Stress-resistant plastic part processing technology

A processing technology and technology of plastic parts, applied in the field of plastic processing, can solve problems affecting product quality, cooling effect reduction, uneven water temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

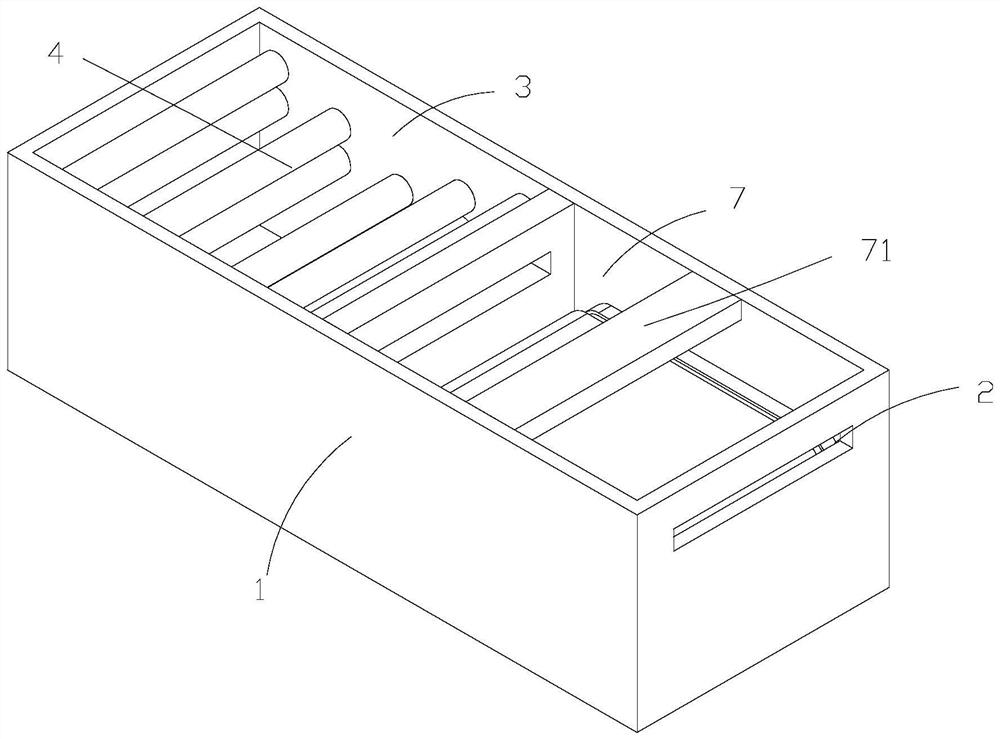

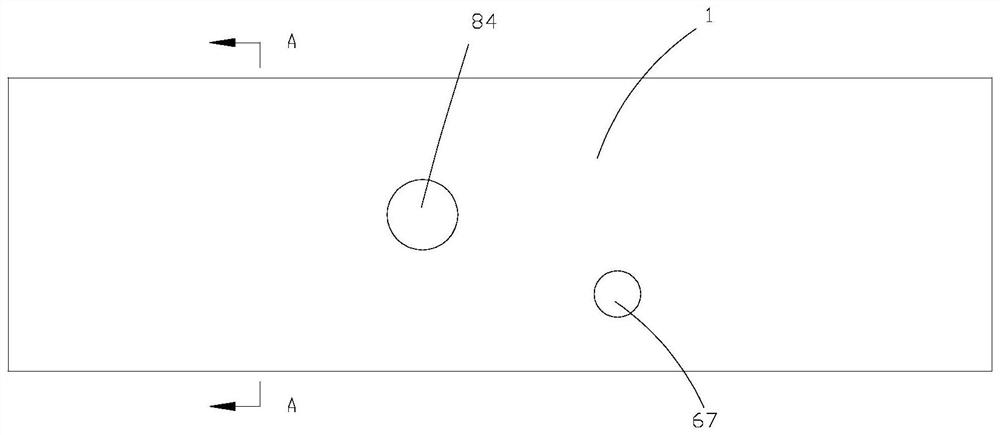

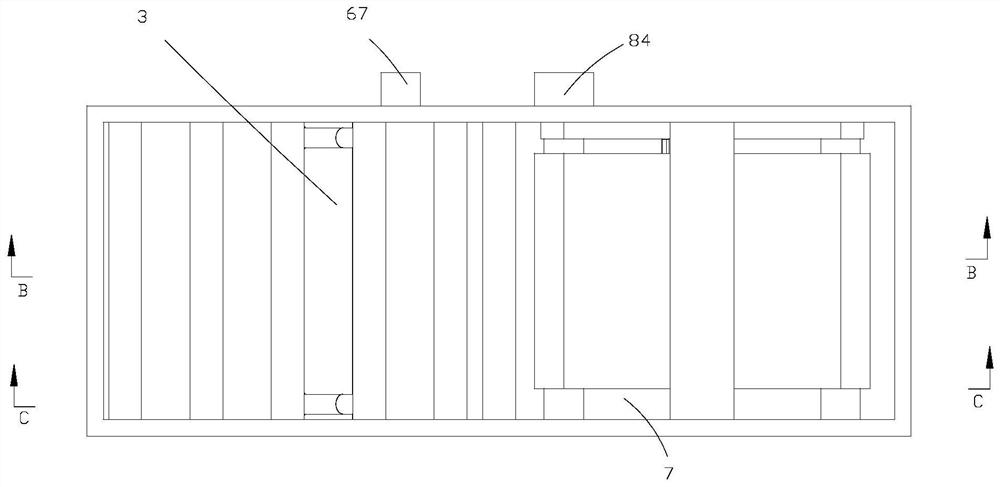

[0039] Such as Figure 1-11 As shown, a stress-resistant plastic parts processing technology is characterized in that: comprising the following steps;

[0040] a. Mixing: 99.50 parts of ethylene hexene copolymerized polyethylene resin

[0041] Antioxidant 0.12 parts

[0042] Auxiliary antioxidant 0.03 parts

[0043] Release agent 0.02 parts mixed;

[0044] b. Mixing: Add the mixture in a to the mixer for mixing. When mixing, adjust the temperature of the second section of the mixer to 230°C, and the temperature of the third section of the barrel. The temperature is 235°C, the temperature of the fourth section of the cylinder is 240°C, the temperature of the fifth section of the cylinder is 245°C, the temperature of the sixth section of the cylinder is 250°C, and the temperature of the seventh section is 260°C; the heat conduction of the heating mixer The oil temperature is 260°C;

[0045] c. Cooling: Pass the extruded mixture in b to the cooling tank for cooling, wherein ...

Embodiment 2

[0054] A processing technology for stress-resistant plastic parts, characterized in that it includes the following steps;

[0055] a. Mixing: 99.70 parts of ethylene hexene copolymerized polyethylene resin

[0056] Antioxidant 0.35 part

[0057] Auxiliary antioxidant 0.15 parts

[0058] 0.06 parts of release agent are mixed;

[0059]b. Mixing: Add the mixture in a to the mixer for mixing. When mixing, adjust the temperature of the second section of the mixer to 230°C, and the temperature of the third section of the barrel. The temperature is 235°C, the temperature of the fourth section of the cylinder is 240°C, the temperature of the fifth section of the cylinder is 245°C, the temperature of the sixth section of the cylinder is 250°C, and the temperature of the seventh section is 260°C; the heat conduction of the heating mixer The oil temperature is 260°C;

[0060] c. Cooling: Pass the extruded mixture in b to the cooling tank for cooling, wherein the temperature of the co...

Embodiment 3

[0063] A processing technology for stress-resistant plastic parts, characterized in that it includes the following steps;

[0064] a. Mixing: 99.6 parts of ethylene hexene copolymerized polyethylene resin

[0065] Antioxidant 0.22 parts

[0066] Auxiliary antioxidant 0.09 parts

[0067] 0.04 parts of release agent are mixed;

[0068] b. Mixing: Add the mixture in a to the mixer for mixing. When mixing, adjust the temperature of the second section of the mixer to 230°C, and the temperature of the third section of the barrel. The temperature is 235°C, the temperature of the fourth section of the cylinder is 240°C, the temperature of the fifth section of the cylinder is 245°C, the temperature of the sixth section of the cylinder is 250°C, and the temperature of the seventh section is 260°C; the heat conduction of the heating mixer The oil temperature is 260°C;

[0069] c. Cooling: Pass the extruded mixture in b to the cooling tank for cooling, wherein the temperature of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com