Cold-resistant plastic barrel and preparation method thereof

A plastic barrel and cold-resistant technology, applied in the field of plastic packaging containers, can solve the problems of narrow molecular weight distribution, poor impact strength and elongation at break, etc., and achieve the effects of good compatibility, enhanced tensile strength, and good mildew resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

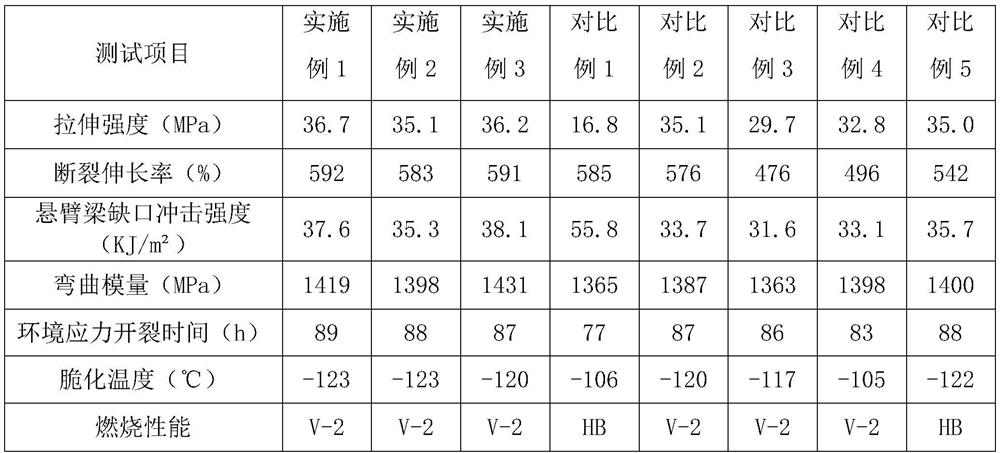

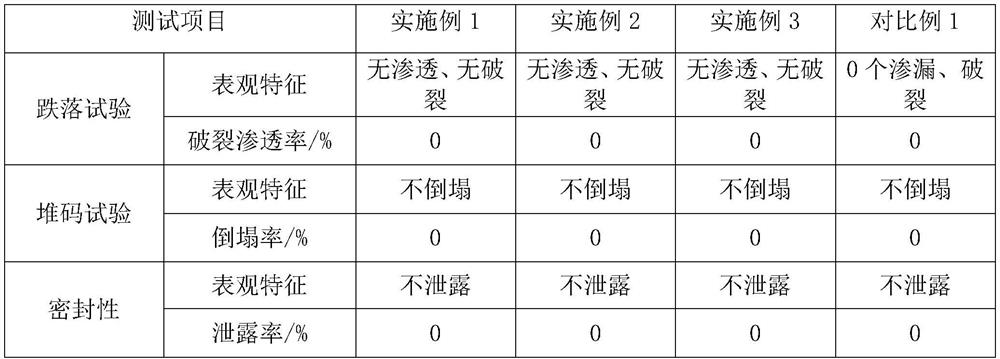

Embodiment 1

[0045] Embodiment 1: A kind of cold-resistant plastic barrel is prepared by the following method:

[0046] (1) Premix: 70kg density is 0.936g / cm 3 , high-density polyethylene with a melt index of 1.4g / 10min, and a density of 0.916g / cm in 20kg 3 , linear low density polyethylene with a melt index of 1.0g / 10min, 15kg of maleic anhydride grafted high density polyethylene with a graft rate of 0.8%-1.2%, 6kg of high degree of polymerization polyvinyl chloride and 7kg of ethylene-vinyl acetate The copolymer is placed in a high-speed mixer, stirred at a temperature of 110°C for 30 minutes, and mixed evenly;

[0047] (2) Mixed material: add 0.8kg ultraviolet absorber UV-531, 0.36kg antioxidant 264, 0.84kg antioxidant DLTP, 0.5kg dioctyl phthalate, 0.5kg epoxy four to the premixed material Dioctyl hydrophthalate, 1.5kg epoxy butyl oleate and 6kg silicon micropowder with a particle size of 0.2-0.3μm were stirred at a temperature of 150°C for 35 minutes and mixed uniformly;

[0048] (...

Embodiment 2

[0051] Embodiment 2: A kind of cold-resistant plastic barrel is prepared by the following method:

[0052] (1) Premix: 60kg density is 0.936g / cm 3 , high-density polyethylene with a melt index of 1.4g / 10min, and a density of 0.916g / cm in 15kg 3 , linear low-density polyethylene with a melt index of 1.0g / 10min, 10kg of maleic anhydride grafted high-density polyethylene with a graft rate of 0.8%-1.2%, 5kg of high-polymerization polyvinyl chloride and 6kg of ethylene-vinyl acetate The copolymer is placed in a high-speed mixer, stirred at a temperature of 100°C for 40 minutes, and mixed evenly;

[0053] (2) Mixed material: add 0.5kg ultraviolet absorber UV-531, 0.3kg antioxidant 264, 0.7kg antioxidant DLTP, 0.4kg dioctyl phthalate, 0.4kg epoxy four to the premixed material Dioctyl hydrophthalate, 1.2kg epoxy butyl oleate, and 5kg silicon micropowder with a particle size of 0.2-0.3 μm were stirred at a temperature of 140°C for 40 minutes, and mixed uniformly;

[0054] (3) Extrus...

Embodiment 3

[0057] Embodiment 3: A kind of cold-resistant plastic barrel is prepared by the following method:

[0058] (1) Premix: 80kg density is 0.936g / cm 3 , high-density polyethylene with a melt index of 1.4g / 10min, and a density of 0.916g / cm in 25kg 3 , linear low-density polyethylene with a melt index of 1.0g / 10min, 20kg of maleic anhydride grafted high-density polyethylene with a graft rate of 0.8%-1.2%, 7kg of high-polymerization polyvinyl chloride and 8kg of ethylene-vinyl acetate The copolymer is placed in a high-speed mixer, stirred at a temperature of 120°C for 20 minutes, and mixed evenly;

[0059] (2) Mixed material: add 1.0kg ultraviolet absorber UV-531, 0.45kg antioxidant 264, 1.05kg antioxidant DLTP, 0.6kg dioctyl phthalate, 0.6kg epoxy four to the premixed material Dioctyl hydrophthalate, 1.8kg epoxy butyl oleate and 7kg silicon micropowder with a particle size of 0.2-0.3μm were stirred at a temperature of 160°C for 30 minutes and mixed uniformly;

[0060] (3) Extrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com