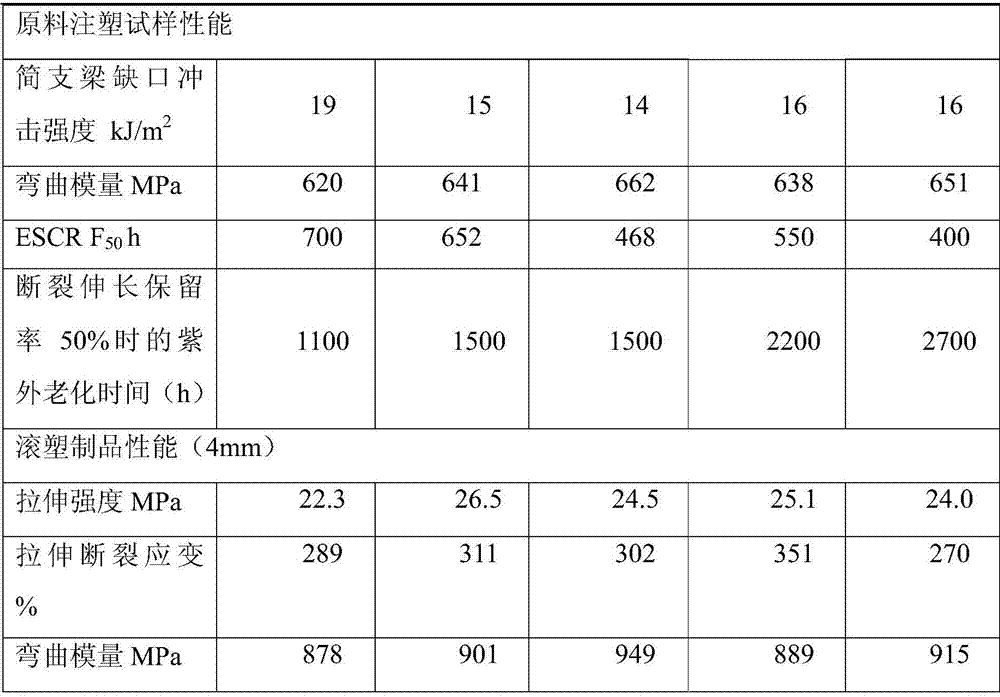

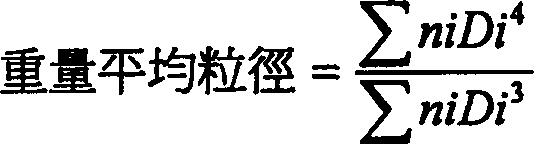

Polyethylene composition for rotomoulding and its preparation method

The invention relates to a polyethylene polymer, in particular to a polyethylene composition for rotational molding. Including polyethylene, the polymerization monomer of polyethylene is: ethylene unit with a volume fraction of 90-98%; 1-butene or 1-hexene copolymerized unit with a volume fraction of 2-10%. The melt mass flow rate of the polyethylene is 3-7g / 10min, the density is 0.940-0.950g / cm3, the weight-average molecular weight is 8-100,000, the molecular weight distribution is 4.0-5.0, and the relative branching degree is 0.1- 0.5, and the crystallization temperature is 112.5-114.5°C. The invention improves the rigidity and strength of raw materials while ensuring good impact and environmental stress cracking resistance, and the produced rotomolded products have high rigidity and toughness, smooth inner and outer surfaces, and good plasticization; the invention also provides The preparation method thereof is provided, and the process is simple and easy for industrialized production.

Owner:CHINA PETROLEUM & CHEM CORP

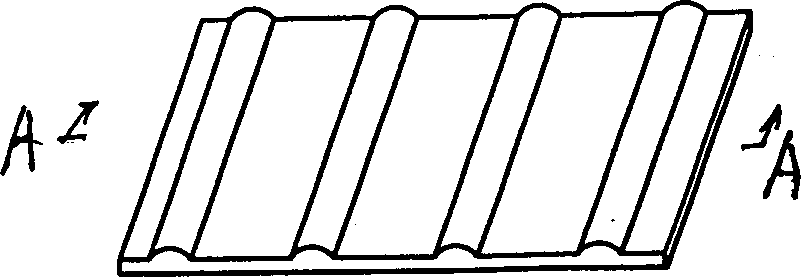

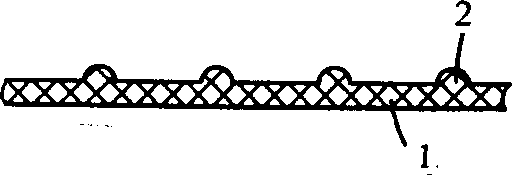

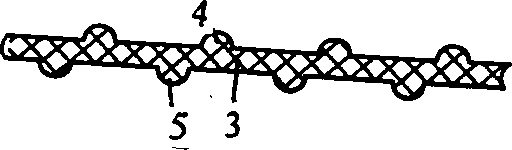

Silane cross-linked and directionally stretched high-strength polymer film

InactiveCN1386621AHigh tensile strengthGood resistance to environmental stress crackingFlat articlesSilanesHigh resistance

A silane cross-linked high-strength polymer film orientated by stretching has at least one layer of silane cross-linked polymer, and is prepared through stretching unidirectionally or bidirectionallyfor orientation, hydrolysis in wet and hot condition, and condensation and cross-linking reaction. It has high concave-convex reinforcing ribs for higher tension strength. Its advantages are high resistance to ageing and cracking, high strength and long service life.

Owner:甘国工

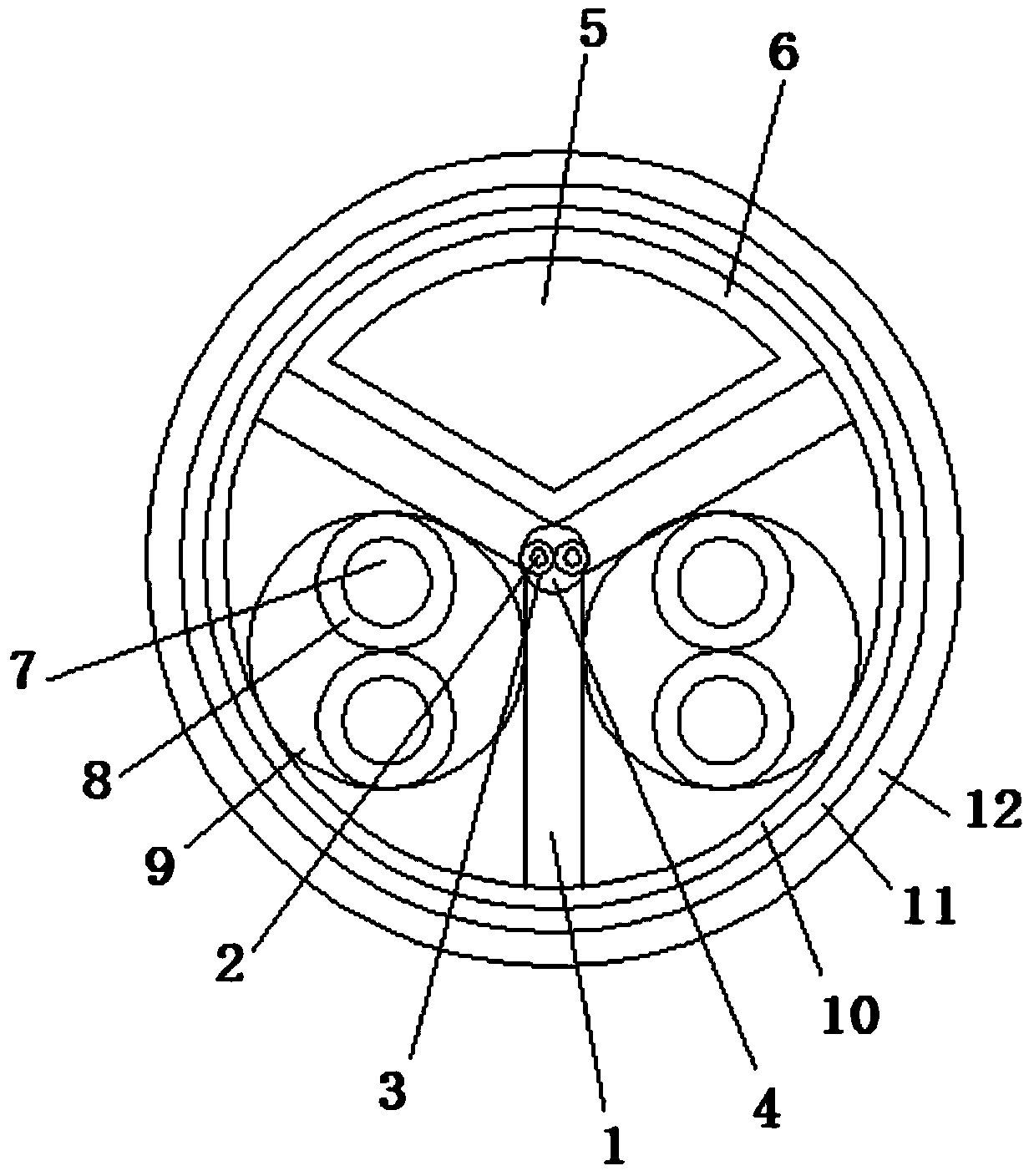

Fan-shaped and round fire-resisting cable provided with Y-shaped nylon framework

InactiveCN103928129AGuaranteed stabilityGood resistance to environmental stress crackingInsulated cablesCable/conductor manufactureCross-linked polyethyleneMica

The invention discloses a fan-shaped and round fire-resisting cable provided with a Y-shaped nylon framework. The cable comprises a cable core which comprises the Y-shaped nylon framework, wherein a temperature measurement cable core body is arranged at the center of the Y-shaped nylon framework, a control cable core body is arranged in each of two interspaces of the Y-shaped nylon framework, and a ground cable core body is arranged in another interspace of the Y-shaped nylon framework. The ground cable core body comprises a fan-shaped conductor which is wrapped in a crosslinked polyethylene insulation layer. Each control cable core body comprises two round conductors and silicon rubber insulation layers arranged outside the round conductors in a wrapping mode, and the two round conductors are twisted together in a pairing mode and then wrapped in a fire-resisting mica layer. The cable core is sequentially wrapped in a glass fiber fire-resisting layer, a steel-plastic strip longitudinal wrapping armor layer and a sheathe layer. According to the cable, a temperature measuring conductor and a control cable are combined through the Y-shaped nylon framework, temperature change occurring when the cable is used can be monitored, and then the warning function is achieved, fire disasters can be stopped or avoided in advance, and the stability of the cable is guaranteed.

Owner:WUHU HANGTIAN SPECIAL CABLE FACTORY

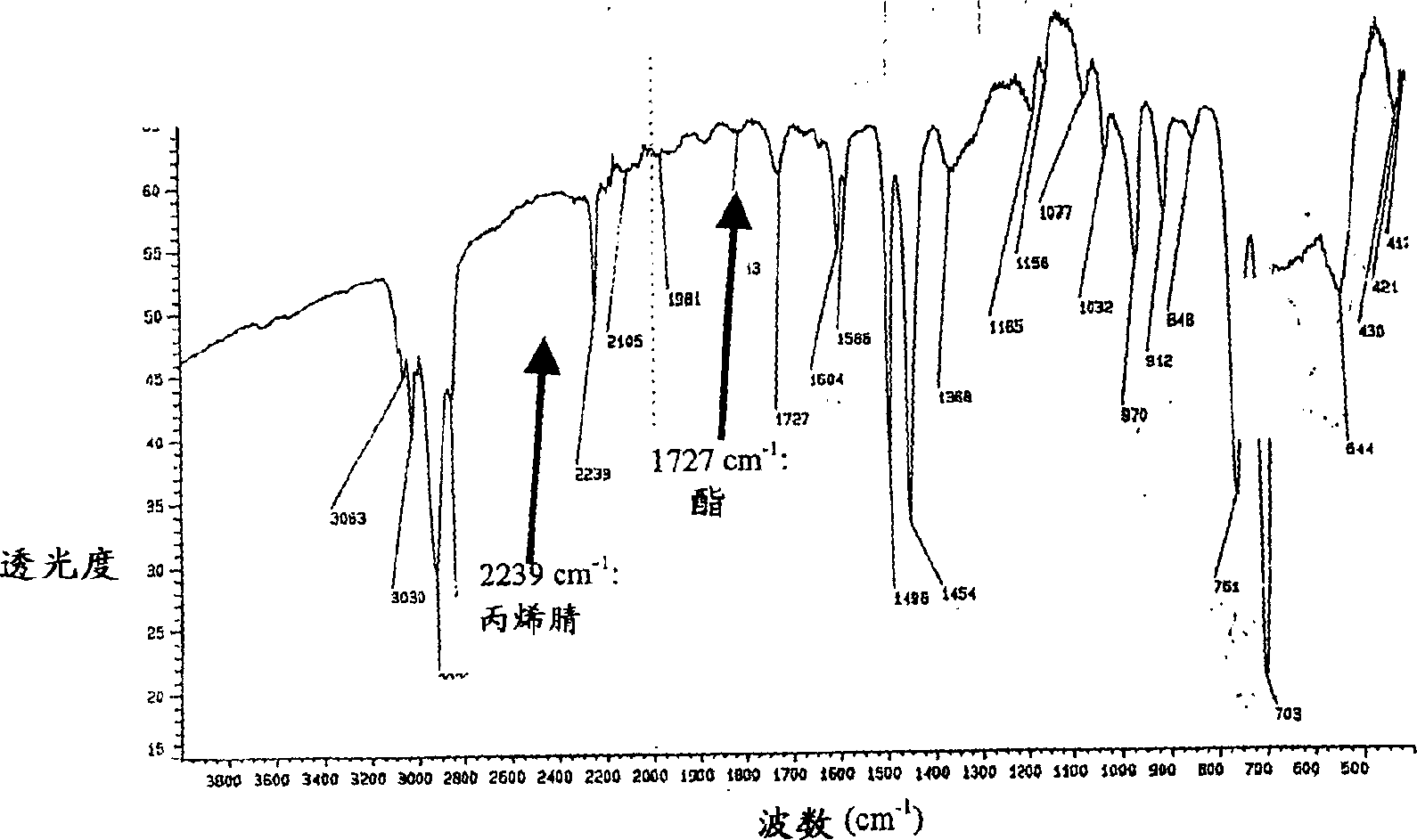

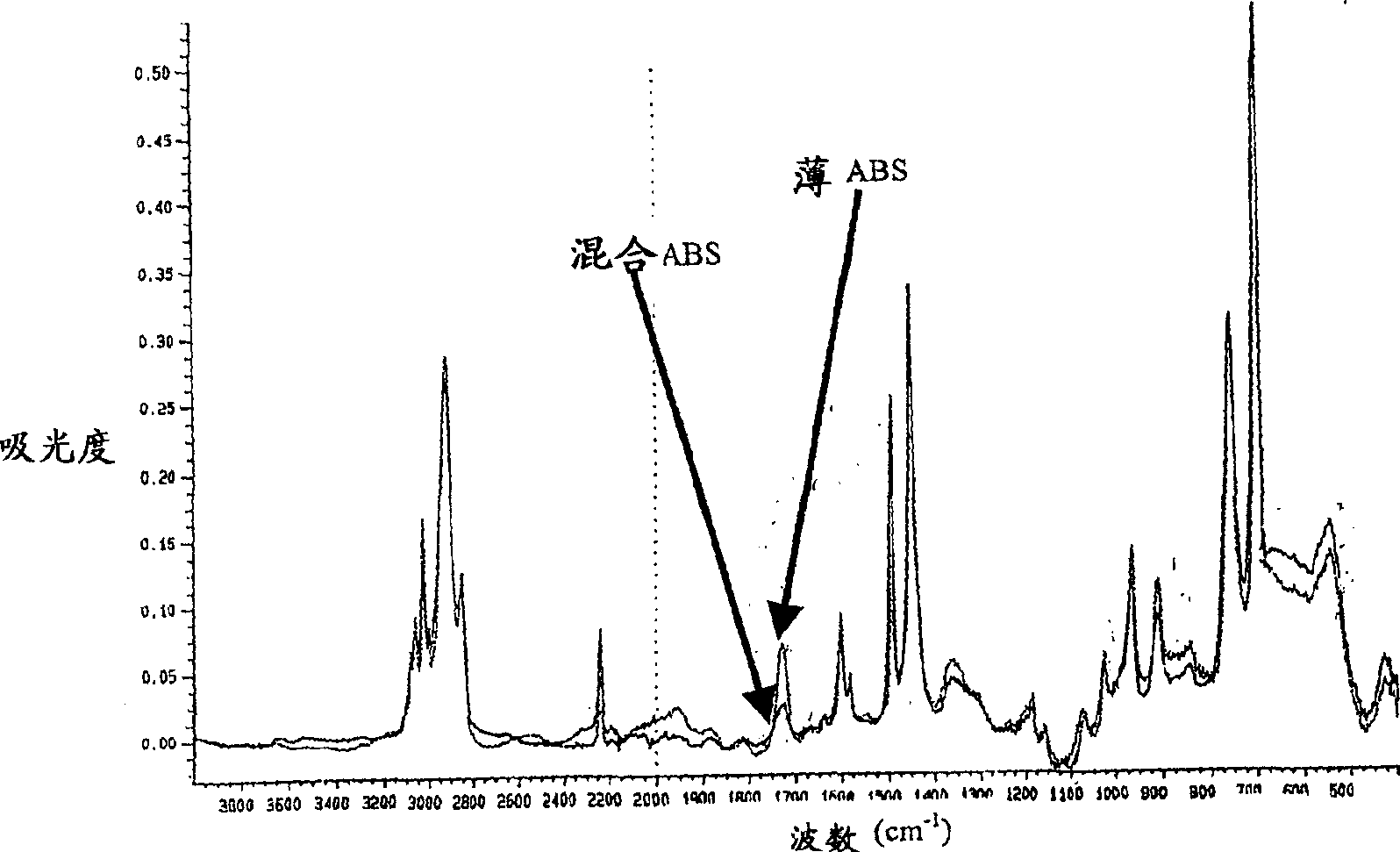

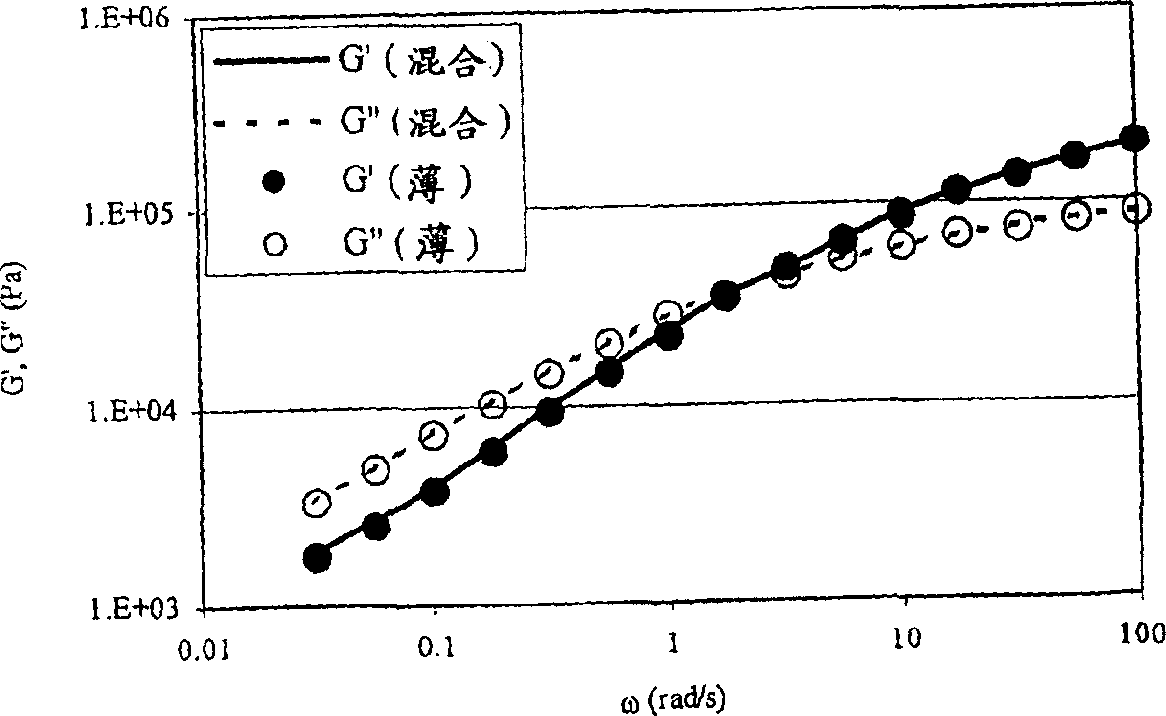

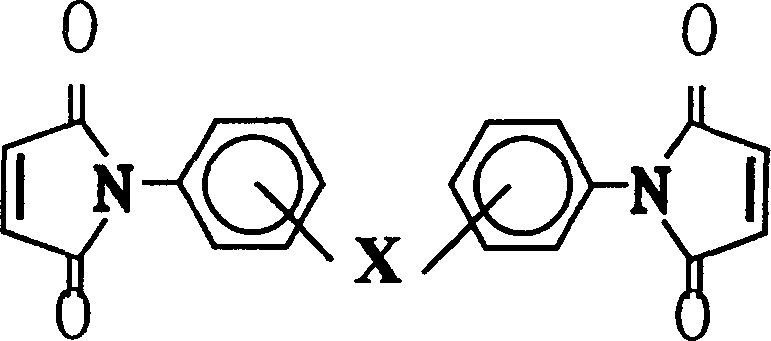

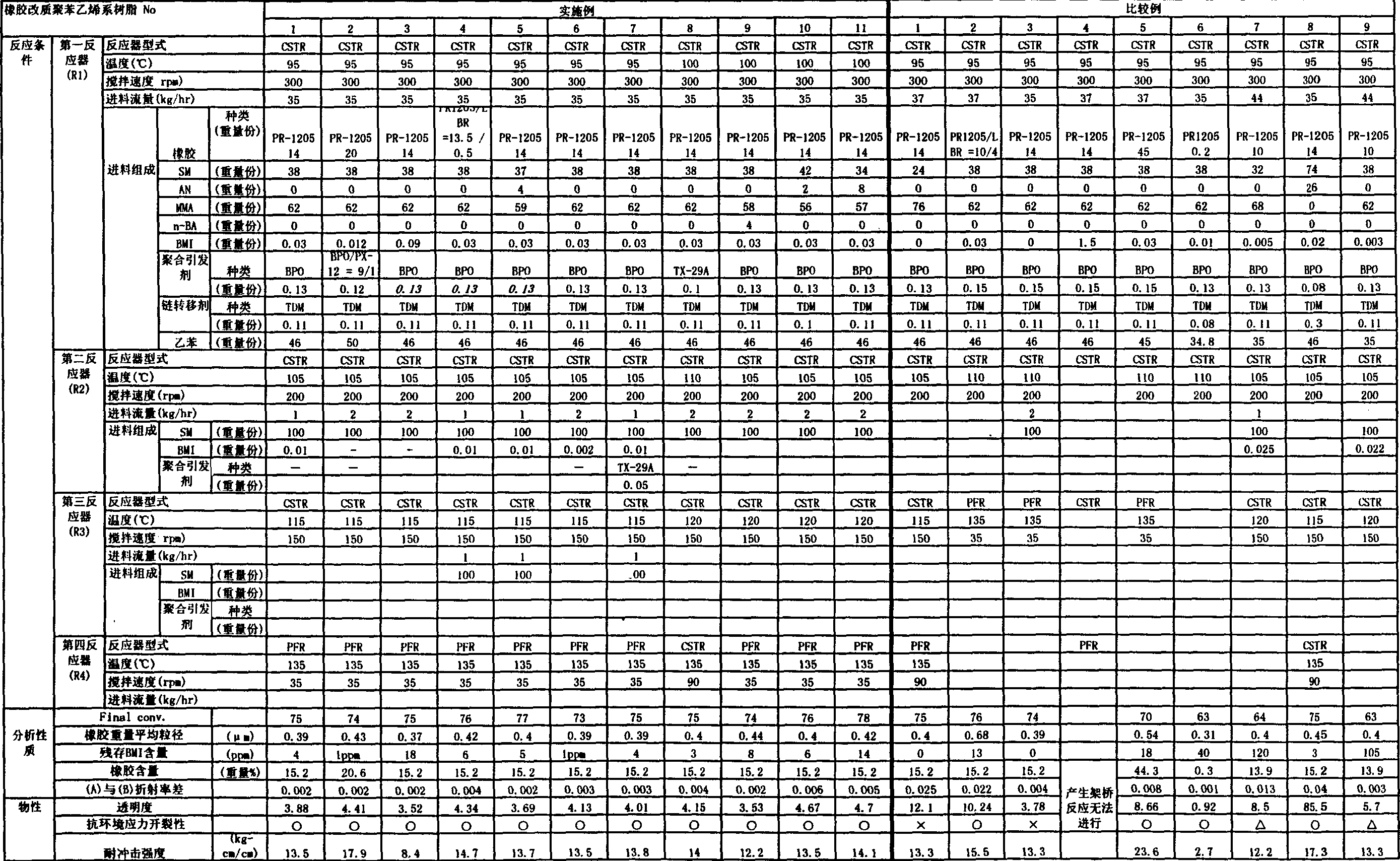

Transparent rubber modified styrene resins

The invention transparent rubber modified styrene resin, which comprises (i-1) phenylethene monomer 20-70 weight portions, (i-2) methacrylate ester 30-80 weight portions, (i-3) copolymarization monomer 0-40 weight portions, and polyfunctional maleimide monomer 0.0005-1.0 weight portion as continuous phase, as well as rubber particles formed by rubber-like polymer as disperse phase, the content rubber in the transparent rubber modified styrene resin is 1-40 wt%.

Owner:CHI MEI CORP

Cold-resistant plastic barrel and preparation method thereof

ActiveCN108822385BImprove cold resistanceImprove heat resistanceLinear low-density polyethylenePolymer science

The invention discloses a cold-resistant plastic bucket and a preparation method thereof, and belongs to the technical field of a plastic packaging container. The cold-resistant plastic bucket is characterized in that the cold-resistant plastic bucket is prepared from the components in parts by weight: 60 to 80 parts of high-density polyethylene, 15 to 25 parts of linear low-density polyethylene,10 to 20 parts of maleic anhydride grafted high-density polyethylene, 5 to 7 parts of high-polymerization-degree polyvinyl chloride, 6 to 8 parts of ethylene-vinyl acetate copolymer, 0.5 to 1.0 part of ultraviolet absorption agent, 1 to 1.5 parts of antioxidant, 2 to 3 parts of plasticizer and 5 to 7 parts of silica power; the high-density polyethylene has a density of 0.936 g / cm<3> and a melt index of 1.4 g / 10 min; the linear low-density polyethylene has a density of 0.920 g / cm<3> and a melt index of 1.0 g / 10 min. The invention reaches the technical effect of enabling the polyethylene plasticbucket to also have excellent printing performance when having cold resistance.

Owner:青岛邦德化工有限公司

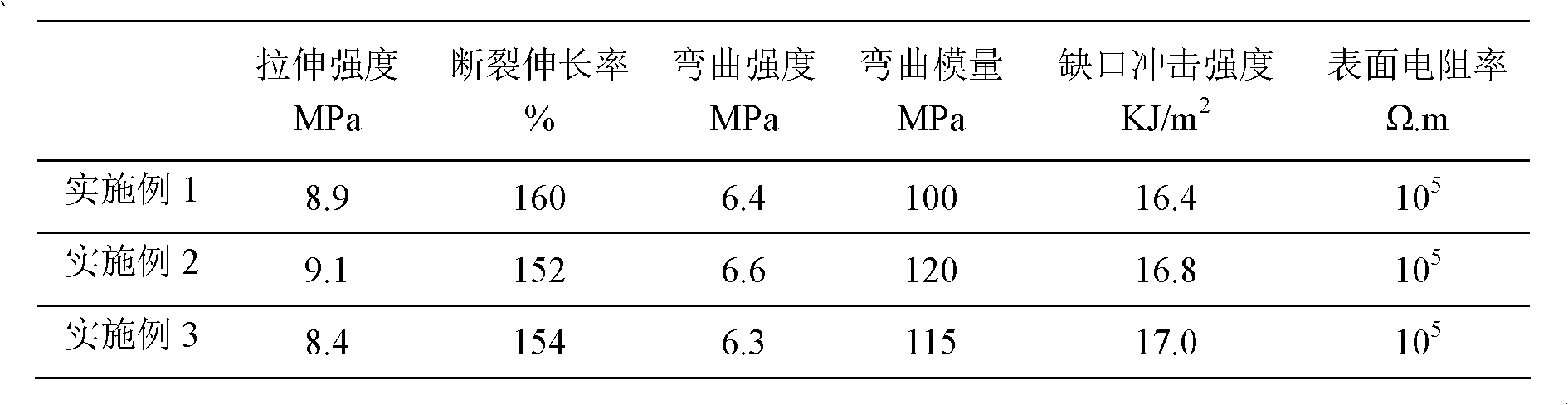

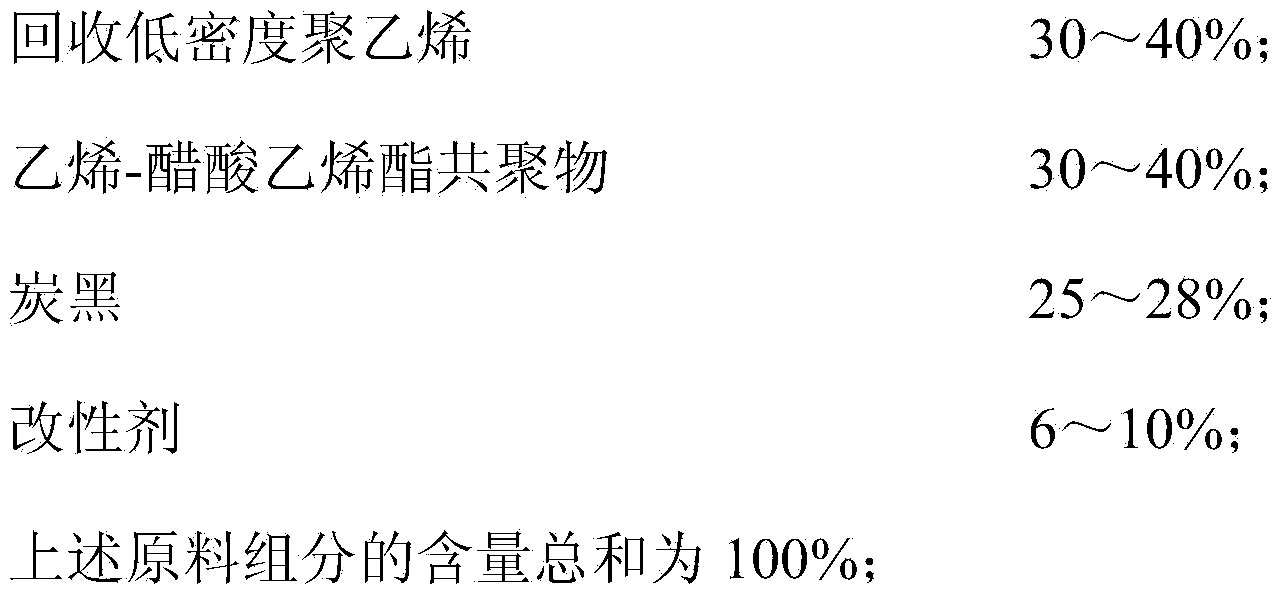

Manufacture method of halogen-free semiconductive shielding cable material

ActiveCN102558658BSimple processing methodReduce manufacturing costPower cables with screens/conductive layersLow-density polyethyleneCarvacryl acetate

The invention relates to the field of high polymer materials and in particular discloses a manufacture method of a halogen-free semiconductive shielding cable material which is prepared by recovering low-density polyethylene and ethylene-vinyl acetate copolymer as a matrix, adding carbon black and a modifying agent and blending. The manufacture method provided by the invention has the advantages of simplicity, lower production cost and high production efficiency; and the manufactured halogen-free semiconductive shielding cable material has the properties of better tensile strength, elongation at break, flexing property, environmental stress crack resistance and the like.

Owner:ANNAZHI THERMAL ENERGY TECH SUZHOU CO LTD

Novel modification formula of steel belt pipe

The invention discloses a novel modification formula of a steel belt pipe. The specific production method comprises the following steps that S1, a production technology principal compiles a special scheme for the production of the novel steel belt pipe, compiles a targeted emergency plan, and carries out the technical disclosure work on the production principal and a worker before production; S2, the steel belt, HDPE polyethylene resin, a PP toughening agent, adhesive resin, an HDPE linear material, glass fibers, a defoaming agent, an antioxidant and a coupling agent are weighed in corresponding parts by weight for later use; S3, the steel belt weighed in the second step is put into an ultrasonic cleaning machine in a segmented mode, clear water and a sodium carbonate solution are added for ultrasonic cleaning, the steel belt is quickly blow-dried in warm air, and dirt and impurities on the surfaces of particles are removed. The produced steel belt pipe is good in quality and performance, the wave crest of the steel belt corrugated pipe can be reduced, the external force impact resistance of the steel belt corrugated pipe is enhanced, and materials can flow smoothly.

Owner:瓯亚管业有限公司

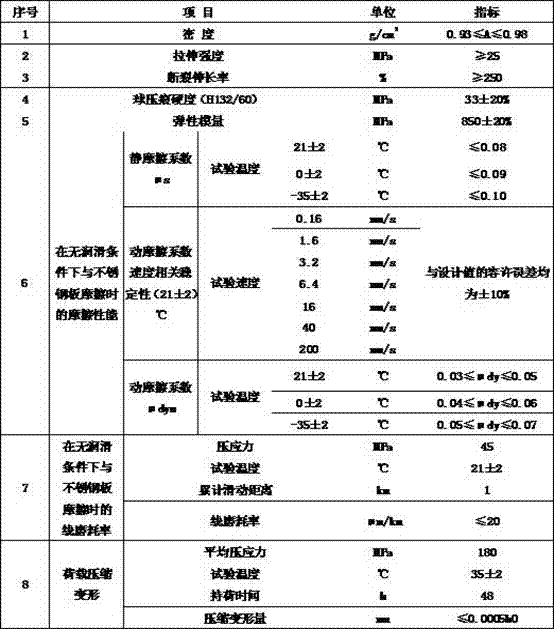

A kind of high friction coefficient wear-resistant composite material and preparation method thereof

The invention belongs to the technical field of wear-resistant materials, and discloses a wear-resistant composite material with a high friction coefficient and a preparation method thereof. The wear-resistant composite material is mainly technically characterized by comprising the following raw materials in parts by weight: 10-30 parts of high-density polyethylene, 30-50 parts of ultra-high molecular weight polyethylene, 10-20 parts of cross-linked rubber powder, 0.1-0.5 part of an antioxidant 1010, 5-20 parts of inorganic powder, and 1-5 parts of carbon black. According to the wear-resistant composite material with the high friction coefficient, provided by the invention, all the components are mixed into pellets by using an internal mixer, then, the compression molding is carried out, and the machinability of the high-density polyethylene, the wear resistance of the ultra-high molecular weight polyethylene, and the high friction coefficient of the cross-linked rubber powder are fully utilized, so that the composite material with a high dynamic friction coefficient, good wear resistance and higher strength is obtained; the wear-resistant composite material with the high friction coefficient is prepared by adopting an internal mixing technology, and leftover materials can be recycled, so that environment friendliness is achieved.

Owner:HENGSHUI ZHONGTIEJIAN ENG RUBBER

A processing technology of stress-resistant plastic parts

ActiveCN112917736BImprove cooling effectQuality improvementMoving filtering element filtersPolymer scienceCooling chamber

The invention discloses a process for processing a stress-resistant plastic part, which comprises the following steps: a. mixing: mixing ethylene hexene copolymerized polyethylene resin, antioxidant, auxiliary antioxidant and mold release agent; b. mixing: The mixture in a is kneaded; c, cooling: the extruded mixture in b is cooled; d, pelletizing: the mixture in c is pelletized; the cooling tank in c includes a main body, a Material port, cooling chamber, transfer roller, transfer spring, guide cylinder, guide device, drying chamber, fan, drying device, rotating wheel, first collection belt, collection spring, second collection belt, second motor, Drive cylinder, scraper, opening and water removal mechanism; the preparation of this method of the present invention can improve the stress resistance of plastics and make the comprehensive mechanical properties of plastics higher; drying the cooled mixture can remove the flushing in the cooling water. Therefore, the quality of the plastic is improved; the impurities in the drying cavity are automatically cleaned at the same time, and the efficiency of cooling and drying is improved.

Owner:KUNSHAN JINLIAN PLASTIC PROD

Acid and alkali resistant anti-interference shielding computer cable

PendingCN114156004AImprove performanceHigh tensile strengthPlastic/resin/waxes insulatorsClimate change adaptationLinear low-density polyethyleneEngineering

The invention discloses an acid and alkali resistant anti-interference shielding computer cable, which relates to the technical field of computer cables and comprises a cable core, an insulating layer wrapping the cable core, a shielding layer wrapping the insulating layer and an outer sheath layer wrapping the shielding layer. The outer sheath layer is prepared from the following raw materials in parts by weight: 35 to 45 parts of linear low-density polyethylene, 50 to 60 parts of high-density polyethylene, 5 to 10 parts of EVA, 20 to 30 parts of polyethylene modified barium sulfate, 1 to 3 parts of ammonium polyphosphate, 1 to 3 parts of melamine borate, 1 to 3 parts of pentaerythritol, 3 to 5 parts of magnesium stearate, 0.5 to 1 part of DCP, 0.5 to 1 part of TAIC, 0.5 to 1 part of antioxidant and 0.2 to 0.6 part of maleic anhydride grafted polyethylene. The prepared cable sheath material is excellent in performance, good in tensile strength and elongation at break, good in environmental stress cracking resistance, oil resistance, heat resistance, acid and alkali resistance and the like, and good in safe use performance in the petrochemical industry and the iron and steel industry.

Owner:ANHUI ELECTRIC GRP SHARES

One-step method for producing silane cross-linked polyethylene hot water hose by single-screw extruder

The invention relates to hot water flexible tubes, and concretely relates to a method for producing silane crosslinked polyethylene hot water flexible tubes through a one-step process of a single screw extruder. The method for producing silane crosslinked polyethylene hot water flexible tubes through a one-step process of a single screw extruder has the advantages of obvious reduction of the equipment investment, reduction of the technological difficulty, and increase of the product competitiveness. The method comprises the following steps: adding raw materials to the single screw extruder, carrying out a grafting reaction and mixing of the raw materials through a fusing segment and a homogenizing segment, carrying out extrusion molding through a head grinding mouth, carrying out vacuum sizing, cooling, drawing and curling of the obtained extruded tubes to obtain grafted polyethylene tubes, and crosslinking the grafted polyethylene tubes in hot water to obtain the silane crosslinked polyethylene hot water flexible tubes, wherein the raw materials are composed of 100 parts by mass of a matrix resin, 0.5-5 parts by mass of a silane crosslinking agent, 0.05-0.5 parts by mass of a grafting initiator, 0.02-0.4 parts by mass of a crosslinking catalyst and 0.05-0.5 parts by mass of an antioxidant.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com